Intensive treatment method of oily sludge

A treatment method and technology of oily sludge, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as pollution and large treatment volume, and achieve good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] An intensive oil sludge treatment method, the treatment method comprises the following steps:

[0039] Step 1. Pretreatment of sludge:

[0040] Take the sewage sludge, import it into the inside of the batching tank, add the water source, stir evenly, and obtain the initial mixing liquid of the sewage sludge;

[0041] Step 2. Intensive treatment of sludge:

[0042] The sludge primary mixture liquid is transported to the inside of the stirring tank, and the sludge primary mixture liquid is simultaneously subjected to mechanical stirring treatment, ultrasonic treatment and heating treatment inside the stirring tank, and the sewage sludge slurry chemical material is obtained after the treatment;

[0043] Step 3. Separation and treatment of sludge:

[0044] Sludge material is taken for separation treatment.

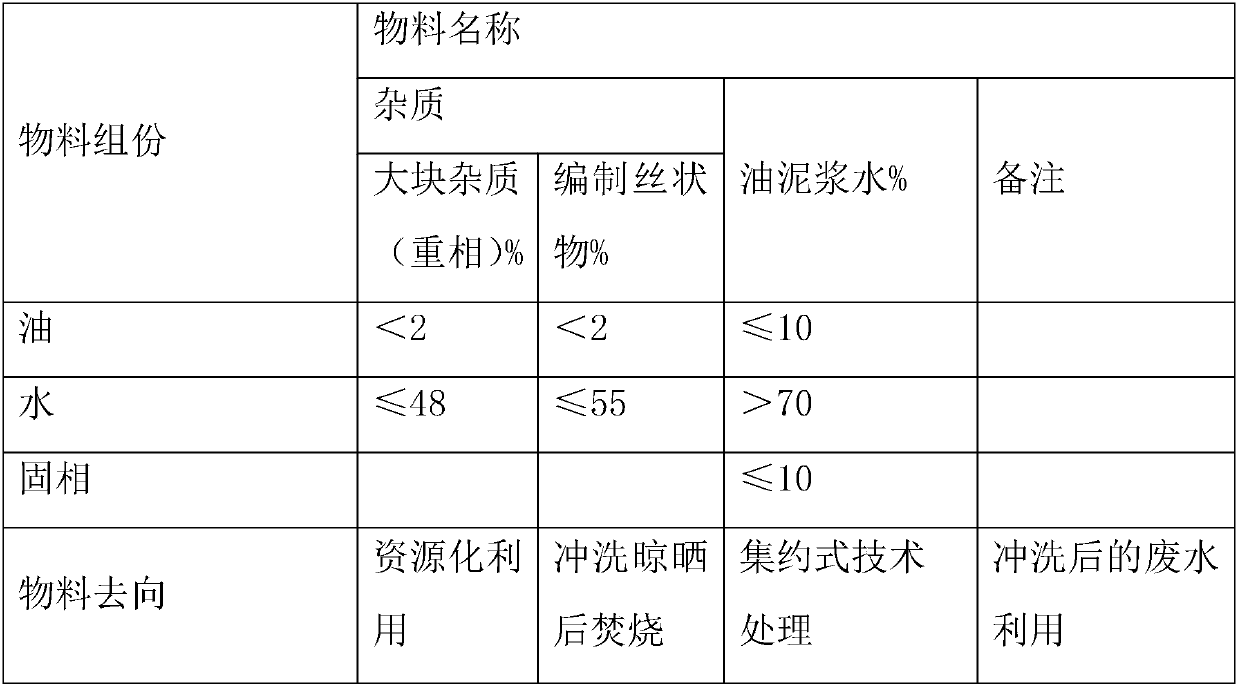

[0045] In said step 1, the sludge includes fluid sludge and solid sludge;

[0046] When the sludge is fluid sludge, the pretreatment step of the sludge is as follow...

specific Embodiment approach 2

[0064] An intensive oil sludge treatment method, the treatment method comprises the following steps:

[0065] Step 1. Pretreatment of sludge:

[0066] Treatment of refinery and drilling sludge:

[0067] Take the liquid sludge, import it into the batching tank, add an appropriate amount of water, and stir evenly to obtain the initial stirring liquid of the sludge;

[0068] Treatment of solid sludge:

[0069] The solid oily sludge is taken, and after being initially screened by the screen, it is transported to the inside of the drum screening sludge washing machine by the elevator for secondary screening;

[0070] The coarse material screened out of the secondary screening enters the crusher for crushing after screening, and then enters the drum screening machine for screening again;

