Method for preparing functional hydrolysate by degrading eggshell membrane by using steam explosion technology

An egg shell membrane and functional technology, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of acid vapor and waste liquid adverse effects, environmental protection, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

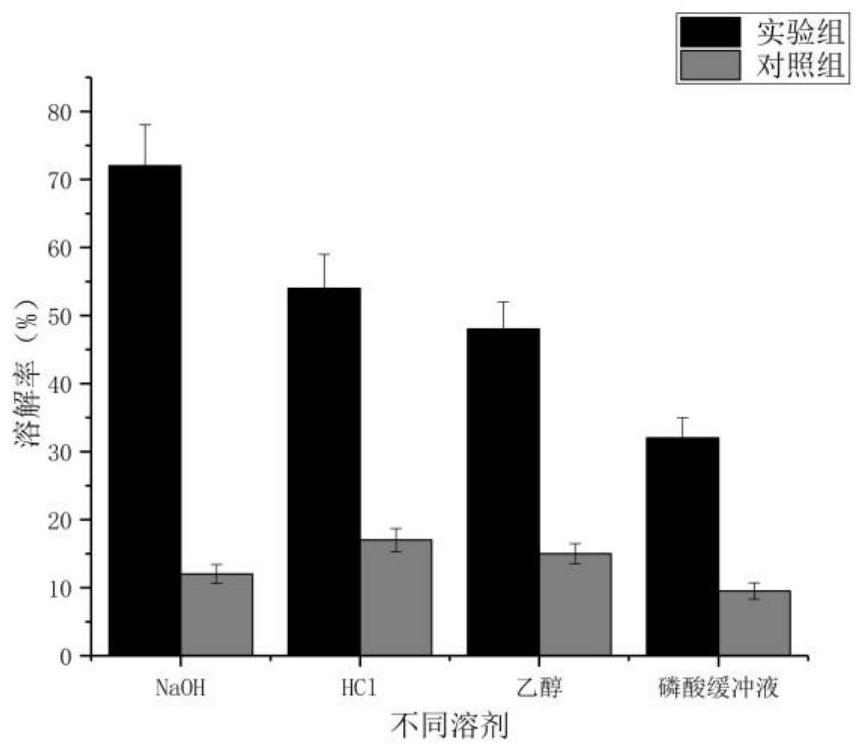

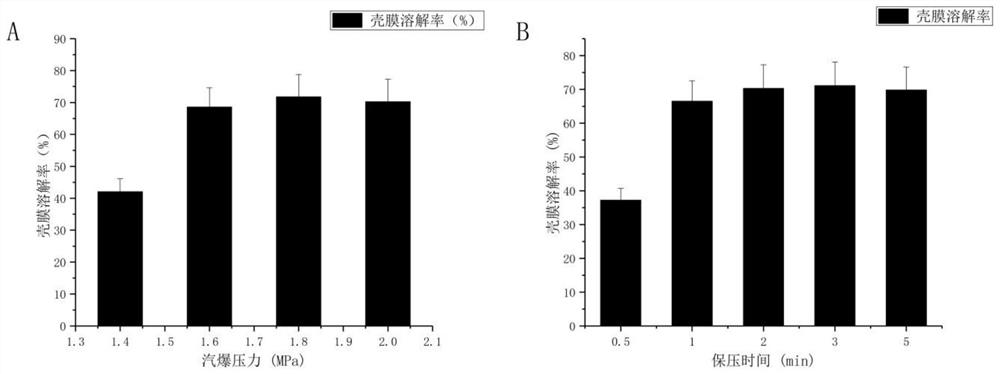

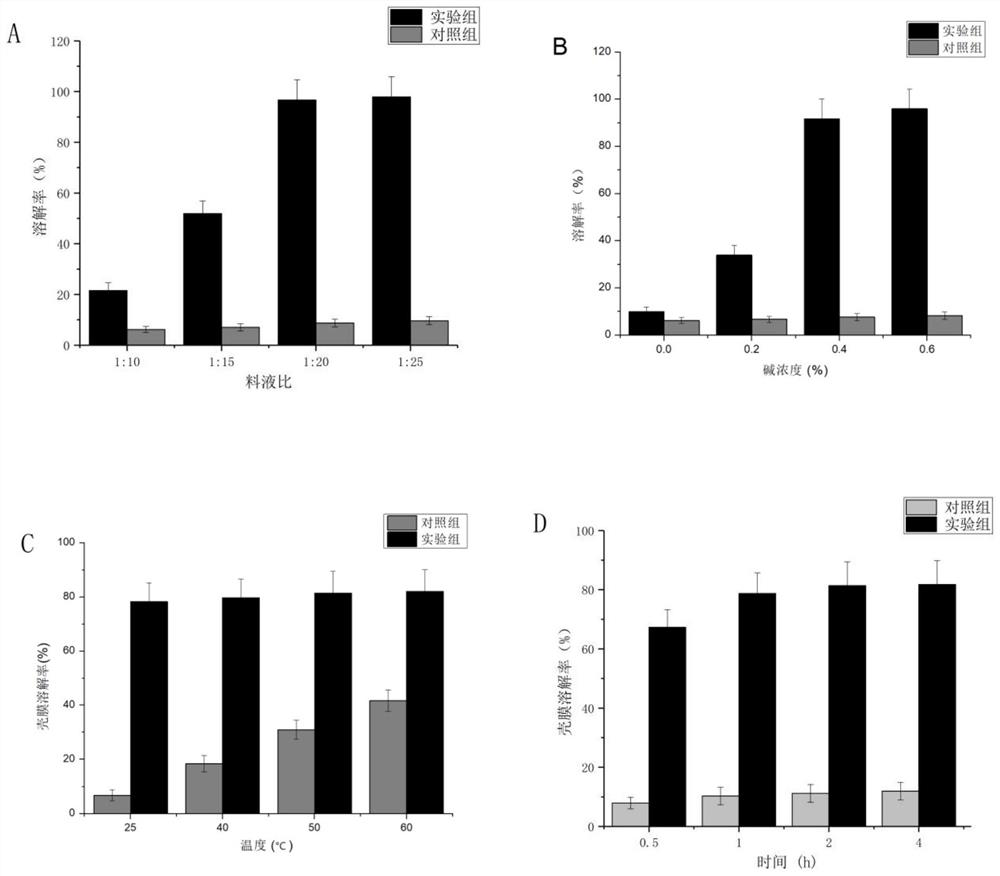

Method used

Image

Examples

Embodiment 1

[0134] The method for preparing functional hydrolyzate 1 by degrading egg shell membranes by steam explosion technology comprises the following steps:

[0135] 1) Steam explosion treatment

[0136] Weigh 1000g and put it in the steam explosion machine reactor, keep the pressure at 1.4MPa for 0.5min, then release the pressure instantly for 0.1s, collect the steam explosion samples, and store them at -4°C for later use;

[0137] 2) The sample is degraded by dilute alkali method

[0138] The steam explosion sample was added into NaOH solution with an alkali concentration of 0.6% according to a solid-liquid ratio of 1:25, and the temperature was 60°C, and the reaction was shaken for 0.5h, filtered to obtain a filtrate, and freeze-dried to obtain a functional hydrolyzate 1.

Embodiment 2

[0140] The method for preparing functional hydrolyzate 2 by degrading egg shell membranes using steam explosion technology comprises the following steps:

[0141] 1) Steam explosion treatment

