Kitchen waste treatment method and equipment

A technology for kitchen waste and treatment methods, which is applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of inability to install large-scale treatment equipment, low utilization rate of kitchen waste, and high treatment methods. , to achieve the effect of facilitating resource utilization, improving utilization rate, and facilitating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

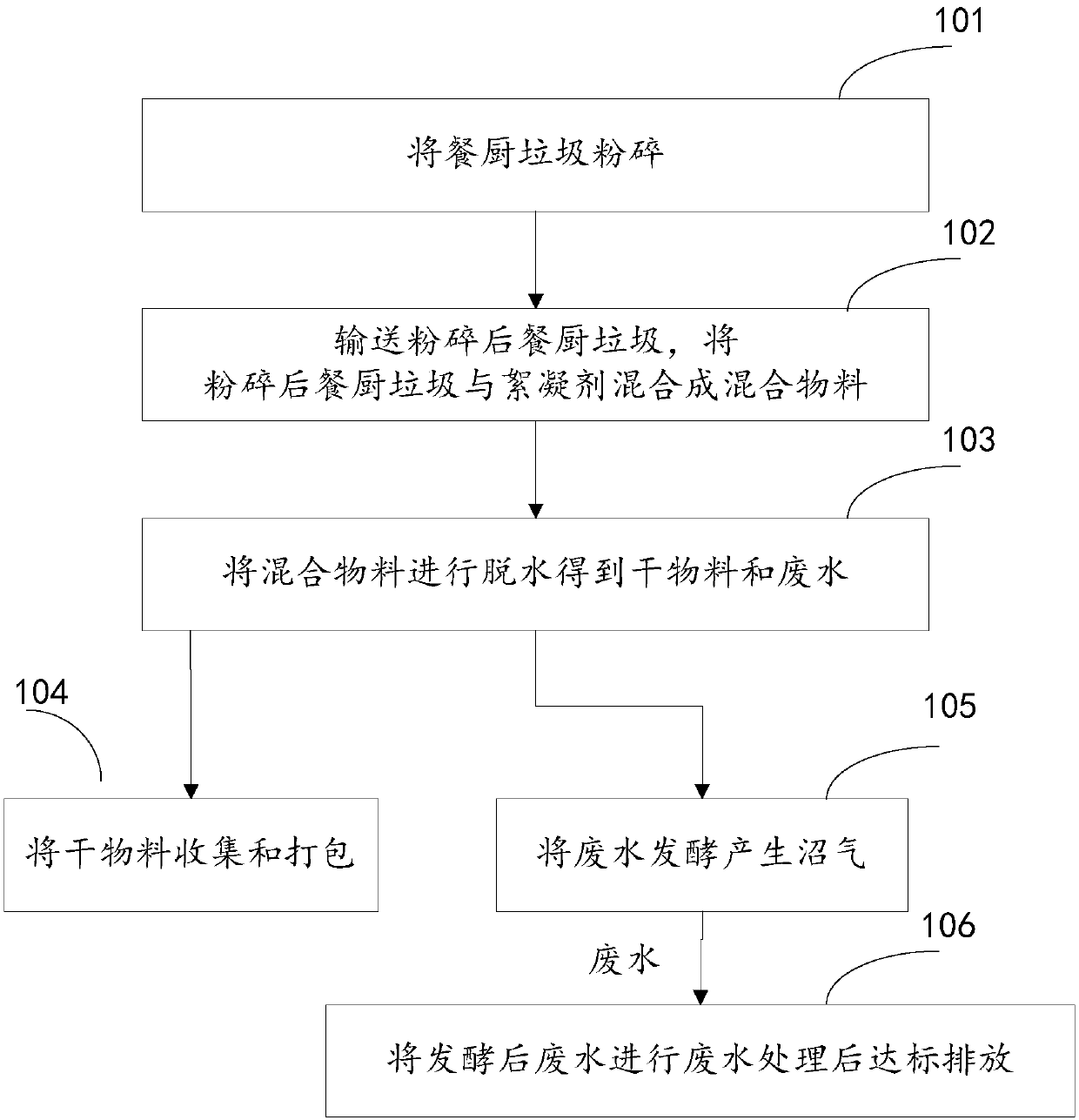

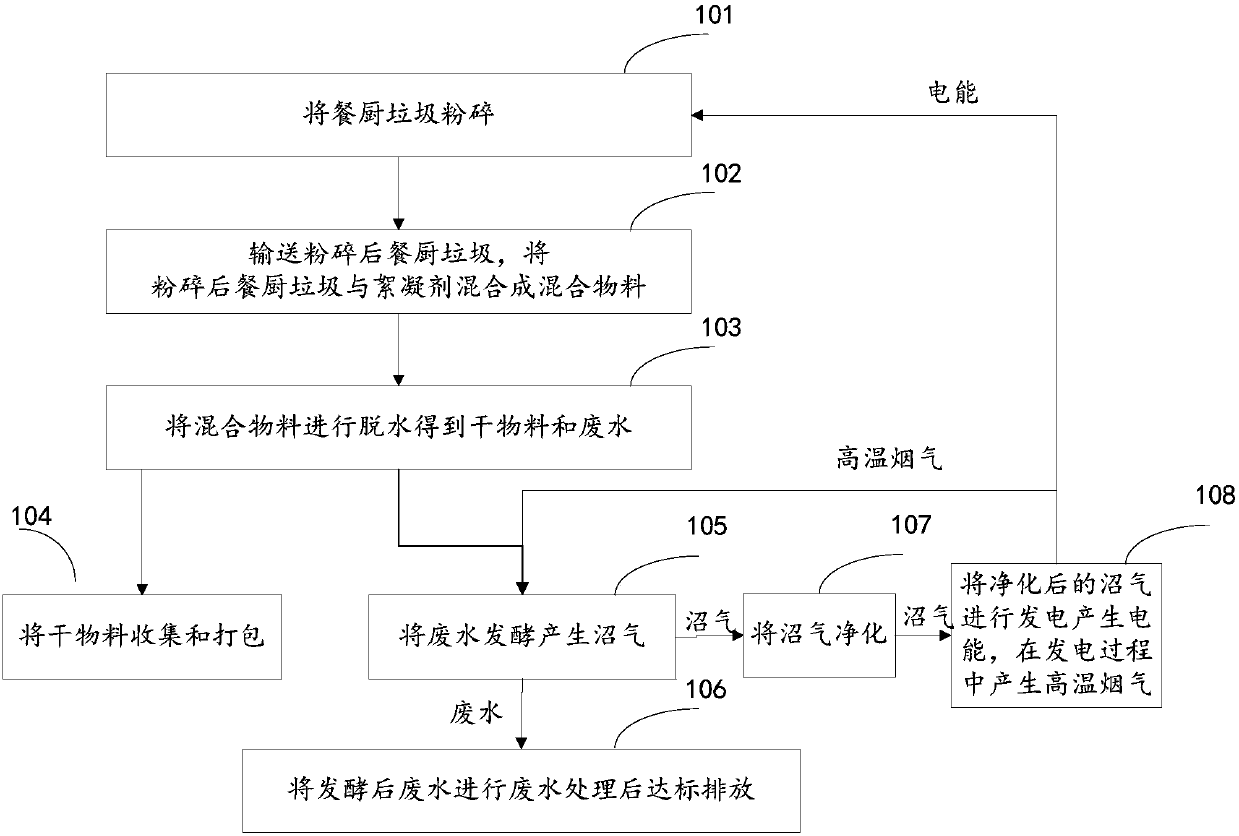

[0038] like figure 1 As shown, the kitchen waste treatment method provided by the embodiment of the present invention comprises:

[0039] Step 101: Pulverize the kitchen waste. Shredded food waste includes rice and flour food residues, vegetables, animal and vegetable oils, meat and bones, and inner bones such as pork ribs and pig foot bones can be effectively shredded. Further, the noise in the crushing process can be controlled to reduce the noise, and the odor in the crushing process can also be controlled to increase the deodorization process. Since the food waste stays for a long time or the weather is hot, it will produce odor, so it is necessary to increase the deodorization step.

[0040] Step 102: transporting the pulverized food waste and mixing it with a flocculant to form a mixed material. After the food waste is crushed, it is transported to the basement of the building and mixed with a flocculant. The flocculant is polyacrylamide (PAM). Polyacrylamide is a non...

