Patents

Literature

41results about How to "Uniform development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for hydrogenation treatment and method for hydrogenation treatment of hydrocarbon oil

InactiveUS6306289B1High desulfurization activityHigh activityCatalyst activation/preparationTreatment with hydrotreatment processesComponent LoadNMR - Nuclear magnetic resonance

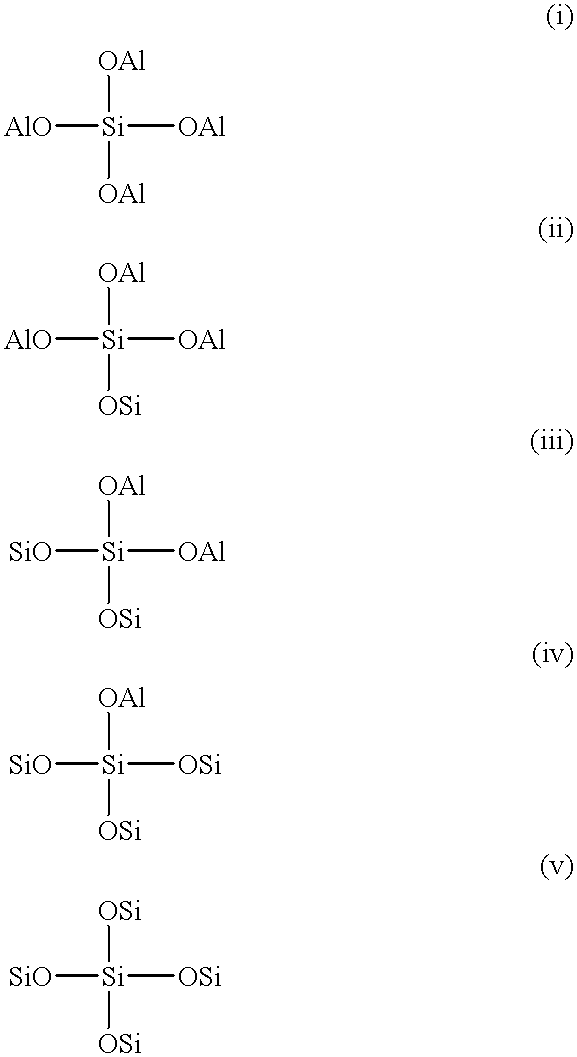

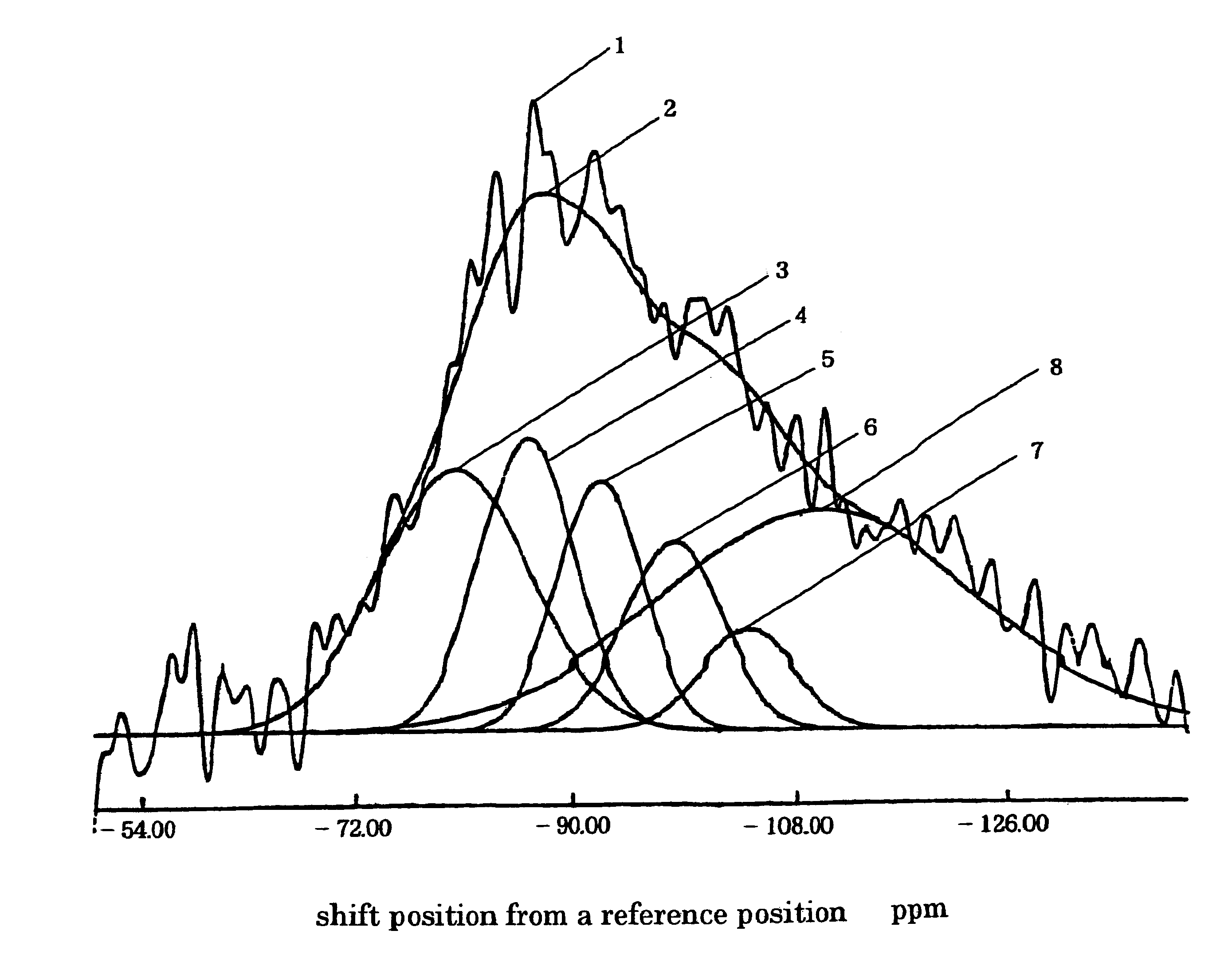

A hydrotreating catalyst having both a high desulfurization activity and a denitrogenation activity and a method of hydrotreating a hydrocarbon oil using the same is provided.A hydrotreatment catalyst comprising a silica-alumina carrier loaded with at least one hydrogenation-active component; wherein (1) the silica content is in the range of 2 to 40% by weight based on the total weight of the carrier; and (2) in the spectrum obtained by nuclear magnetic resonance analysis (29Si-NMR), (i) the area of the peak at -80 ppm is 10% or more of the combined area of all the peaks; and (ii) the combined area of peaks at -80 ppm, -86 ppm and -92 ppm is 20% or more of the combined area of all peaks; a hydrotreating catalyst comprising a silica-alumina carrier containing a specific amount of a third component loaded with at lest one hydrogenation-active metal component and having a specific pore structure; and a method of hydrotreating a hydrocarbon oil comprising contacting a hydrocarbon oil with hydrogen in the presence of said hydrotreating catalyst.

Owner:TONENGENERAL SEKIYU

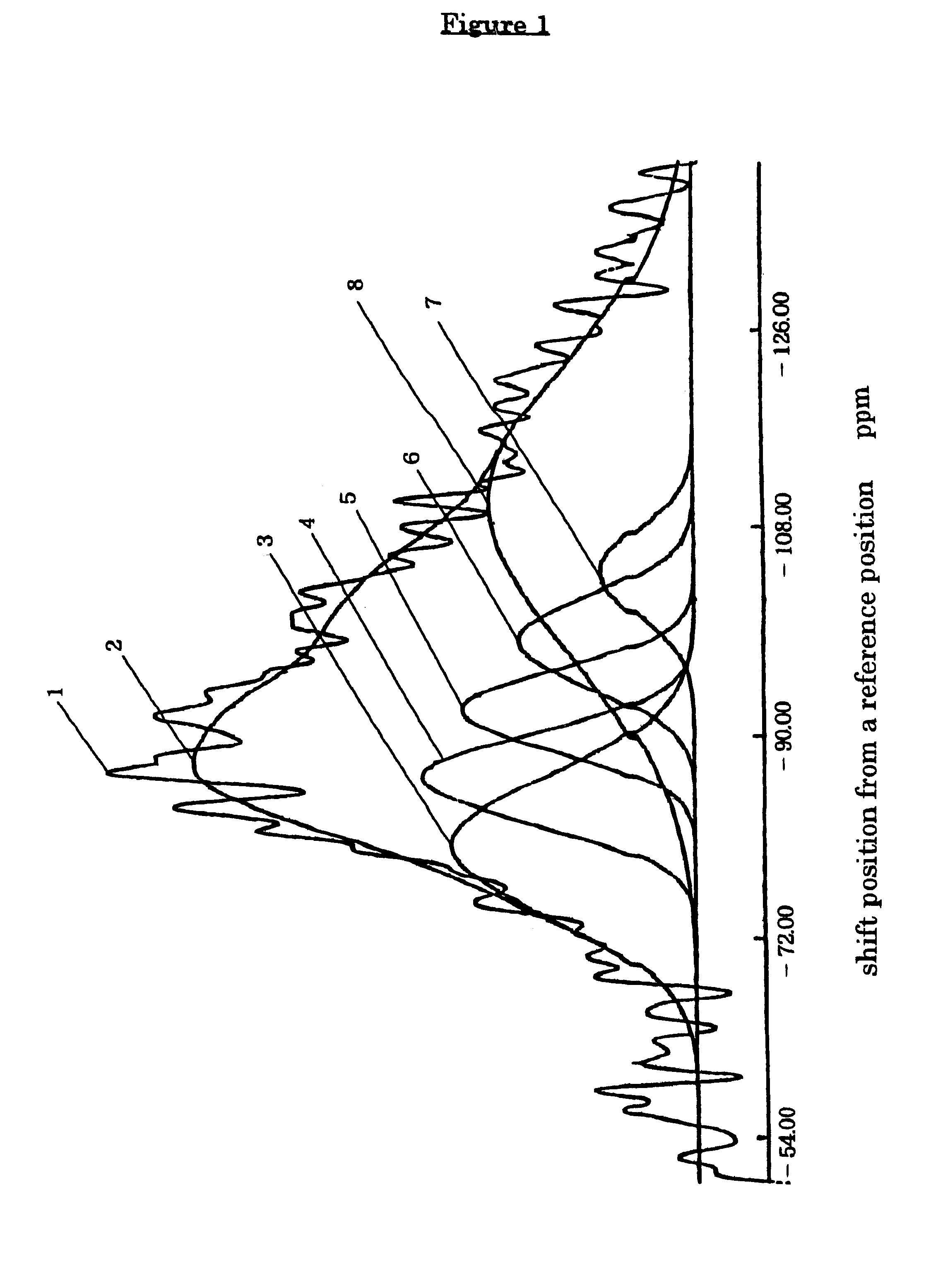

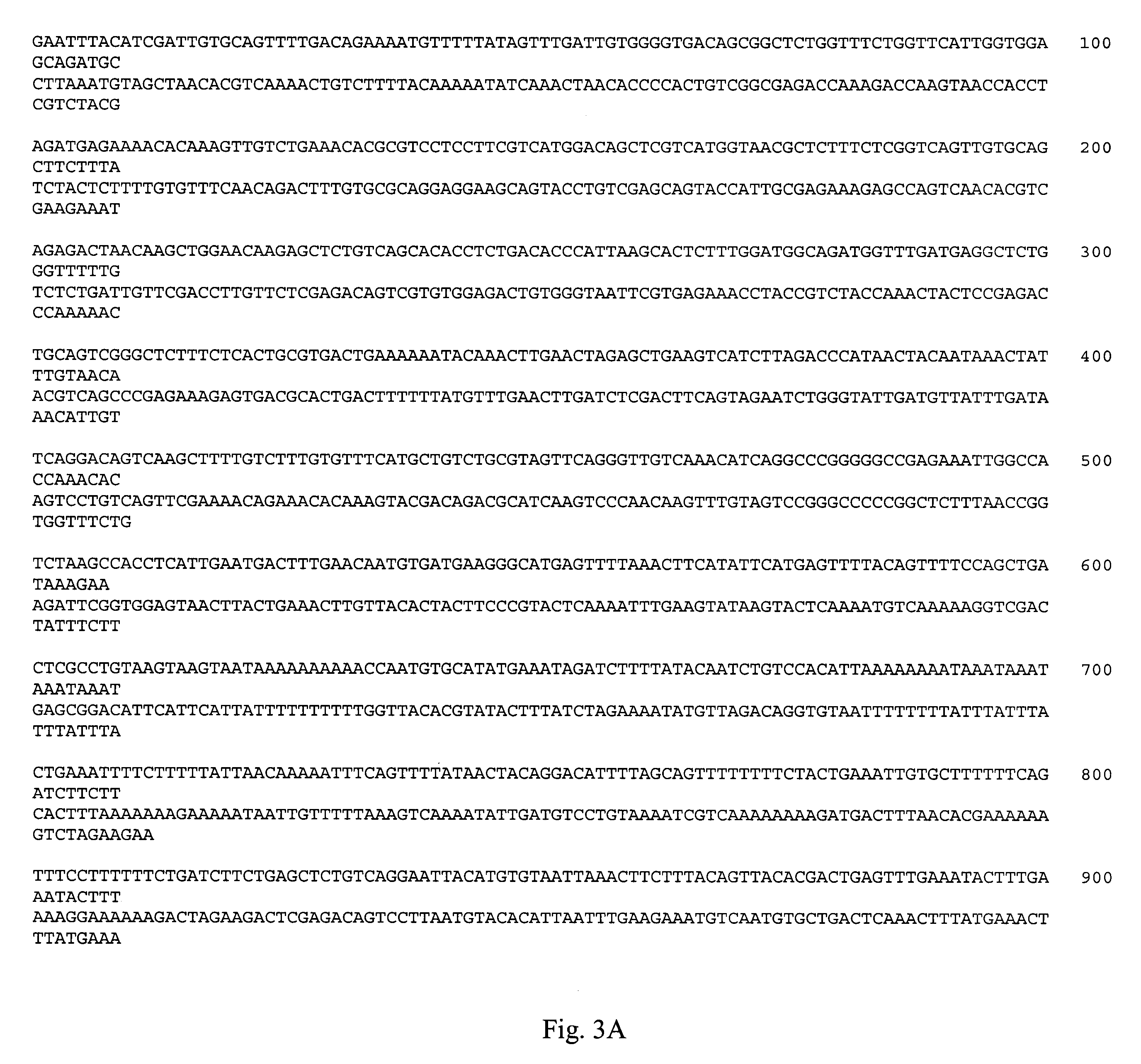

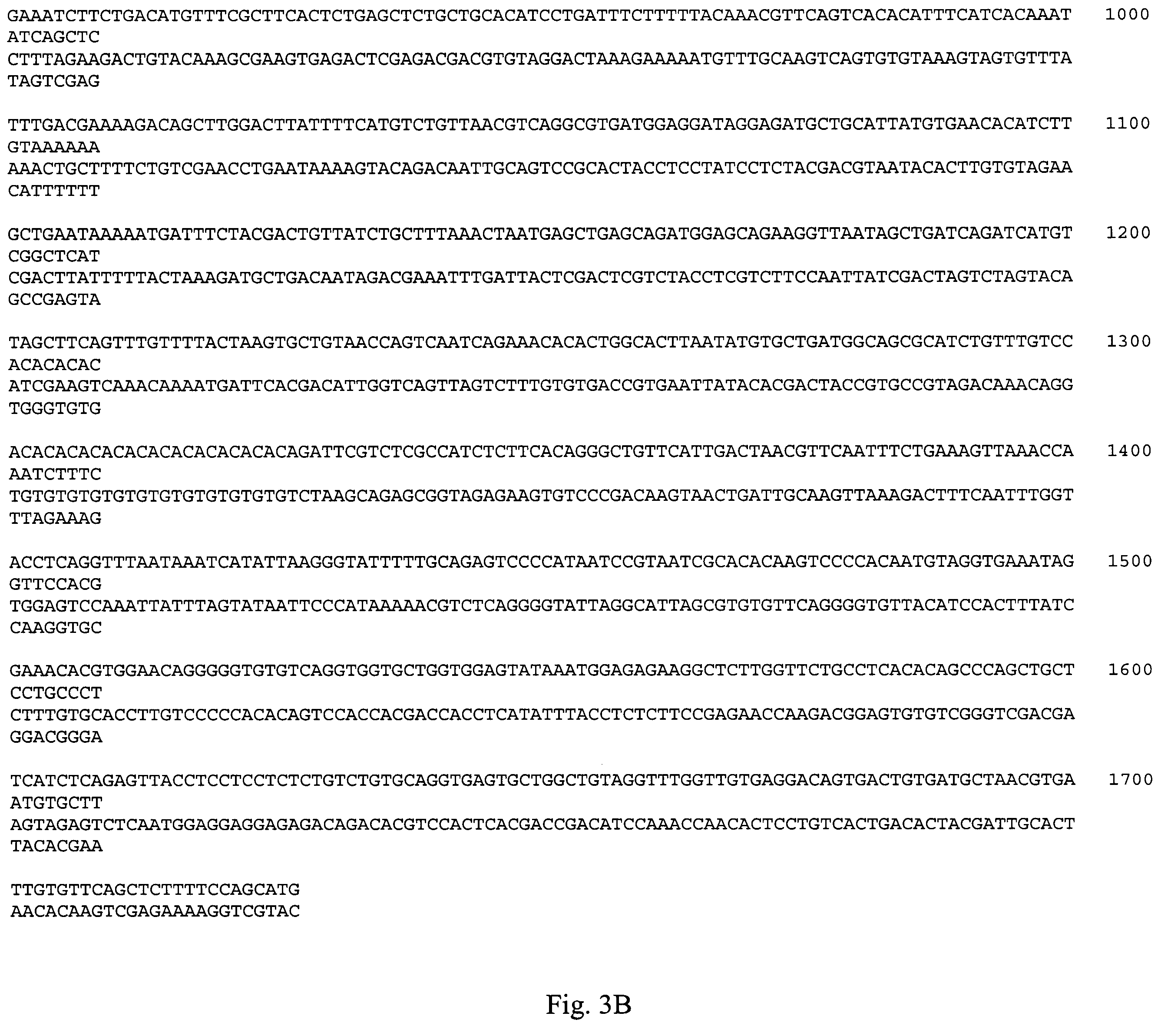

Transgenic tilapia comprising a humanized insulin gene

InactiveUS6476290B1Stable integrationDevelopmental stability and uniformityNew breed animal cellsMammal material medical ingredientsTilapiaIslet cells

In accordance with the present invention, there are provided humanized fish insulin genes. Humanized insulin the present invention encode human insulin alpha and / or beta chains while using fish-preferred codons and regulatory sequences. These humanized genes are thus expressible in fish islet cells. Also provided are transgenic fish having islet cells containing and capable of expressing humanized insulin genes. These islet cells (Brockmann Bodies) can be xenotransplanted into subjects having diabetes. In this manner normoglycemia can be achieved in the recipient of the islets.

Owner:DALHOUSIE UNIV

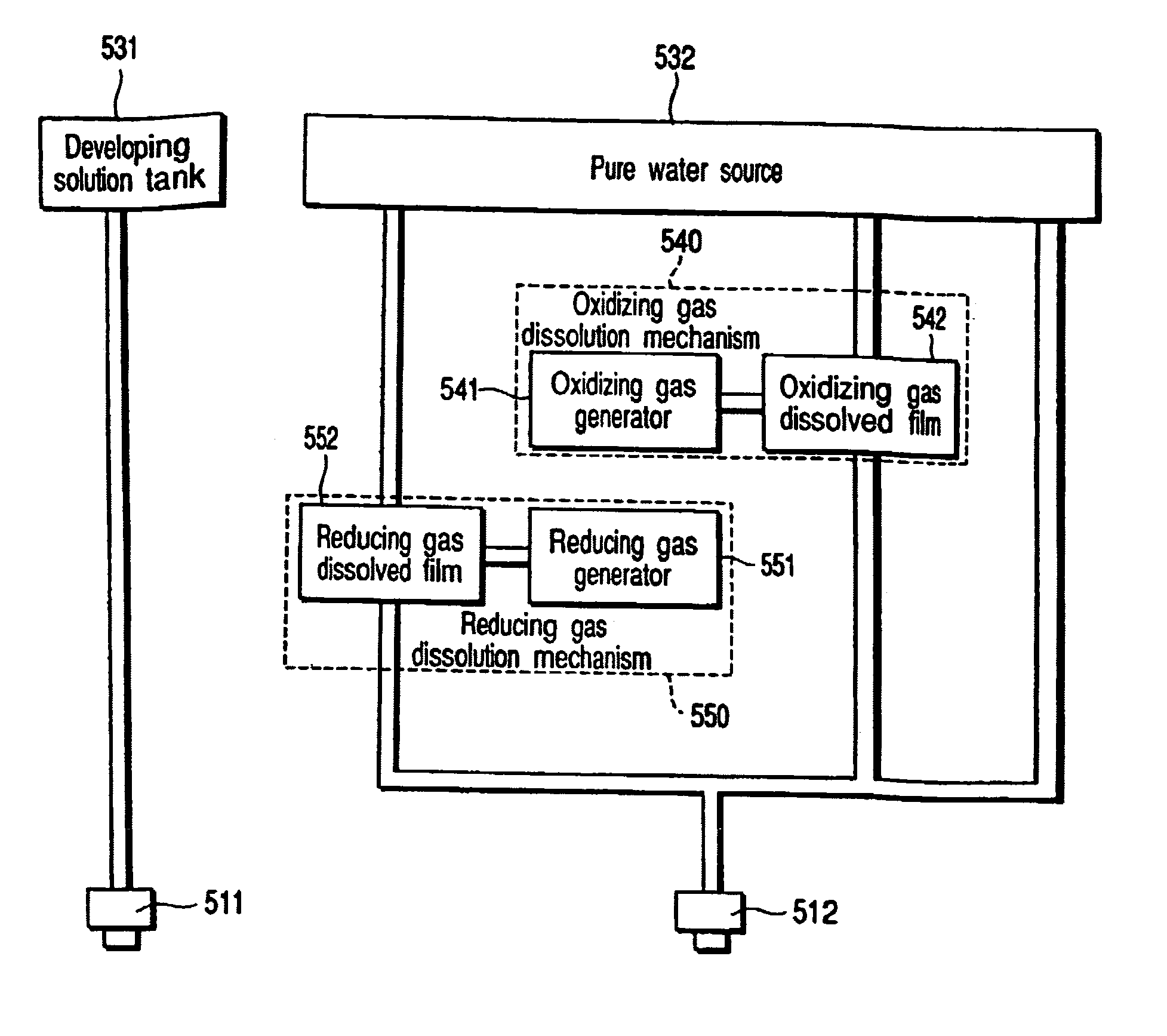

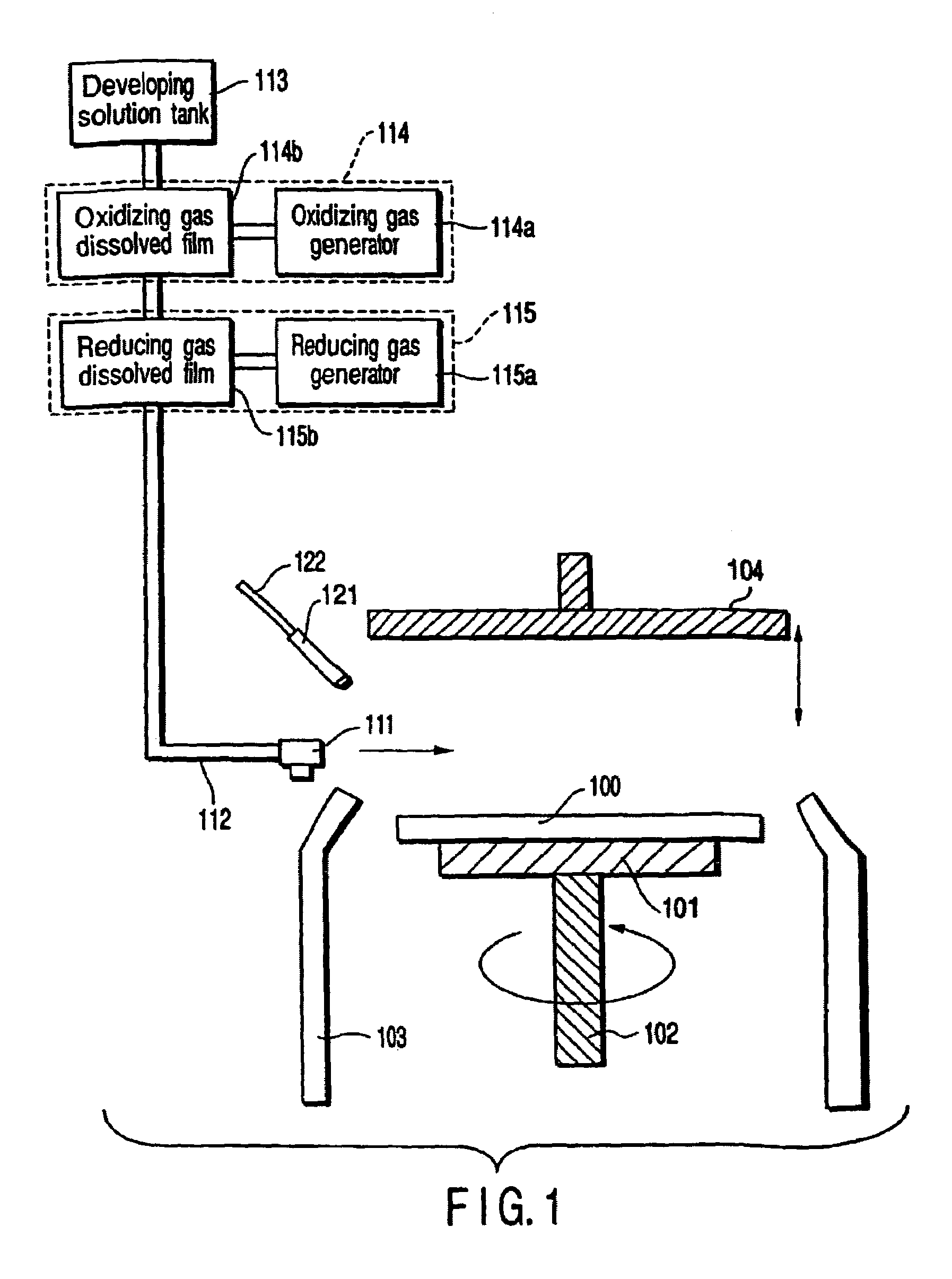

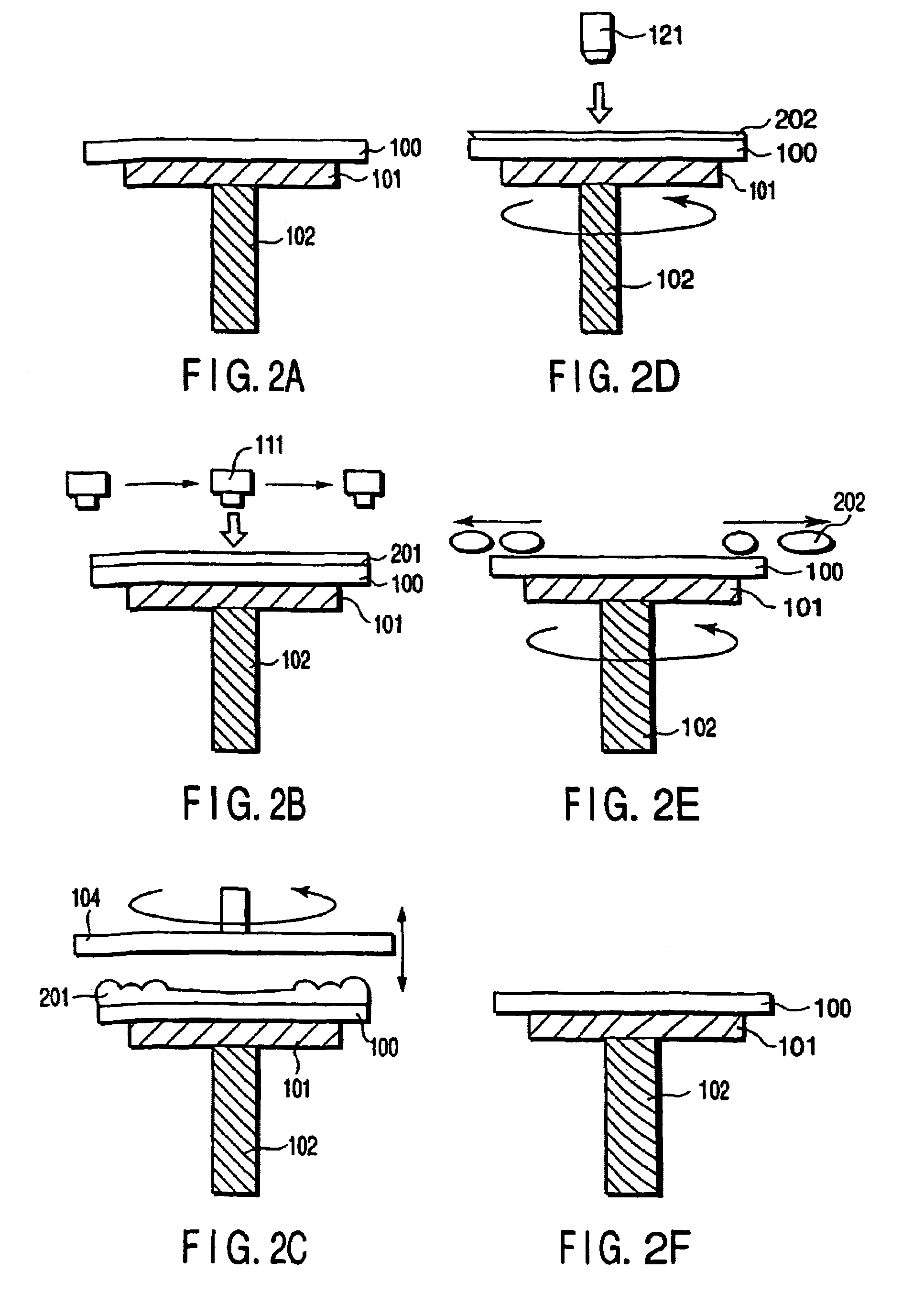

Alkaline solution and manufacturing method, and alkaline solution applied to patern forming method, resist film removing method, solution application method, substrate treatment method, solotion supply method, and semiconductor device manufacturing method

InactiveUS20050058944A1Improve suppression propertiesDifference of the affinity of the exposed portion surfaceOther chemical processesSemiconductor/solid-state device manufacturingResistSolvent

