Graphene and preparation method thereof

A technology of graphene and flake graphite, which is applied in the field of graphene and its preparation, can solve the problems of slow preparation process and poor layering effect, and achieve the effects of fast preparation process, good reduction effect and dispersion effect, and accelerated preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

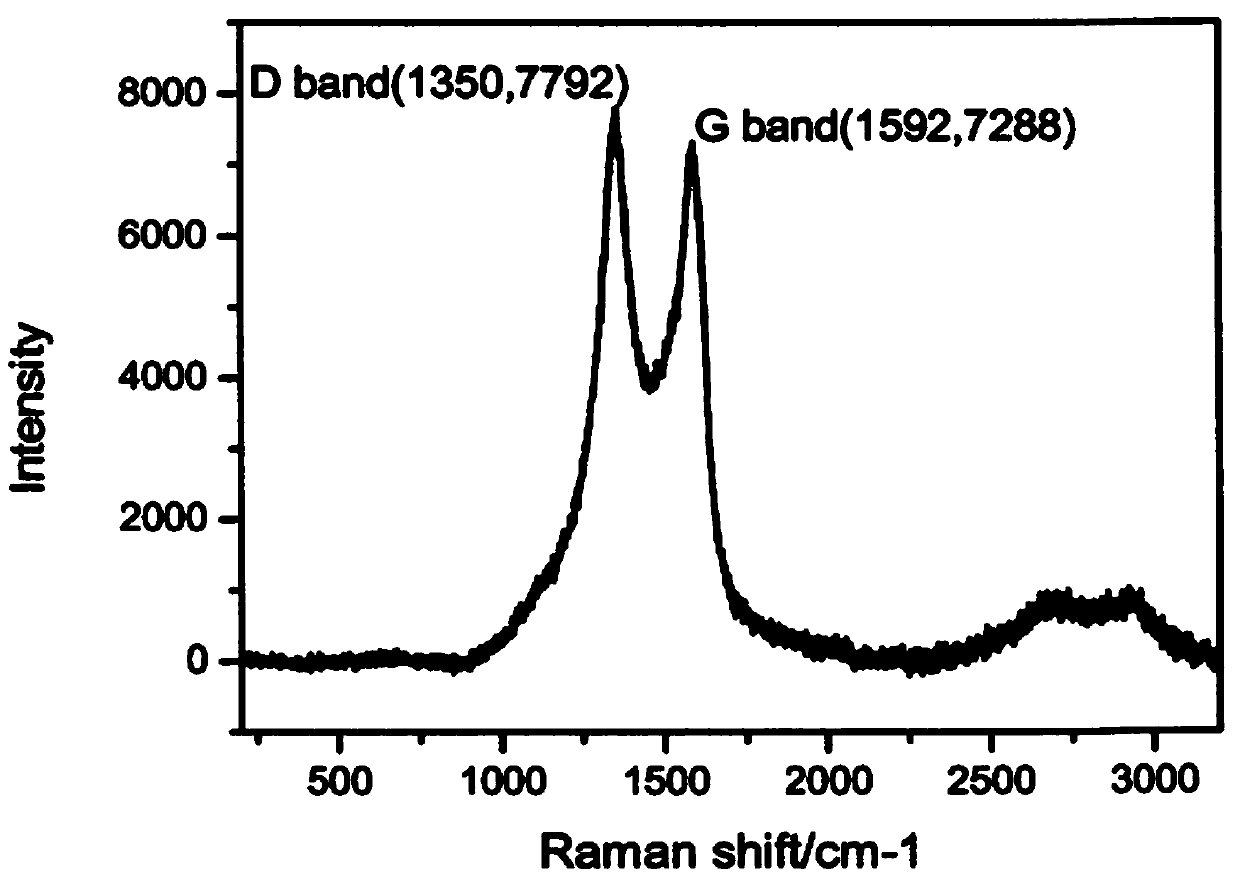

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of graphene, which comprises steps in turn: the first flake graphite intercalation treatment; the first microwave pretreatment; the first mechanical refinement; the second intercalation treatment; the second microwave pretreatment Treatment; second mechanical refinement; high-frequency ultrasonic oxidation; microwave low-temperature reduction, the specific steps are as follows.

[0032] 1. The first flake graphite intercalation treatment

[0033] Using flake graphite with a carbon content of 99% as raw material, potassium ferrate, phosphorus pentoxide, concentrated sulfuric acid, concentrated nitric acid and potassium permanganate as oxidant and intercalation agent; flake graphite, potassium ferrate, The mass ratio of phosphorus, concentrated sulfuric acid, concentrated nitric acid and potassium permanganate is 1:4.5:0.30:30:30:0.1;

[0034] Put the raw materials, intercalation agent and oxidant into the reaction kettle, and ...

Embodiment

[0060] The present embodiment provides a method for preparing graphene, which includes steps in turn: the first flake graphite intercalation treatment; the first microwave pretreatment; the first mechanical refinement; the second intercalation treatment; the second microwave Pretreatment; second mechanical refinement; high-frequency ultrasonic oxidation; microwave low-temperature reduction, the specific steps are as follows.

[0061] 1. The first flake graphite intercalation treatment

[0062] Using flake graphite with a carbon content of 99% as raw material, potassium ferrate, phosphorus pentoxide, concentrated sulfuric acid, concentrated nitric acid and potassium permanganate as oxidant and intercalation agent; flake graphite, potassium ferrate, The mass ratio of phosphorus, concentrated sulfuric acid, concentrated nitric acid and potassium permanganate is 1:4.5:0.30:30:30:0.1;

[0063] Put the raw materials, intercalation agent and oxidant into the reaction kettle, and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com