Embodiment 2

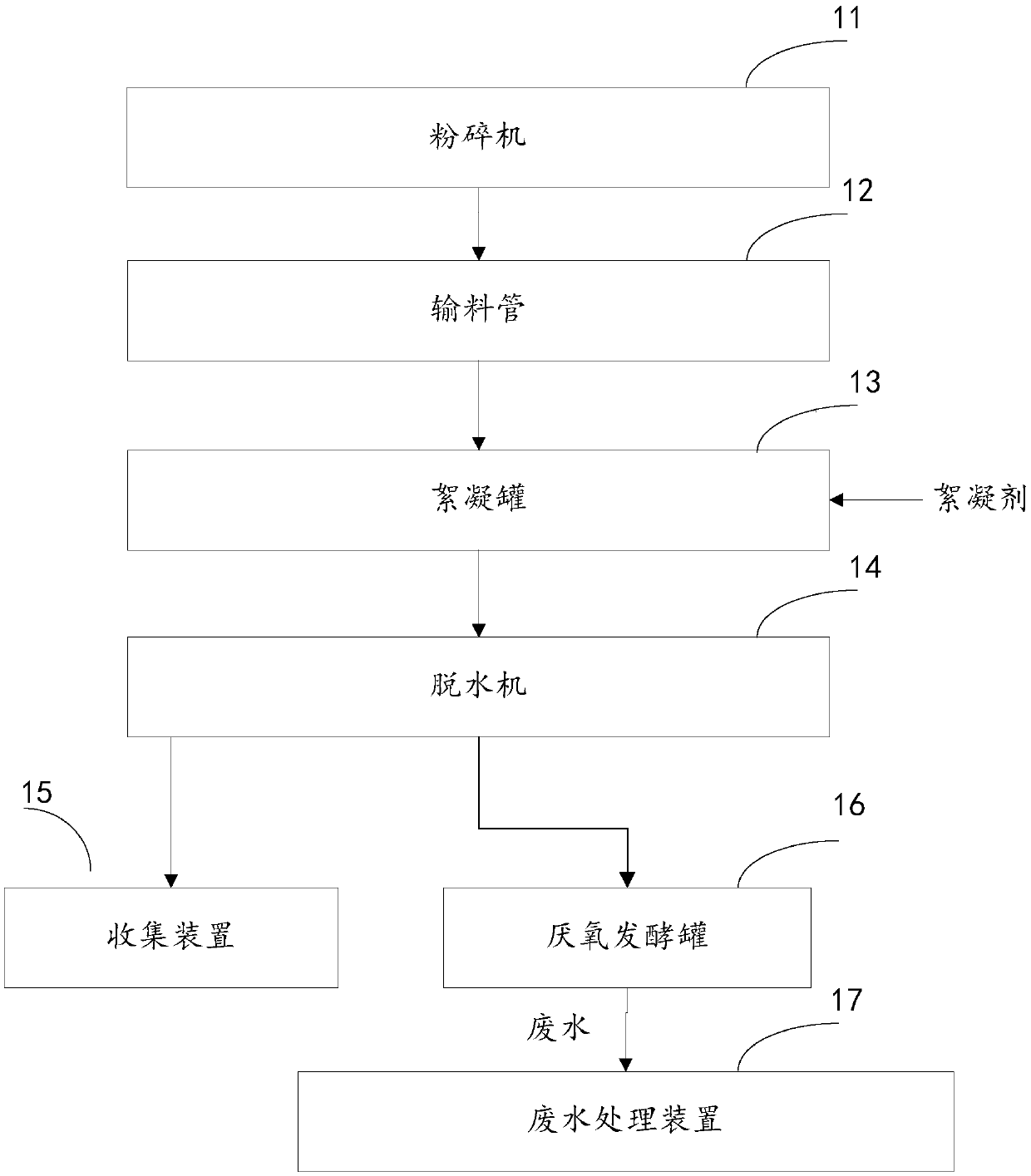

[0051] Correspondingly, the embodiment of the present invention also provides food waste treatment equipment, such as image 3 As shown, the equipment includes a pulverizer 11 , a feeding pipe 12 , a flocculation tank 13 , a dehydration tank 14 , a collecting device 15 , an anaerobic fermentation tank 16 and a wastewater treatment device 17 . Concretely comprise: the pulverizer 11 that is used to pulverize food waste; The conveying pipe 12 that is used to convey the crushed food waste; The flocculation tank 13 that is connected with the discharge end of feed pipe 12, and the flocculation tank 13 is used for meal The kitchen waste is mixed with the flocculant, and the kitchen waste is mixed with the flocculant to form a mixed material; the dehydration tank 14 connected to the flocculation tank 13 is used to dehydrate the mixed material into dry material and waste water; the dehydration tank 14 is connected to collect and a collection device 15 for packing dry materials; an anae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com