Owner:KK TOSHIBA

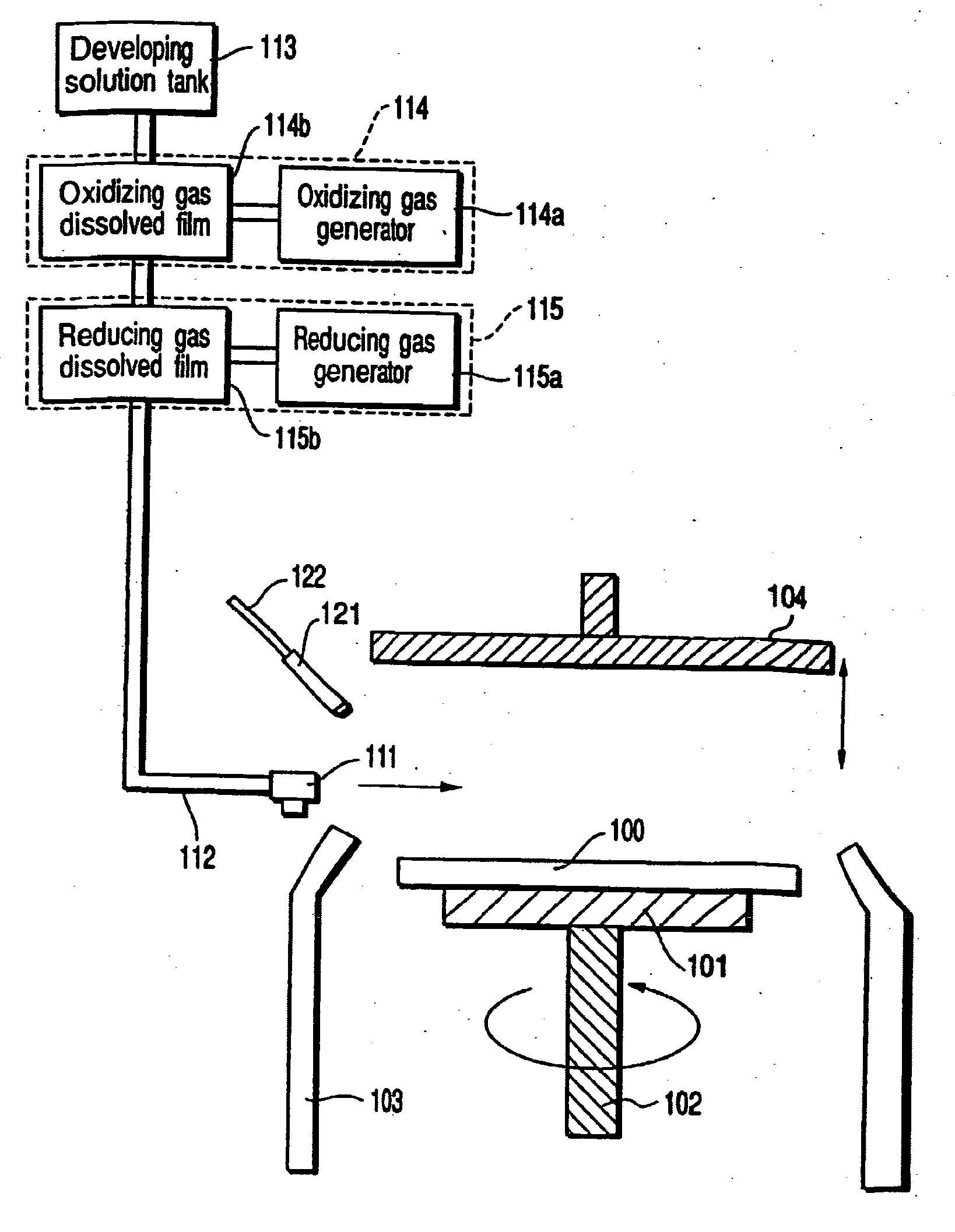

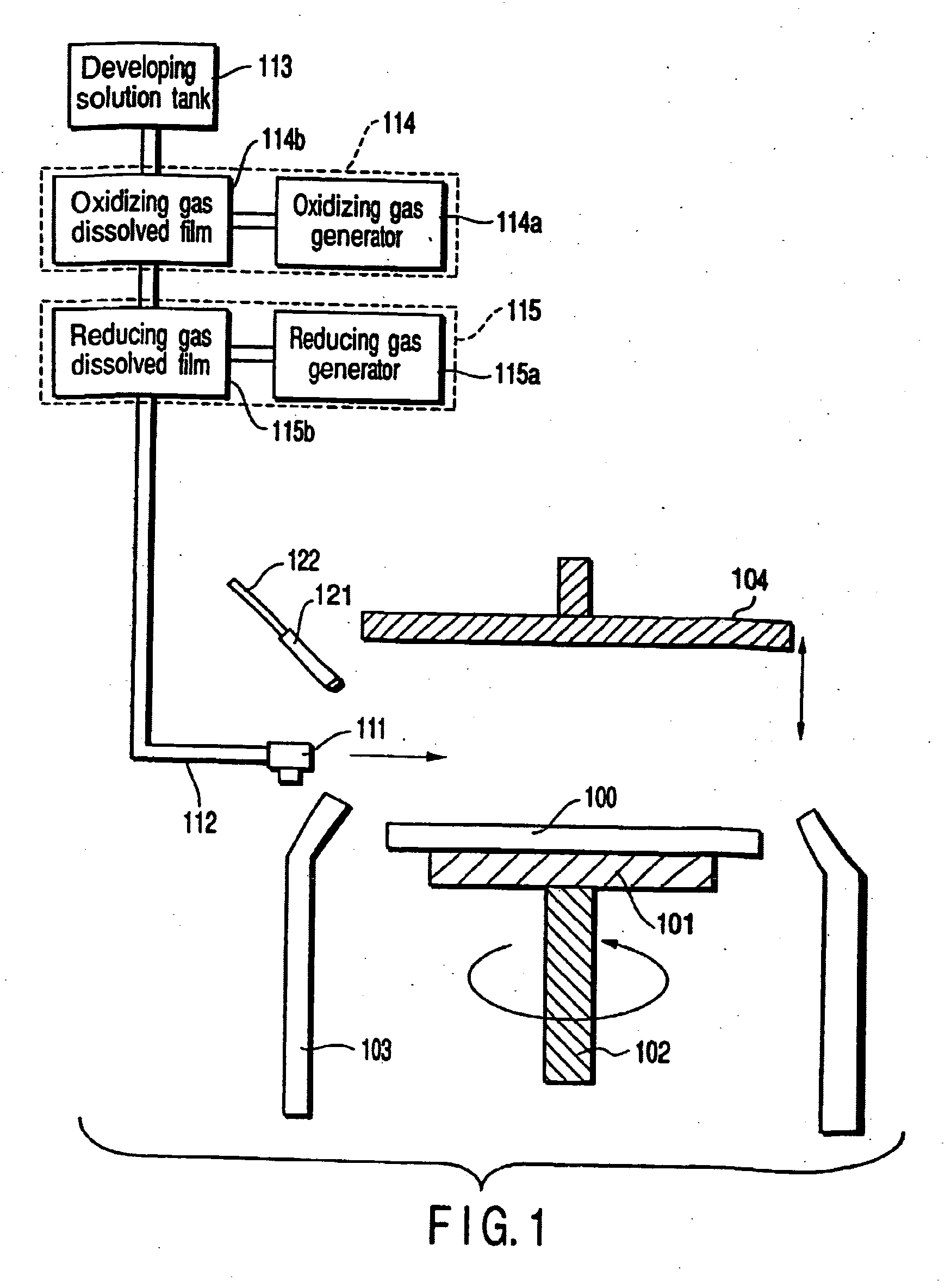

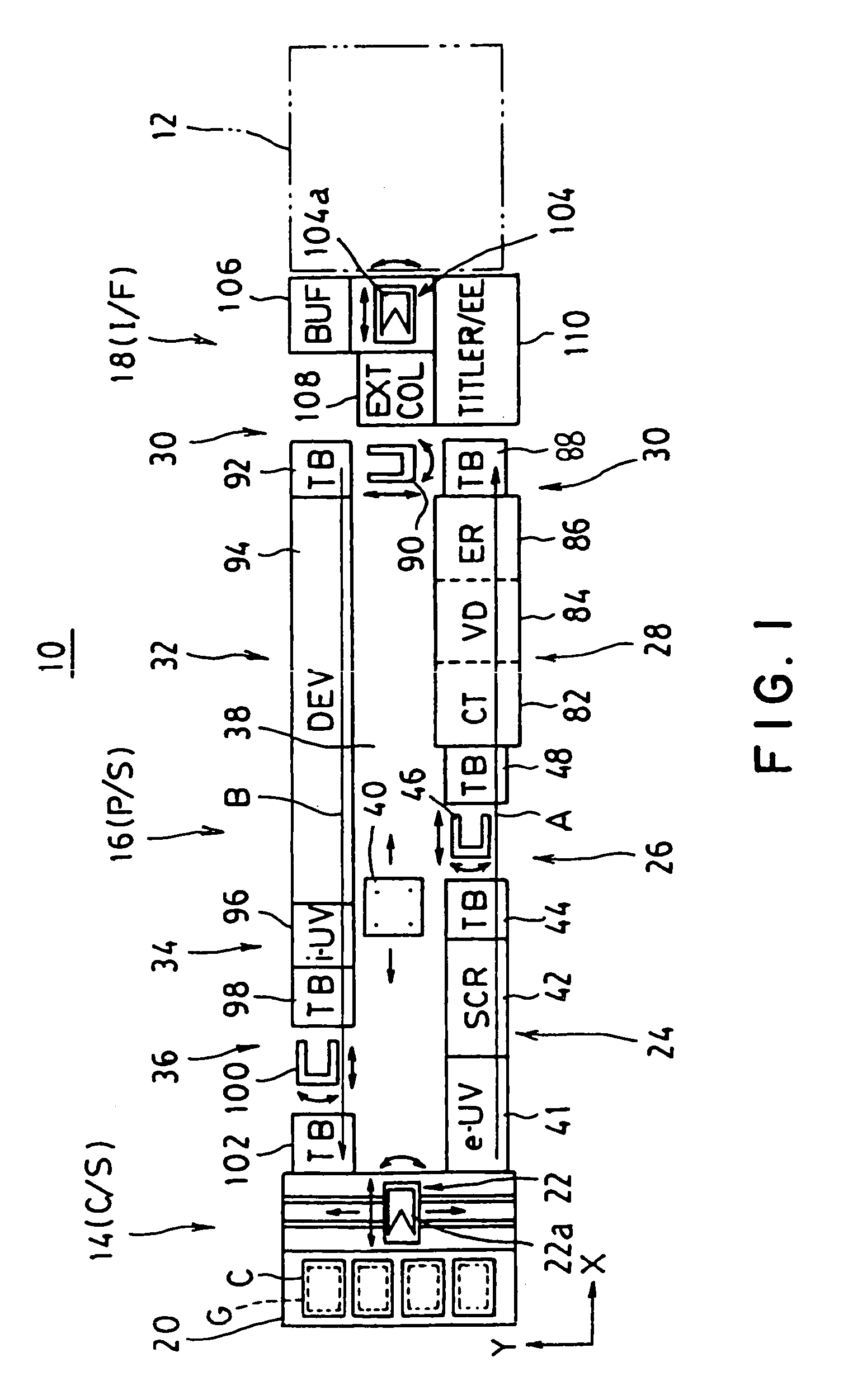

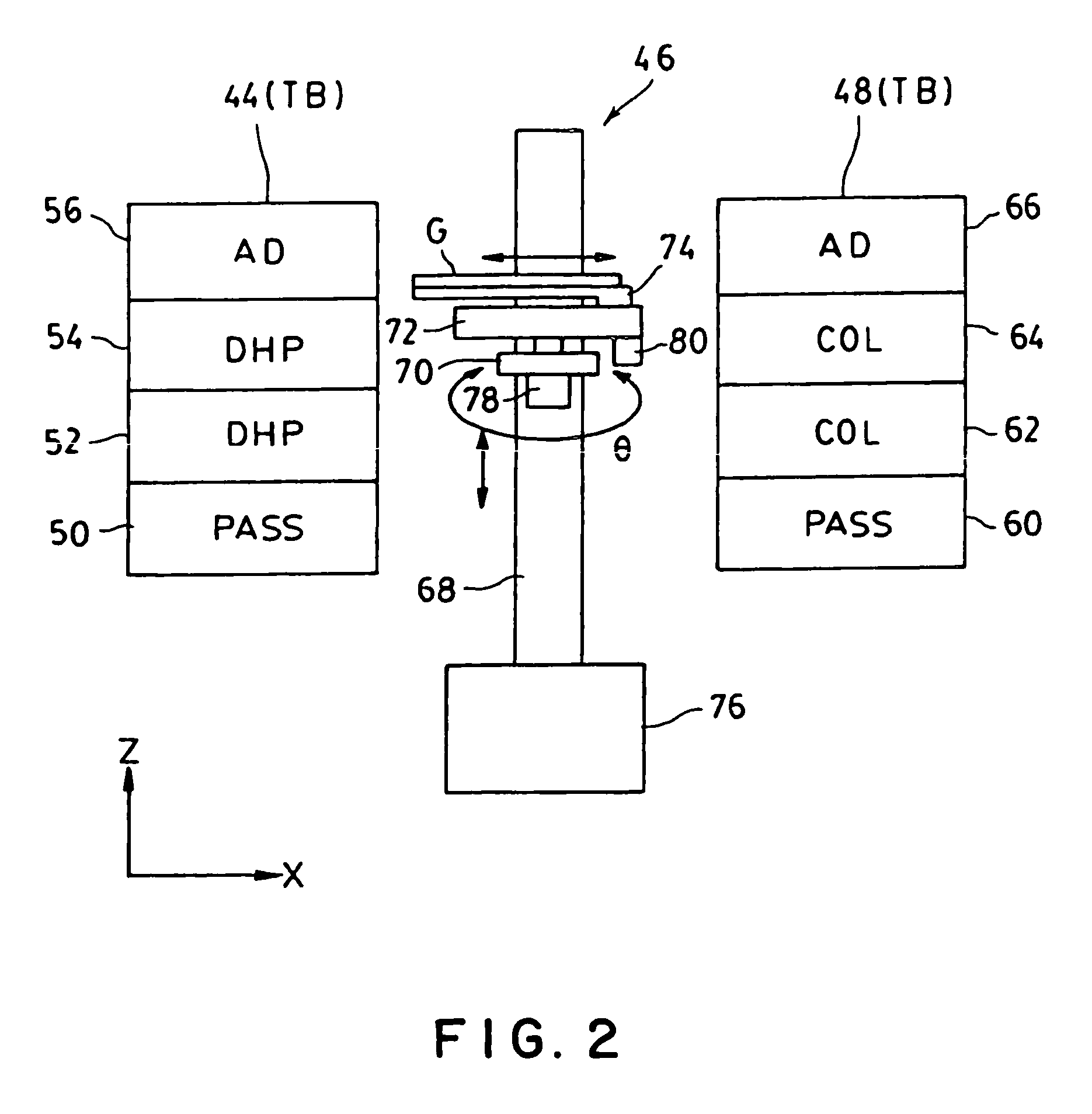

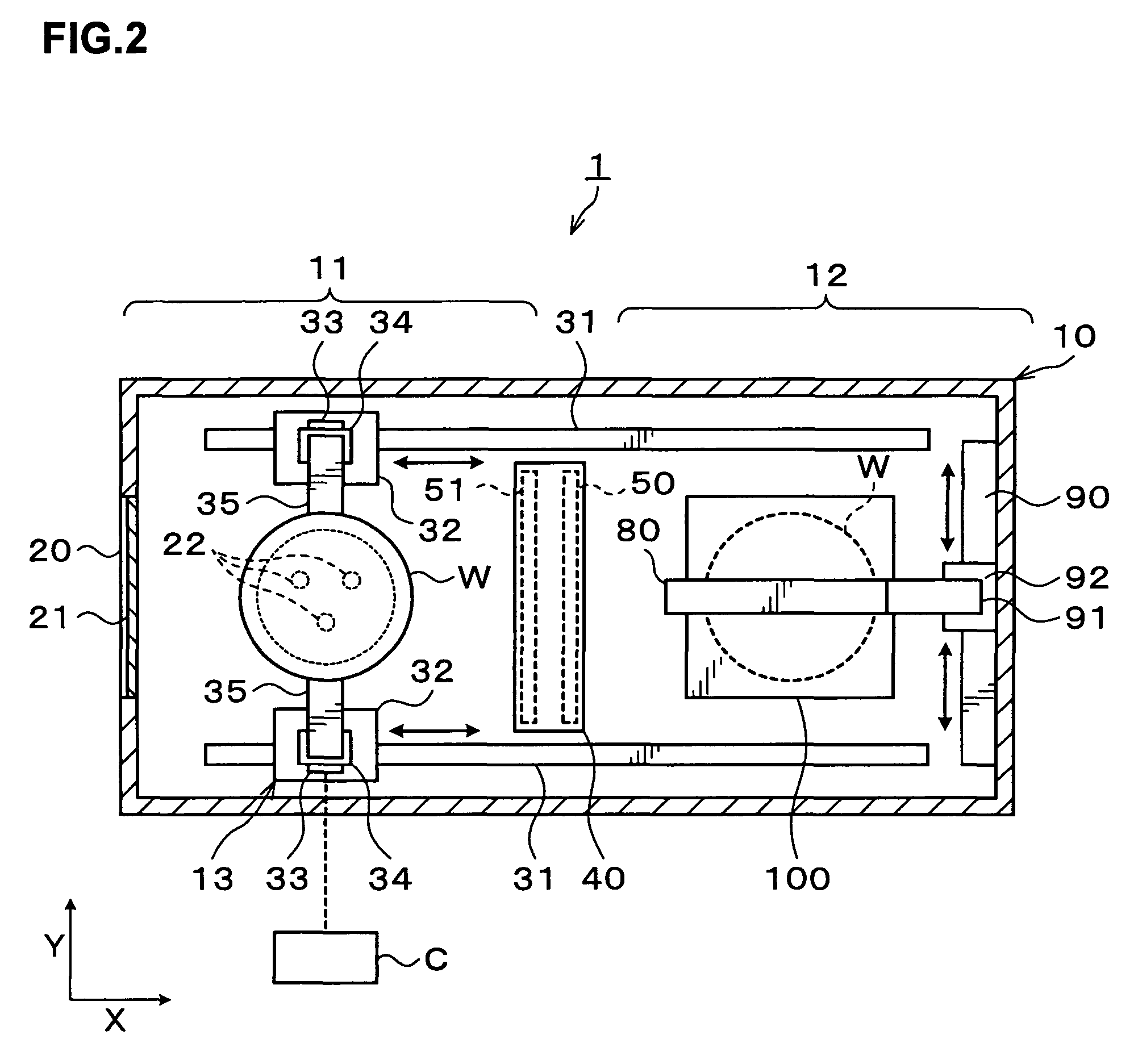

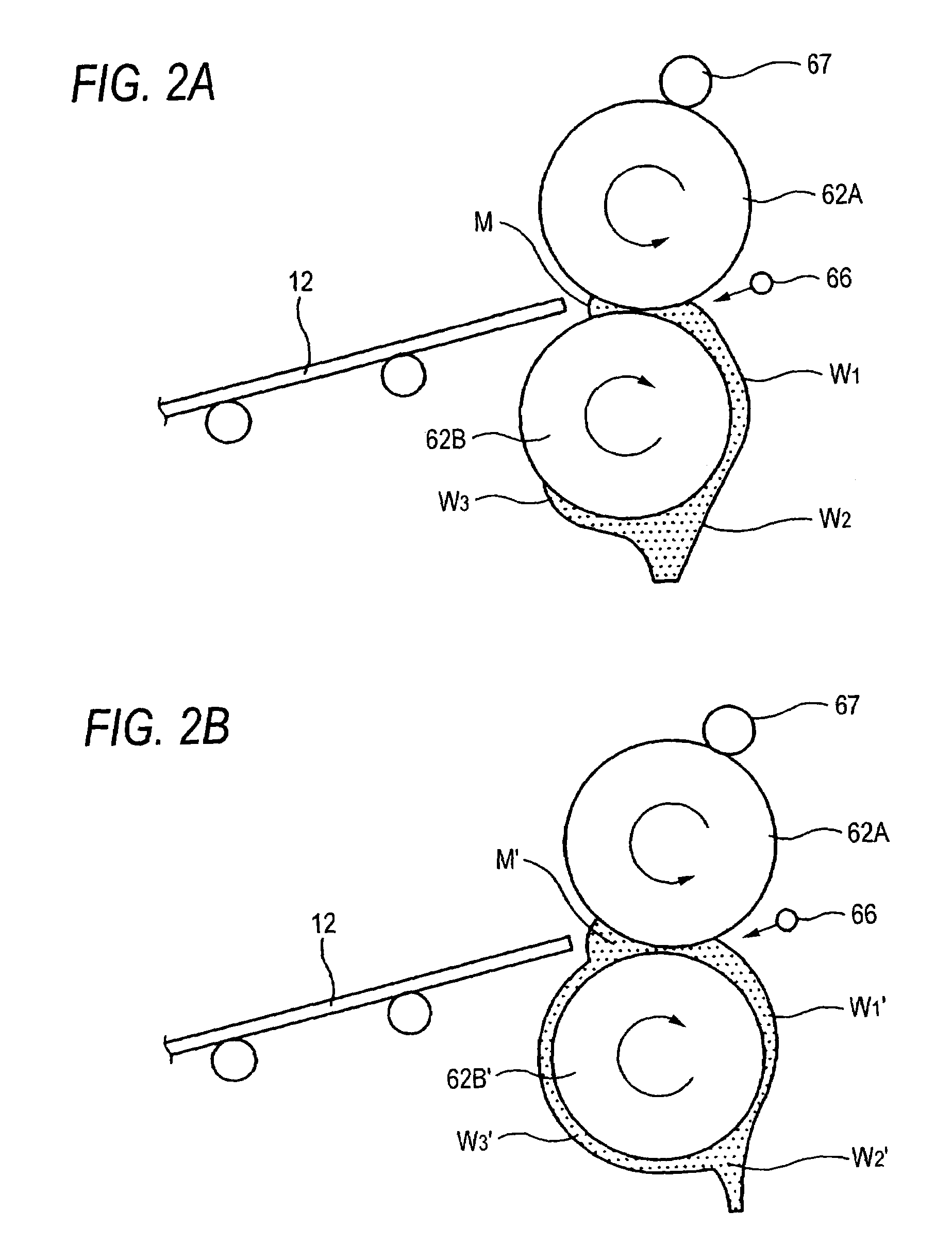

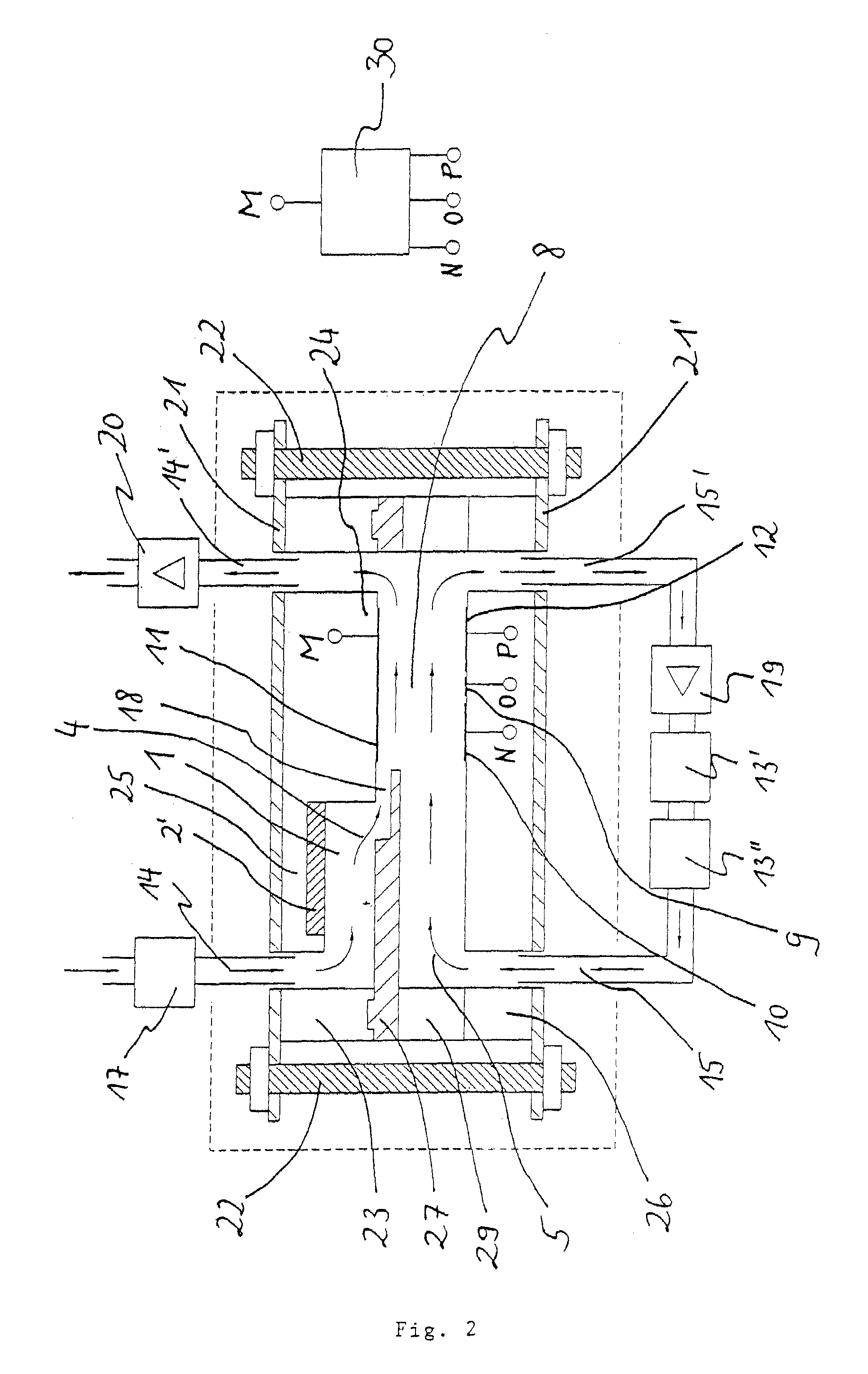

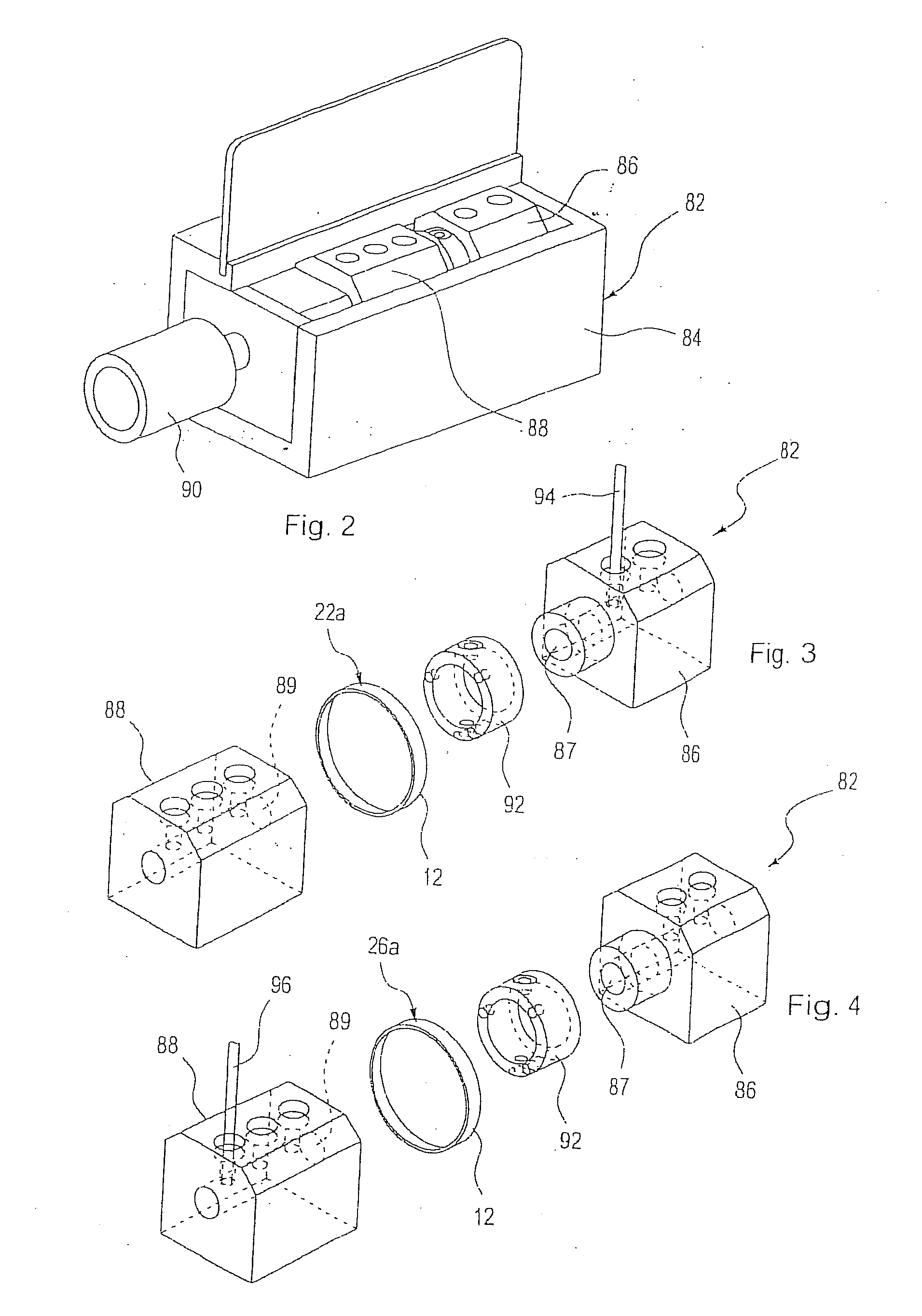

Developing treatment apparatus and developing treatment method

InactiveCN1908819ALow sliding resistanceDoes not produce passSemiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringContamination

In the present invention, a substrate transfer unit from which a substrate is transferred from / to the outside of a treatment container and a developing treatment unit in which development of the substrate is performed are arranged side by side in the treatment container, and a carrier mechanism is provided which carries the substrate while grasping an outside surface of the substrate from both sides, between the substrate transfer unit and the developing treatment unit. A developing solution supply nozzle for supplying a developing solution onto the substrate and a gas blow nozzle for blowing a gas to the substrate, are provided between the substrate transfer unit and the developing treatment unit and above a carriage path along which the substrate is carried, and a cleaning solution supply nozzle is provided in the developing treatment unit for supplying a cleaning solution onto the substrate. According to the present invention, since the substrate is carried with its outside surface being grasped, spread of contamination can be prevented to restrain generation of particles in the treatment container.

