Indium sulfide doped cuprous sulfide thermoelectric material and preparation method thereof

A technology of cuprous sulfide and thermoelectric materials, which is applied in the direction of copper sulfide, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of restricting large-scale application, Te element poisonous earth content, etc., and achieves easy macro preparation and simple preparation method Ease of operation, the effect of inhibiting high temperature phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

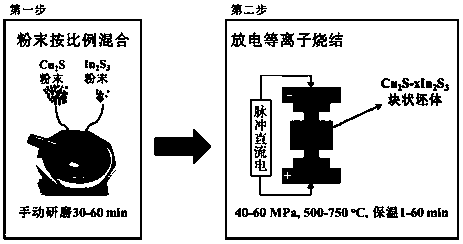

[0039] Cuprous sulfide thermoelectric material, the specific preparation method is as follows:

[0040] (1) Weigh 3g of cuprous sulfide powder, place it in an agate mortar, and grind it for 30 minutes with an agate mortar.

[0041] (2) Put the ground powder into a graphite mold with an inner diameter of 12.7mm, and apply a pressure of 50MPa at both ends of the mold, and then vacuumize the SPS sintering furnace cavity. When the vacuum degree is less than 2Pa, start high-temperature sintering , Gradually increase the current during sintering to increase the temperature. After 12 minutes, the temperature rises to 600°C, keep at 600°C for 5 minutes, and then end the sintering process, and immediately remove the pressure at both ends of the mold. The sample was allowed to cool down to room temperature naturally while maintaining a constant vacuum.

Embodiment 2

[0043] Indium sulfide doped cuprous sulfide thermoelectric material, the specific preparation method is as follows:

[0044] (1) take by weighing 3g cuprous sulfide powder and place in agate mortar, then take by weighing the indium sulfide powder that is equivalent to 3g cuprous sulfide and be 1% molar percentage in agate mortar, and the two are fully mixed, then Grind with an agate mortar for 30 minutes.

[0045] (2) Put the ground powder into a graphite mold with an inner diameter of 12.7mm, and apply a pressure of 50MPa at both ends of the mold, and then vacuumize the SPS sintering furnace cavity. When the vacuum degree is less than 2Pa, start high-temperature sintering , Gradually increase the current during sintering to increase the temperature. After 12 minutes, the temperature rises to 600°C, keep at 600°C for 5 minutes, and then end the sintering process, and immediately remove the pressure at both ends of the mold. The sample was allowed to cool down to room temperat...

Embodiment 3

[0047] Indium sulfide doped cuprous sulfide thermoelectric material, the specific preparation method is as follows:

[0048] (1) take by weighing 3g cuprous sulfide powder and place in agate mortar, then take by weighing the indium sulfide powder that is equivalent to 3g cuprous sulfide and be 2% molar percentage in agate mortar, and the two are fully mixed, then Grind with an agate mortar for 30 minutes.

[0049] (2) Put the ground powder into a graphite mold with an inner diameter of 12.7mm, and apply a pressure of 50MPa at both ends of the mold, and then vacuumize the SPS sintering furnace cavity. When the vacuum degree is less than 2Pa, start high-temperature sintering , Gradually increase the current during sintering to increase the temperature. After 12 minutes, the temperature rises to 600°C, keep at 600°C for 5 minutes, and then end the sintering process, and immediately remove the pressure at both ends of the mold. The sample was allowed to cool down to room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com