Graphene modified foamed plaster sound-absorbing material and preparation method thereof

A graphene modification and sound-absorbing material technology, applied in the field of building materials, can solve the problems of large raw materials, inability to meet the requirements of low-carbon materials, waste, etc., and achieve the effect of simplifying the production process, good environmental protection effect, and realizing the effect of recycling and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

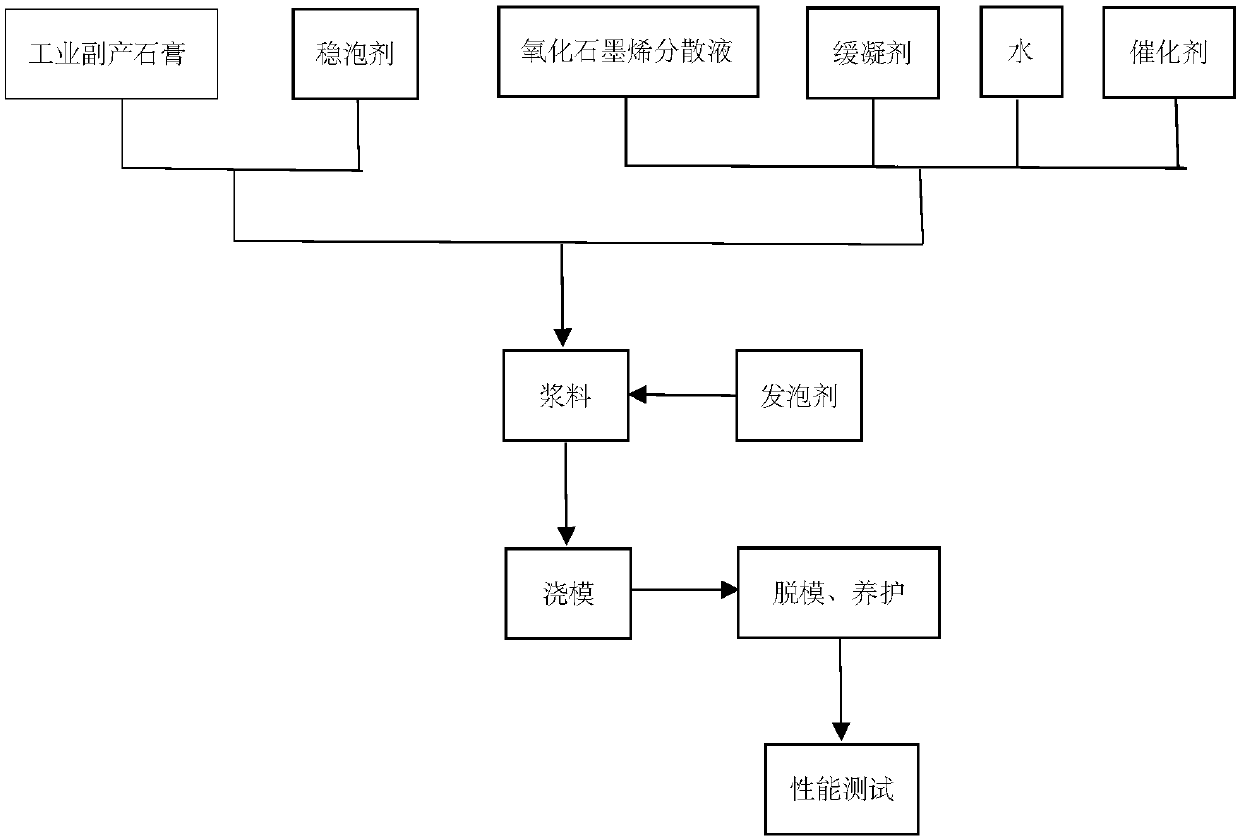

Method used

Image

Examples

Embodiment 1

[0055] A graphene-modified foamed gypsum sound-absorbing material, comprising the following mass percent materials:

[0056] Phosphogypsum: 60.68%,

[0057] Sodium tripolyphosphate: 0.00%,

[0058] Water: 33.91%,

[0059] Hydrogen peroxide: 3.94%,

[0060] Potassium permanganate: 0.01%,

[0061] Calcium stearate: 1.46%,

[0063] Among them, the bulk density of the sound-absorbing material is 455kg / m 3 .

[0064] A method for preparing the above-mentioned graphene modified foamed gypsum sound-absorbing material, comprising the following steps:

[0065] 1) Pour the weighed phosphogypsum and calcium stearate powder into a blender and stir for 2-3 minutes to obtain a mixed powder;

[0066] 2) Add the weighed graphene oxide powder material into water, stir for 2 to 3 minutes, and then disperse in an ultrasonic disperser for 20 minutes to prepare a graphene oxide dispersion;

[0067]3) Mix the weighed sodium tripolyphosphate, water and potass...

Embodiment 2

[0071] A graphene-modified foamed gypsum sound-absorbing material, comprising the following mass percent materials:

[0072] Desulfurized gypsum: 58%,

[0073] Sodium tripolyphosphate: 0.1%,

[0074] Water: 36%,

[0075] Hydrogen peroxide: 4.5%,

[0076] Potassium permanganate: 0.02%,

[0077] Calcium stearate: 1.36%,

[0078] Graphene oxide: 0.02%.

[0079] Among them, the bulk density of the sound-absorbing material is 350kg / m 3 .

[0080] A method for preparing the above-mentioned graphene modified foamed gypsum sound-absorbing material, comprising the following steps:

[0081] 1) Pour the weighed desulfurized gypsum and calcium stearate powder into a mixer and stir for 2 to 3 minutes to obtain a mixed powder;

[0082] 2) Add the weighed graphene oxide powder material into water, stir for 2 to 3 minutes, and then disperse in an ultrasonic disperser for 20 minutes to prepare a graphene oxide dispersion;

[0083] 3) Mix the weighed sodium tripolyphosphate, water and ...

Embodiment 3

[0087] A graphene-modified foamed gypsum sound-absorbing material, comprising the following mass percent materials:

[0088] Phosphogypsum: 50.65%,

[0089] Desulfurized gypsum: 10%,

[0090] Sodium tripolyphosphate: 0.00%,

[0091] Water: 33.91%,

[0092] Hydrogen peroxide: 3.94%,

[0093] Potassium permanganate: 0.01%,

[0094] Calcium stearate: 1.46%,

[0095] Graphene oxide: 0.03%.

[0096] Among them, the bulk density of the sound-absorbing material is 455kg / m 3 .

[0097] A method for preparing the above-mentioned graphene modified foamed gypsum sound-absorbing material, comprising the following steps:

[0098] 1) Pour the weighed phosphogypsum, desulfurized gypsum, and calcium stearate powder into a mixer and stir for 2 to 3 minutes to obtain a mixed powder;

[0099] 2) Add the weighed graphene oxide powder material into water, stir for 2 to 3 minutes, and then disperse in an ultrasonic disperser for 20 minutes to prepare a graphene oxide dispersion;

[0100] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com