Owner:TOKYO ELECTRON LTD

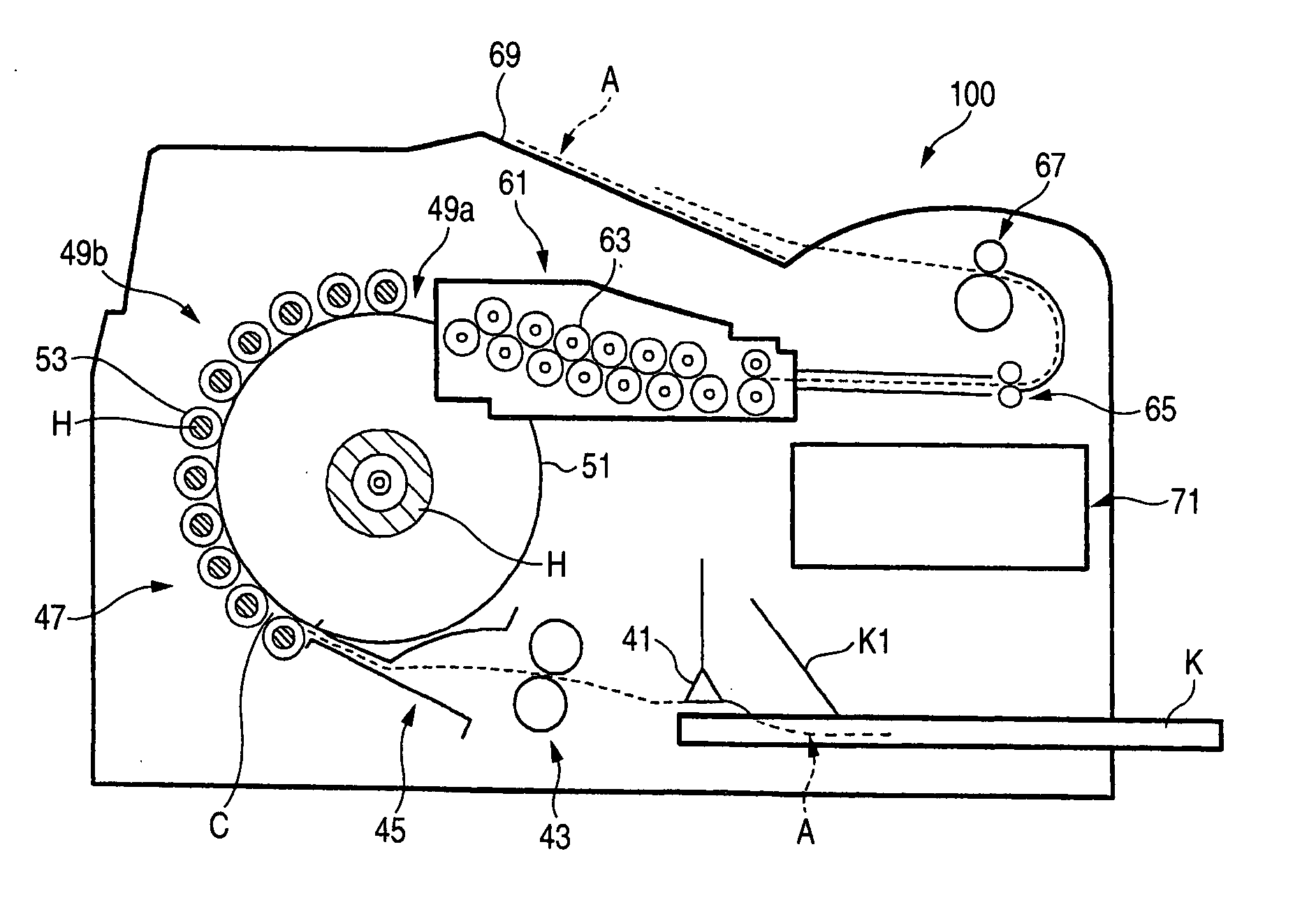

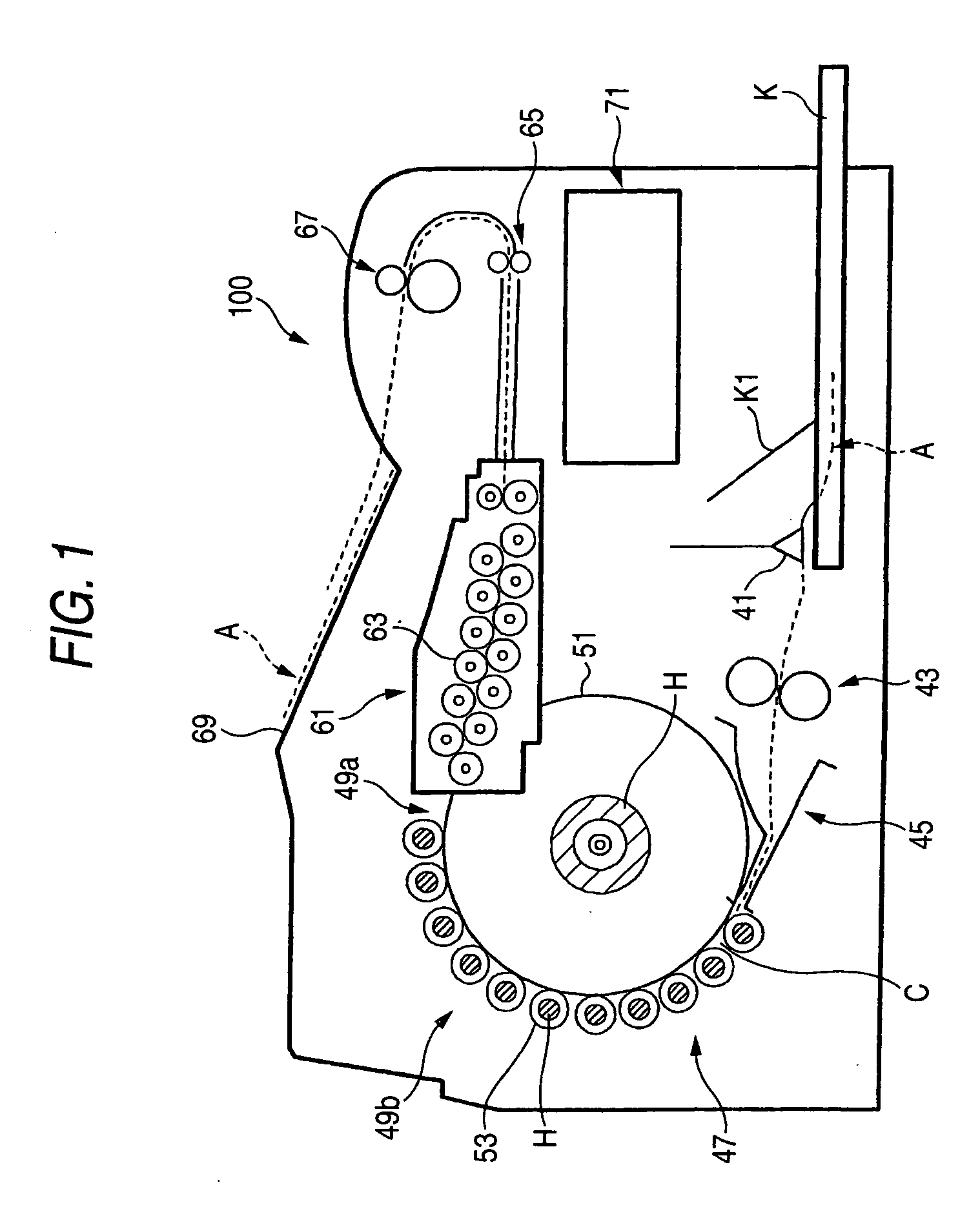

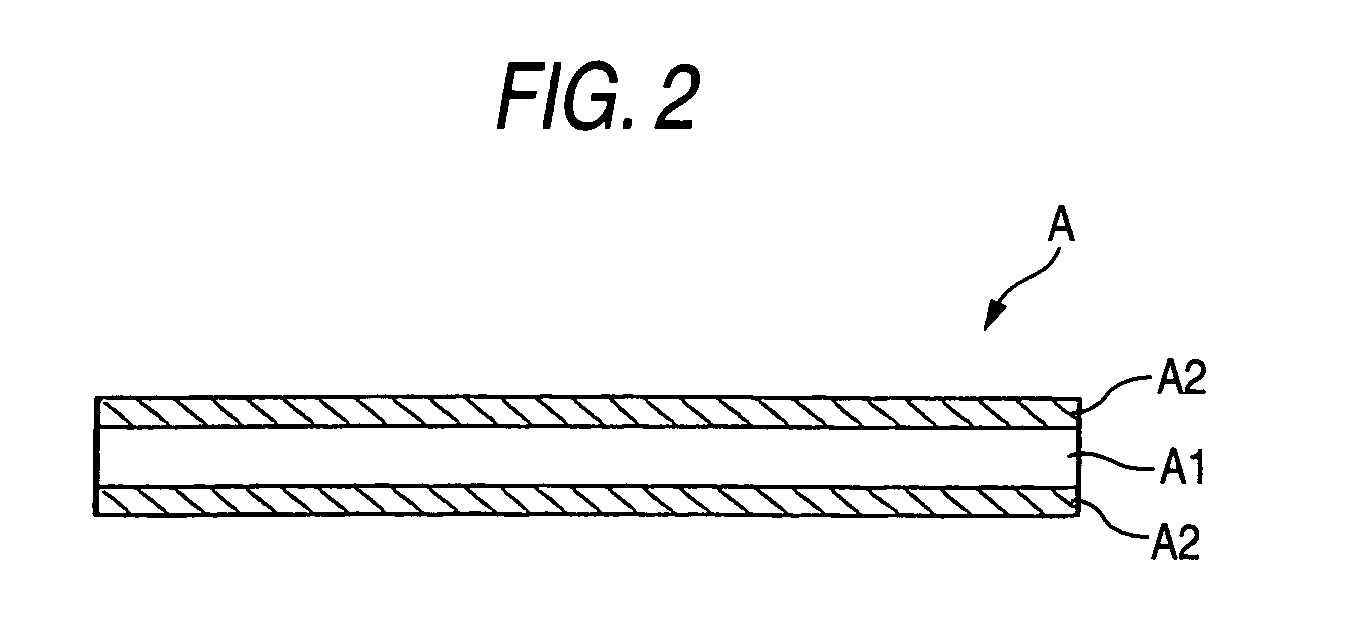

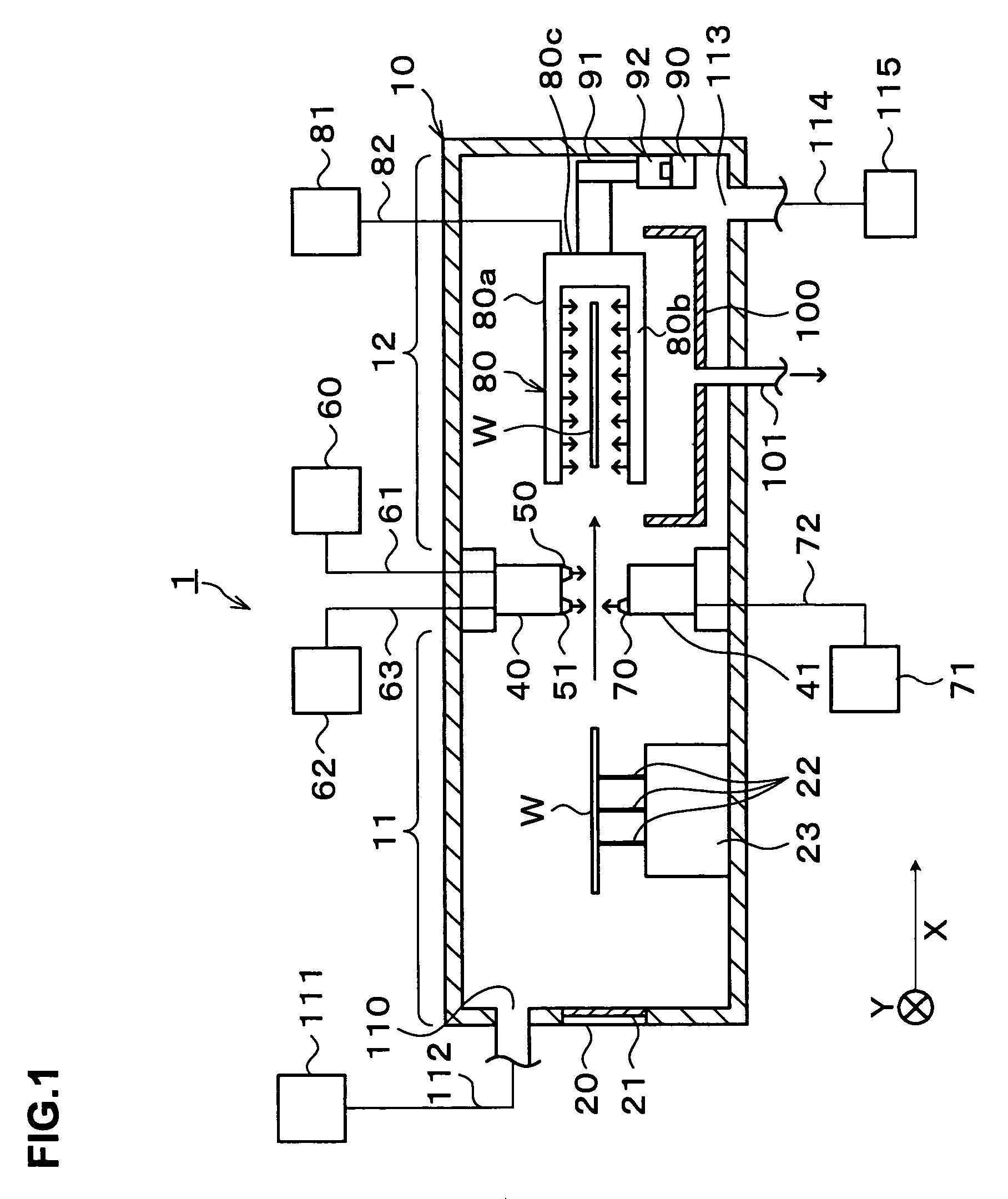

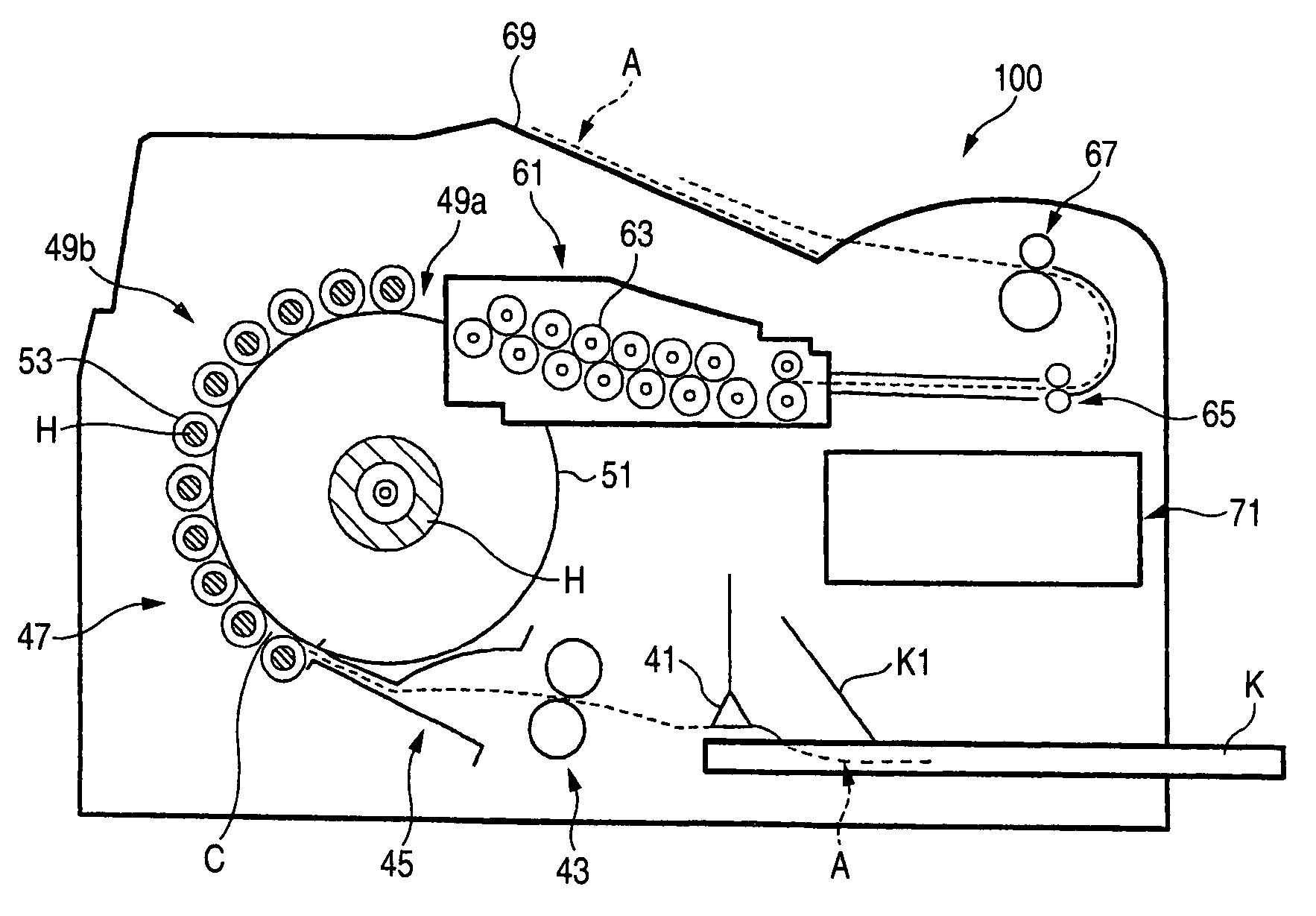

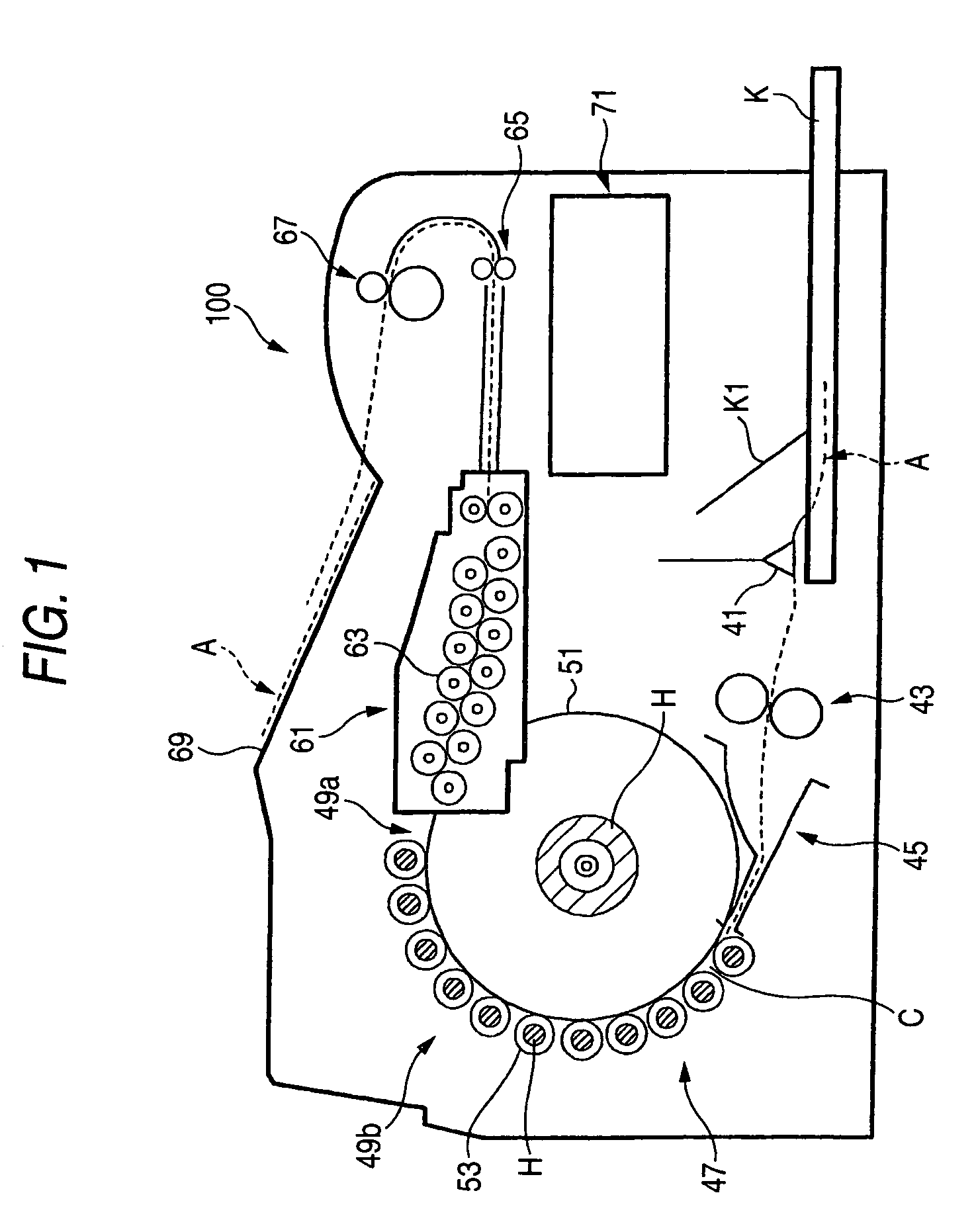

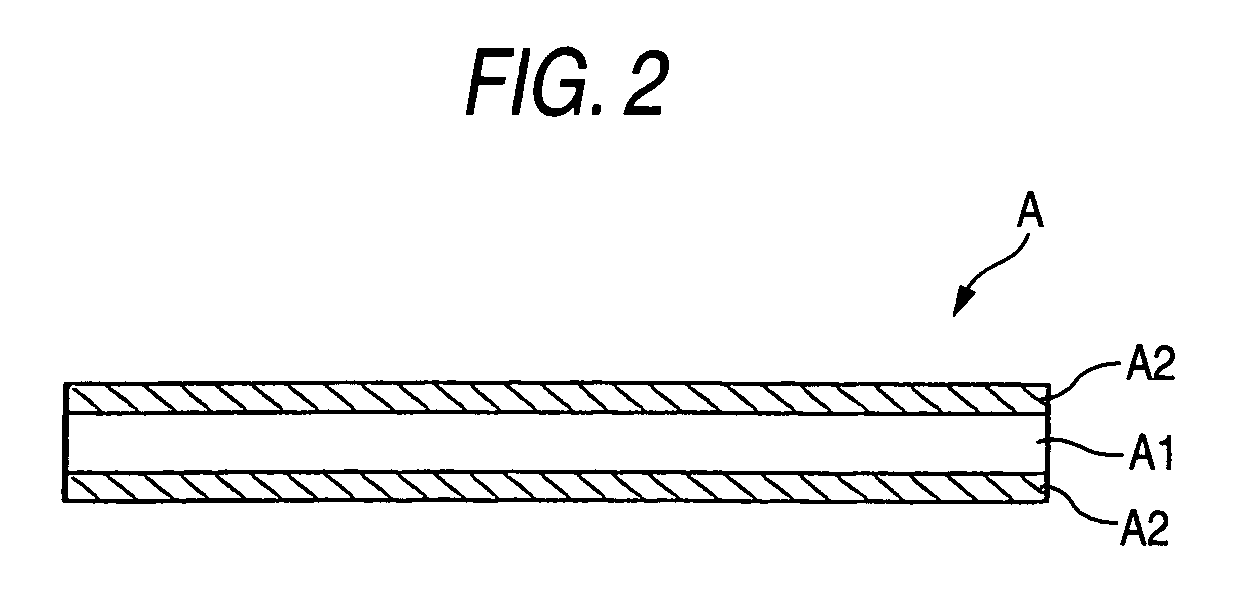

Thermal developing apparatus

InactiveUS20050195271A1Reduced space required for installationConvey evenlyRecording apparatusElectrode and associated part arrangementsLatent imageEngineering

A thermal developing apparatus for visualizing a latent image recorded on a photosensitive thermal developing recording material by heating the photosensitive thermal developing recording material with heating unit while conveying the photosensitive thermal developing recording material with conveying unit along a conveying path having the heating unit equipped therewith, the thermal developing apparatus containing a manual feeding tray for manually feeding the exposed photosensitive thermal developing recording material into the thermal developing apparatus.

Owner:FUJIFILM CORP +1

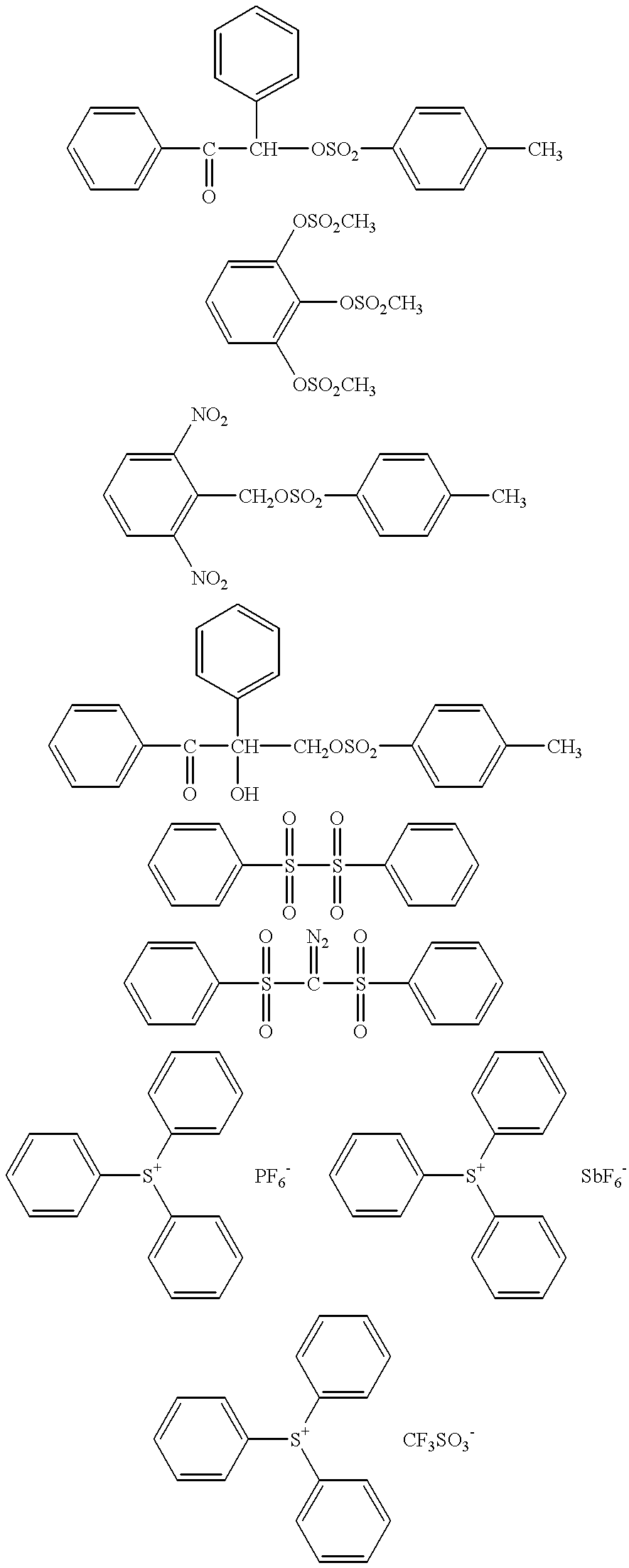

Photosensitive resin composition and process for producing the same

InactiveUS20020012867A1Improve cross-linking efficiencyGenerate efficientlySemiconductor/solid-state device manufacturingDiazo compound compositionsNaphthoquinonePerylene derivatives

A photosensitive resin composition comprises a base resin (e.g., novolak resins, polyvinylphenol-series polymers), a first photoactive ingredient (e.g., diazobenzoquinone derivatives, diazonaphthoquinone derivatives) and a second photoactive ingredient (e.g., mixtures with azide compounds) each having an absorption range at wavelength lambd1 or lambd2, the wavelengths thereof being different from each other. Between the first and second photoactive ingredients, at least one photoactive ingredient is substantially inert at the absorption wavelength of the other. After exposing the photosensitive resin composition to a light to form a pattern, the whole surface of the photosensitive layer is exposed to a light of the other wavelength to make the surface hardly soluble (in the case a positive pattern is formed) or readily soluble (in the case a negative pattern is formed) in a developer, and developed, thereby forming a pattern of high resolution. Utilizing an existing exposure system, there can be obtained photosensitive resin compositions (especially, resists for semiconductor production) having improved sensitivity and resolution.

Owner:KRI INC

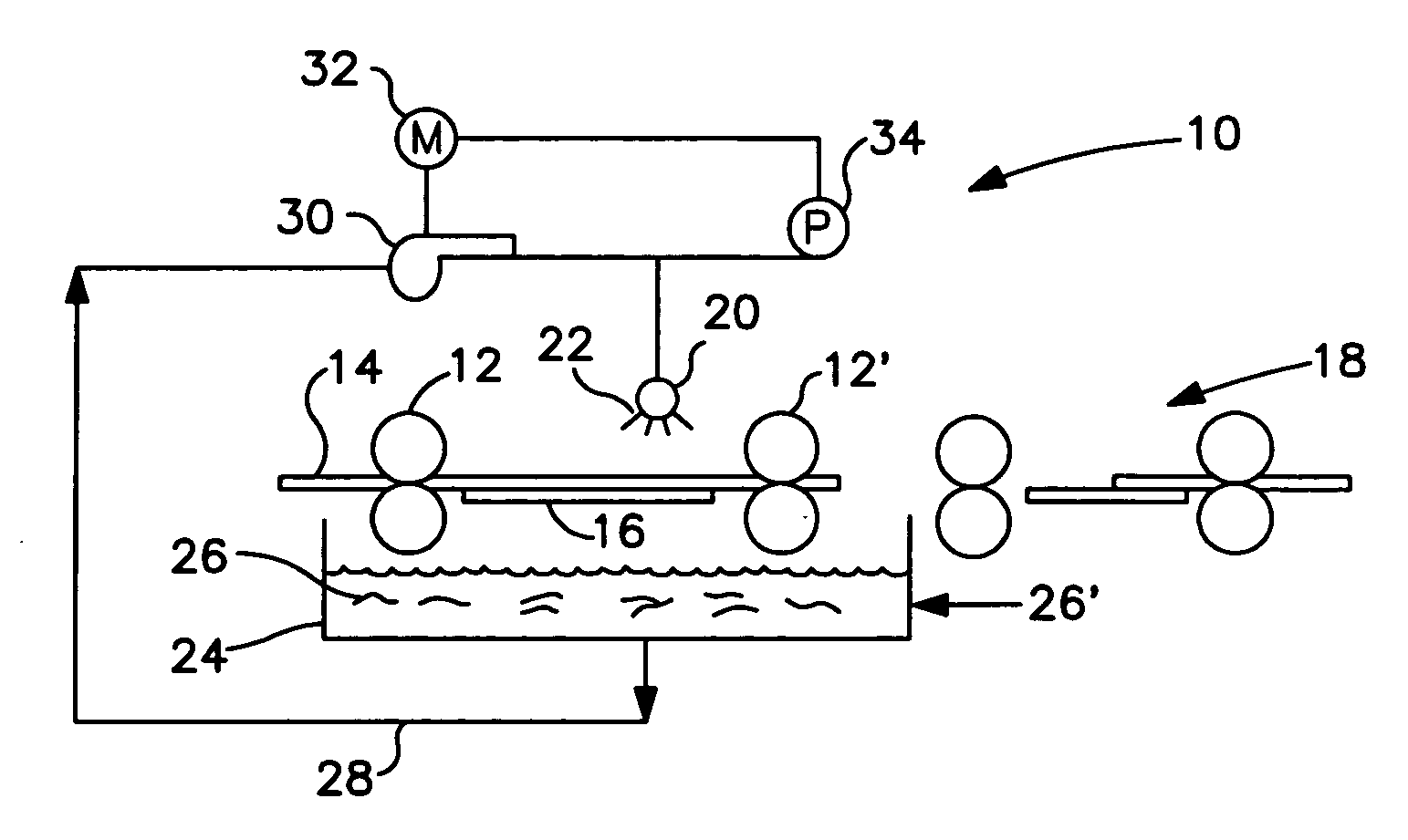

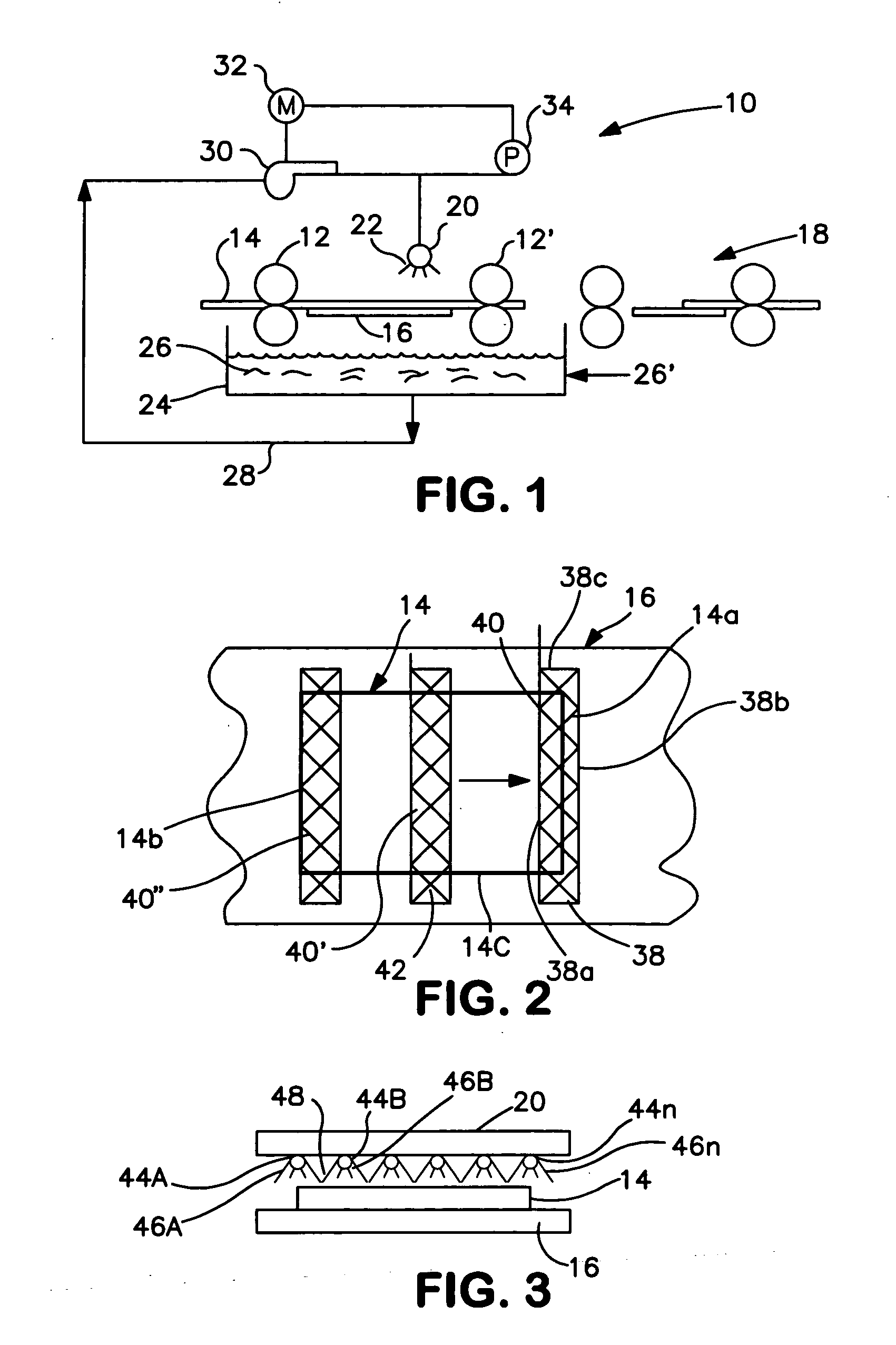

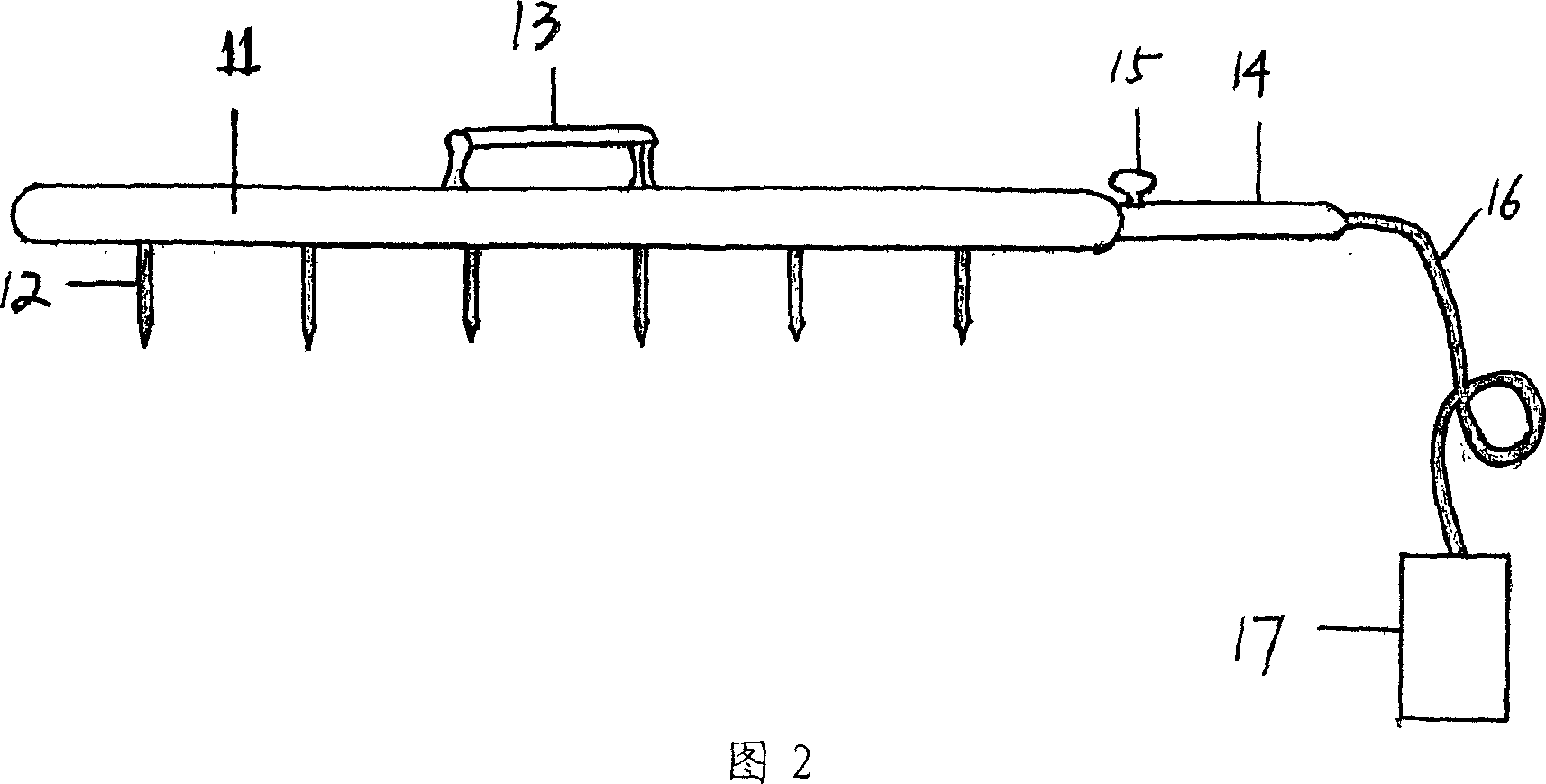

Spray development of photosensitive plates

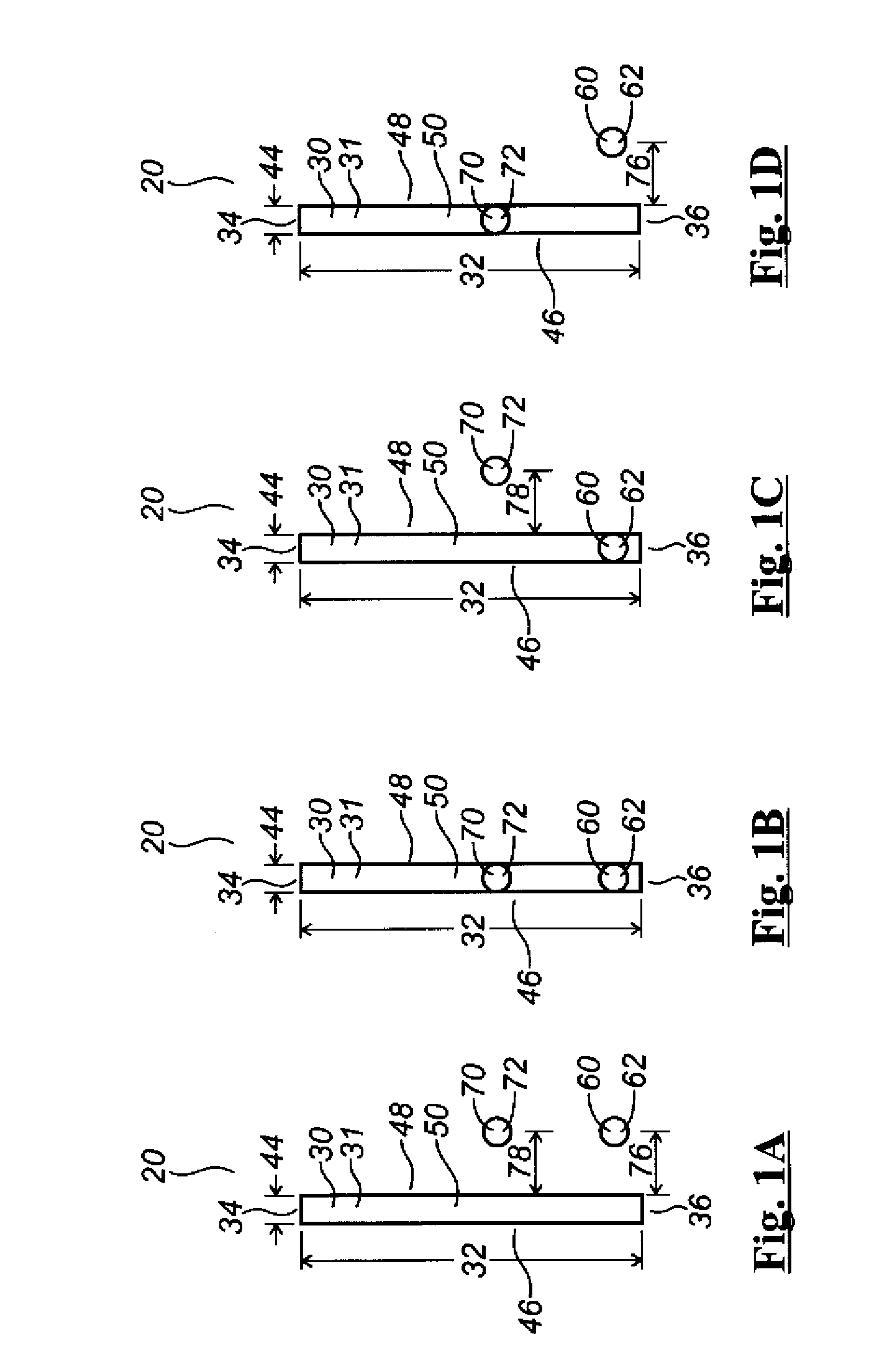

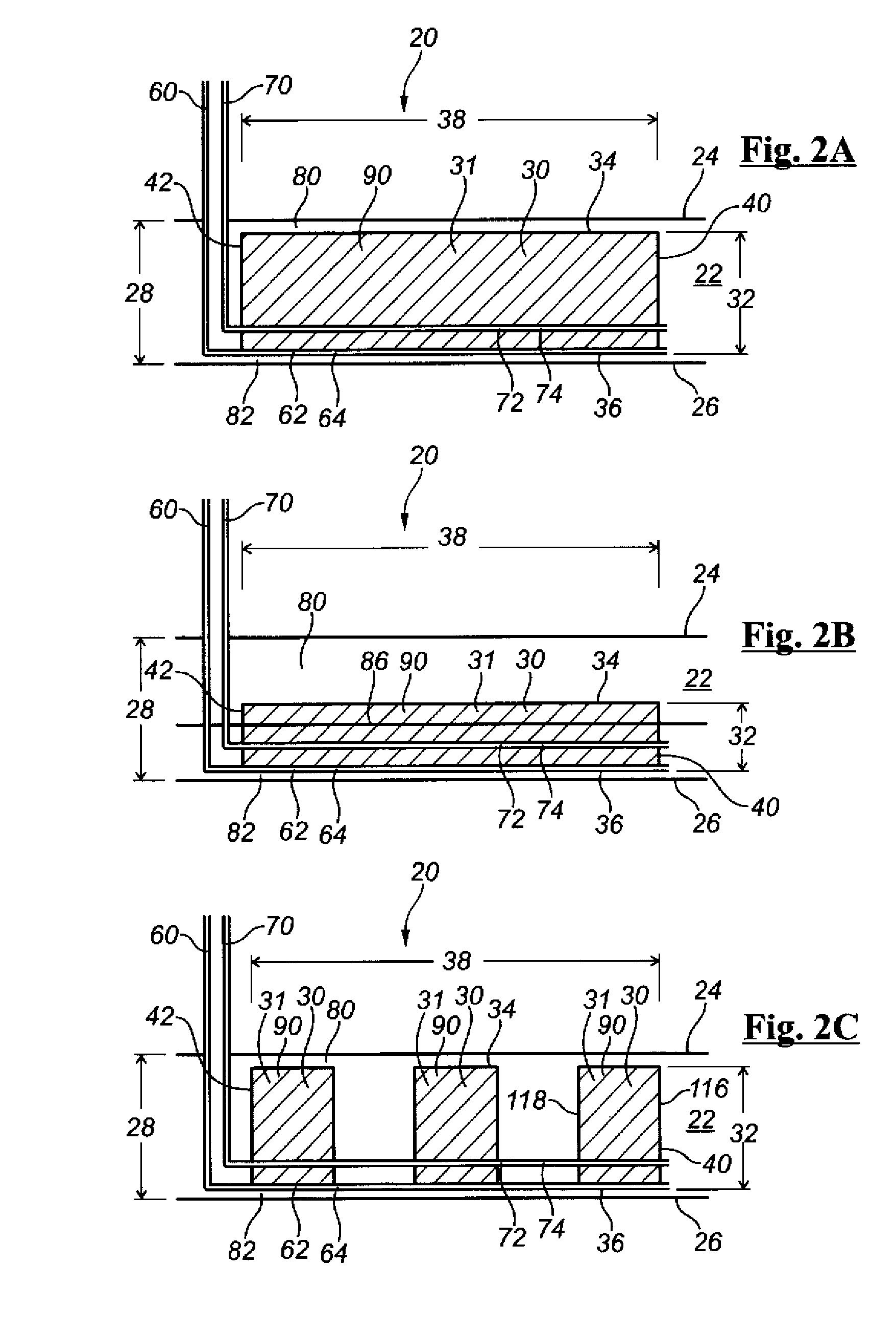

InactiveUS20080101792A1Promote resultsUniform developmentLiquid processingPhotomechanical apparatusSoftware engineeringPlanographic printing

