Drainage rate analysis method based on tackifying-type emulsion

An analysis method and rate technology, which is applied in the field of water separation rate analysis based on viscosified emulsions, can solve the problem of large resources, oil displacement systems that cannot meet the requirements of enhanced oil recovery for ultra-high temperature reservoirs, and difficult recovery rates for conventional water flooding. and other problems, to achieve the effect of good effect, low cost and simple test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

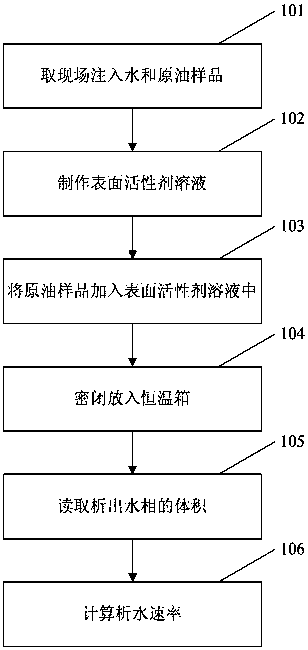

[0021] Such as figure 1 as shown, figure 1 It is a flow chart of a specific embodiment of the viscosity-increasing emulsion water separation rate analysis method of the present invention.

[0022] In step 101, samples of water and crude oil injected into the target block are taken for future use.

[0023] In step 102, the surfactant is added into the on-site injection water according to a certain proportion, and stirred evenly to prepare a surfactant solution. The content of the surfactant in the surfactant solution is (1.0-2.0)%.

[0024] In step 103, the crude oil sample is added to the surfactant solution in a certain proportion in the high-temperature resistant screw-top graduated test tube; the mixing ratio of the crude oil sample and the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com