A burr-free photolithography method

A burr-free, lithography technology, used in microlithography exposure equipment, optics, opto-mechanical equipment, etc., can solve the problems of metal layer metal burrs, affecting product yield, difficult to adjust, etc., to improve device electrical properties, improve The effect of device yield and development uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For simplicity, some technical features known to those skilled in the art are omitted from the following description.

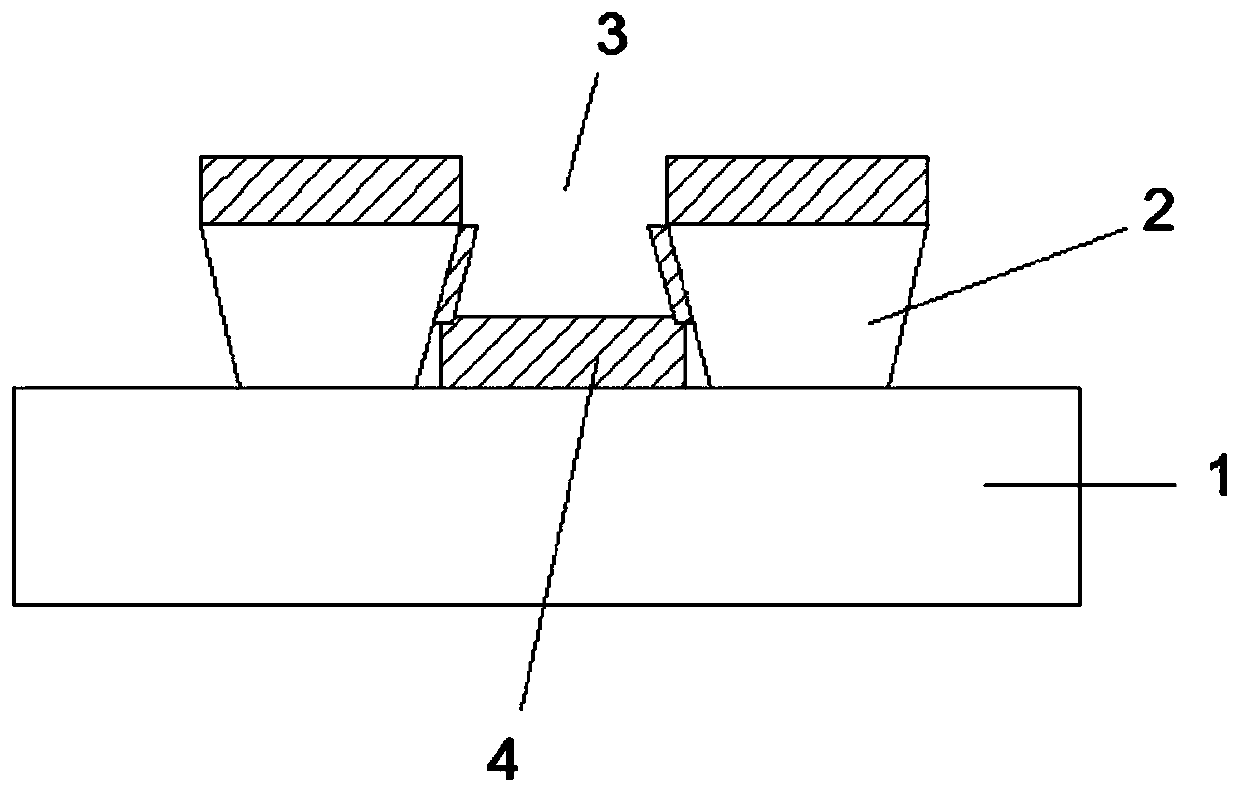

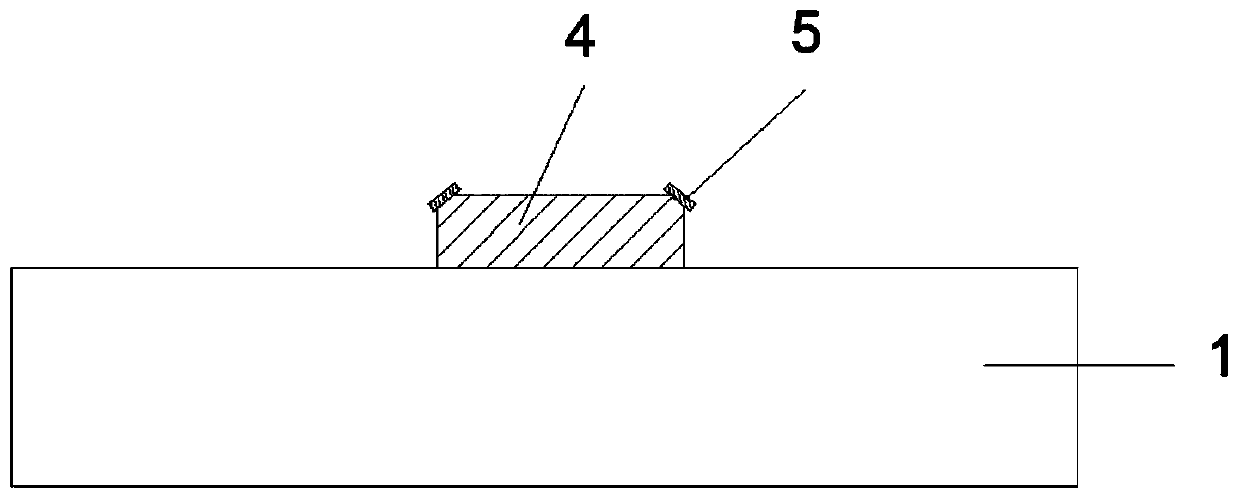

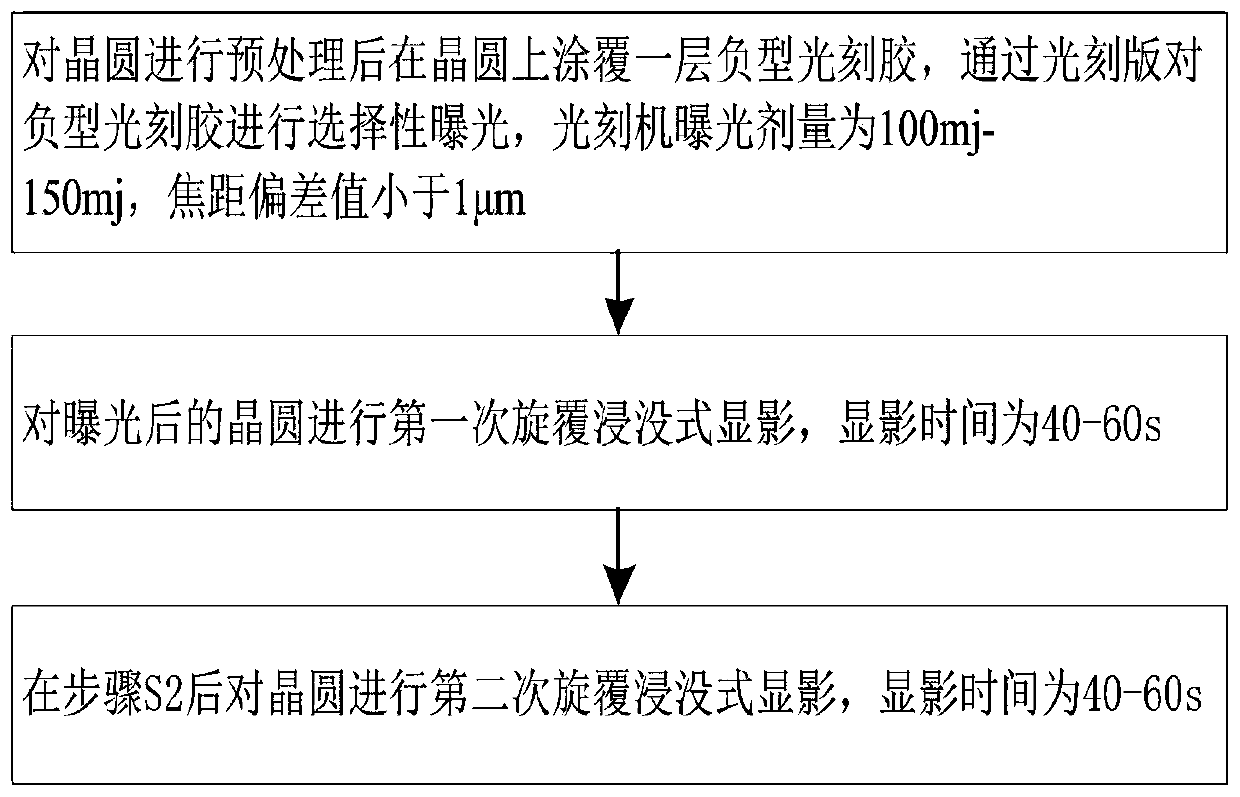

[0019] Such as image 3 As shown, the present embodiment provides a burr-free photolithography method, comprising the following steps:

[0020] S11. Perform pretreatment on the wafer 11. Clean the surface of the wafer 11 with deionized water. After cleaning, use a hot plate to remove moisture from the surface of the wafer 11 under the protection of nitrogen. The temperature of the hot plate is 150-250° C., and the baking time is 1~2min;

[0021] S12. Spin-coat a layer of negative photoresist on the wafer 11. The thickness of the negative photoresist must match the thickness of the metal to be evaporated. Generally, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com