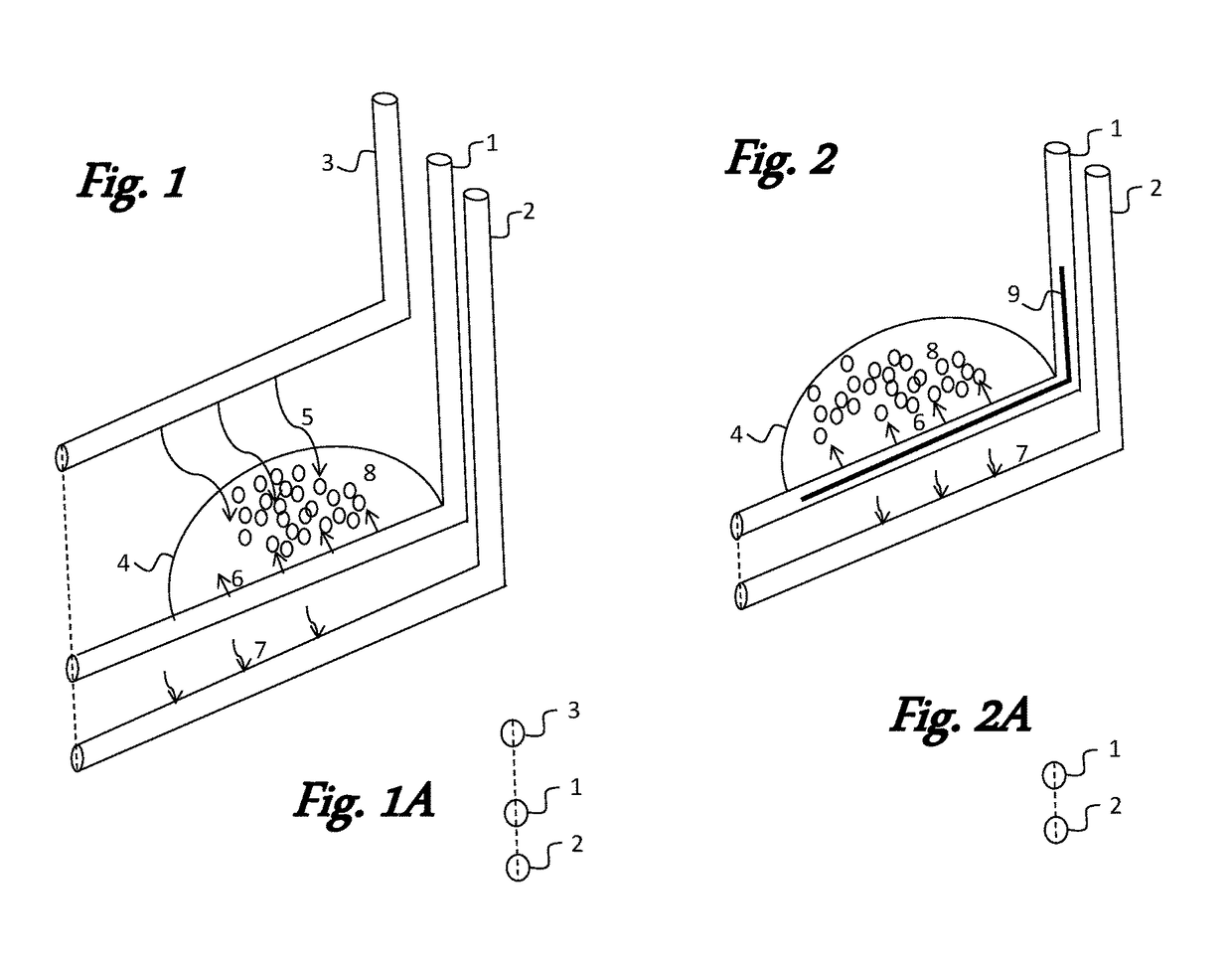

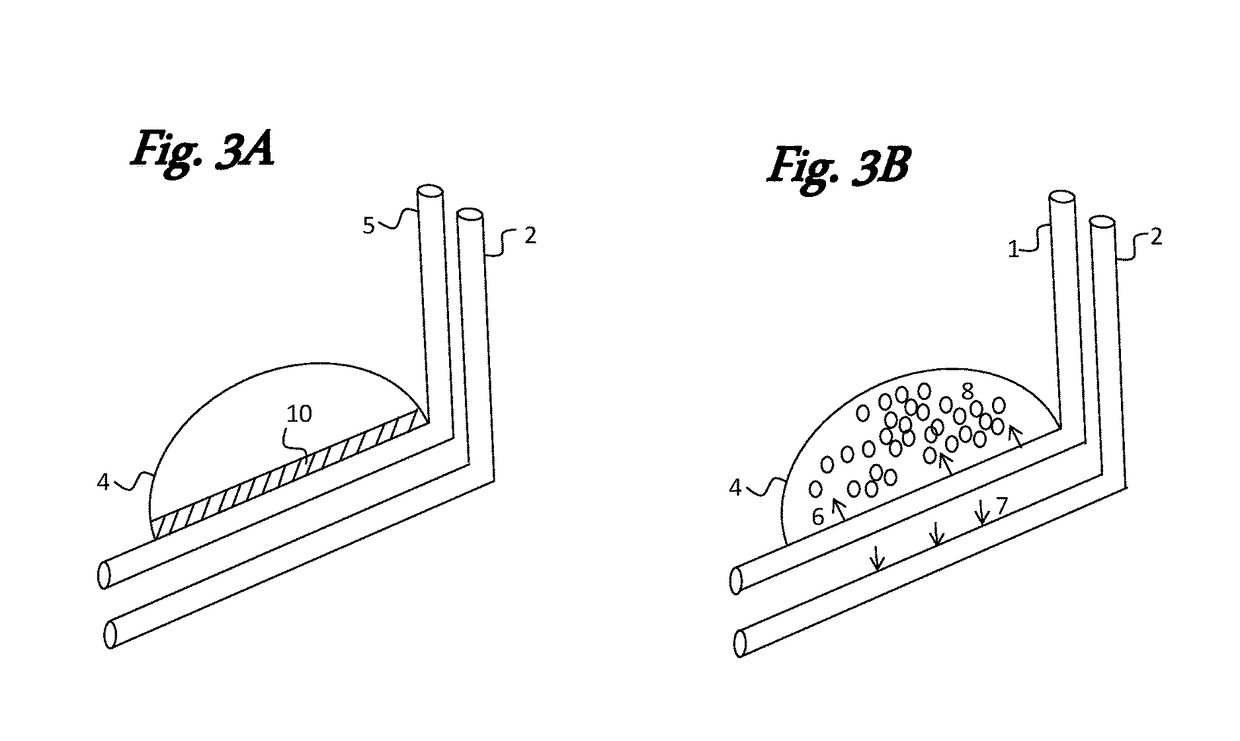

Excellent development of photosensitive coatings on planographic printing plates is achieved by directing a dynamic flow of fresh alkaline developer solution that impinges on a target area of the coating extending the width of the plate and floods the target area with a turbulent flow. At sufficient volumetric flow rate, the developer solution at the target area is constantly displaced during the development time, whereby no boundary layer forms on and travels with the plate during the development time and thus the target area is always in contact with fresh developer solution.

Owner:ANOCOIL

Steam foam methods for steam-assisted gravity drainage

ActiveUS20170226836A1Low mobilityImproves heavy oil productionFluid removalDrilling compositionFully developedInjection site

Methods for making efficient use of steam in a steam-assisted gravity drainage (SAGD) process for recovering heavy oils from tar sands and similar petroleum deposits are disclosed. The methods utilize a surfactant to generate steam foam in ways that maximize efficient use of steam. In some aspects, steam foam is used in water layers or gas caps that reside above steam chambers to prevent loss of steam from the steam chamber. The predominant use of relatively dry steam in SAGD processes makes it challenging to find ways to introduce surfactants and generate steam foam. However, decreasing the mobility of the steam by converting at least some of it to foam allows the wellbore and steam chambers above the injection site to be more fully developed, provides for more effective heat transfer to the heavy oil and rock, improves production, and allows recovery of the heavy oil with a minimum amount of steam usage.

Owner:STEPAN COMPANY

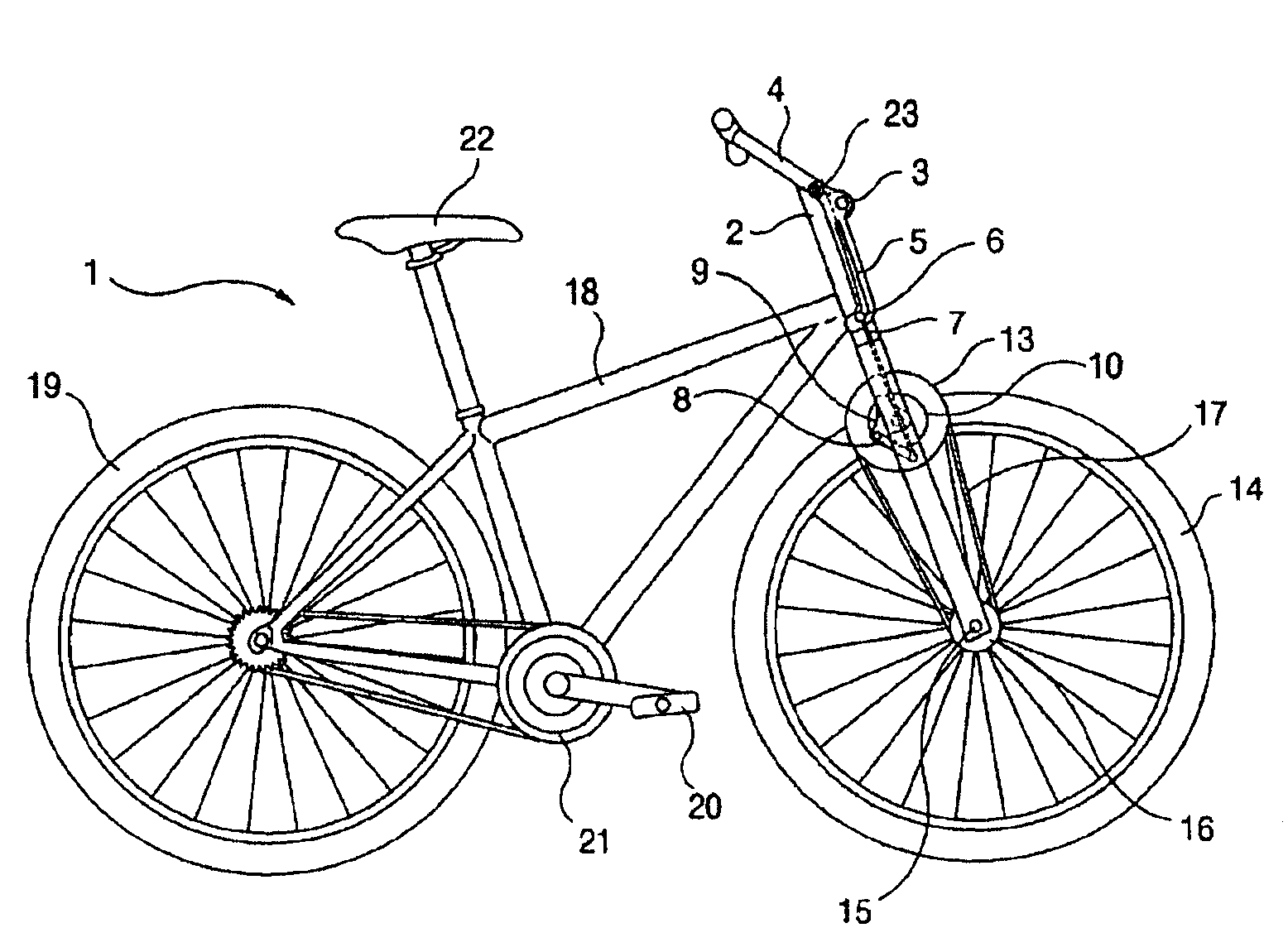

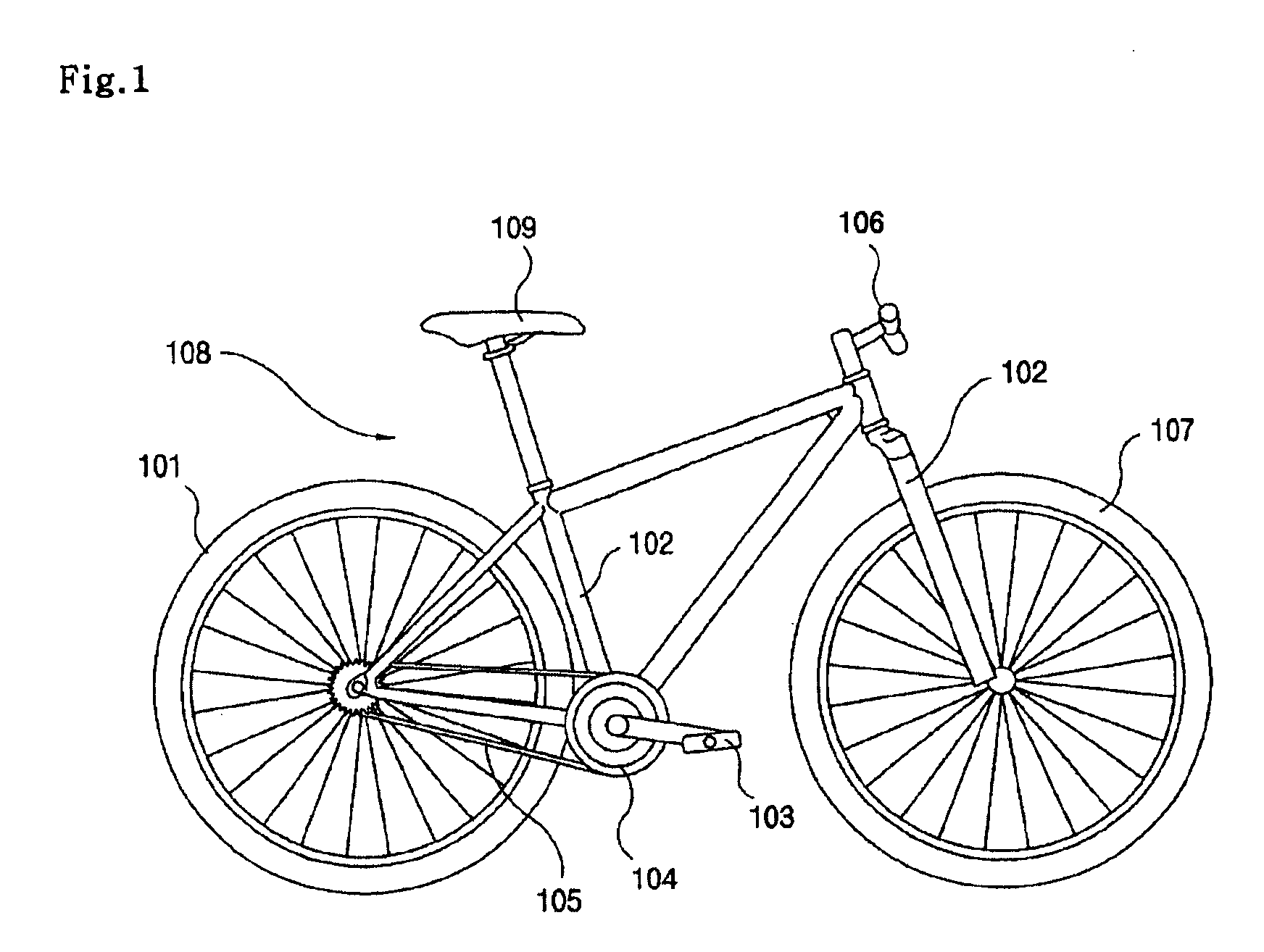

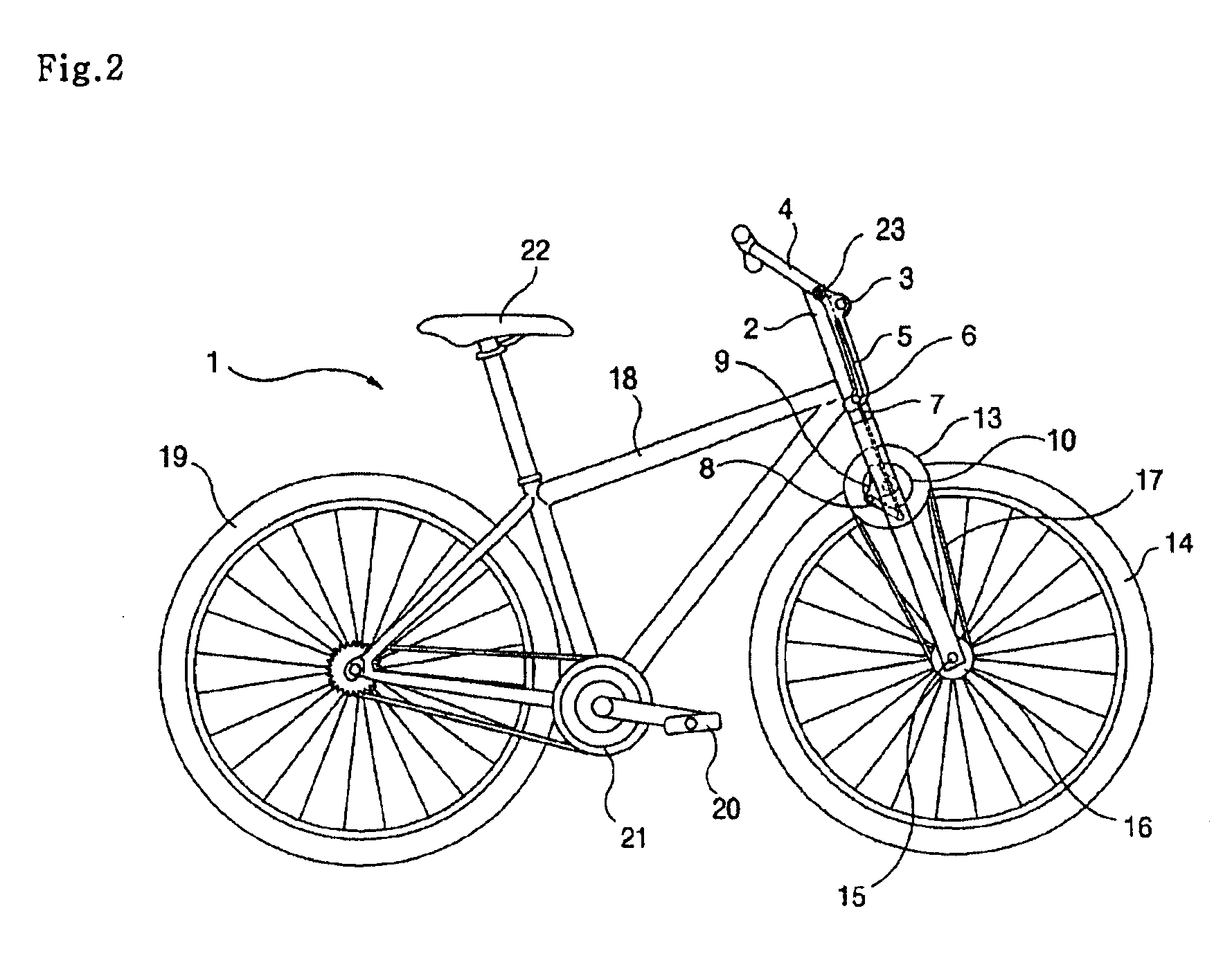

Bicycle of type driven by operation of handle

Disclosed herein is a bicycle of the type driven by operation of a handle. According to the present invention, a shaft rod of the bicycle is installed with a hinge so as to enable the handle to rotate forward or backward. The handle is bent by a constant angle on the basis of the hinge, thereby being divided into both upper and lower portions on the basis of the hinge. The handle is formed at the lower portion thereof with an elongated guide bore, and a roller is inserted inside the guide bore so as to move upward and downward along the guide bore. The roller is connected to the upper end of a rod, which is installed so as to move upward and downward in a rectilinear course according to pulling and pushing operation of the handle.

Owner:PARK HUN GEUN

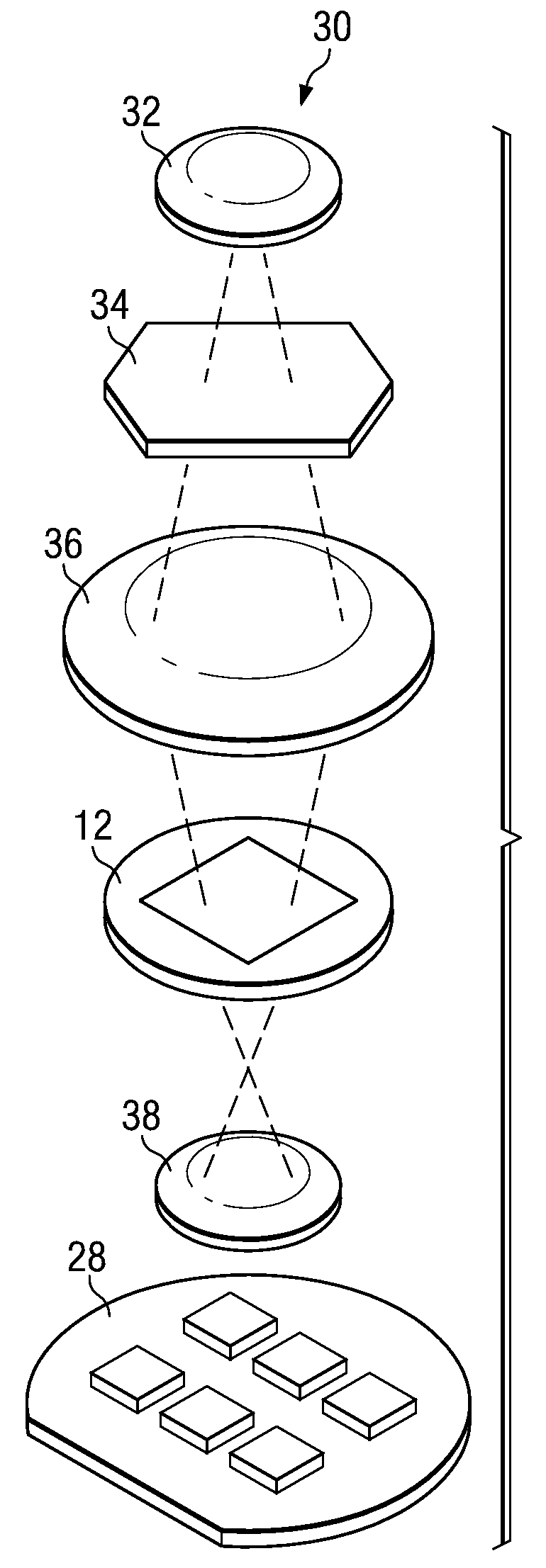

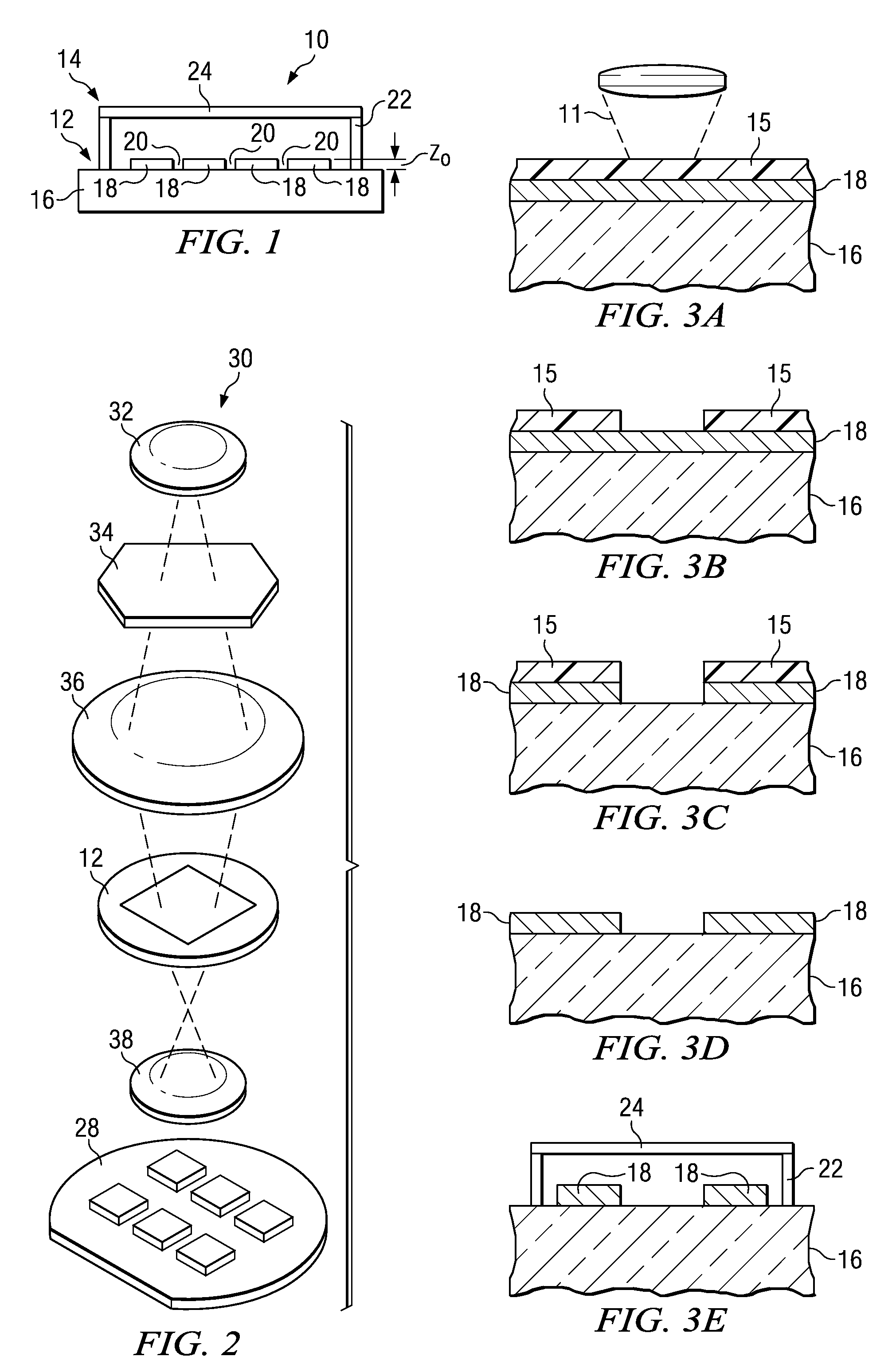

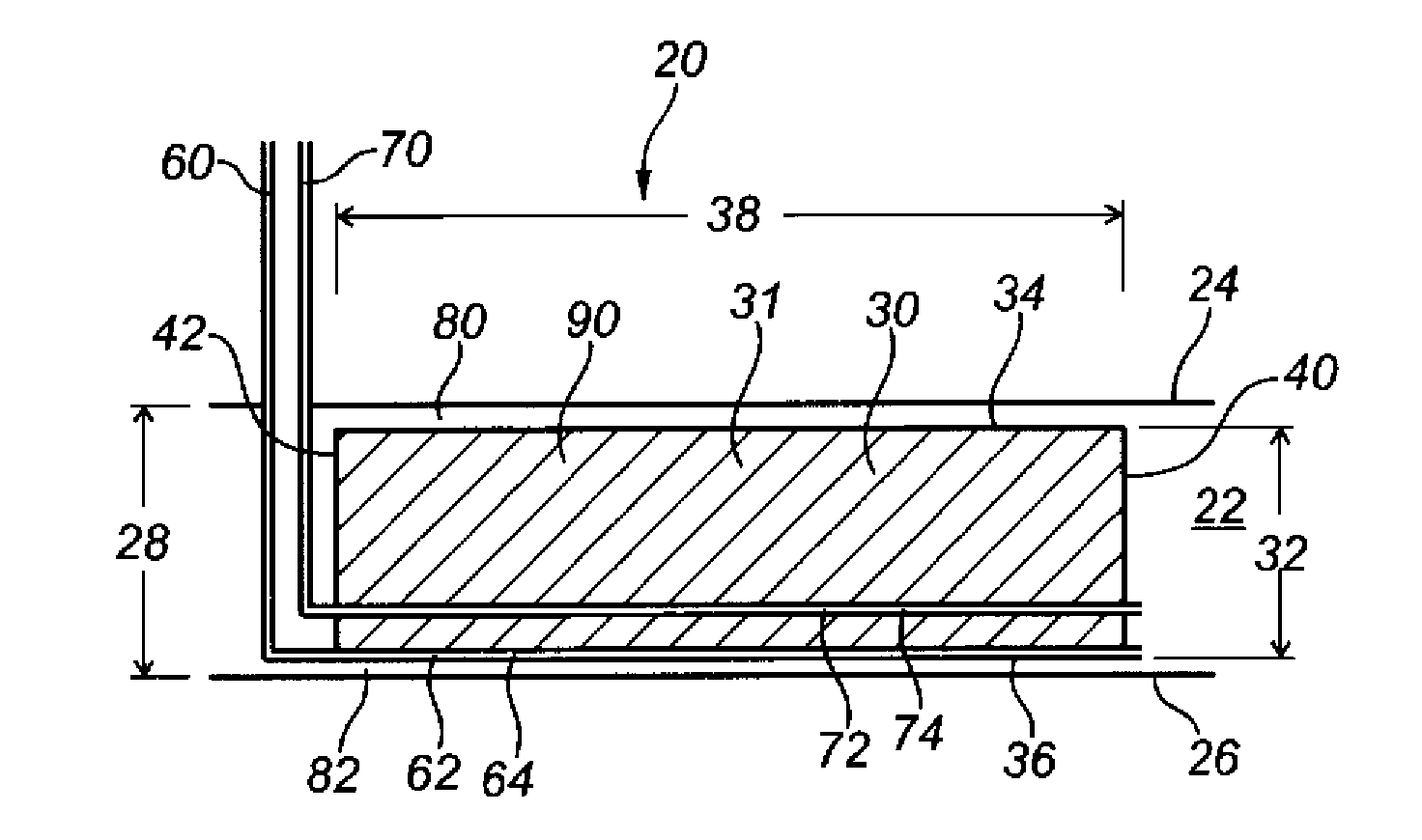

System and Method for Performing High Flow Rate Dispensation of a Chemical onto a Photolithographic Component

InactiveUS20090166319A1Reduce harmful effectsIncrease flow rateLiquid surface applicatorsAfter-treatment detailsSpray nozzleEngineering

A system and method for performing high flow rate dispensation of a chemical onto a photolithographic component are disclosed. The system and method includes providing a photolithographic component in a manufacturing tool. The photolithographic is positioned at a predetermined distance from a nozzle dispensing a chemical. Dispensation of a chemical at a high flow rate onto a photolithographic component, the rate of flow operable to reduce harmful effects from occurring on the surface of the photolithographic substrate.

