A kind of preparation method and application of iron oxide, ferrous sulfide and sulfur composite material

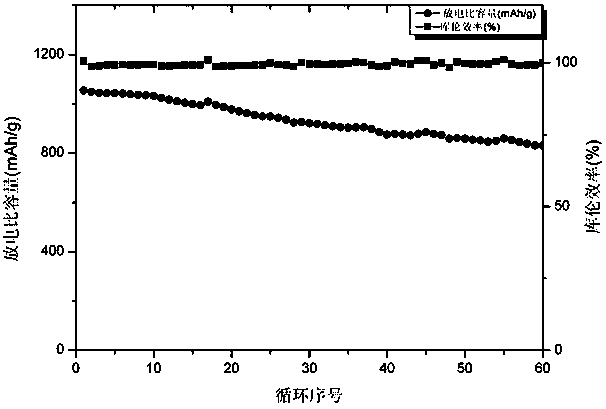

A technology of ferrous disulfide and composite materials, which is applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of loss of electroactive substances, and achieve the effects of improved stability, easy price, and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

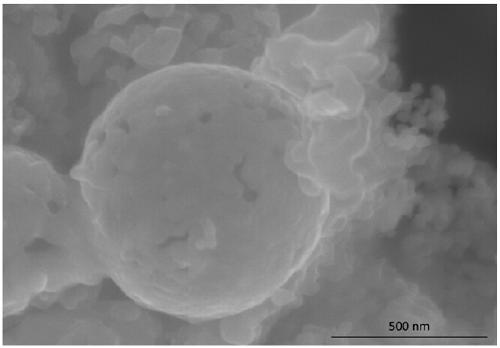

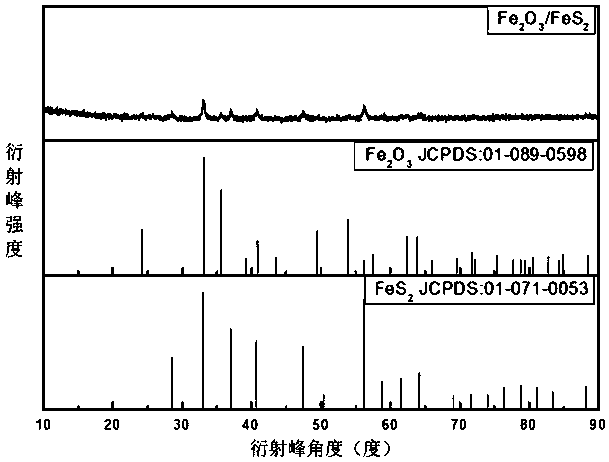

[0023] Specific embodiment one: what this embodiment records is a kind of preparation method of iron oxide, ferrous disulfide and sulfur composite material, and described method step is as follows:

[0024] Step 1: Add 1-5 mmol FeSO 4 •7H 2 O was added to 25-100 mL of methanol and stirred to fully dissolve, which was recorded as solution 1; 4-20 mmol of 2-methylimidazole and 0.3-1.5 g of polyvinylpyrrolidone were added to 25 mL of methanol and stirred to fully dissolve, Record it as solution 2; slowly add the above solution 1 into solution 2, stir for 5-20 min, then let it stand for 24 h, centrifuge at 8000-10000r / min for 5-10 min to collect the precipitate, wash it with methanol for 5 times, put it in a dry In the oven, dry at a temperature of 40-100 ℃ for 6-48 h to obtain Fe-metal organic framework materials (Fe-MOFs);

[0025] Step 2: Put the Fe-metal organic framework material prepared in Step 1 in a tube furnace, heat up to 400-600°C under air conditions, and keep it wa...

specific Embodiment approach 2

[0028] Specific embodiment two: the preparation method of a kind of iron oxide, ferrous disulfide and sulfur composite material described in specific embodiment one, in step two, the rate when heating up is 2 ℃ / min, 5 ℃ / min or 10 ℃ / min.

specific Embodiment approach 3

[0029] Specific embodiment three: the preparation method of a kind of iron oxide, ferrous sulfide and sulfur composite material described in specific embodiment one, in step three and step four, described elemental sulfur is sublimated sulfur, settled sulfur, refined sulfur kind of.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com