Chain type cement mixing pile machine

A cement mixing pile and chain technology, which is applied in the field of cement mixing piles, can solve the problems of affecting operation efficiency, cumbersome assembly, difficult handling, etc., and achieve the effects of saving transportation costs, facilitating transportation or storage, and facilitating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

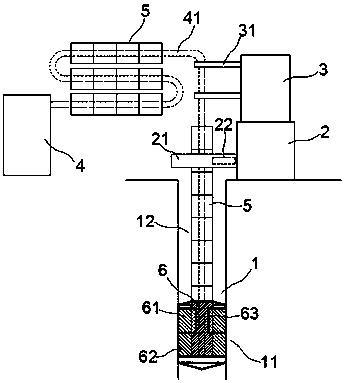

[0023] exist Figure 1 to Figure 3 In the shown embodiment, the chain cement mixing pile driver includes a drill pipe 1, a driving machine 2, a bearing frame 3 and a grouting machine 4;

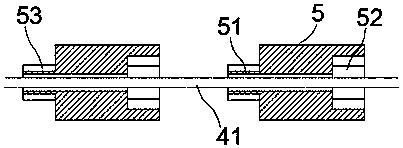

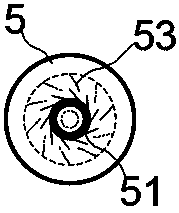

[0024] The drill pipe 1 includes a drill bit 11 and a rod body 12, the drill bit 11 is detachably mounted on the end of the rod body 12; a spray port is provided at the bottom of the drill bit 11; the rod body 12 is assembled from the transmission column 5 head to tail, The upper end of the transmission column 5 is provided with a transmission head 51, and the lower end is provided with a transmission groove 52 matched with the transmission head 51, and the transmission head 51 and the transmission groove 52 are provided with matching transmission teeth 53; the transmission head 51 and the transmission groove The transmission tooth 53 on the 52 is a ratchet tooth, and the transmission head 51 and the transmission groove 52 rotate synchronously in the clockwise direction, and rotate relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com