Owner:TOPPAN PHOTOMASKS INC

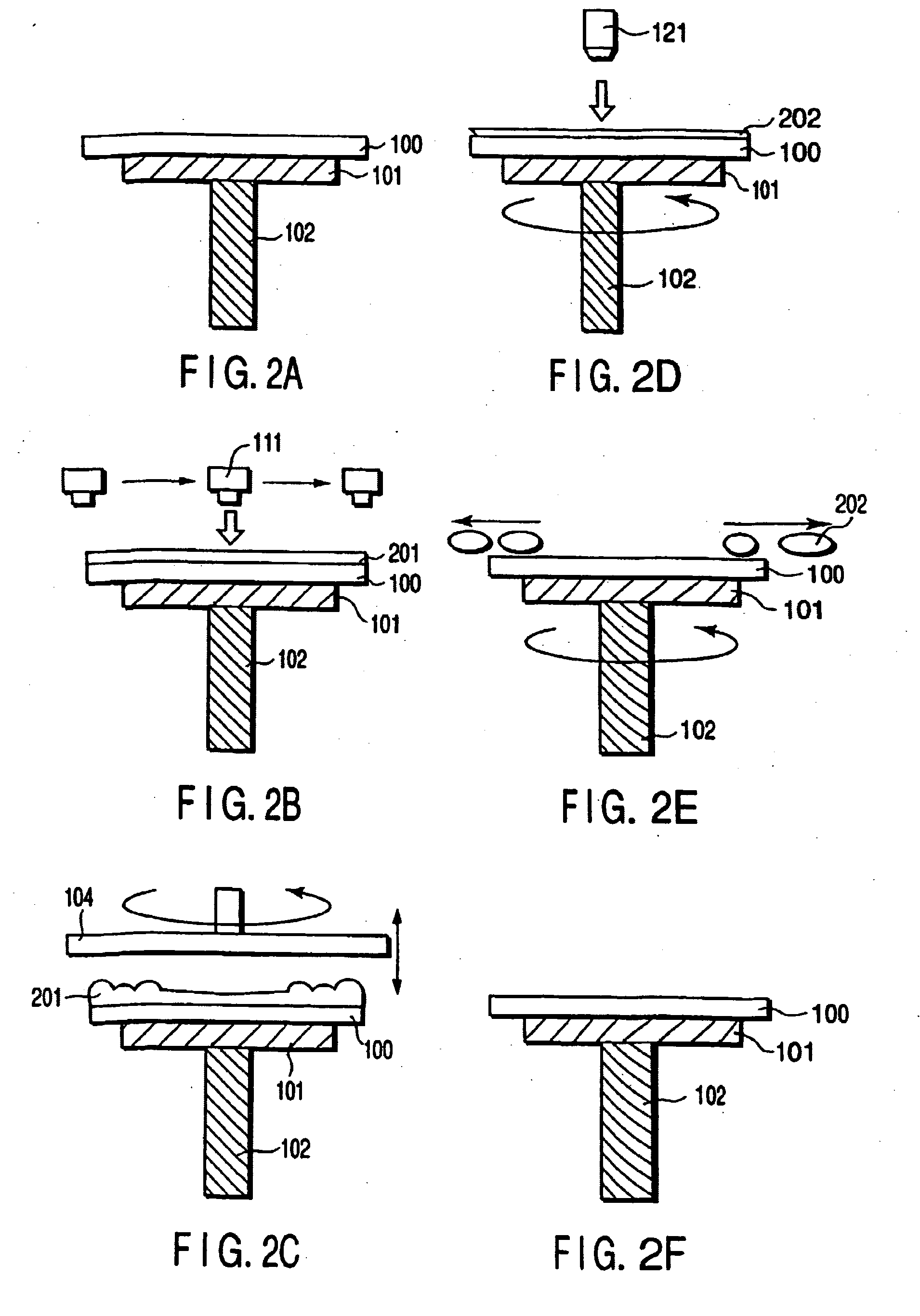

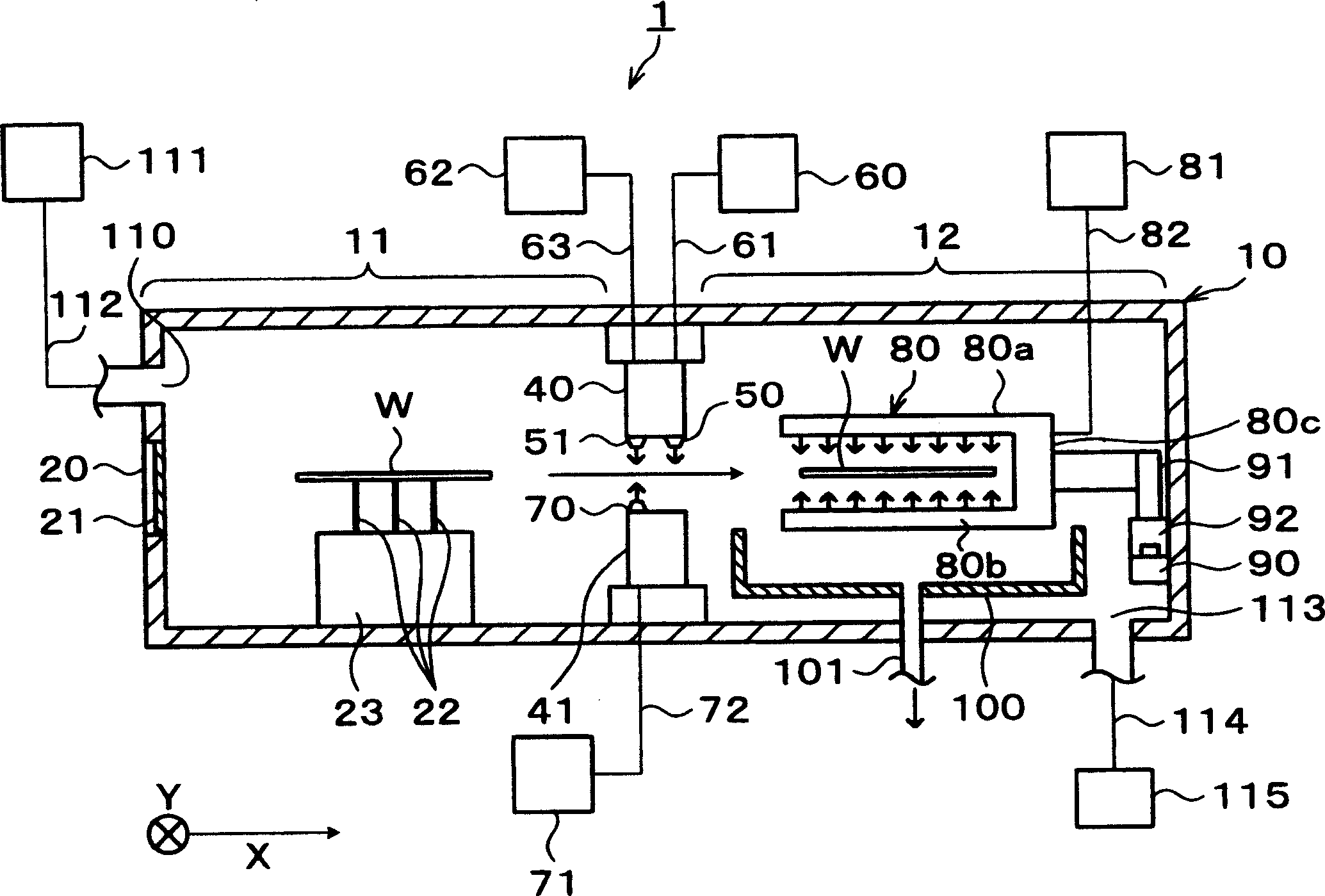

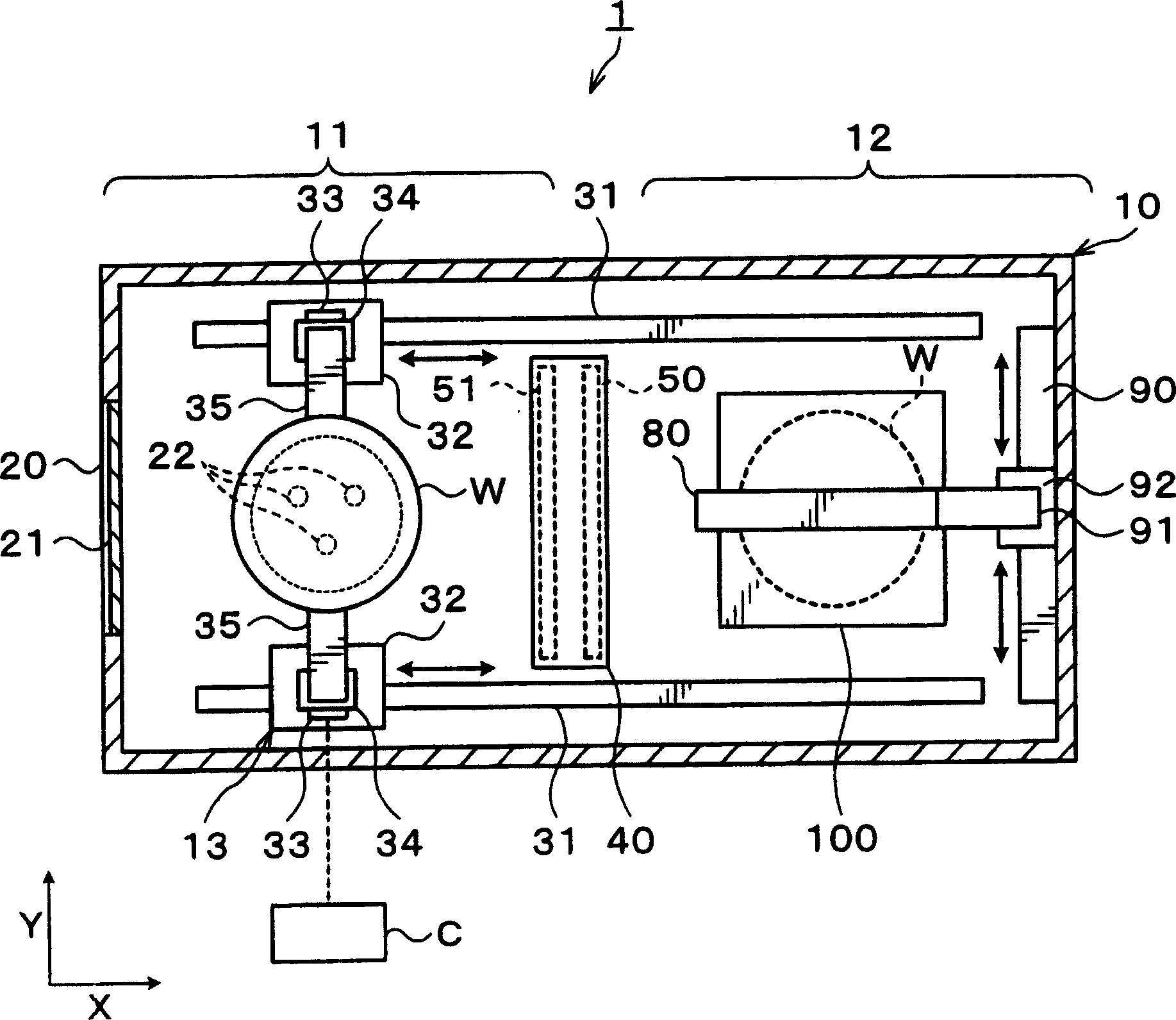

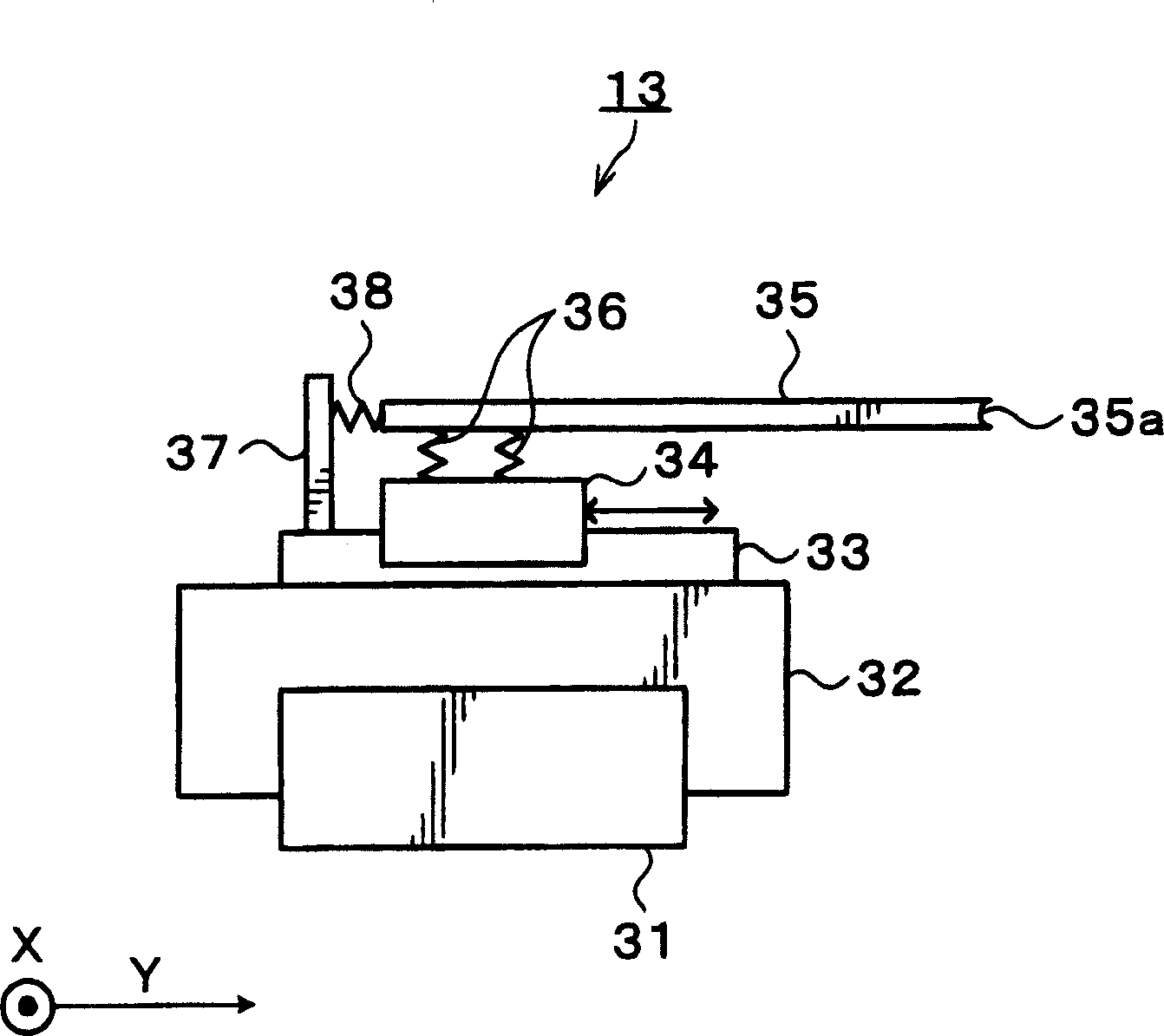

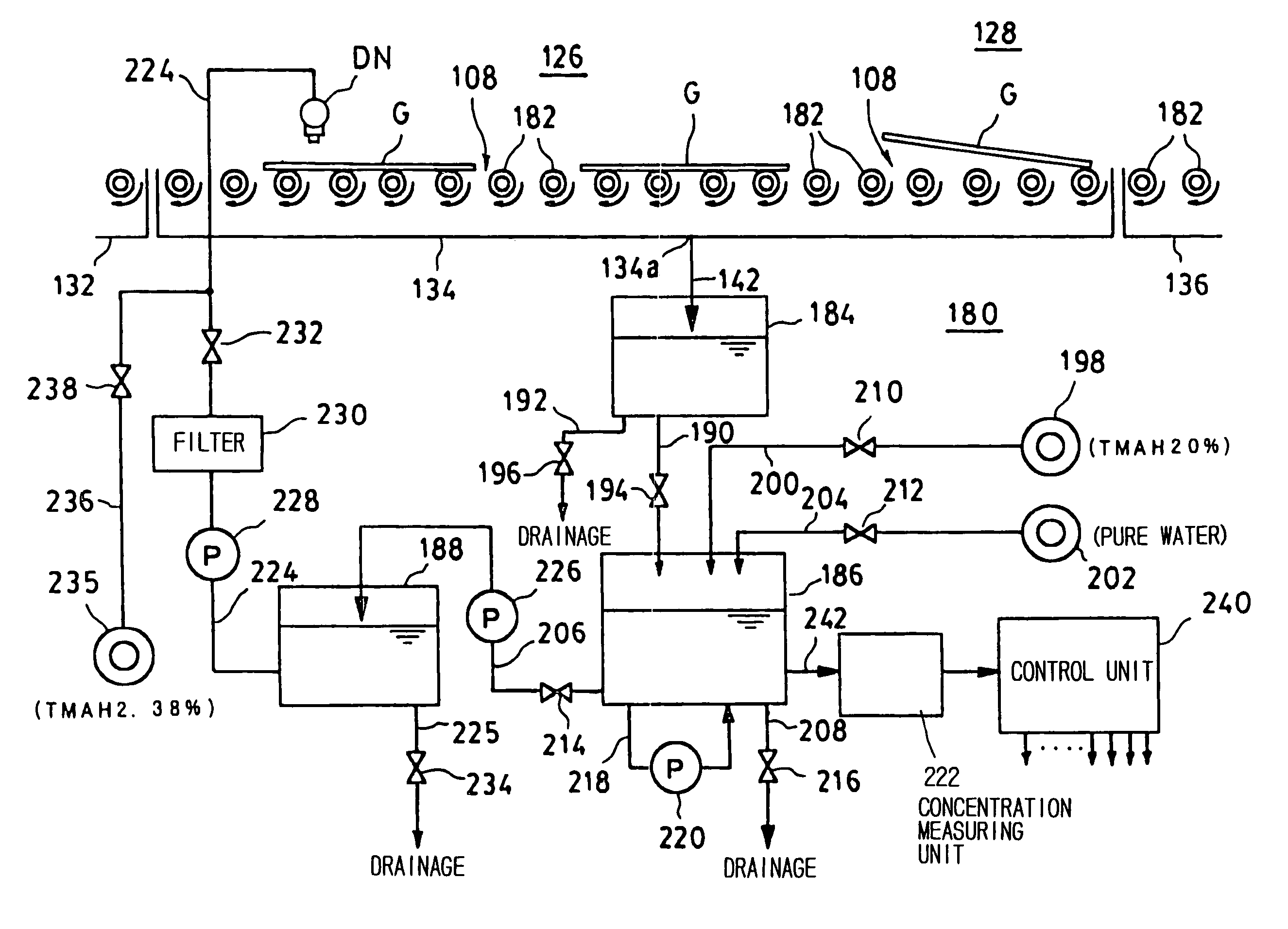

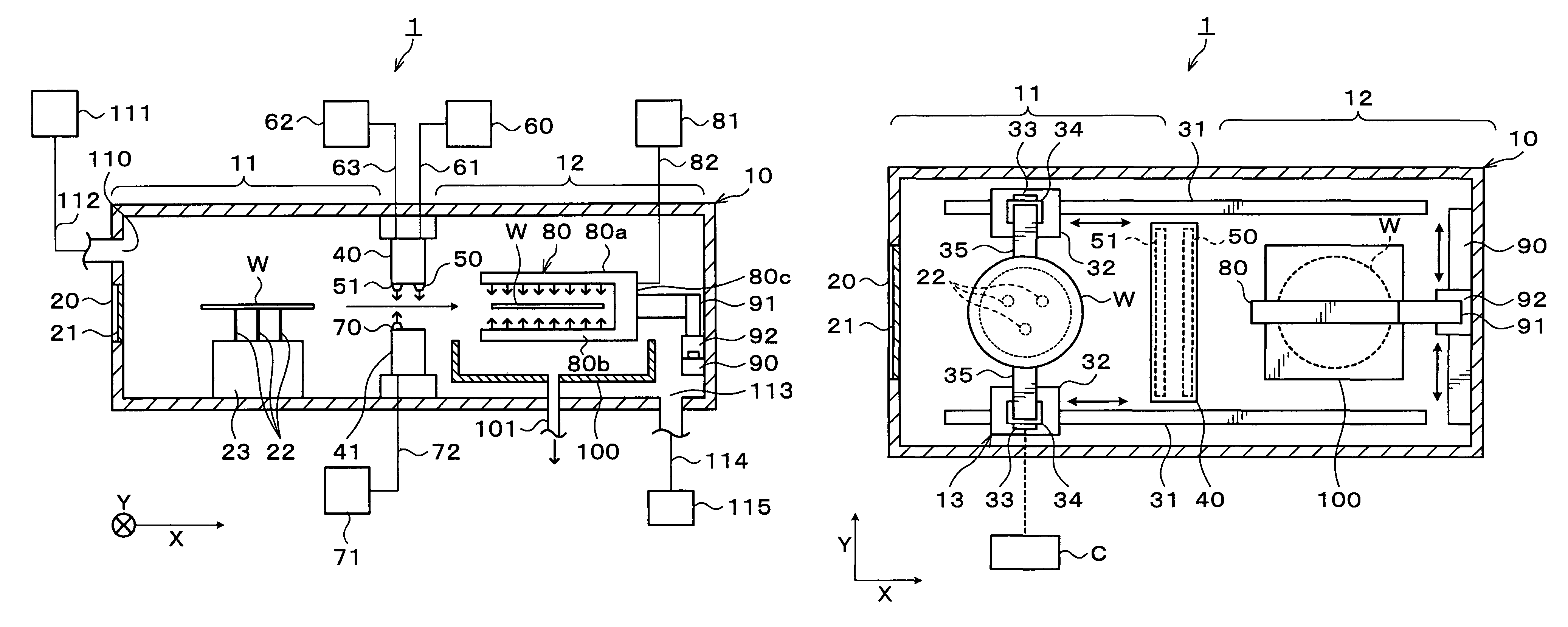

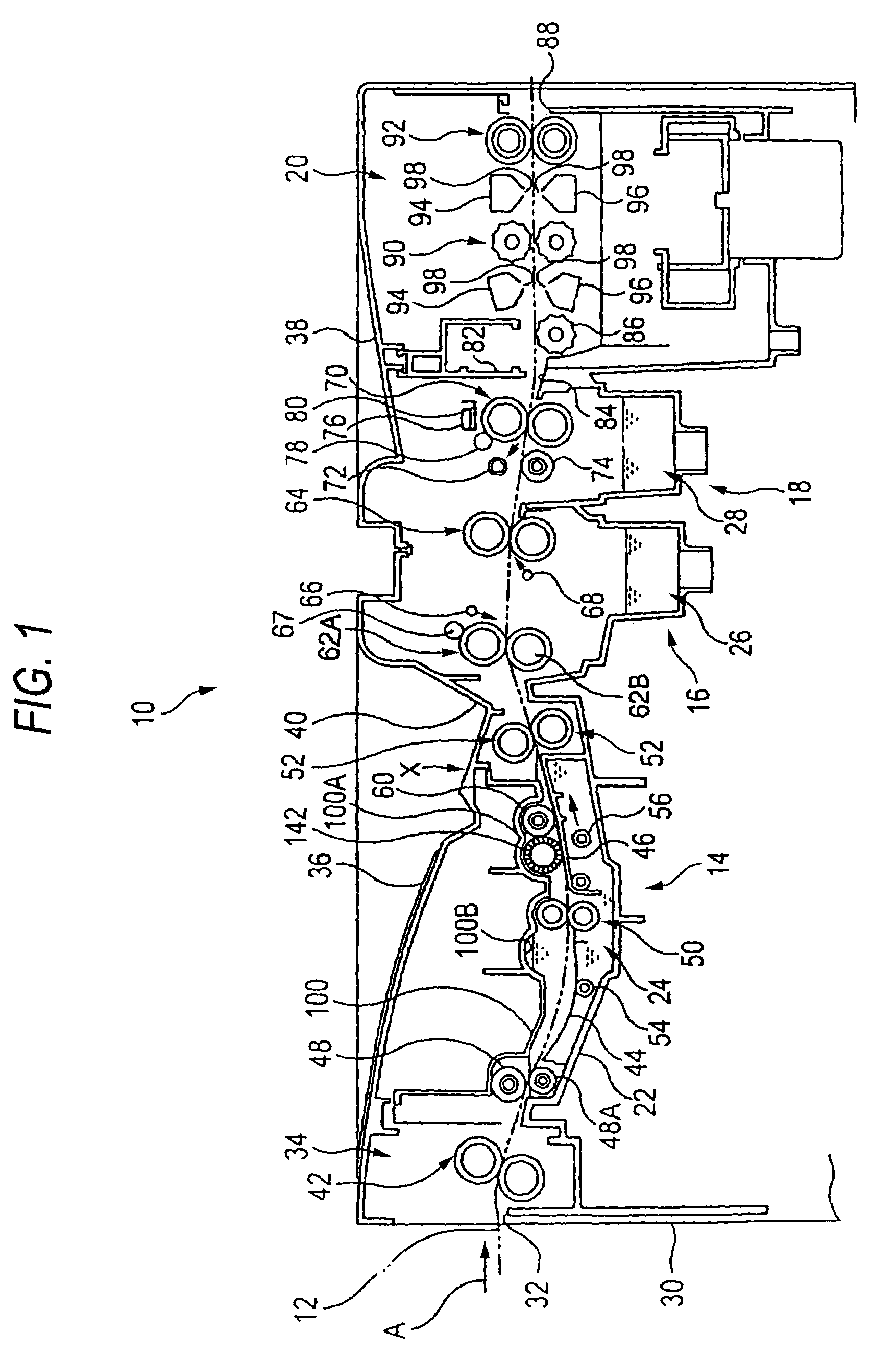

Developing method and apparatus

InactiveUS6969572B2Save consumptionUniform developmentLiquid processing by liquid spraysPhotoprinting processesSolventResist

In this developing method and apparatus, a concentration measuring unit 222 picks part of developing fluid in a blending tank 186 to measure the resist concentration by an absorption photometry and feeds the detected resist concentration to a control unit 240. The control unit 240 controls respective valves 210, 212, 216 of a TMAH concentrate solution 200, a solvent pipe 204 and a drain pipe 208 in a manner that the developing fluid in the blending tank 186 has a TMAH concentration corresponding to a measured resist-concentration value to accomplish a constant developing rate, performing component control of the developing fluid. The developing fluid transferred from the blending tank 186 to a supply tank 188 is fed to a developer nozzle DN in a developing section 126 through a developer pipe 224 owing to the drive of a pump 228. Accordingly, even if the developing fluid is reused in the developing process in multiple times, it is possible to make sure of the uniformity in development.

Owner:TOKYO ELECTRON LTD

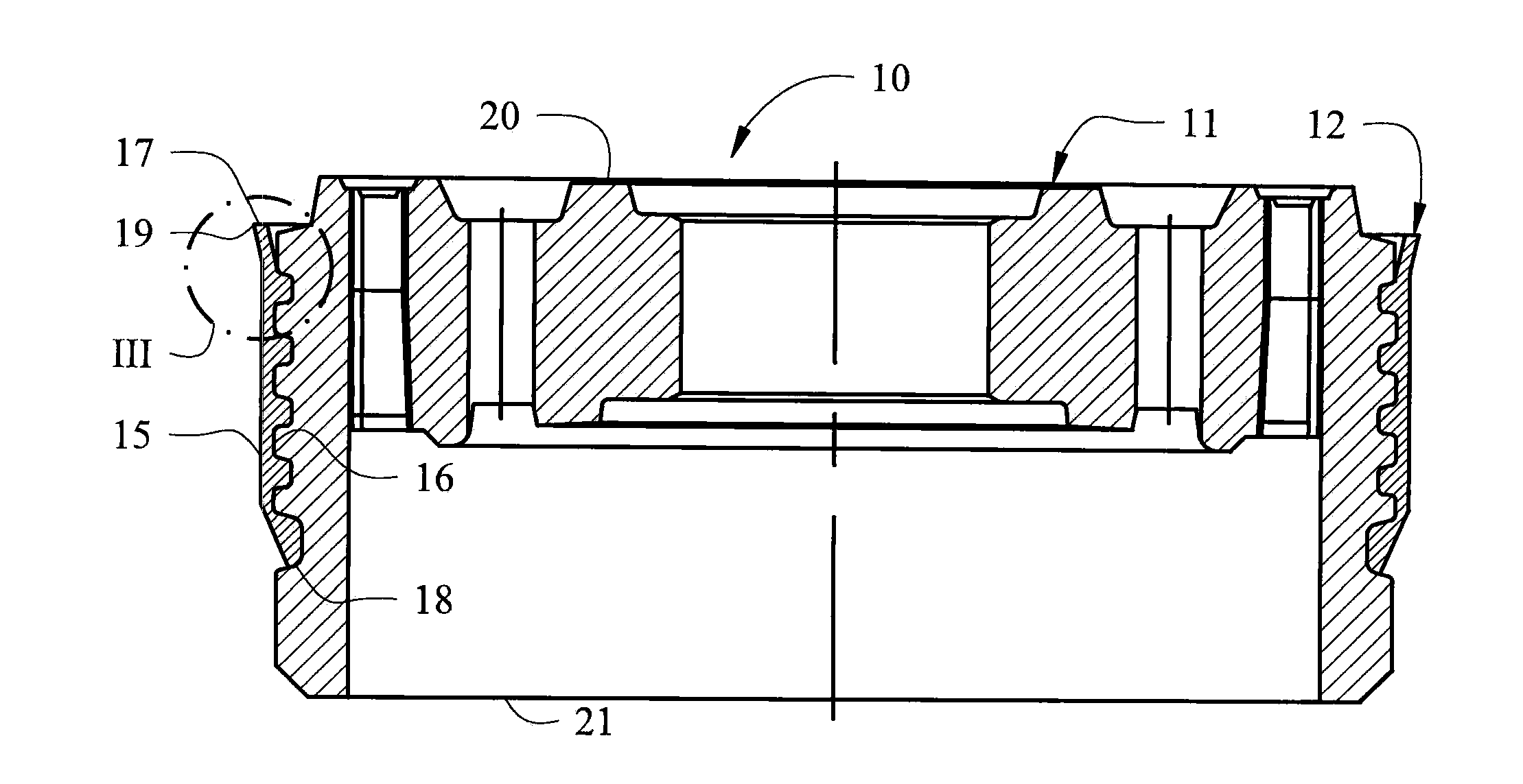

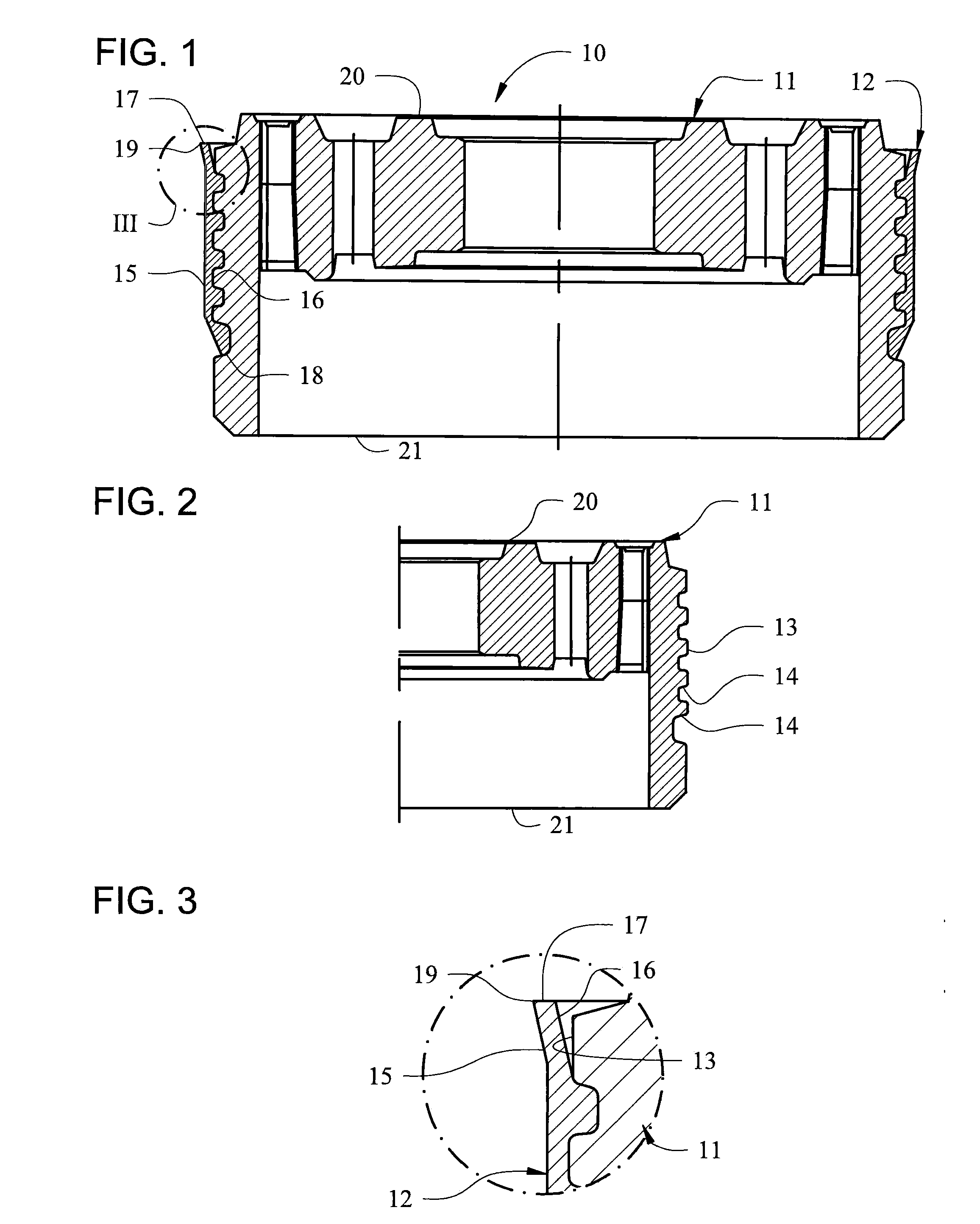

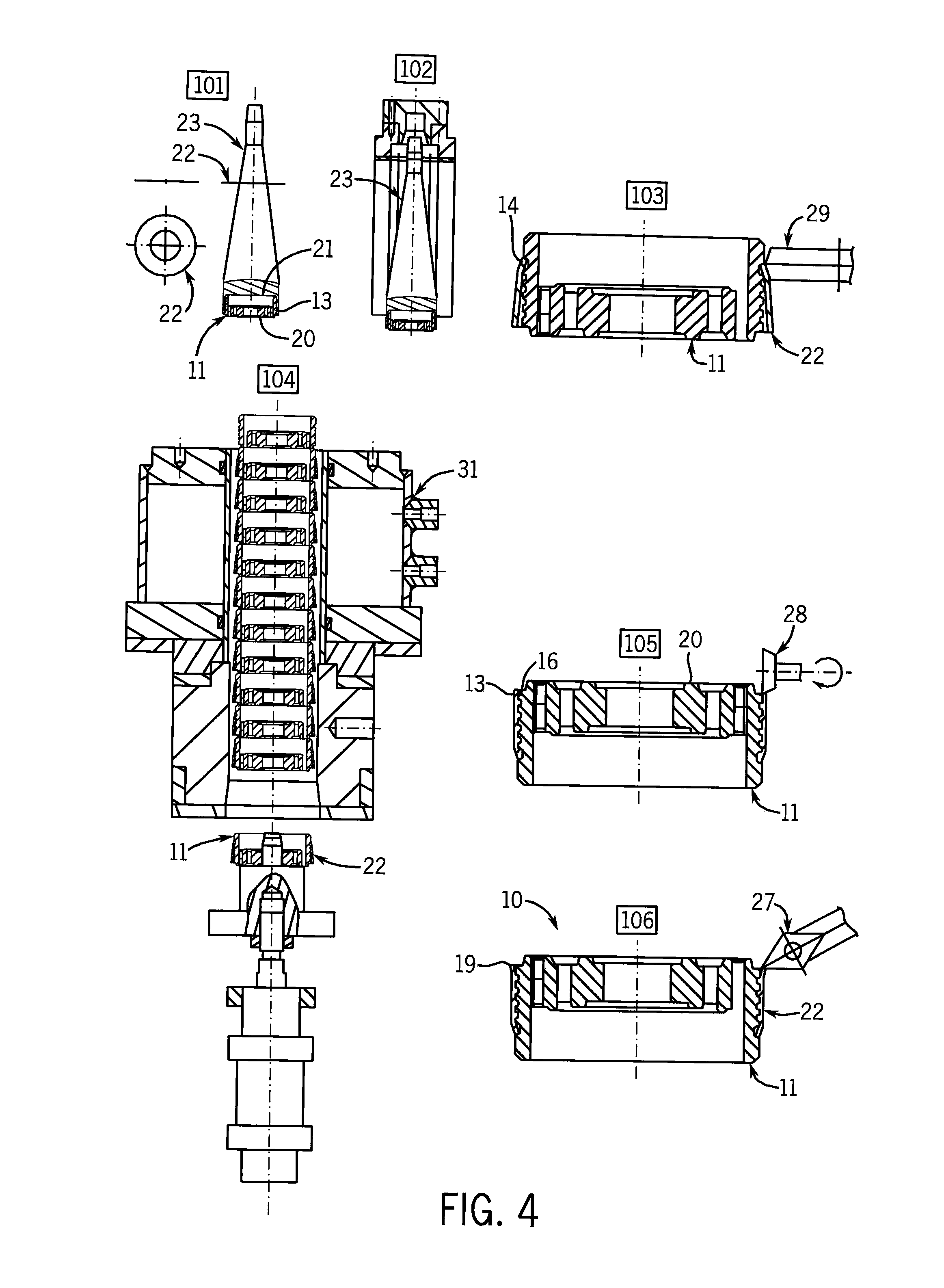

Piston for a piston-cylinder arrangement and production method

The invention relates to a piston for a piston-cylinder arrangement, particularly a shock absorber piston, which includes a piston body, that has a circumferential surface. A sealing collar has an outer circumferential surface, an inner circumferential surface, a first peripheral surface, and a first sealing lip, and extends around the circumferential surface of the piston body and covers at least part of the circumferential surface in the axial direction. The first peripheral surface connects the two circumferential surfaces to each other at a first end of the sealing collar. The first sealing lip is delimited by the first peripheral surface and the outer circumferential surface, and the first sealing lip is configured evenly in the circumferential direction.

