A kind of pullulan/sodium alginate composite fiber membrane and its preparation method and application

A composite fiber membrane, sodium alginate technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve problems such as high price, achieve high production efficiency, increase stability, and improve water vapor resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

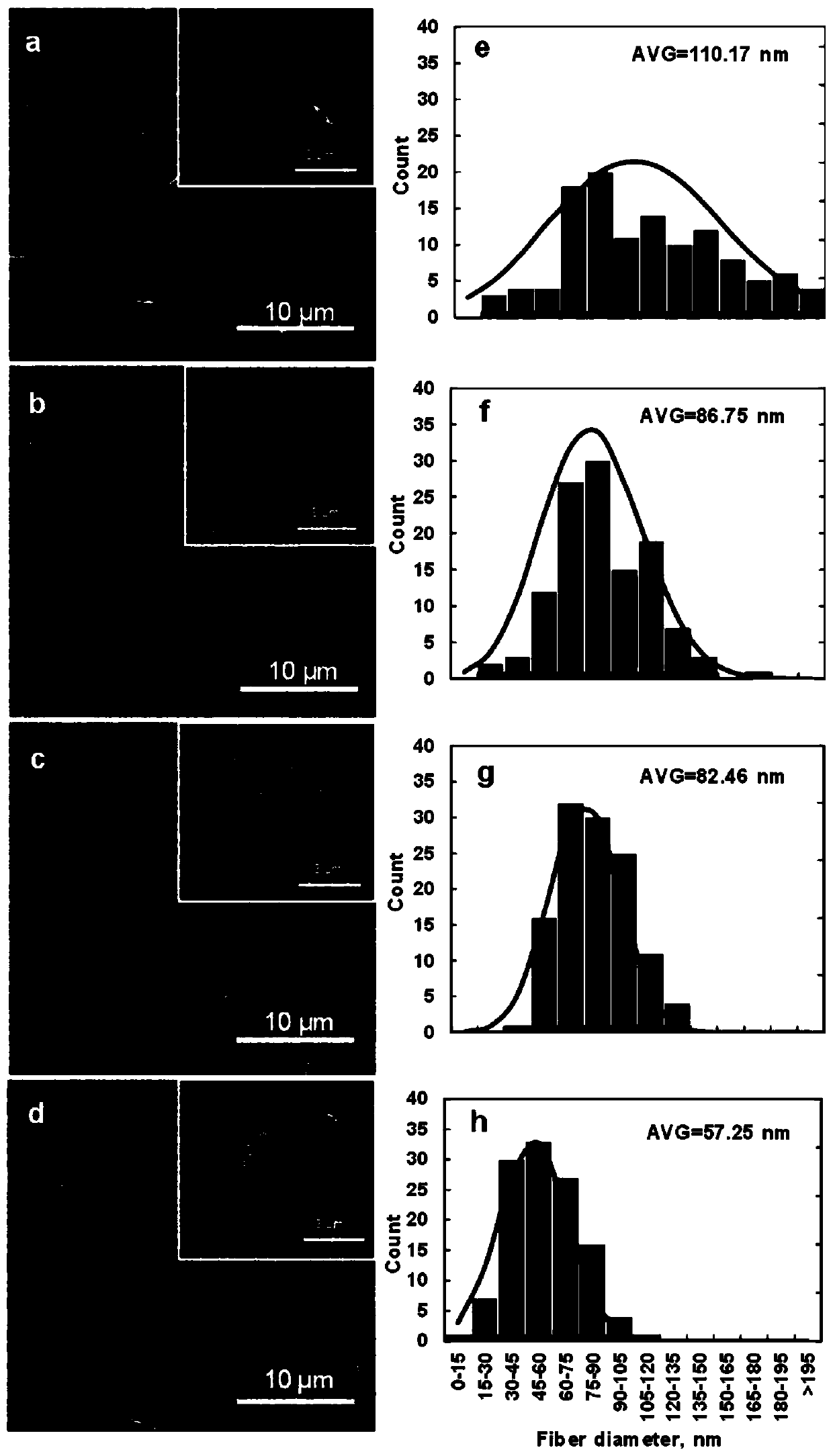

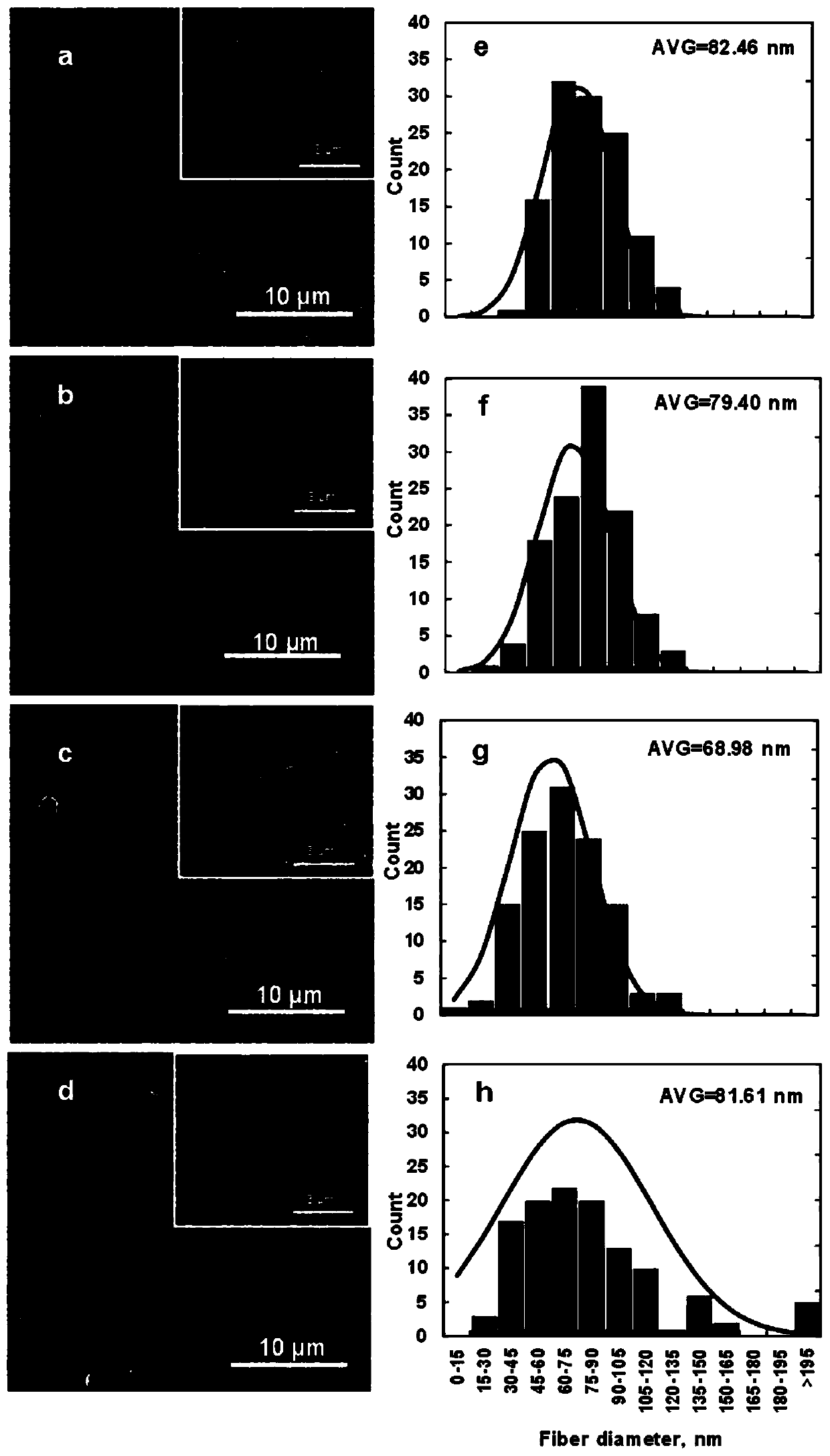

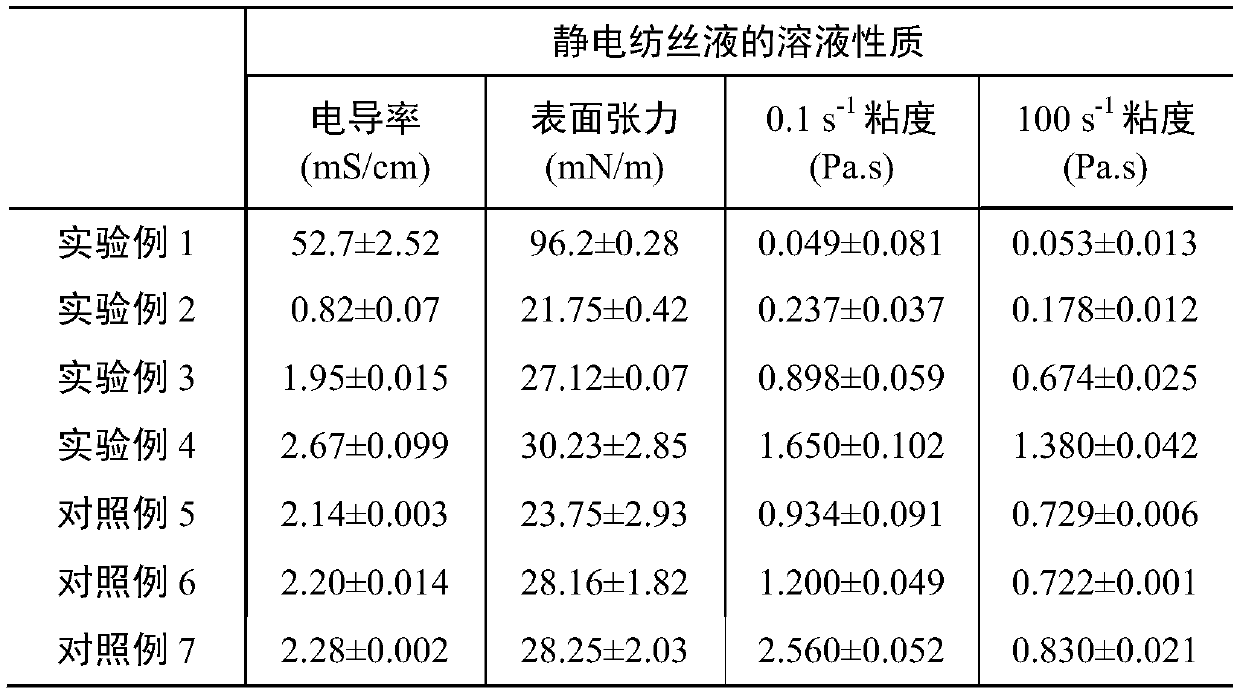

Embodiment 1

[0030] Dissolve 10g of pullulan in 100mL of pure water, stir it with a magnetic stirrer to completely dissolve it to form a uniform solution; carry out electrospinning of the prepared solution, set the spinning voltage to 18kv, and the receiving distance to 12cm, The speed of the spinning propeller was 0.6 mL / h, and the diameter of the spinneret was 0.9 mm.

Embodiment 2

[0032]Add 10g of pullulan and 0.8g of sodium alginate to 100mL of pure water, stir with a magnetic stirrer to completely dissolve and form a uniform solution; carry out electrospinning of the prepared solution, and set the spinning voltage to 15kv, receiving distance 10cm, spinning propeller speed 0.4mL / h, spinneret diameter 0.9mm.

Embodiment 3

[0034] Dissolve 10g of pullulan and 1.6g of sodium alginate in 100mL of pure water, stir with a magnetic stirrer to completely dissolve and form a uniform solution; electrospin the prepared solution, and set the spinning voltage It is 14kv, the receiving distance is 10cm, the speed of the spinning propeller is 0.4mL / h, and the diameter of the spinneret is 0.9mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com