[0142] Weigh 1000g of eggshell membranes and place them in a steam explosion machine reactor, hold the pressure at 1.6MPa for 1min, then release the pressure instantly for 0.1s, collect the steam explosion samples, store them at -4°C, and keep them for later use;

[0143] 2) The sample is degraded by dilute alkali method

[0144] Add the steam explosion sample into NaOH solution with an alkali concentration of 0.4% according to the ratio of solid to liquid 1:20, and shake the reaction for 1 h at a temperature of 25°C, filter to obtain the filtrate, and freeze-dry to obtain functional hydrolyzate 2.

Embodiment 3

[0146] The method for preparing functional hydrolyzate 3 by degrading egg shell membranes by steam explosion technology comprises the following steps:

[0147] 1) Steam explosion treatment

[0148] Weigh 1000g of eggshell membranes and place them in a steam explosion machine reactor, hold the pressure at 1.8MPa for 2min, then release the pressure instantly for 0.1s, collect the steam explosion samples, and store them at -4°C for later use;

[0149] 2) The sample is degraded by dilute alkali method

[0150] Add the steam explosion sample into NaOH solution with an alkali concentration of 0.2% according to the ratio of solid to liquid 1:15, and shake the reaction for 2 hours at a temperature of 40°C, filter to obtain the filtrate, and freeze-dry to obtain functional hydrolyzate 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com