Owner:GKN SINTER METALS GMBH & CO KG

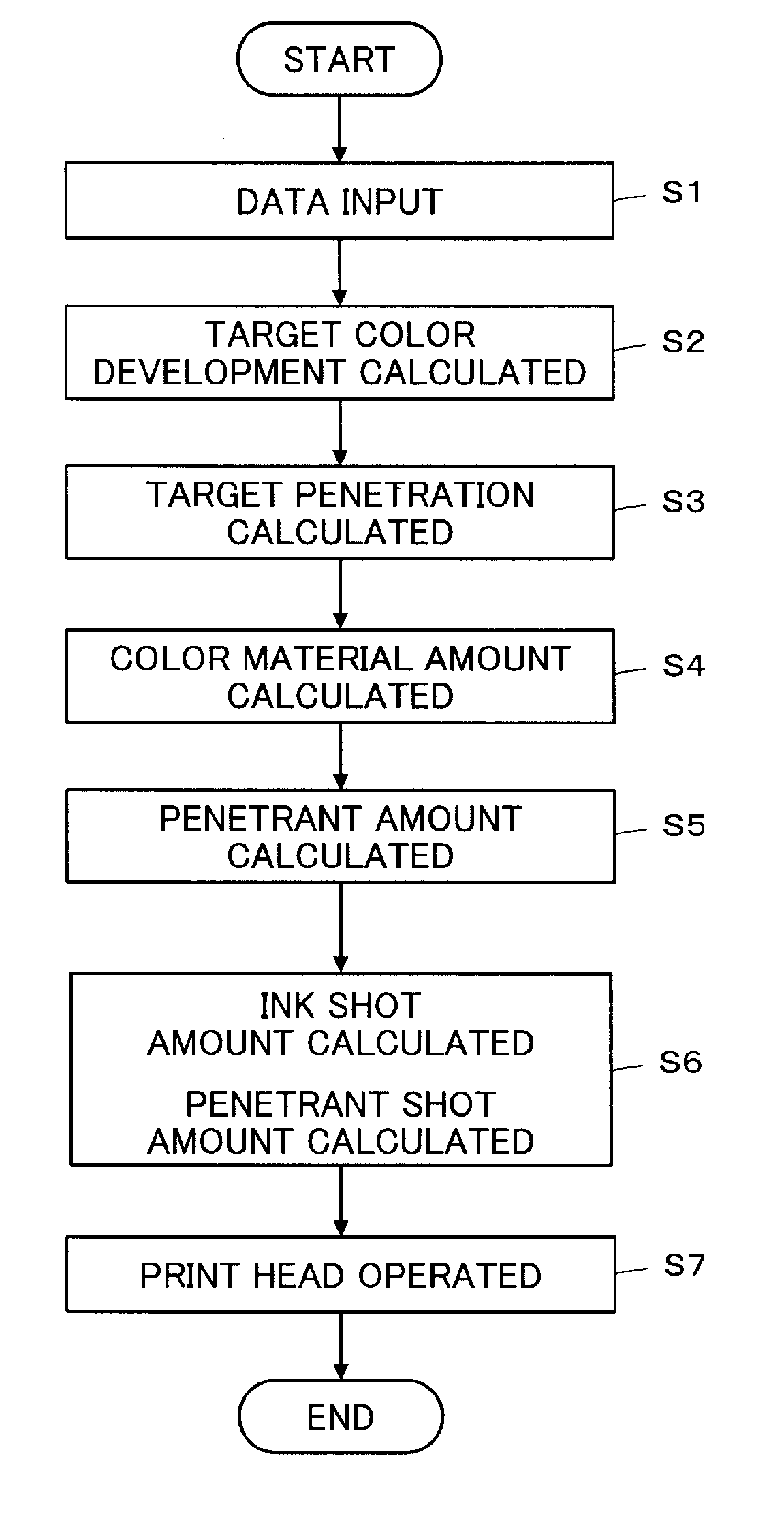

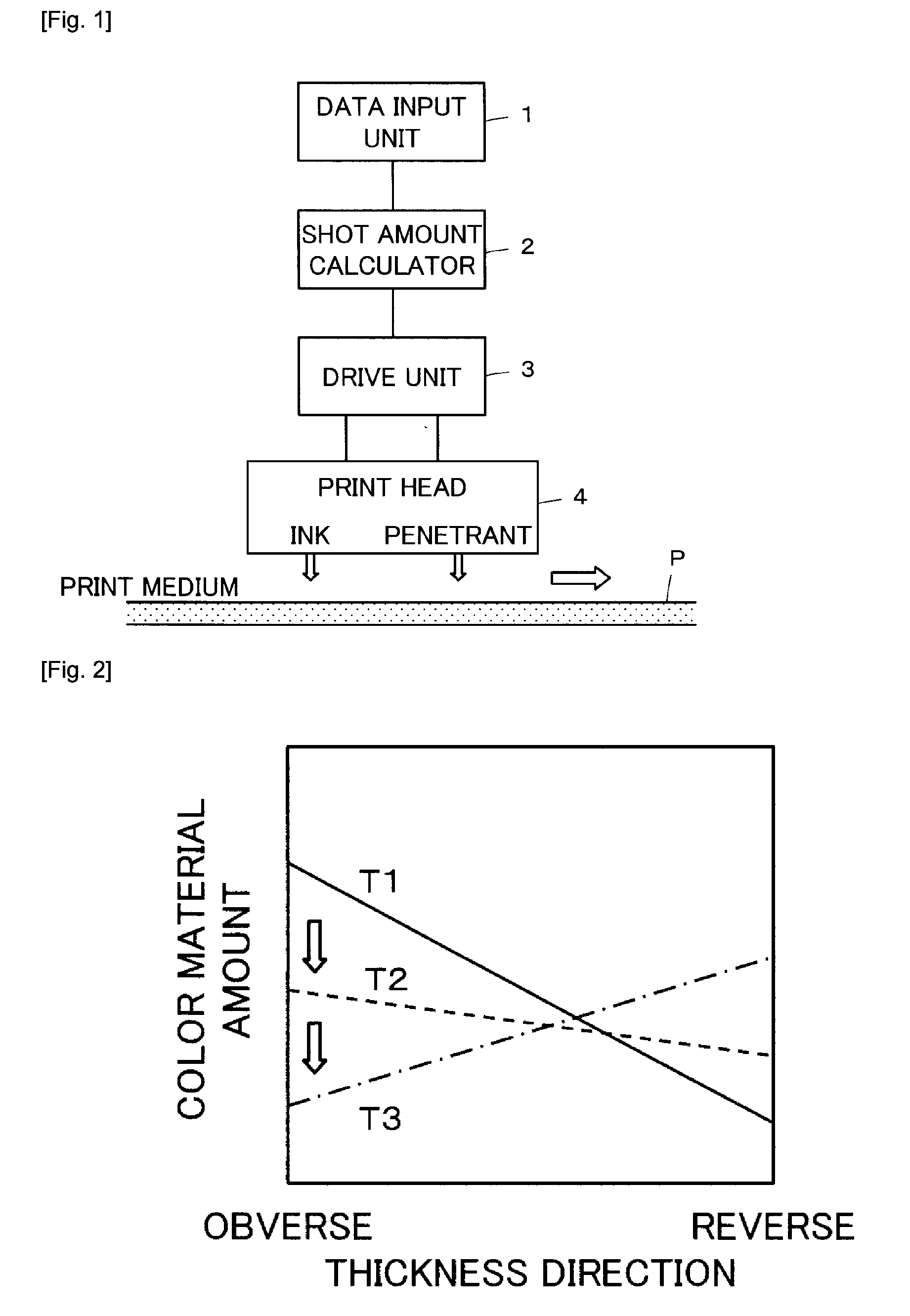

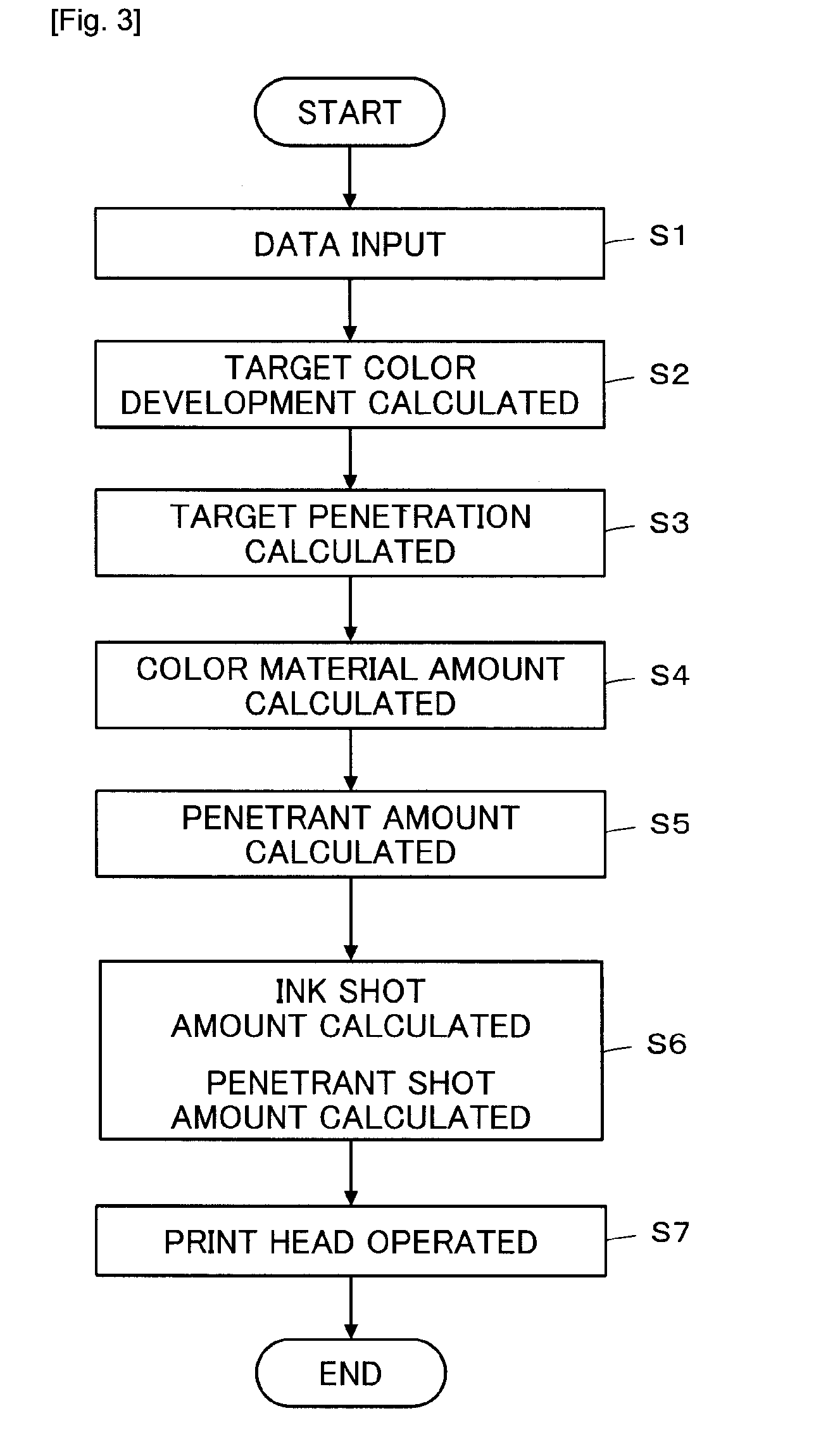

Ink jet printing method and device

Owner:FUJIFILM CORP

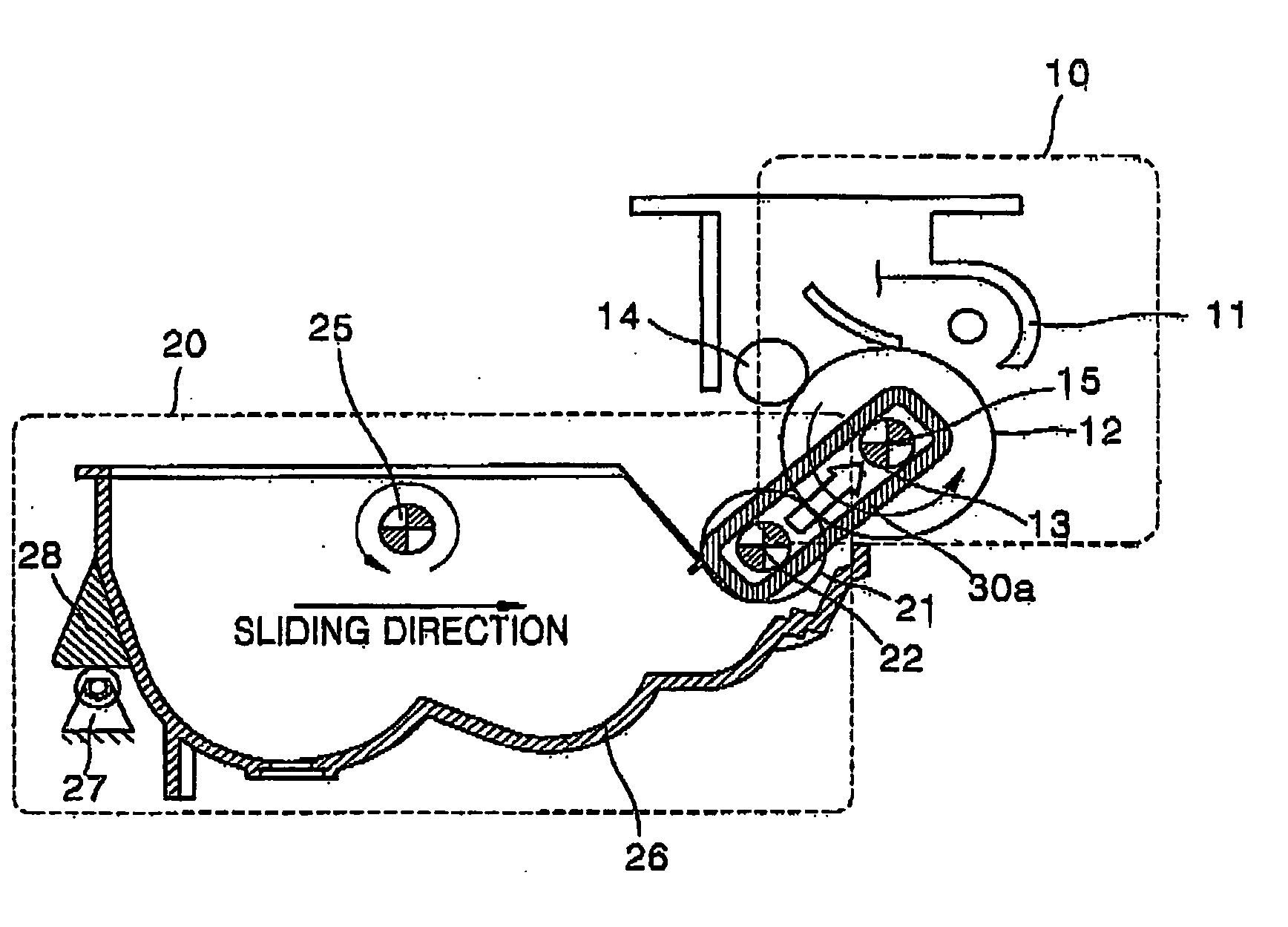

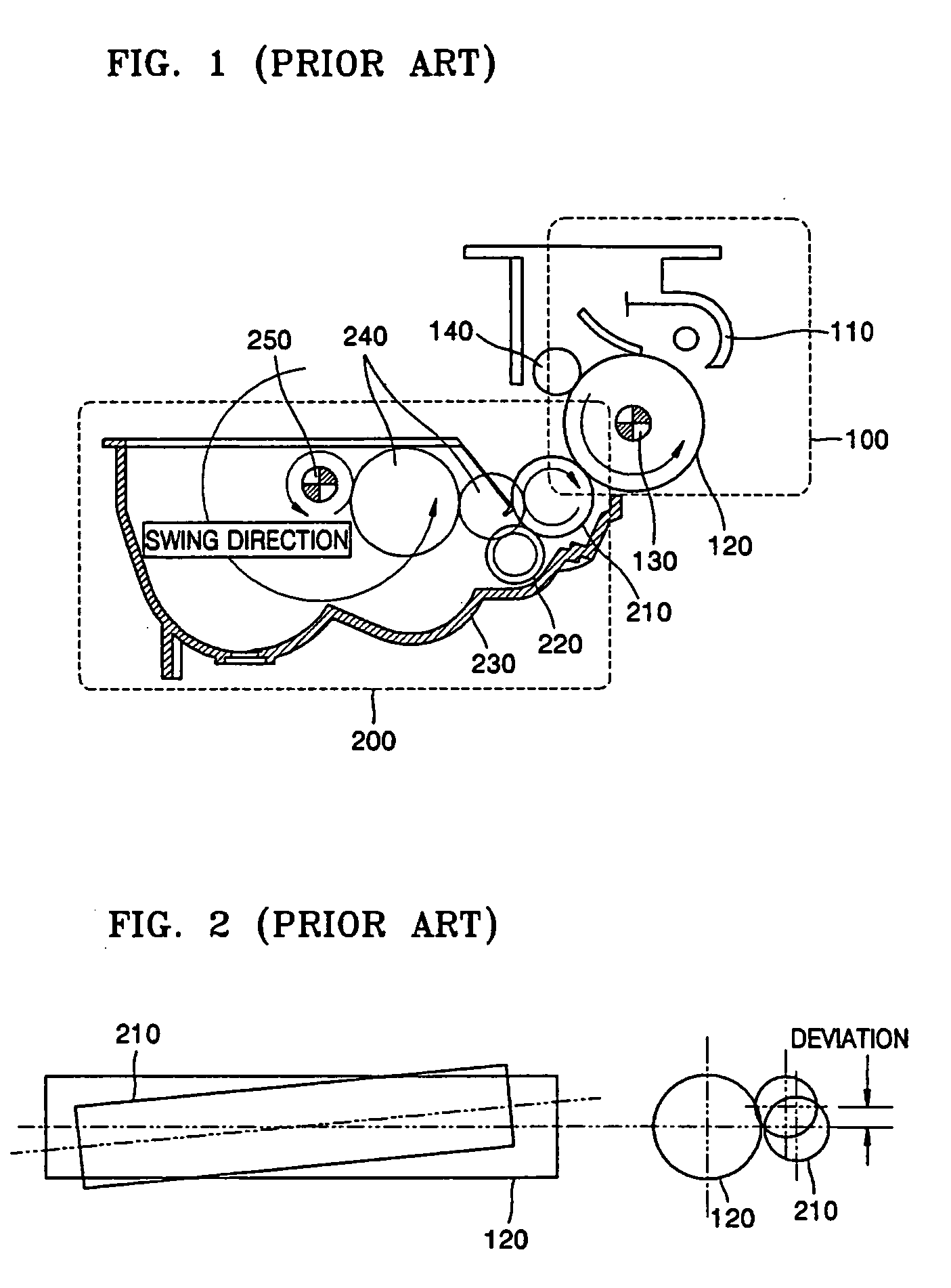

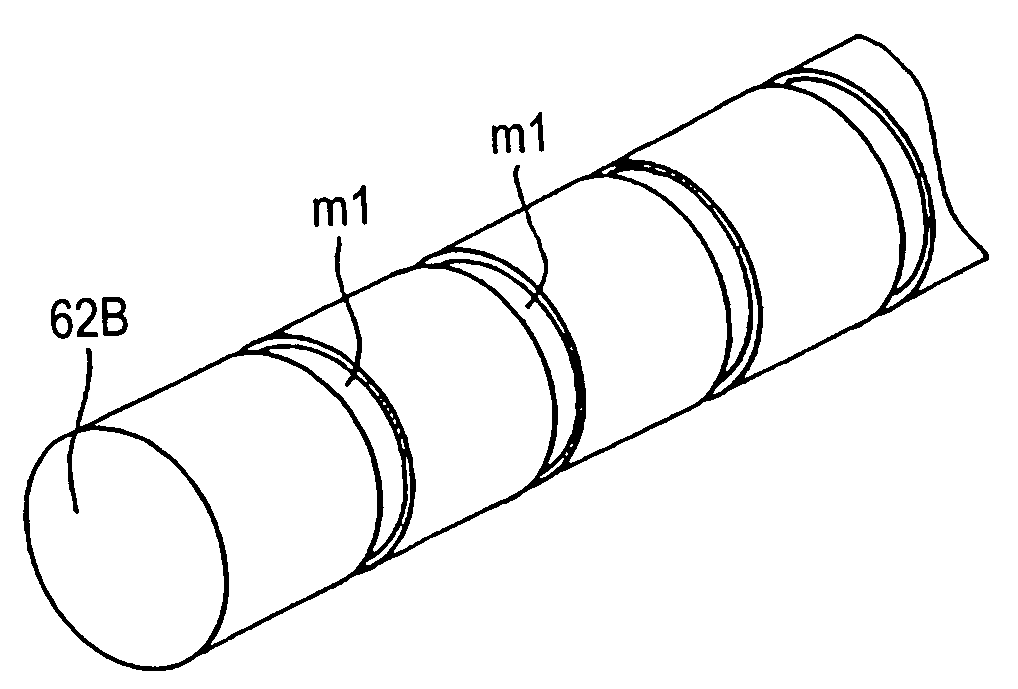

Detachable developer capable of maintaining nip

ActiveUS20050265748A1Uniform development nipImprove image qualitySewerage structuresElectrographic process apparatusEngineeringMechanical engineering

Owner:HEWLETT PACKARD DEV CO LP

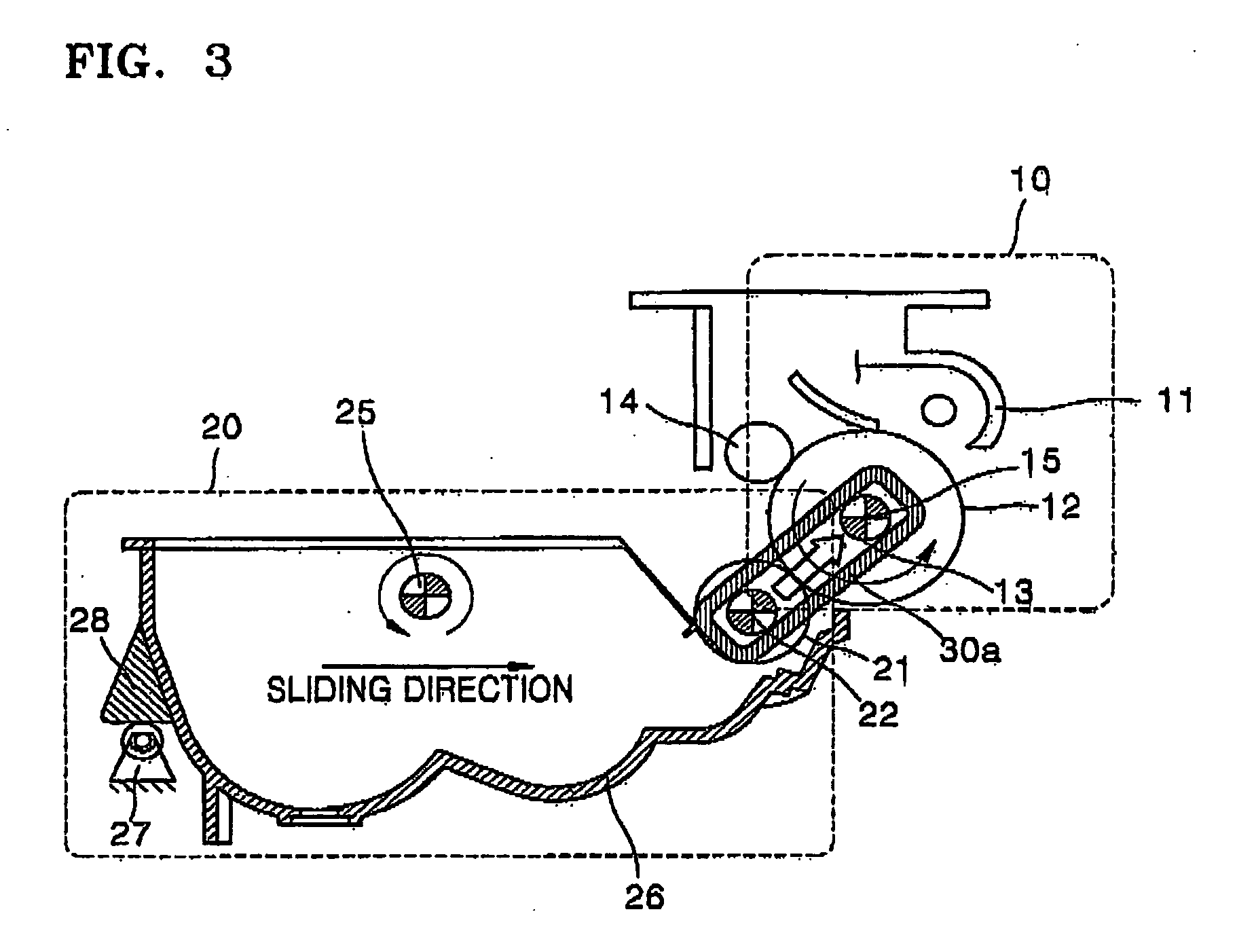

Developing treatment apparatus and developing treatment method

InactiveUS7766566B2Improve uniformityAvoid it happening againLiquid processing by liquid spraysSemiconductor/solid-state device manufacturingTherapeutic DevicesEngineering

In the present invention, a substrate transfer unit into / from which a substrate is transferred from / to the outside of a treatment container and a developing treatment unit in which development of the substrate is performed are arranged side by side in the treatment container, and a carrier mechanism is provided which carries the substrate while grasping an outside surface of the substrate from both sides, between the substrate transfer unit and the developing treatment unit. A developing solution supply nozzle for supplying a developing solution onto the substrate and a gas blow nozzle for blowing a gas to the substrate, are provided between the substrate transfer unit and the developing treatment unit and above a carriage path along which the substrate is carried, and a cleaning solution supply nozzle is provided in the developing treatment unit for supplying a cleaning solution onto the substrate. According to the present invention, since the substrate is carried with its outside surface being grasped, spread of contamination can be prevented to restrain generation of particles in the treatment container.

Owner:TOKYO ELECTRON LTD

Processing apparatus for lithographic printing plate and process for processing the same

InactiveUS7306384B2Prevent image unevennessUniform developmentDuplicating/marking methodsPhotomechanical apparatusEngineeringPlanographic printing

Owner:FUJIFILM CORP

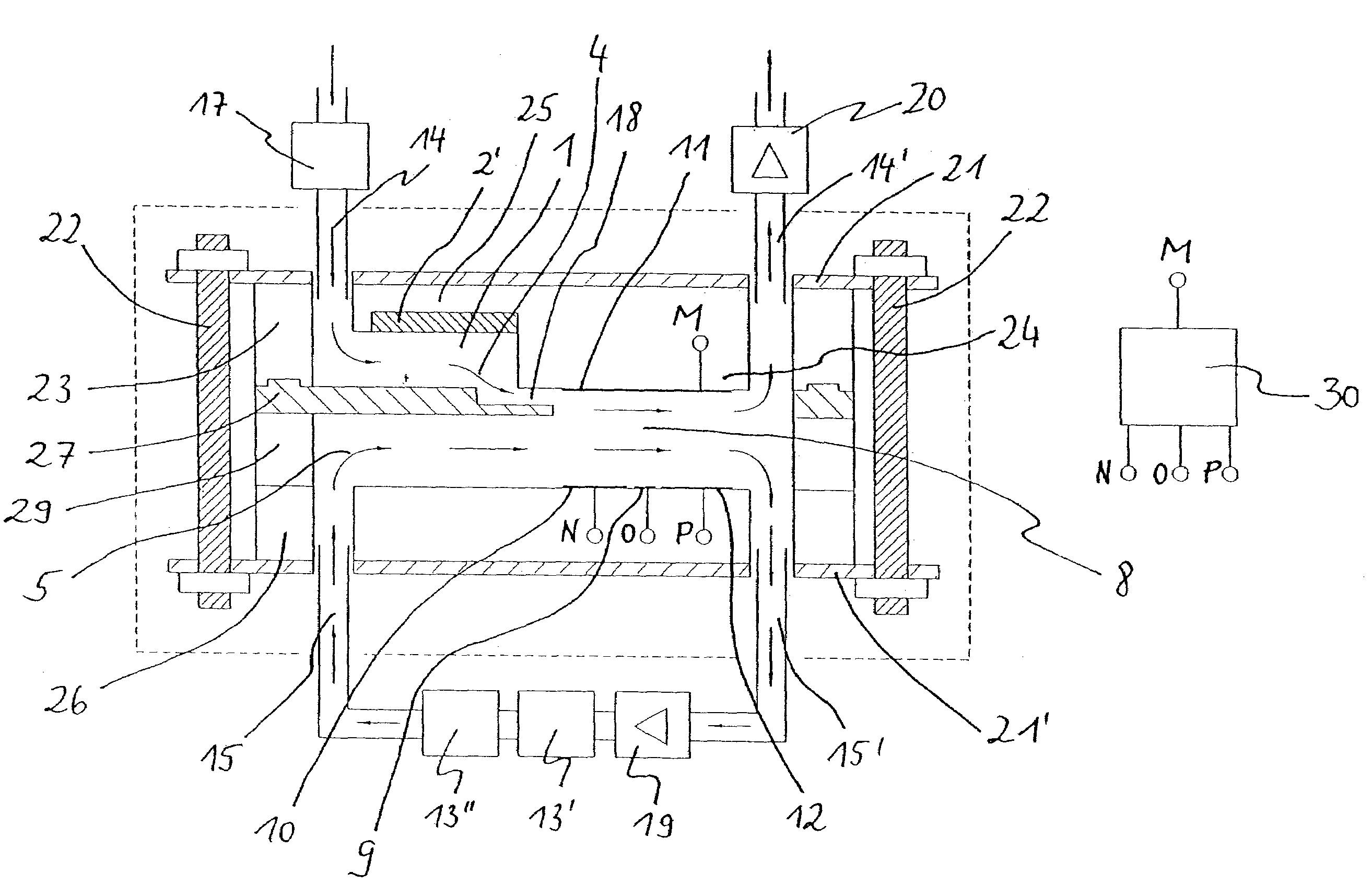

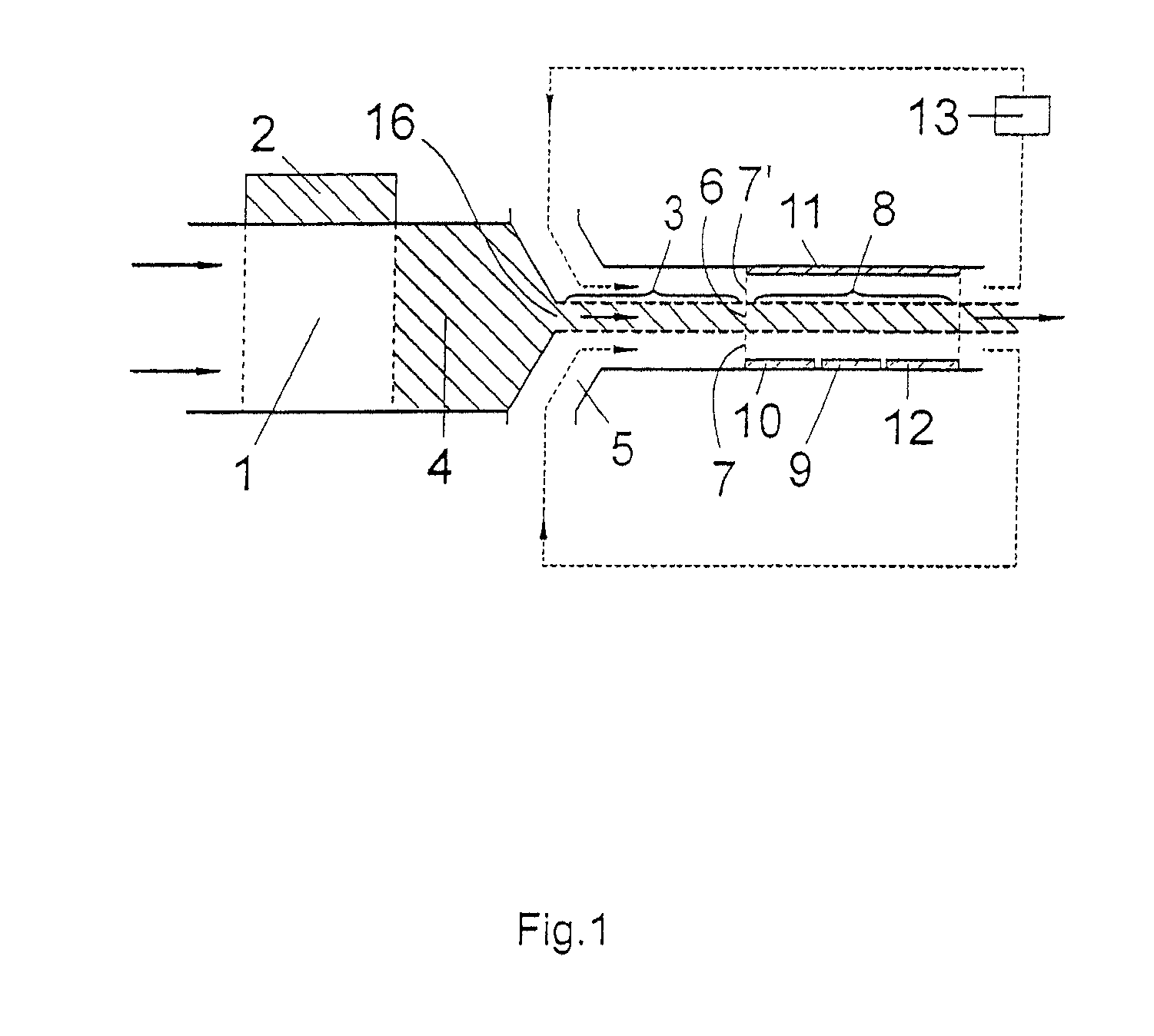

Ion mobility spectrometer with parallel drift gas and ion carrier gas flows

ActiveUS7417224B2Takes effortObtain goodTime-of-flight spectrometersMaterial analysis by electric/magnetic meansAnalyteIonization chamber

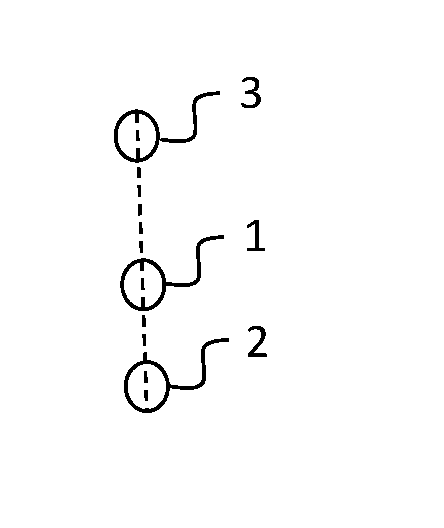

An ion mobility spectrometer is provided with at least one ionization chamber (1) through which analyte-containing gas can flow. A radiation source (2) is provided from which ionizing radiation is suitable for ionizing the analyte-containing gas at least partially, enters the ionization space (1). A separation area is located behind the ionization space (1) in the direction of flow, into which the partially ionized gas is admitted as an ion carrier gas (4) and a nearly ion-free gas is admitted as a drift gas (5) in such a way that a flow in which predominantly ion carrier gas (4) flows through cross-sectional areas (6) and predominantly drift gas (5) flows through other cross-sectional areas (7, 7′), becomes established at least in the inlet area of the separation area (8). The drift gas (5) and ion carrier gas (4) flow unidirectionally and the cross-sectional areas (6), through which predominantly ion carrier gas (4) flows, are smaller in at least one dimension than the cross-sectional areas (7, 7′), through which predominantly drift gas (5) flows.

Owner:DRAGER SAFETY

Developing unit

InactiveCN104076622AHigh speedQuality improvementPhotosensitive material processingBiochemical engineeringLarge size

Owner:BOE TECH GRP CO LTD +1

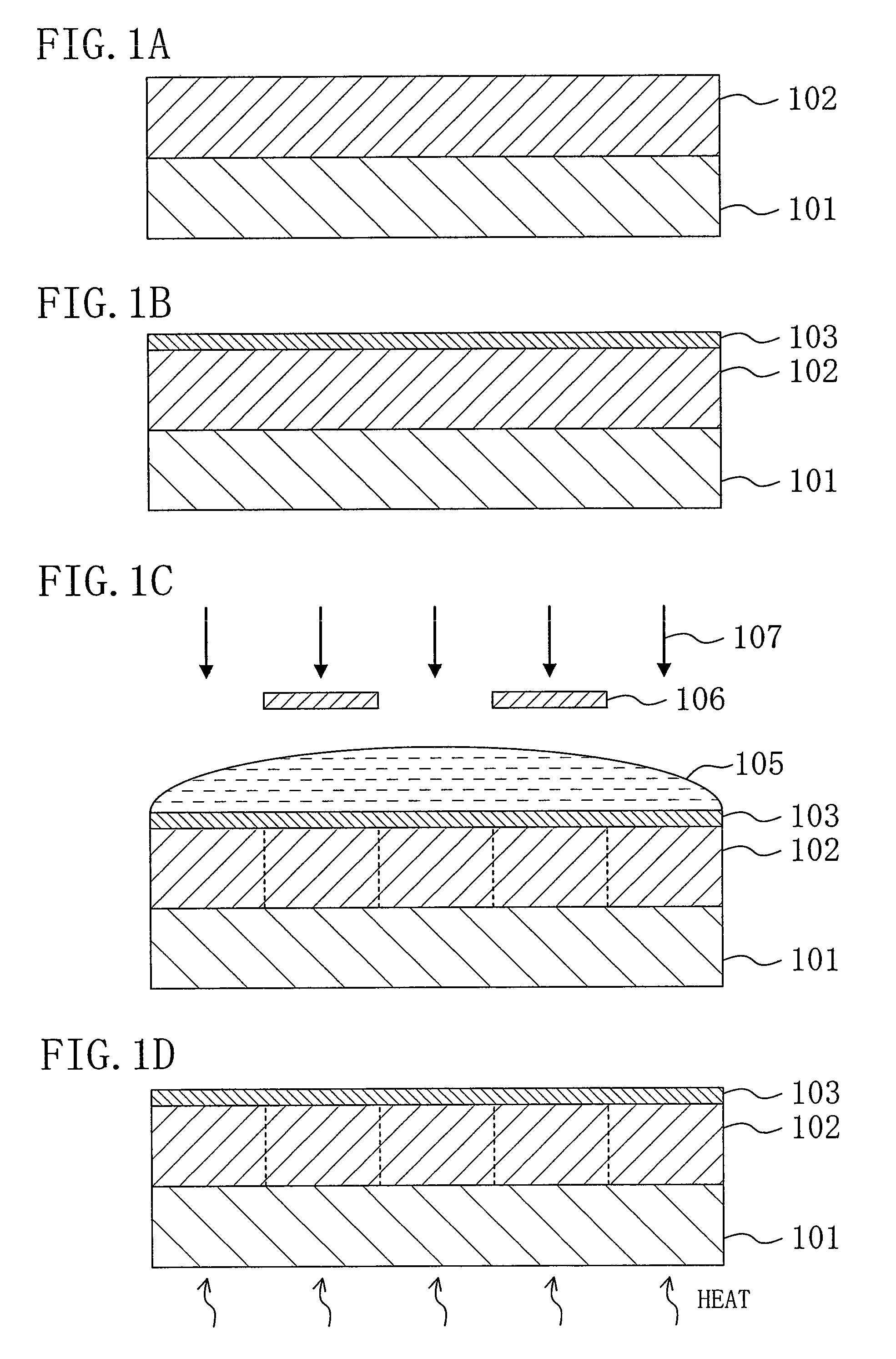

Thermal developing apparatus

InactiveUS7405744B2Uniform developmentReduced space required for installationRecording apparatusElectrode and associated part arrangementsLatent imageEngineering

A thermal developing apparatus for visualizing a latent image recorded on a photosensitive thermal developing recording material by heating the photosensitive thermal developing recording material with heating unit while conveying the photosensitive thermal developing recording material with conveying unit along a conveying path having the heating unit equipped therewith, the thermal developing apparatus containing a manual feeding tray for manually feeding the exposed photosensitive thermal developing recording material into the thermal developing apparatus.