[0071] The fine material screened out by the second time is introduced into the inside of the batching tank, and an appropriate amount of water is added, and after stirring evenly, the initial ...

specific Embodiment approach 3

[0074] In the step 2, in the intensive treatment of the sludge sludge, the sludge primary mixing liquid obtained by the mixing treatment is transported to the inside of the stirring tank, and the sludge primary mixing liquid is simultaneously mechanically stirred and ultrasonically treated inside the stirring tank And heating treatment, after the treatment, the sewage sludge material is obtained;

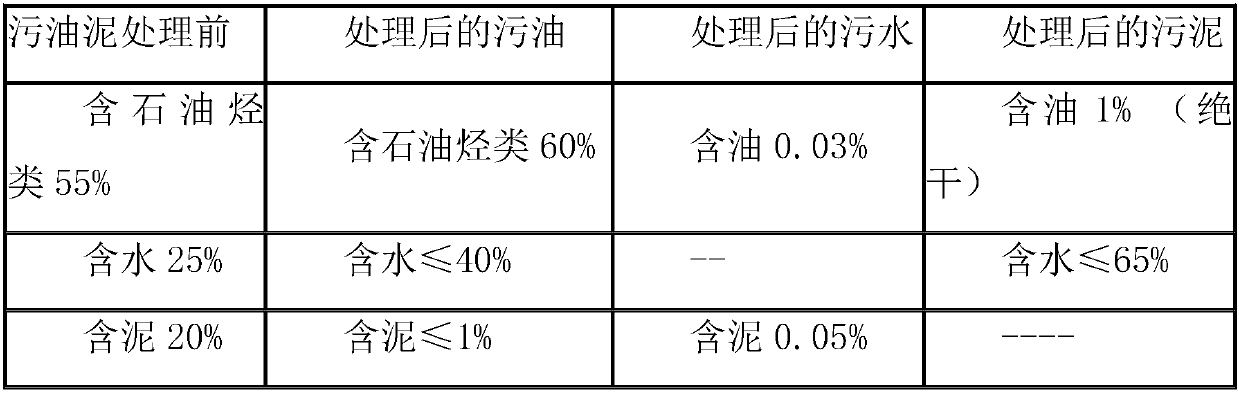

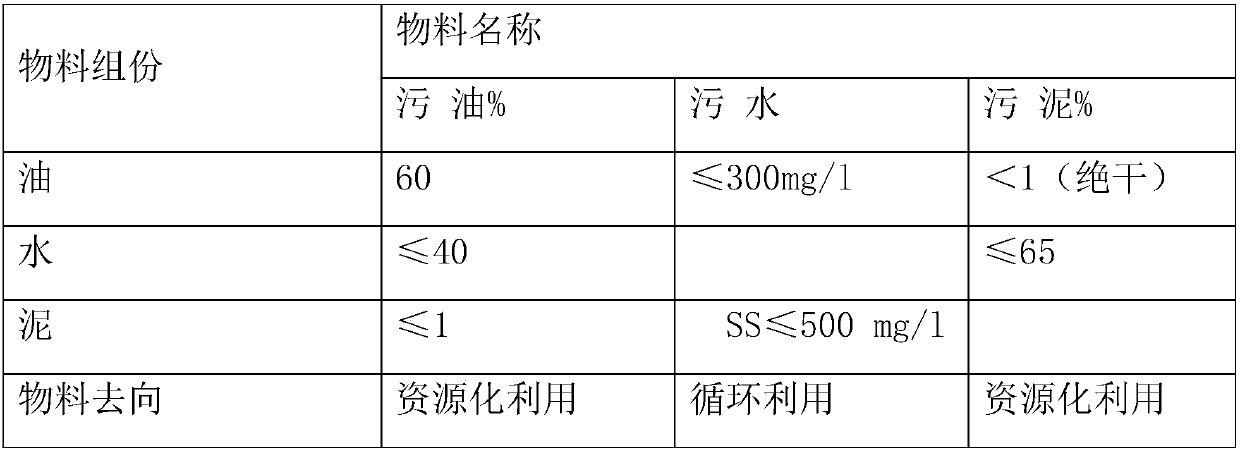

[0075] The technical index of described waste oil slurry material is as follows

[0076]

[0077] An intensive oil sludge treatment method of the present invention can effectively solve the problems existing in the prior art in the treatment process of sludge oil; in the treatment process of the present invention, there is no need to add chemicals, the treatment efficiency is high, and the treatment capacity is large, which can effectively The oil, sand, and water in the sludge are separated and recovered, which can reduce the treatment cost of the sludge, quickly and completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com