Foaming dentifrice with desensitizing agents

A technology of thickener and surfactant, applied in the field of treating or preventing dental hypersensitivity, dentifrice compositions, and oral care compositions for treating or preventing dental hypersensitivity, and can solve the problems of difficulty in achieving foam level and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

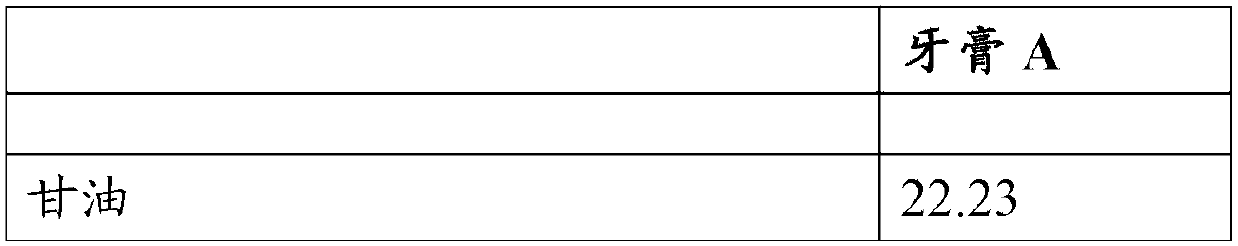

[0080] Embodiment 1: Toothpaste A

[0081] Example 1 illustrates a moderately abrasive oral composition comprising 2.18% by weight of SLS, 1.25% by weight of 30% CAPB in water (0.38% by weight of CAPB) and 0.4% by weight of the oral care composition % xanthan gum in foam system A.

[0082]

[0083]

