A Belt Filter Press Separation System with Deviation Adjustment and Tension Integration

A belt filter press and separation system technology, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve the problems of inability to adjust in time, low degree of automatic control, single type of chemical slurry, etc. Accurate, prolong the gravity separation time, reduce the effect of waste in efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] Embodiments of the present invention refer to Figure 1-6 shown.

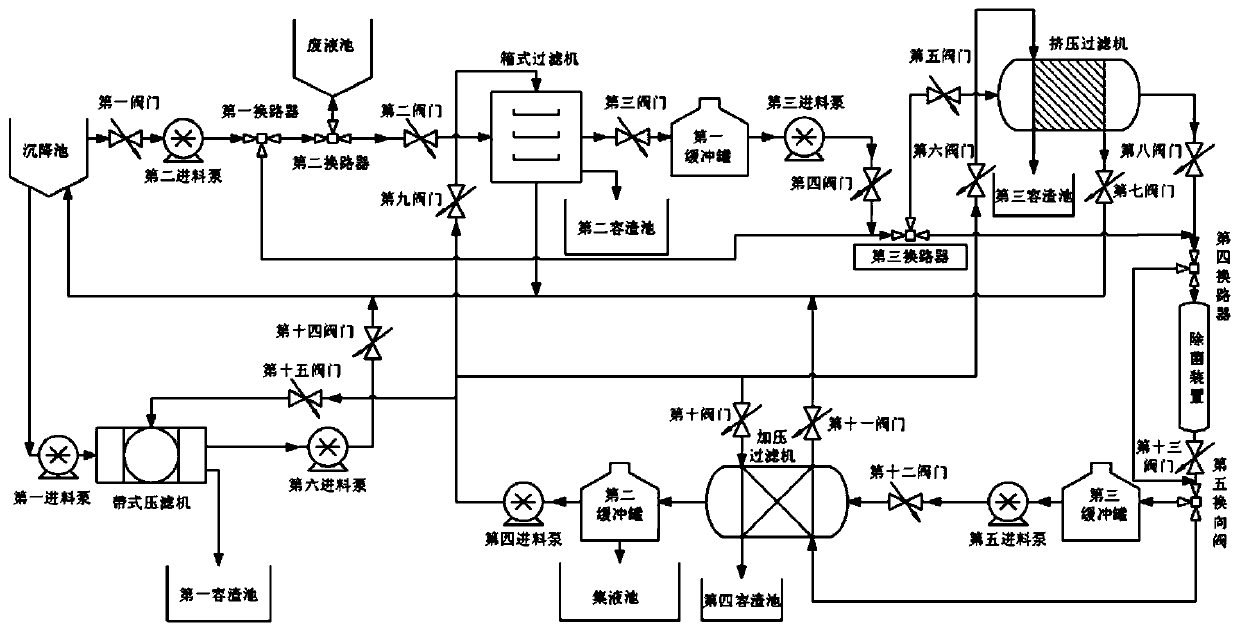

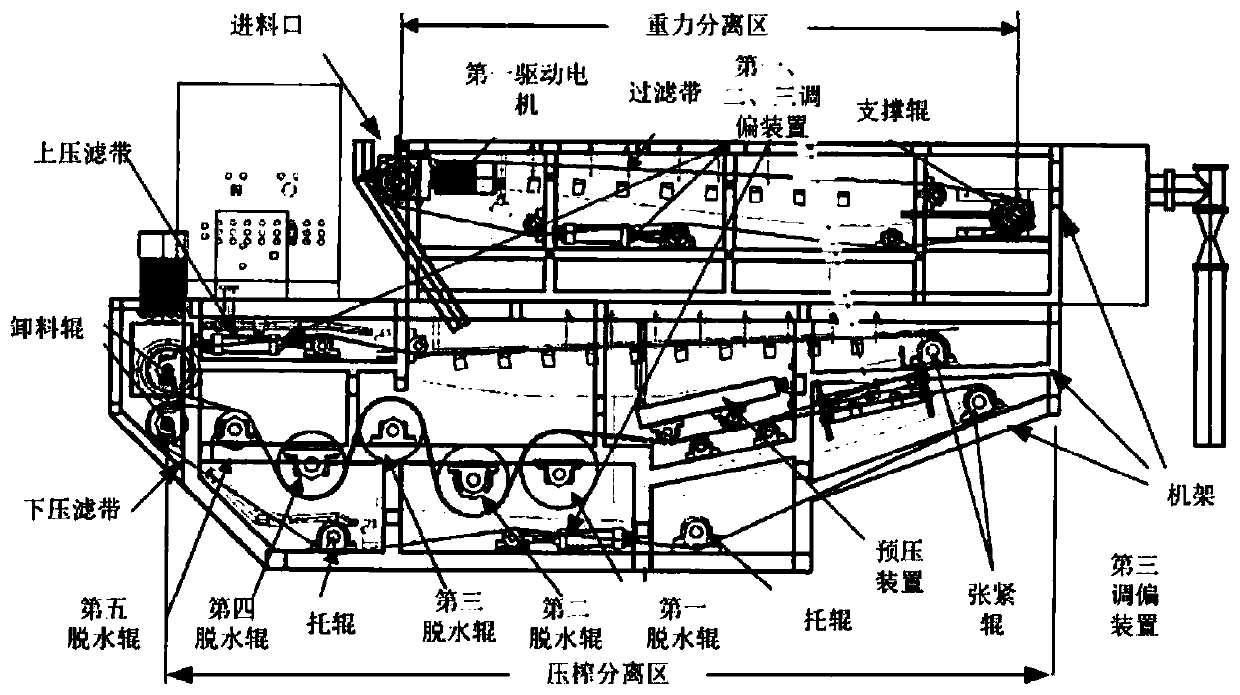

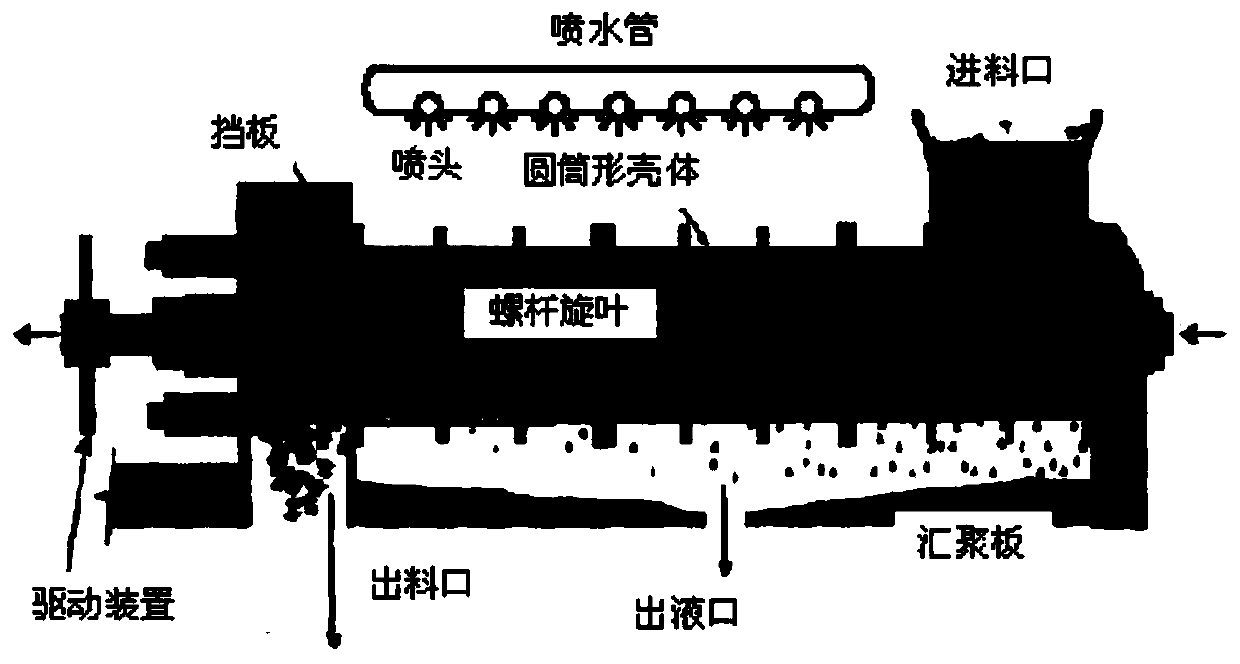

[0025] A belt filter press separation system integrated with deviation adjustment and tension, which includes a belt filter press, a box filter, a pressure filter, a squeeze filter, and a sterilizer The device, 1 settling tank, 1 waste liquid tank, 1 liquid collection tank, 4 slag holding tanks, 3 buffer tanks, 6 feed pumps, 5 circuit changers and 15 valves are characterized in that: The settling tank contains chemical slurry, and the settled chemical slurry enters the belt filter press through the bottom of the settling tank under the action of the first feed pump, and the belt filter press puts the filtered chemical material into the first container Slag tank, the chemical filtrate produced enters the recovery main line through the sixth feed pump and the fourteenth valve and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com