Owner:FUJIFILM CORP +1

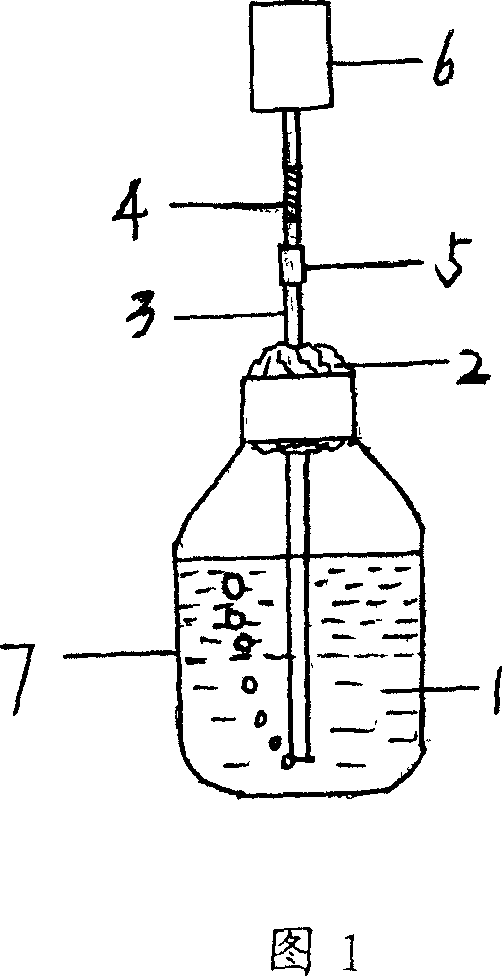

Formulation of aweto culture medium and oxygenating culture method of aweto

The present invention is formulation of aweto culture medium and oxygenating culture method of aweto. By means of high efficiency culture medium, deep culture of the liquid spawn and the oxygenating in the initial growth stage of sporophore, the present invention has high aweto sporophore producing efficiency and high yield. The culture medium for liquid spawn, which is obtained through spore or tissue separation and inoculated to culture medium solution, consists of glucose, peptone, yeast powder, potassium dihydrogen phosphate, magnesium sulfate, sodium chloride, vitamin B1 and water in certain weight proportion.

Owner:袁有宝 +1

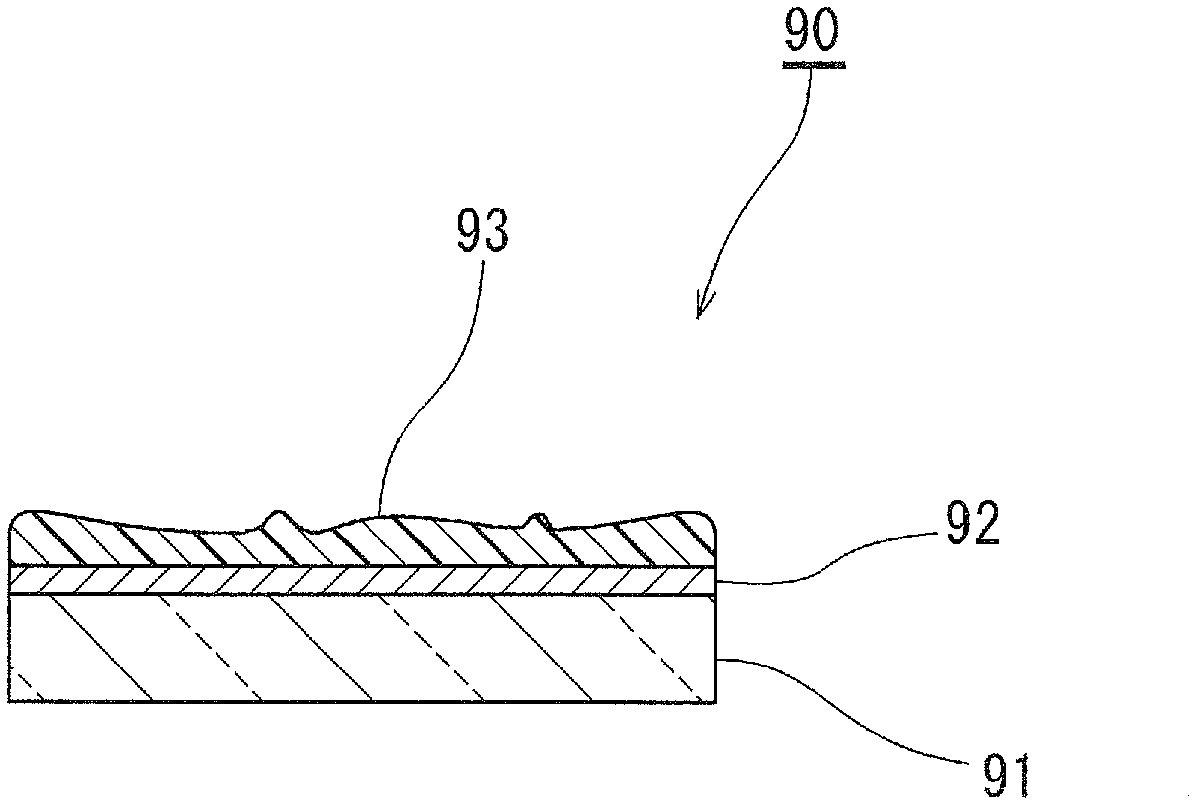

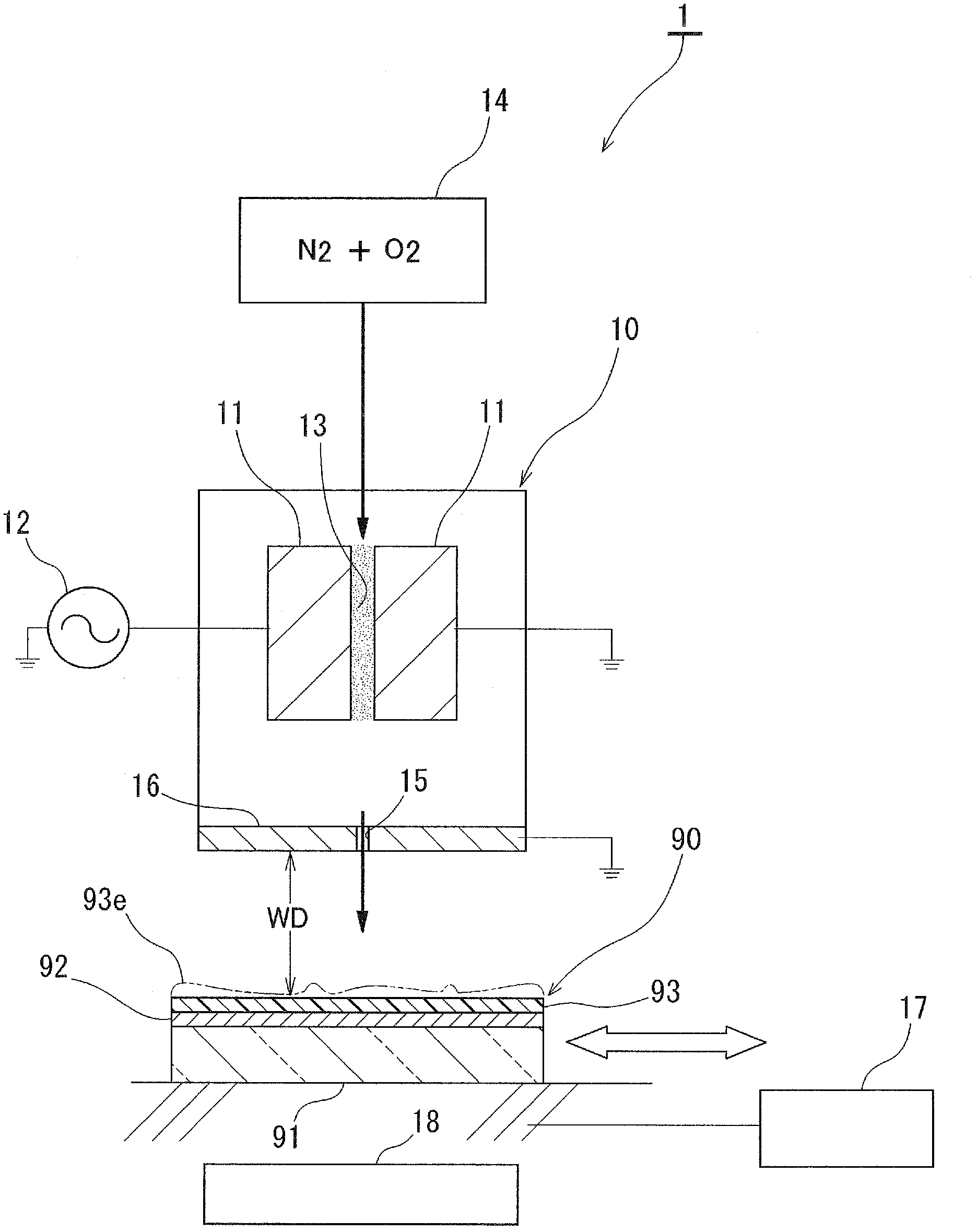

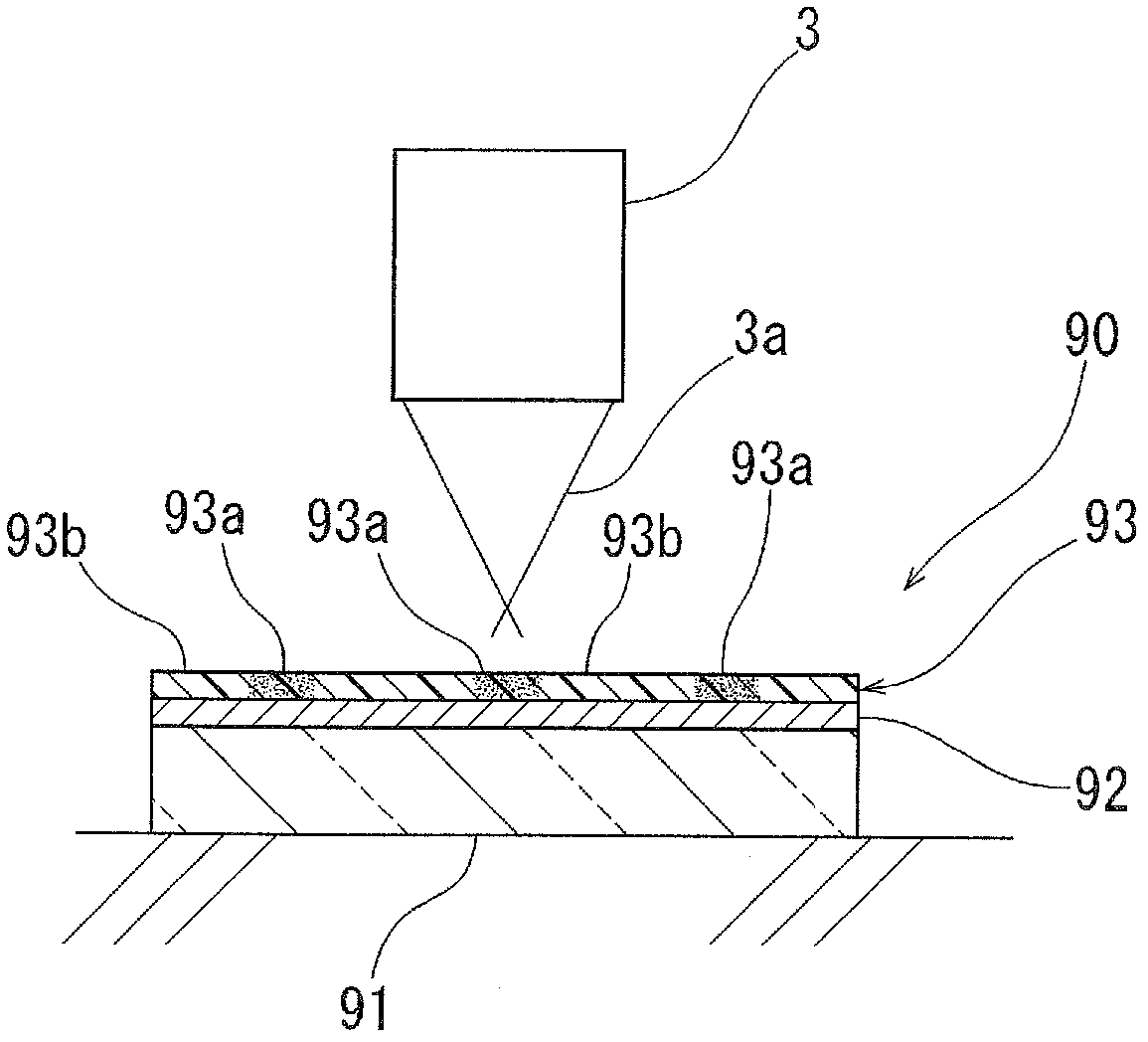

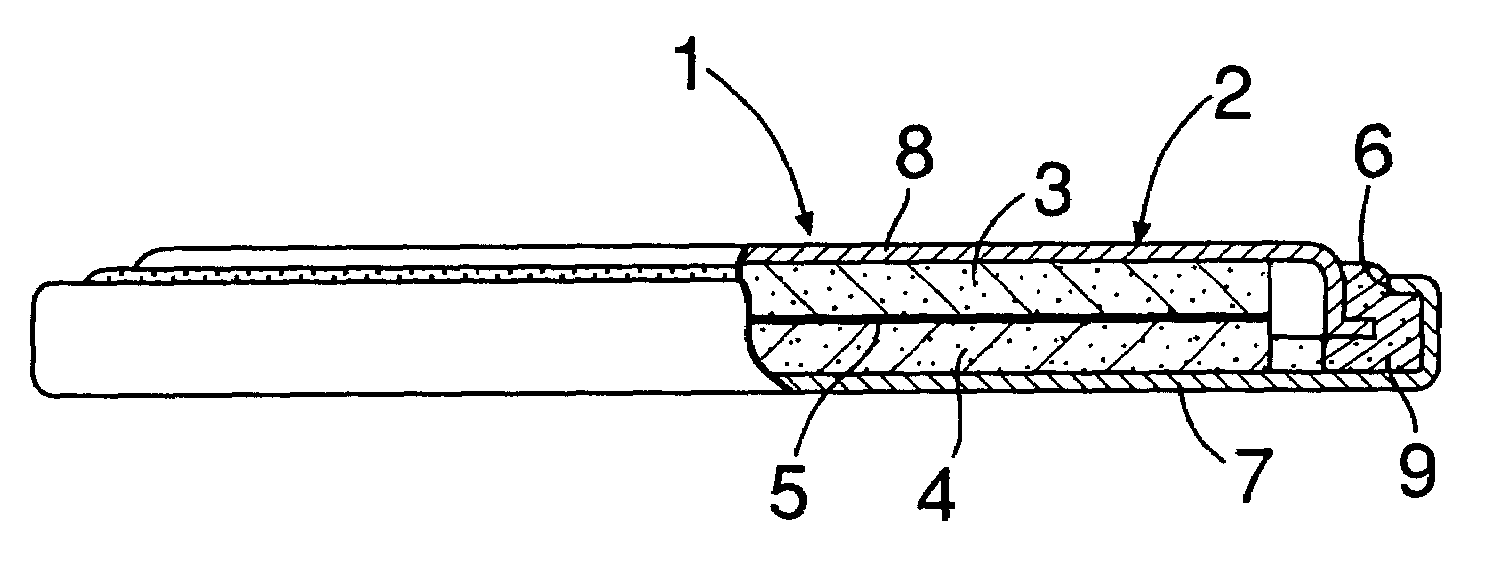

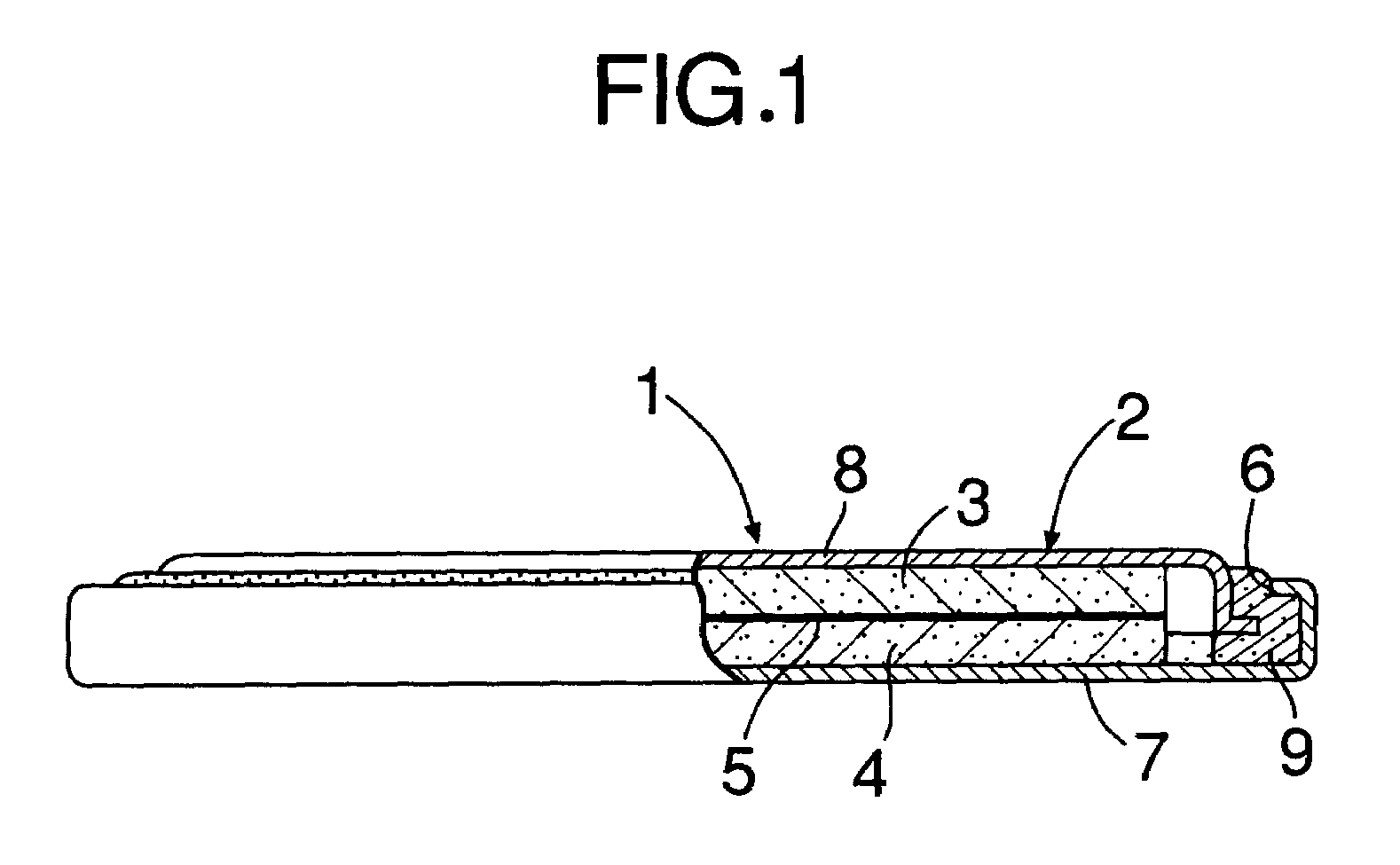

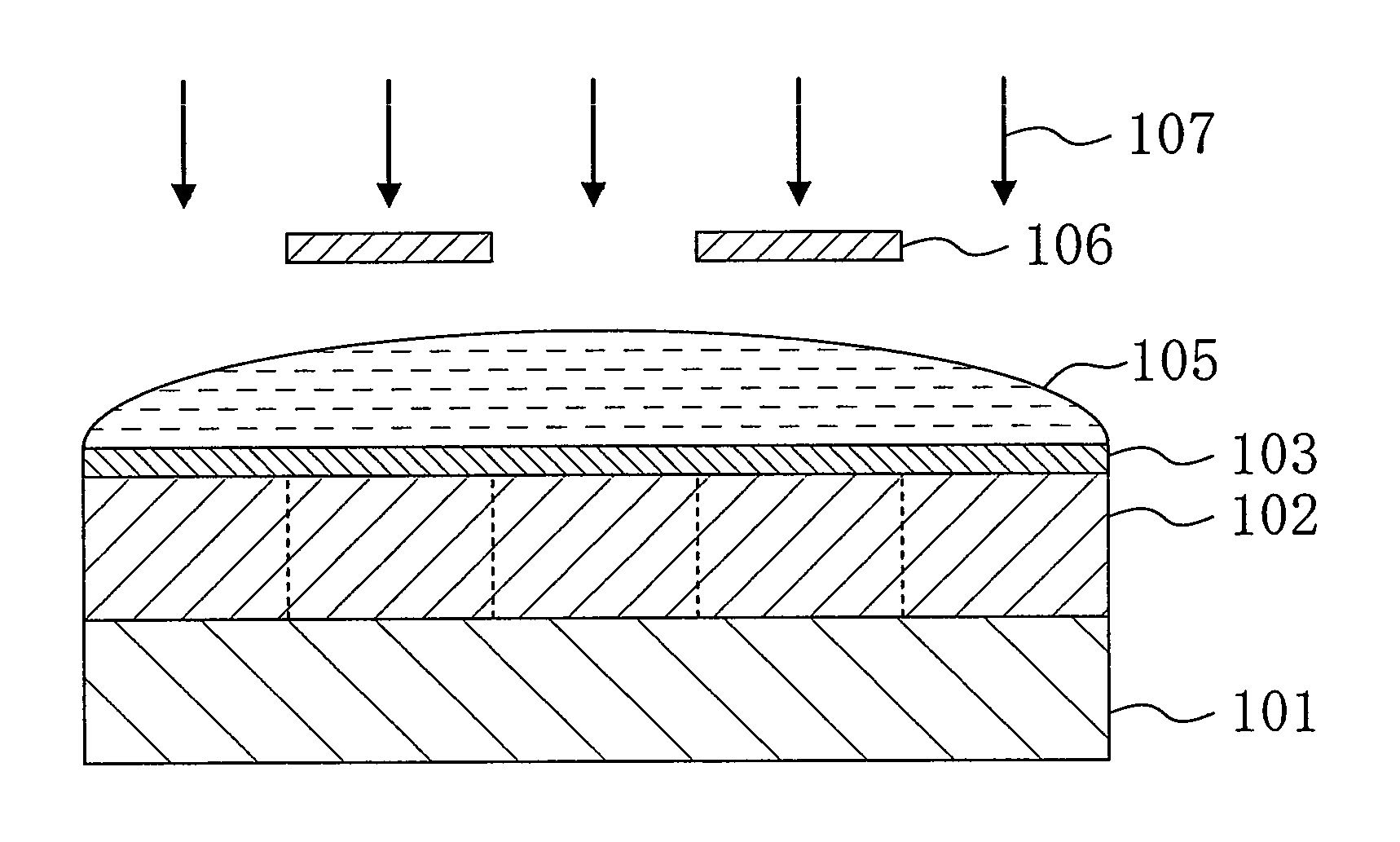

Method for forming resist pattern, and device

InactiveCN102362224AUniform coatingReduce consumptionSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistRemote plasma

Disclosed is a method for forming a resist pattern, wherein the uniformity of development is improved by increasing the wettability of the surface of a resist layer when the resist pattern is formed on a device such as a photoresist. Specifically, a resist layer (93) is formed by applying a photosensitive resist over a substrate (91) (resist application step). Then, the resist layer (93) is partially irradiated with light (light exposure step). After that, a process gas for lyophilization is brought into contact with the resist layer (93) by being expelled through a discharge space (23) at near atmospheric pressure (atmospheric-pressure remote plasma lyophilization step). Then, a developer liquid (5) is brought into contact with the resist layer (93) (development step).

Owner:SEKISUI CHEM CO LTD

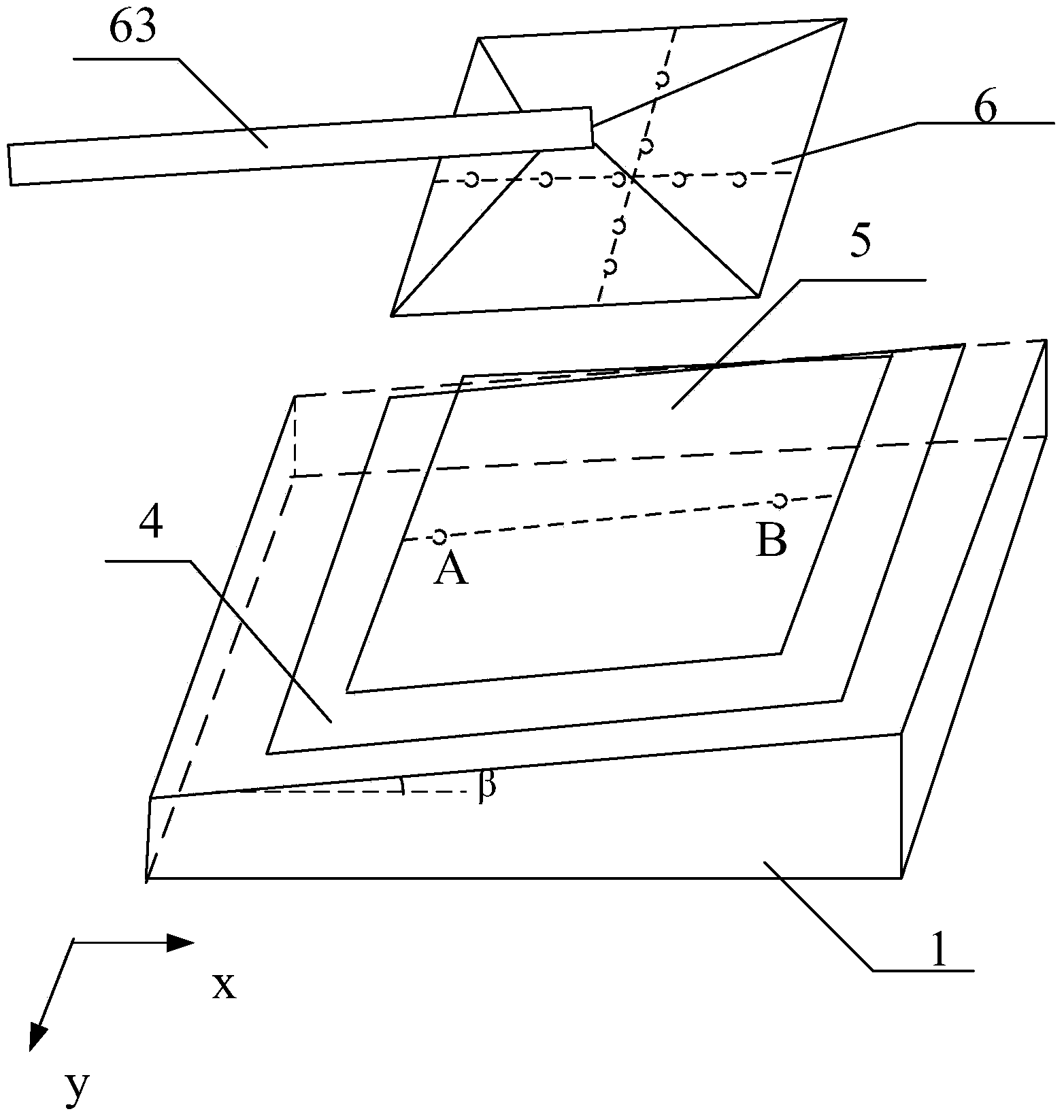

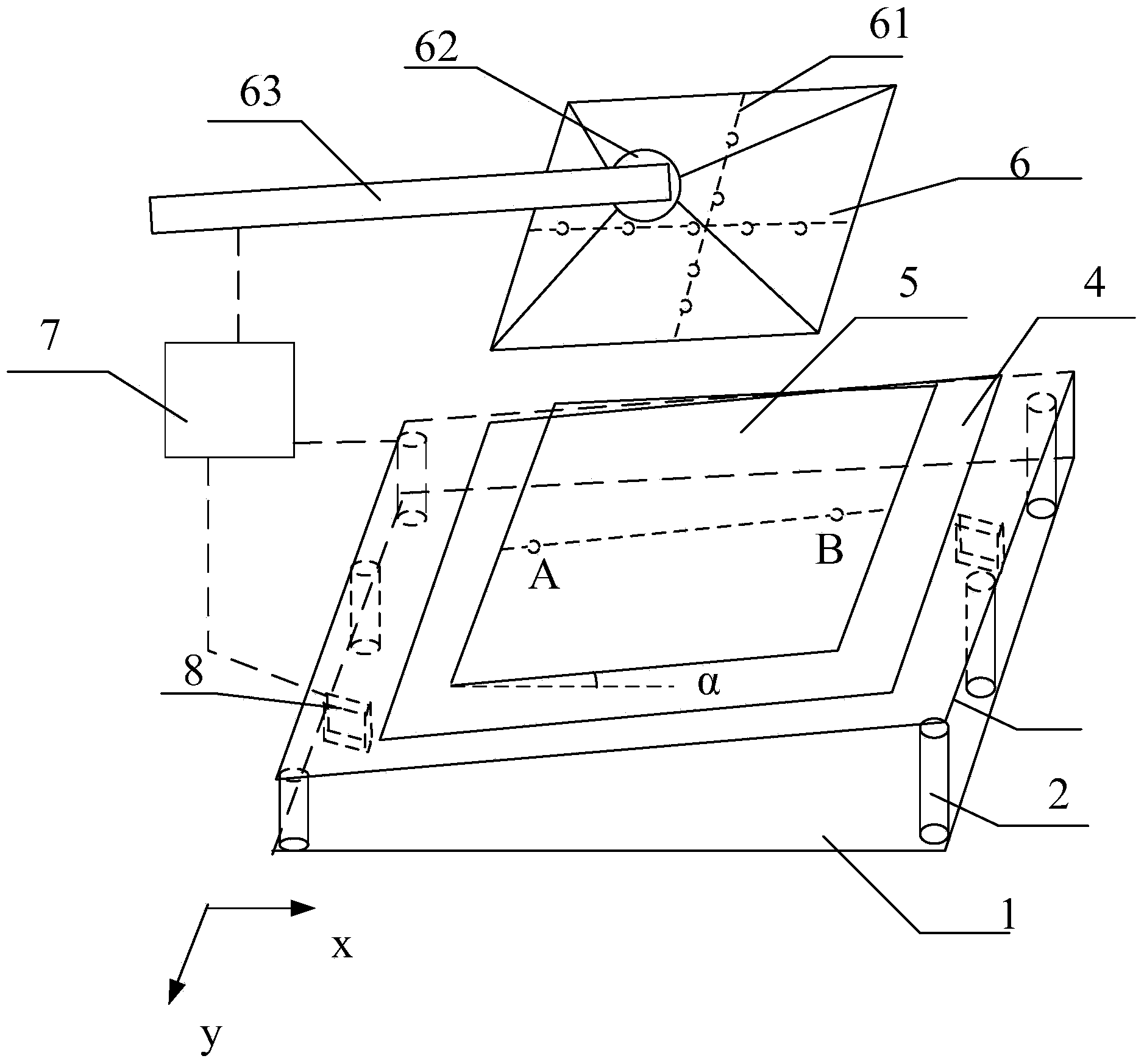

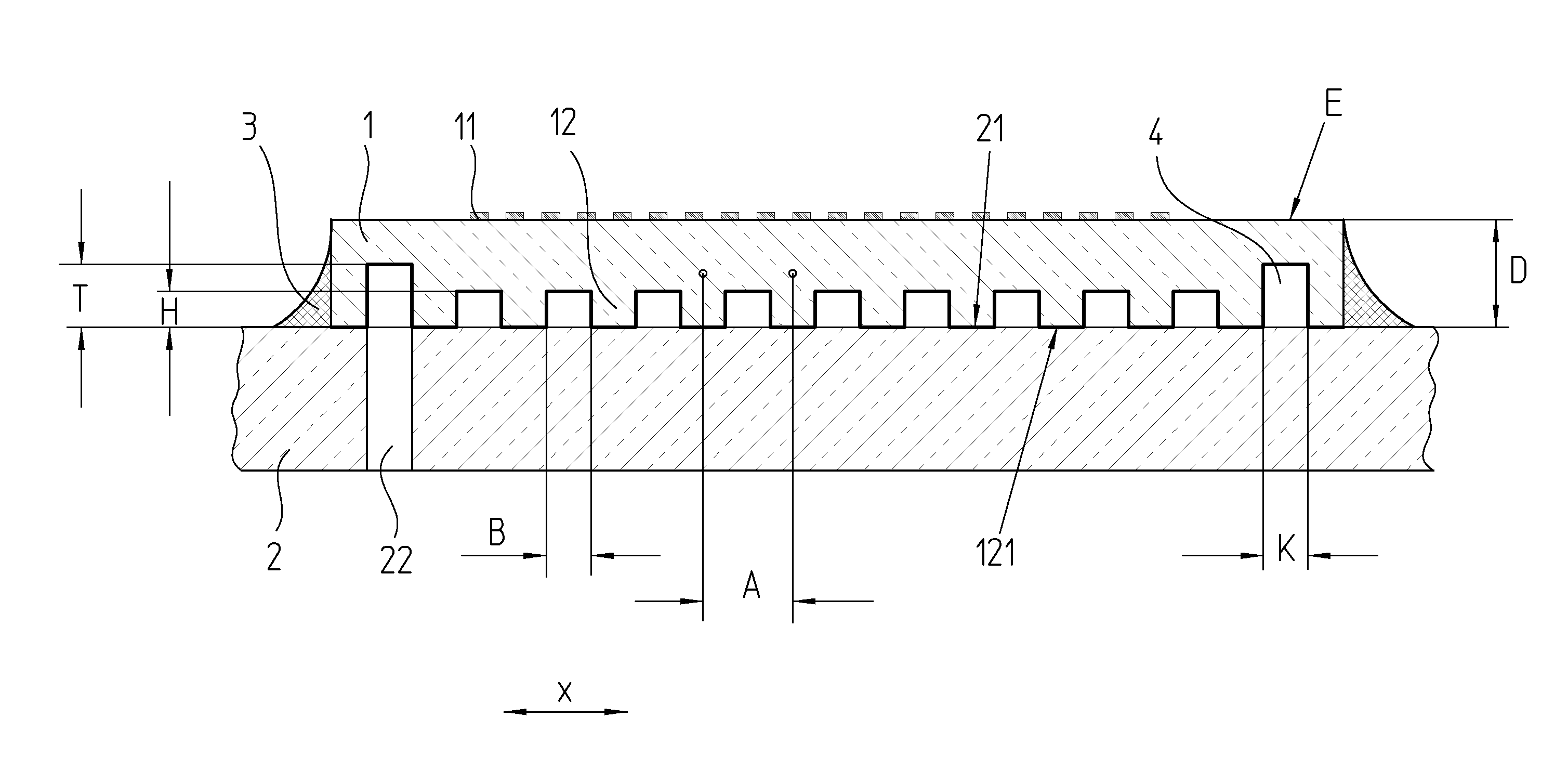

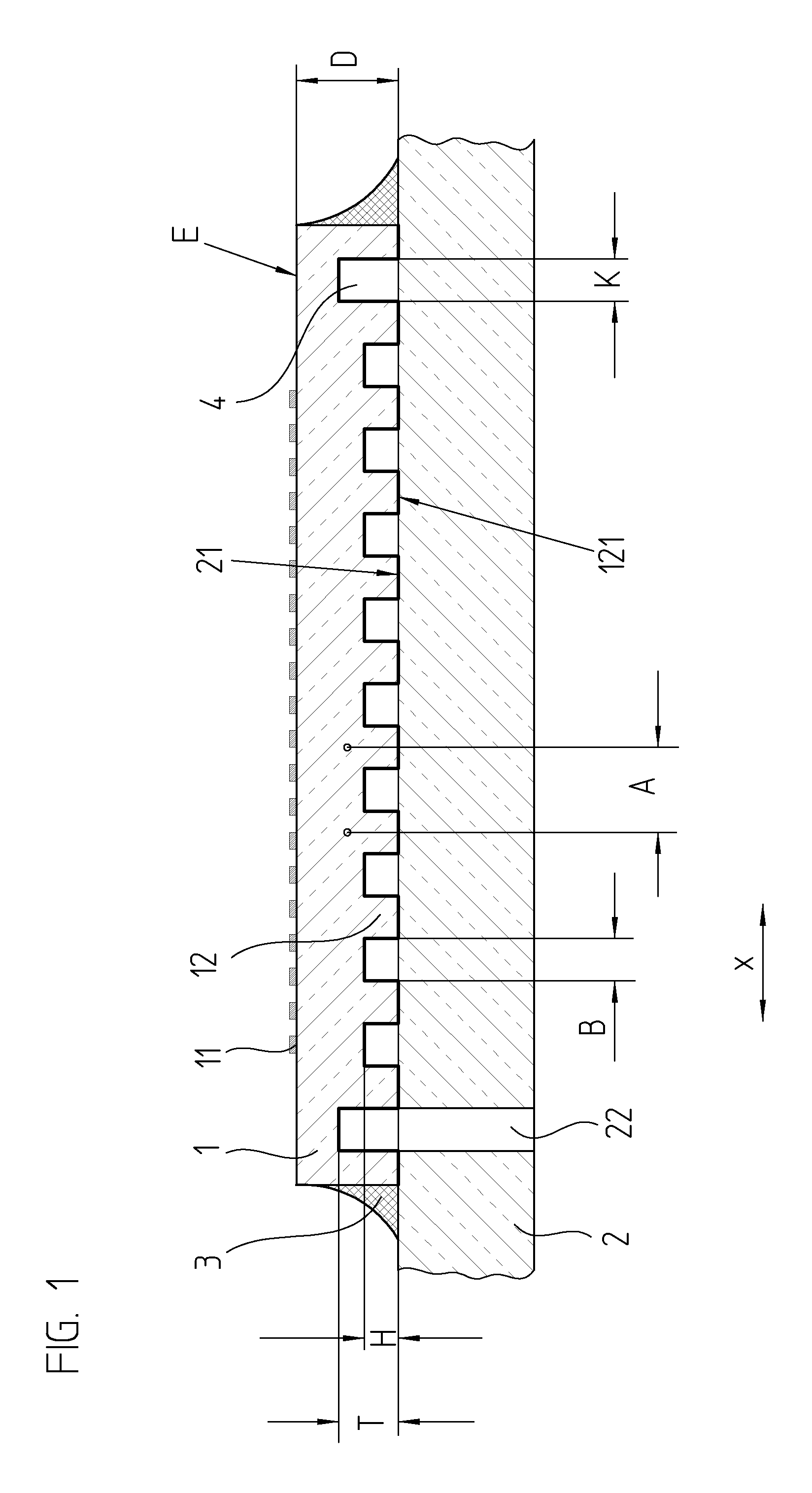

Assembly comprising a measuring scale attached to a substrate and method for holding a measuring scale against a substrate

ActiveUS8650769B2Avoid disadvantagesHigh measurement accuracyWalking sticksUsing optical meansOptical contact bondingEngineering

An assembly including a substrate and a scale held on the substrate, wherein the scale has a measuring graduation, and the scale is held on the substrate by pneumatic suction. The scale is braced on the substrate via two-dimensionally distributed, spaced-apart supports, which are disposed facing a measurement area defined by the measuring graduation and wherein adjacent ones of the supports are spaced apart from one another at a mutual period that is less than a thickness of the scale. In addition, the supports have a structure such that a connection by optical contact bonding between the supports and the scale and / or between the supports and the substrate is prevented at least in the measurement area. A space between the scale and the substrate is sealed off from surroundings by a sealing structure.

