Filtration device for pulp

A filtering device and pulp technology, applied in the field of papermaking, can solve the problems of small slag discharge sealing door and difficulty in removing impurities, and achieve the effects of good effect, less difficulty in removing impurities and speeding up the filtration speed.

Inactive Publication Date: 2018-02-09

SUIYANG COUNTY SHUANGLONG PAPER IND CO LTD

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

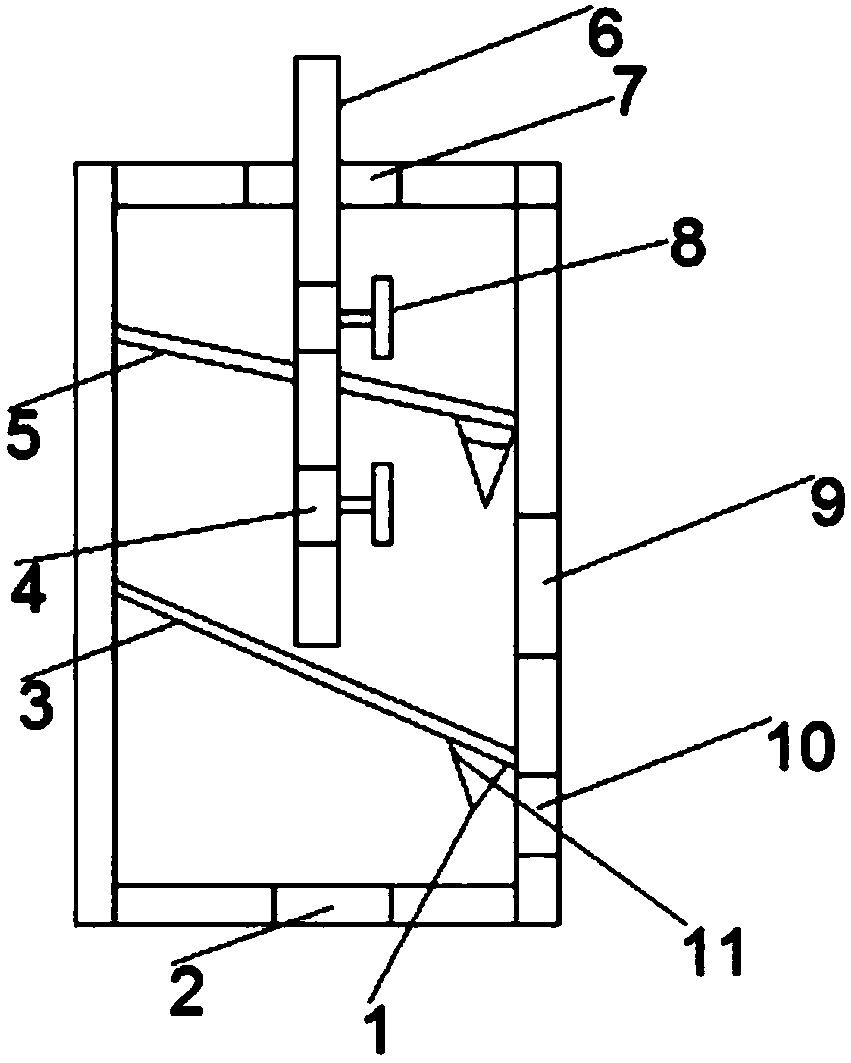

The present application discloses a filtration device for pulp, the filtration device for the pulp comprises a cylindrical filter cartridge which is disposed upright. A first filter net and a second filter net are obliquely arranged in the cylindrical filter cartridge, and the second filter net is located below the first filter net. The first filter net and the second filter net both include a high end and a low end, the low end of the first filter net is provided with a detachable first filter bag, the detachable first filter bag is matched with the first filter net in mesh diameter, the lowend of the second filter net is provided with a detachable second filter bag, and the detachable second filter bag is matched with the second filter net in the mesh diameter. A first sealing door anda second sealing door are arranged on the side wall of the cylindrical filter cartridge, a water pipe is also arranged on the top of the cylindrical filter cartridge, and one end of the water pipe penetrates through the first filter net and extends to above the second filter net. The water pipe is provided with rotating nozzles which are respectively located above the first filter net and betweenthe first filter net and the second filter net. Impurities are accumulated in the filter bags under the flushing of the rotary nozzles, the sealing doors are opened, and the filter bags are taken down, and the impurities are removed.

Description

technical field [0001] The invention relates to the technical field of papermaking, in particular to a filter device for pulp. Background technique [0002] A lot of waste paper is produced every day in daily life, and these waste papers will pollute the nature if not handled properly. In the recycling process of waste paper, it needs to go through processing processes such as crushing, adding water to melt into pulp, filtering and drying to form. Since waste paper raw materials contain a lot of impurities such as sand, if these impurities are not filtered out, it will affect the quality of the pulp. Drying and molding, the existing filtering equipment has complex structure, high production cost, and poor filtering effect of impurities. [0003] In view of the above deficiencies, the Chinese patent with the authorized announcement number CN205399066U discloses "a kind of pulp filtration and recovery device", which includes a vertically arranged cylindrical filter recovery c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D29/03B01D29/58B01D29/66B01D29/94

CPCB01D29/03B01D29/58B01D29/66B01D29/94

Inventor 李泽世张善芳彭绅彭铂祯

Owner SUIYANG COUNTY SHUANGLONG PAPER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com