[0084] Table 1 Composition of Toothpaste A

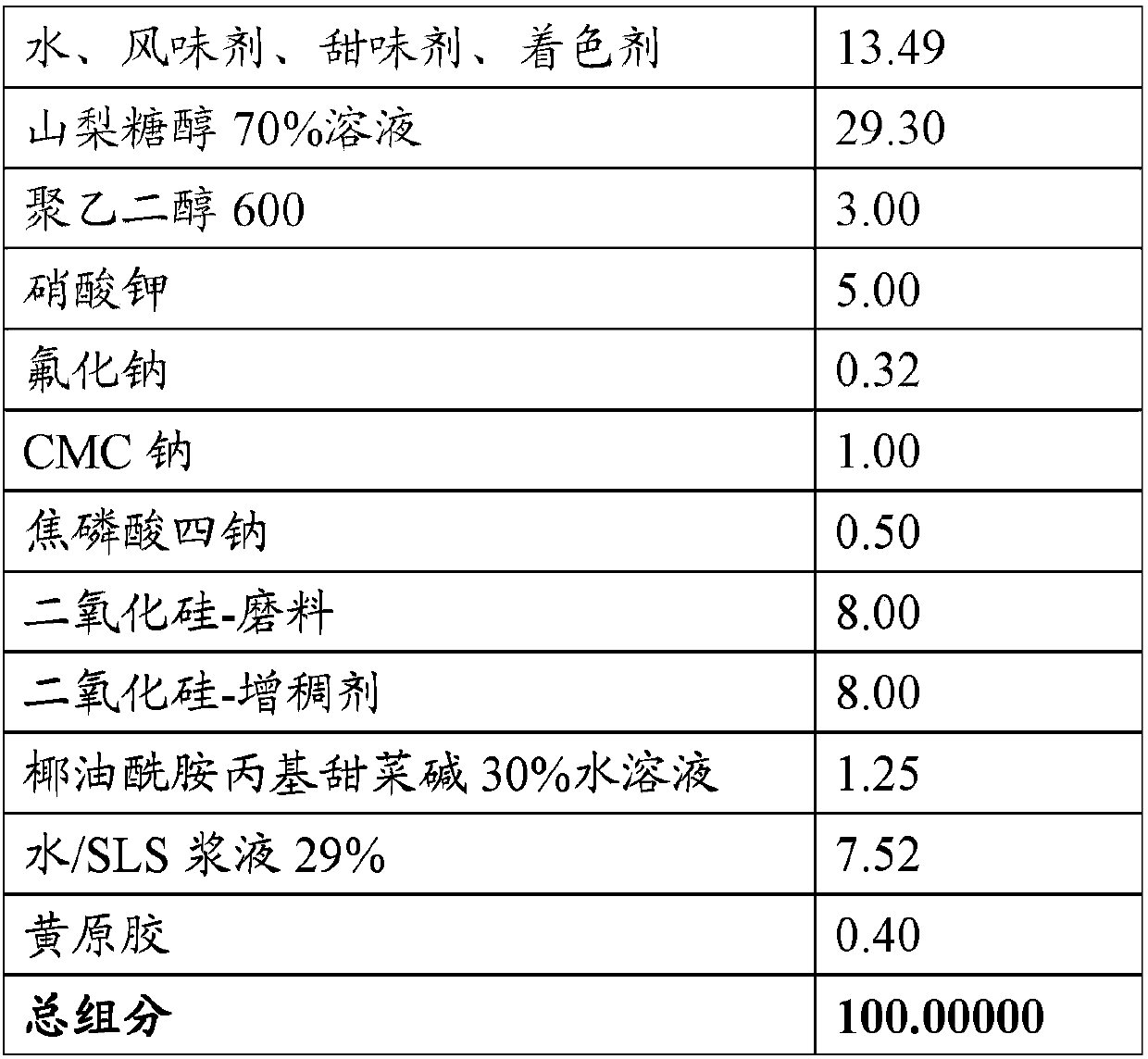

[0085] The graph below illustrates the dramatic difference in foam volume within the first minute of application to artificial saliva. This table compares toothpaste A with foam system A with a comparative composition A which has the same components as toothpaste A but with the following difference: the comparative composition A does not contain foam system A (SLS+CAPB) Foam system consisting of 3.90 wt% water / SLS slurry 29% (1.13 wt% SLS; balance of difference is additional water).

[0086]

[0087]

[0088] Table 2 Foam volume data of toothpaste A in artificial saliva with and without foam system A

Embodiment 2

[0089] Embodiment 2: Toothpaste B

[0090] Example 2 illustrates a more abrasive oral composition comprising 2.18% by weight of SLS, 1.25% by weight of 30% CAPB in water (0.38% by weight of CAPB) and 0.65 Foam system B with weight % xanthan gum.

[0091]

Toothpaste B

glycerin

26.00

Water, flavoring, sweetening, coloring

17.20

Sorbitol 70% solution

17.26

polyethylene glycol 600

3.00

5.00

0.32

Sodium CMC

0.50

Silica - Abrasive

8.00

Silica - Thickener

3.00

High cleaning power silica

10.00

Cocamidopropyl Betaine 30% in water

1.25

Water / SLS slurry 29%

7.52

0.65

50% KOH

0.30

total composition

100.000000

[0092] Table 3 Composition of Toothpaste B

[0093] The graph below illustrates the significantly more foam obtained with foam system A according to the inven...

Embodiment 3

[0098] Embodiment 3: Toothpaste C

[0099] Example 3 illustrates a moderately abrasive oral composition comprising 2.18% by weight of SLS, 1.25% by weight of 30% CAPB in water (0.38% by weight of CAPB), 0.65% by weight, based on the total weight of the oral care composition % xanthan gum, 2.44% by weight tetrasodium pyrophosphate and 2.00% by weight zinc citrate foam system C.

[0100]

[0101]

[0102] Table 5 Composition of Toothpaste C

[0103] The graph below illustrates the significantly more foam obtained with foam system C according to the invention, especially within the consumer-relevant first 60 seconds of application to artificial saliva. This table compares Toothpaste C with Foam System C with Comparative Composition C which has the same components as Toothpaste C with the following difference: The Comparative Composition C does not contain Foam System C but contains 4.91% by weight of water Foam system consisting of / SLS slurry 29% (1.42% by weight SLS; ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com