Owner:DR JOHANNES HEIDENHAIN GMBH

Enhanced permeability subterranean fluid recovery system and methods

ActiveUS8893788B2Increase loopEasy to controlFluid removalDrinking water installationWellboreEnvironmental geology

Owner:INNOTECH ALBERTA INC

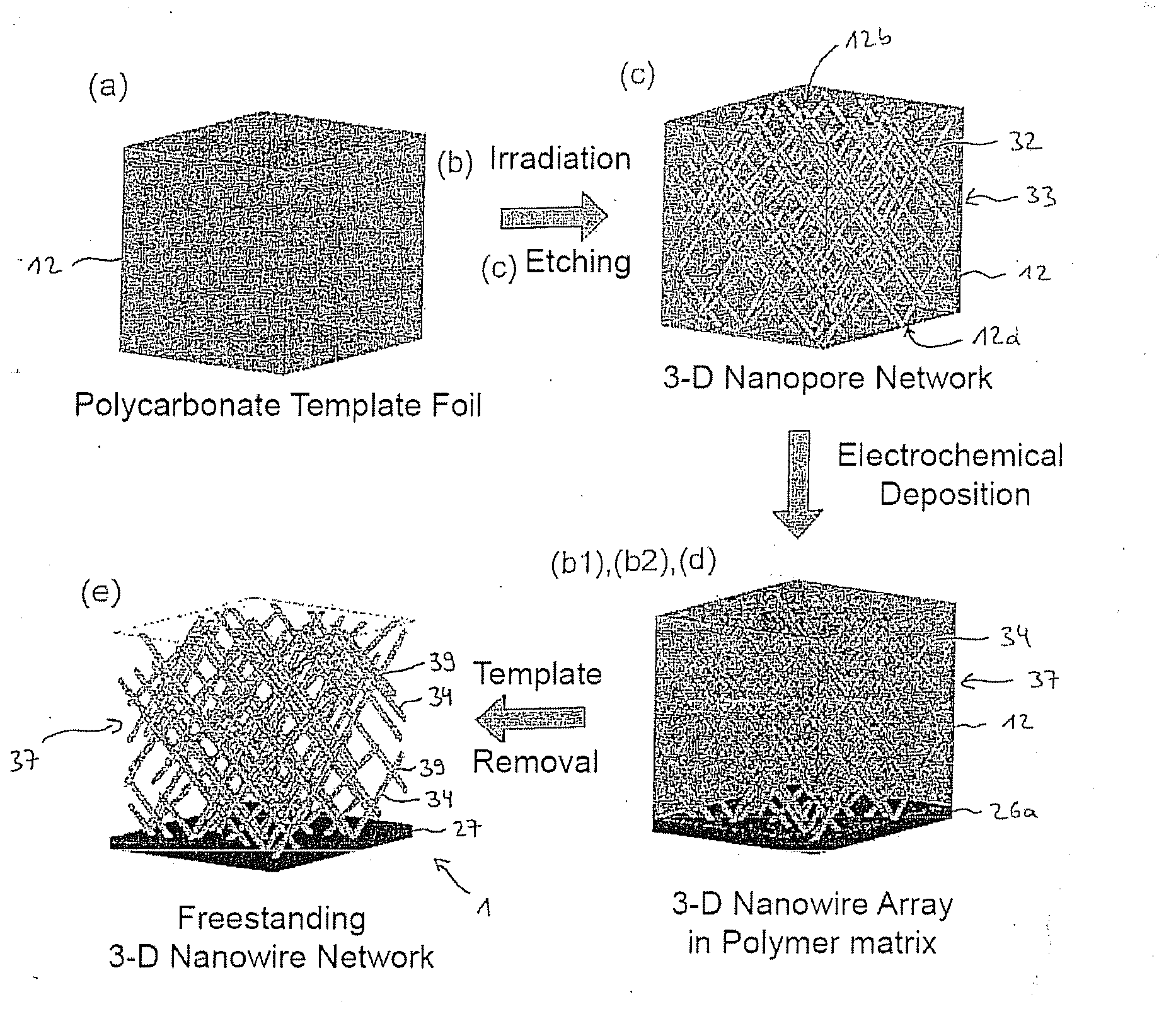

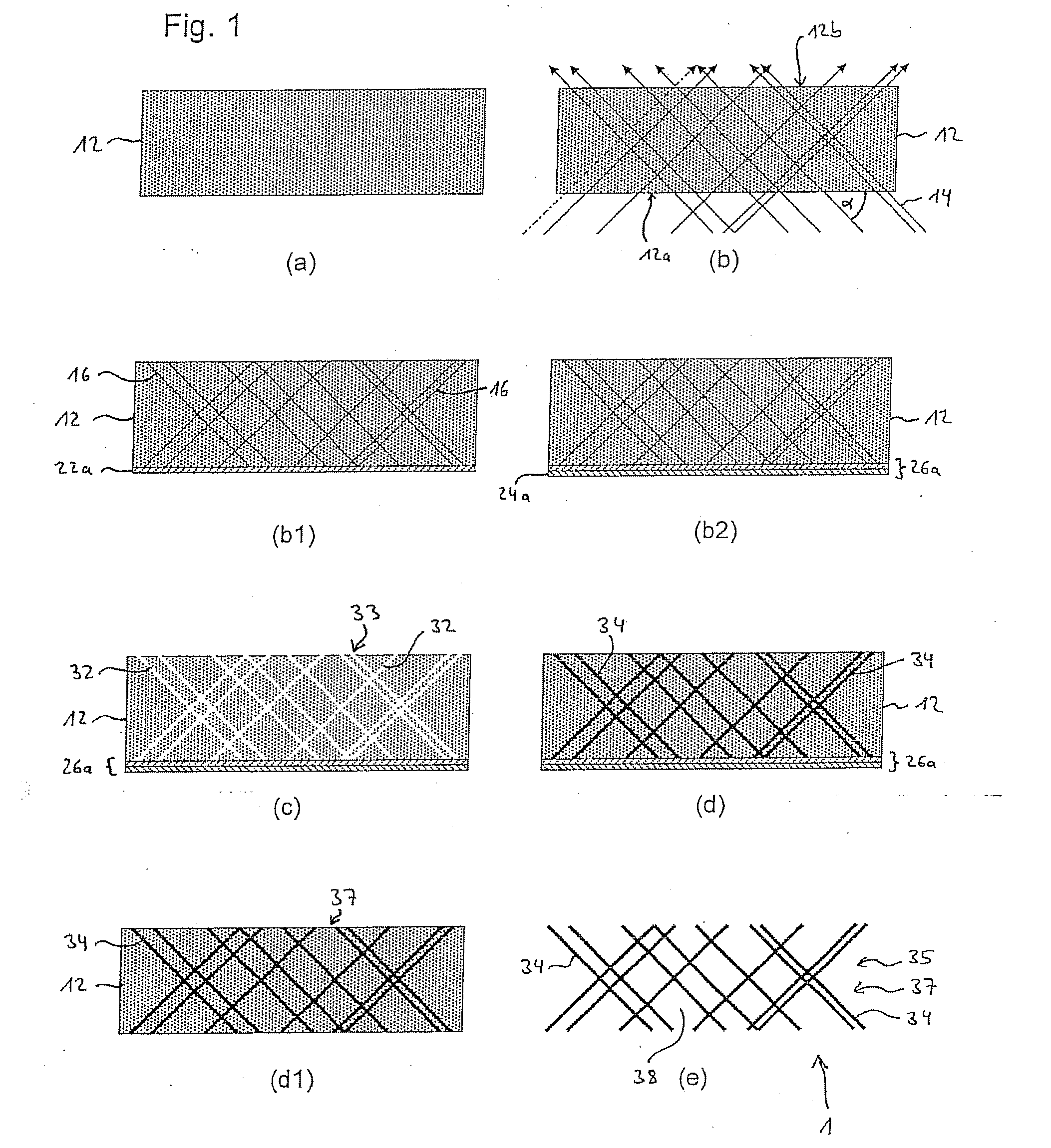

Nanowire Structural Element

ActiveUS20110211994A1Improve the level ofGuaranteed smooth progressMaterial nanotechnologyVolume/mass flow measurementElectricityMicroreactor

The invention concerns a nanowire structural element suited for use in a microreactor system or microcatalyzer system.A template based process is used for the production of the nanowire structural element, wherein the nanowires are electrochemically depositioned in the nanopores. The irradiation is carried out at different angles, such that a nanowire network is formed. The hollow chamber-like structure in the nanowire network is established through the dissolving of the template foil and removal of the dissolved template material. The interconnecting of the nanowires provides stability to the nanowire structural element and an electrical connection between the nanowires is created thereby.

Owner:GSI HELMHOLTZZENT FUR SCHWERIONENFORSCHUNG

Process for producing carbonized product used for producing activated carbon for electrode of electric double-layer capacitor, and organic material for carbonized product

InactiveUS7067051B2High capacity densityIncrease capacitance densityCarbon compoundsProtecting/adjusting hybrid/EDL capacitorActivated carbonHeating time

To produce a carbonized product used for producing activated carbon for en electrode of an electric double-layer capacitor, a condensed polycyclic aromatic pitch having an optical anisotropic rate Oa in a range of 1%≦Oa≦90% and a softening point Ts in a range of 140° C.≦Ts≦260° C. is subjected to an oxygen crosslinking treatment at a heating temperature Th set at Th<260° C. to provide an organic material for a carbonized product having a light component content L equal to or higher than 14.5% by weight, and the organic material is subjected to a carbonizing treatment at a temperature-raising rate Rt set at Rt≧500° C. / hr and at a heating temperature Th set in a range of 600° C.≦Th≦1,000° C. for a heating time t set at t≦2 hr.

Owner:HONDA MOTOR CO LTD +1

Easy-to-prepare PS plate developing liquid and preparation method thereof

InactiveCN104281016AReduce erosionErosion free fromPhotosensitive material processingSodium phosphatesPotassium hydroxide

The invention discloses easy-to-prepare PS plate developing liquid and a preparation method thereof, relating to the field of printing. The developing liquid comprises the components with contents as follows: 51-55g / L of potassium hydroxide, 155-175g / L of sodium silicate, 9-11g / L of sodium phosphate, 20-25g / L of sodium dodecyl benzene sulfonate and the balance being ion water or distilled water. The easy-to-prepare PS plate developing liquid has the advantages of high developing capability, high stability, long service life, easiness in clearing of residual alkaline liquid, uniform developing and the like; furthermore, the influence on no photosensitive coating caused by erosion is low, and a photosensitive layer of an image-text part cannot be eroded by the developing liquid.

Owner:ANHUI ZHONGCAI PRINTING

Alkaline solution and manufacturing method, and alkaline solution applied to pattern forming method, resist film removing method, solution application method, substrate treatment method, solution supply method, and semiconductor device manufacturing method

InactiveUS7097960B2Difference of the affinity of the exposed portion surfaceReduce the differenceOther chemical processesPretreated surfacesResistReduced properties

Owner:KK TOSHIBA

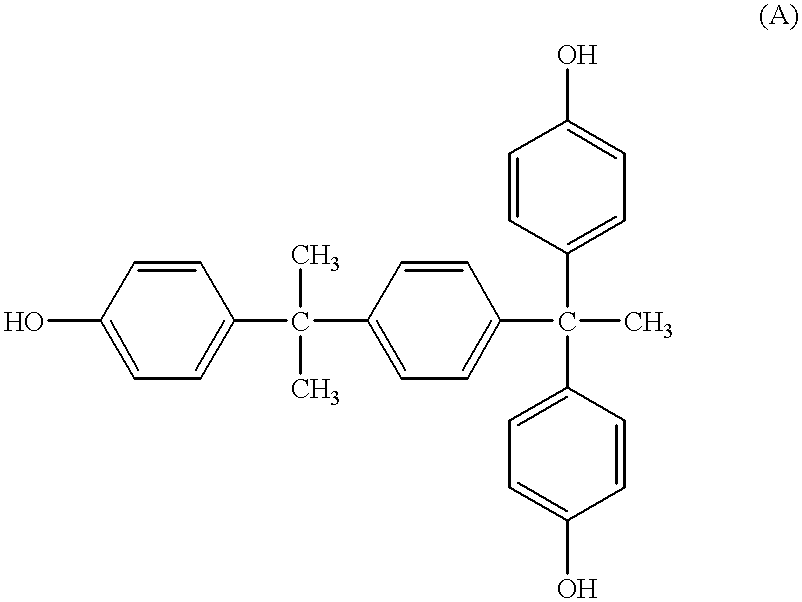

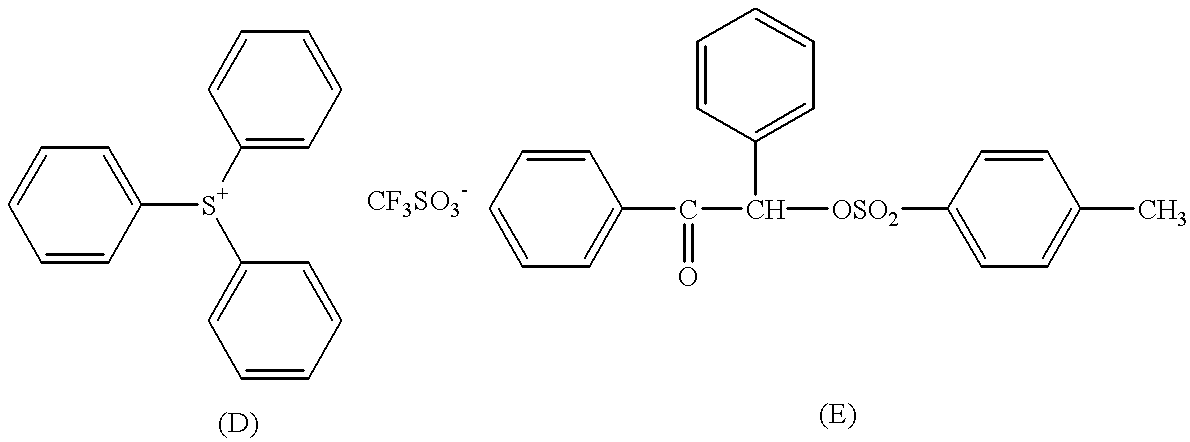

Barrier film material and pattern formation method using the same

InactiveUS7939242B2Decrease productivityReduce yieldPhotosensitive materialsPhoto-taking processesResistPolyol

A barrier film material includes, in addition to an alkali-soluble polymer, a multivalent carboxylic acid compound having a plurality of carboxyl groups or a multivalent alcohol compound. Thus, the multivalent carboxylic acid compound or the multivalent alcohol compound is adhered onto the surface of a resist film, and hence, particles having been adhered to the surface of the resist film are removed in removing the barrier film. Also, in the case where the barrier film is removed simultaneously with development, the resist film can be prevented from remaining partly undissolved.

Owner:RPX CORP

Hybrid mushroom strain J9277 and its descendants

ActiveUS20080182321A1Uniform developmentHuman cost was highSugar derivativesFungi productsBasidiosporeMicrobiology

A novel hybrid fungus culture, designated J9277, of the mushroom species Agaricus bisporus produces crops of mushrooms having white, rounded, thick-fleshed caps and proportionally long stems in a relatively short interval of time. Diverse additional strains can be developed from J9277 by various means including somatic and tissue culture selection, basidiospore selection, and hybridization to other strains of Agaricus bisporus, and the resulting derivative strains can be screened for desirable commercial characteristics.

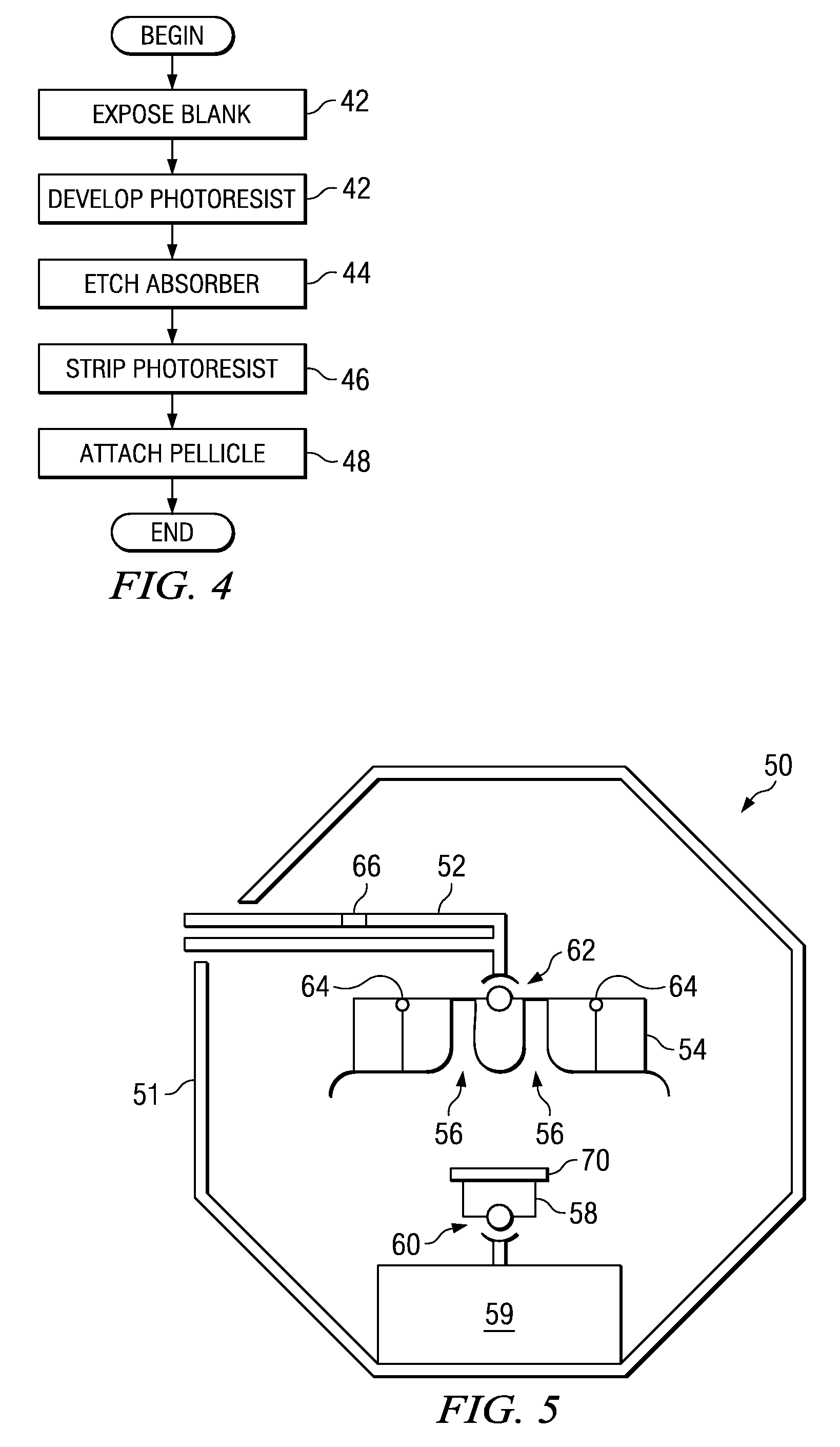

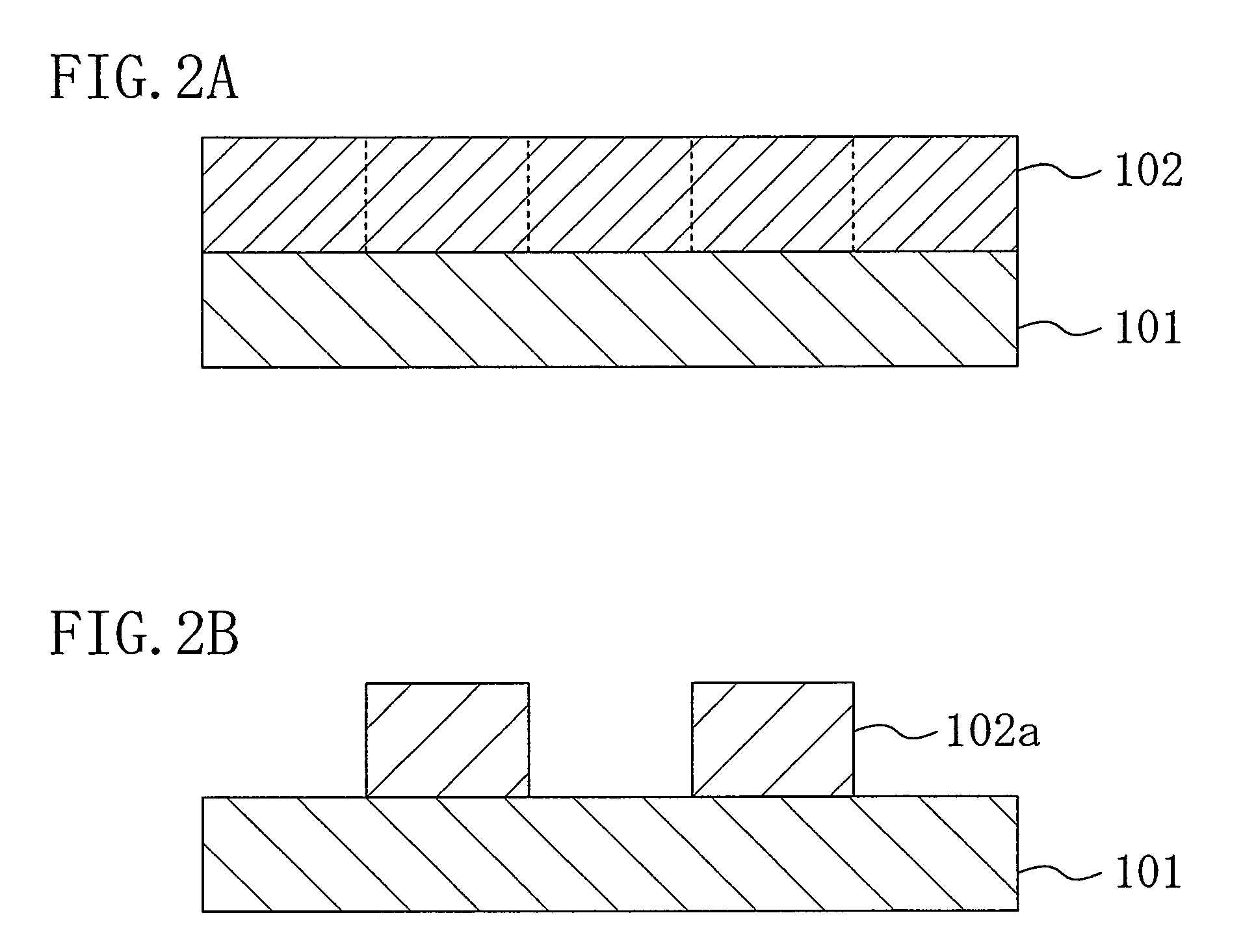

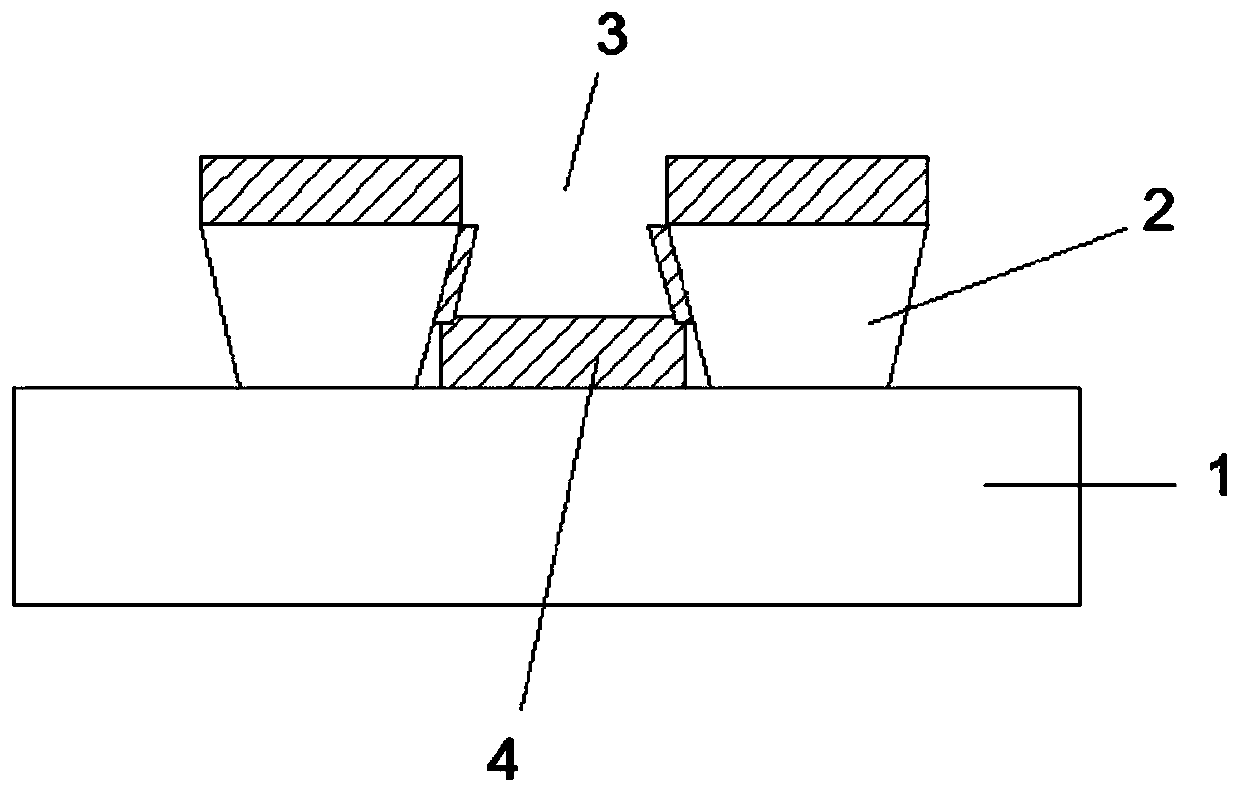

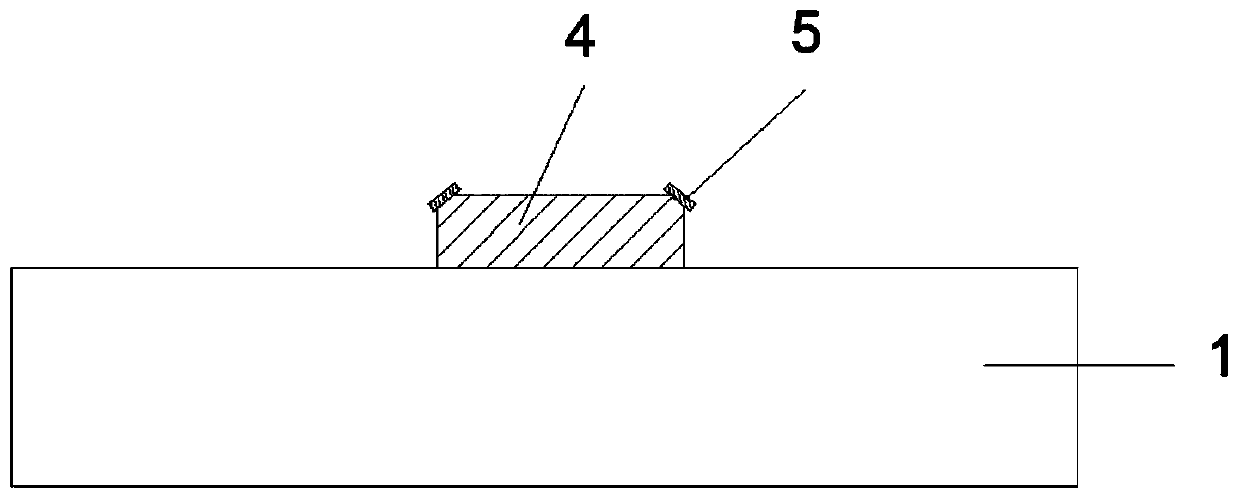

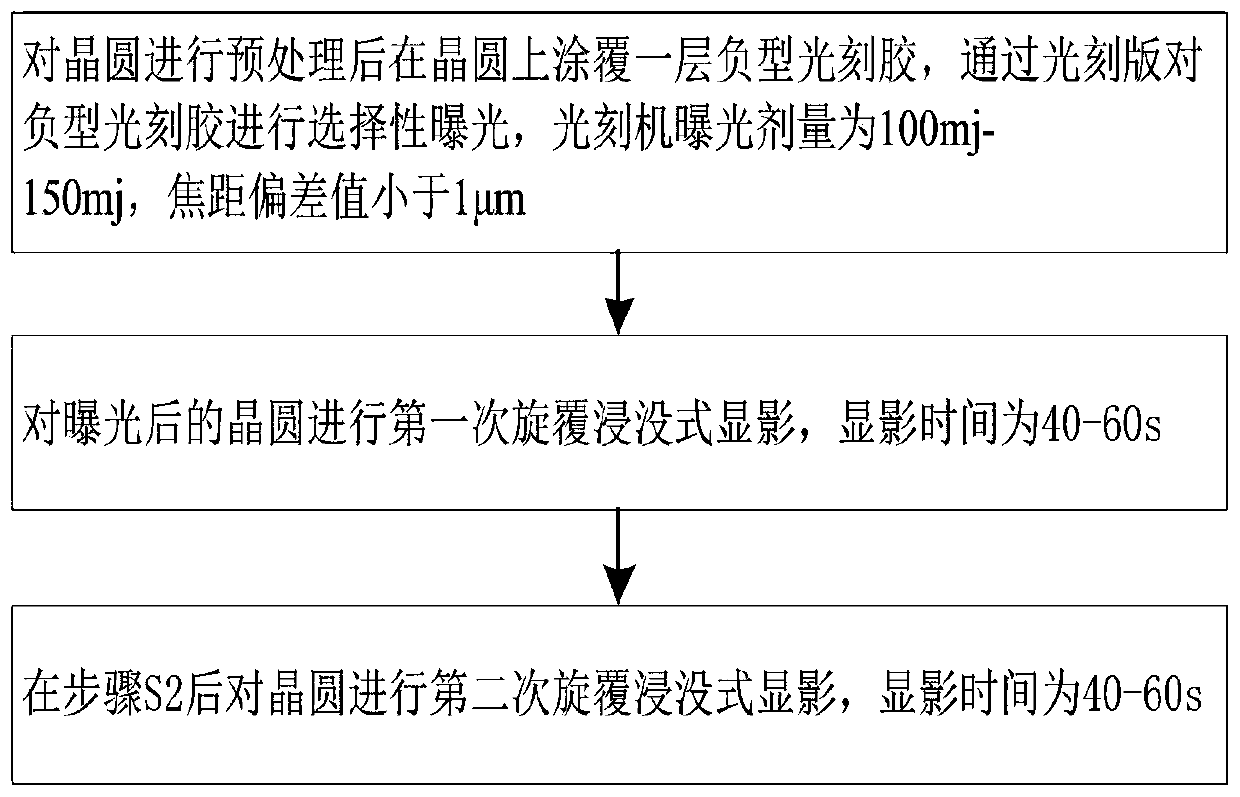

A burr-free photolithography method

ActiveCN107664926BAvoid stickingImprove electrical performancePhotomechanical exposure apparatusPhotosensitive material processingWaferPhysical chemistry

The invention relates to the technical field of semiconductor manufacturing and in particular relates to a burr-free photoetching method. The burr-free photoetching method comprises the following steps: S1, after pre-treating a wafer, coating the wafer with one layer of negative photoresist; carrying out selective exposure on the negative photoresist through a photoetching mask, wherein the exposure dosage of a photoetching machine is 100mj to 150mj and the focal distance deviation value is less than 1mu m; S2, carrying out first time of rotary covering and immersing type development on the exposed wafer, wherein the development time is 40s to 60s; S3, carrying out second time of rotary covering and immersing type development on the wafer after step S2, wherein the development time is 40sto 60s. According to properties of the negative photoresist, the negative photoresist can form a pattern better through limiting the exposure dosage, a exposure focal distance and time of 2 to 3 timesof the rotary covering and immersing type development, the pattern is wide in top and narrow in bottom and a lower layer of the pattern is concave inward; metal is not continuously distributed on thewhole photoresist in an evaporation process, so that a condition that the lower layer of the photoresist is stuck with the metal is avoided and a degummed metal layer is smooth and has no burrs; theelectrical property of appliances is improved and the yield of the appliances is improved.

Owner:CHENGDU HIWAFER SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com