Commercial stove

A stove and commercial technology, applied in the field of commercial stoves, can solve the problems of insufficient combustion of liquefied gas, high flue temperature, elevated ambient temperature, etc., and achieve the effects of effectively utilizing energy, avoiding environmental pollution, and preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

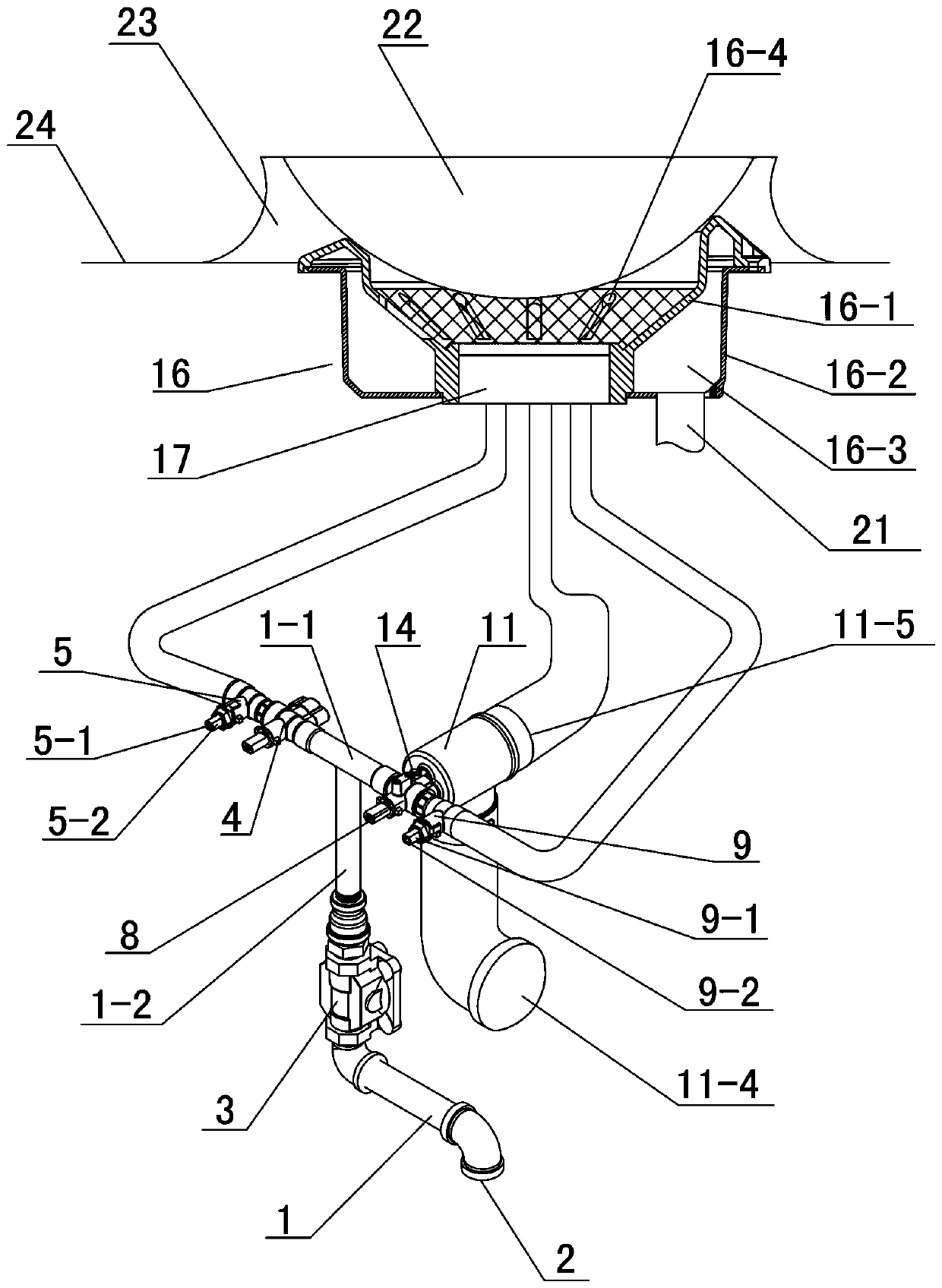

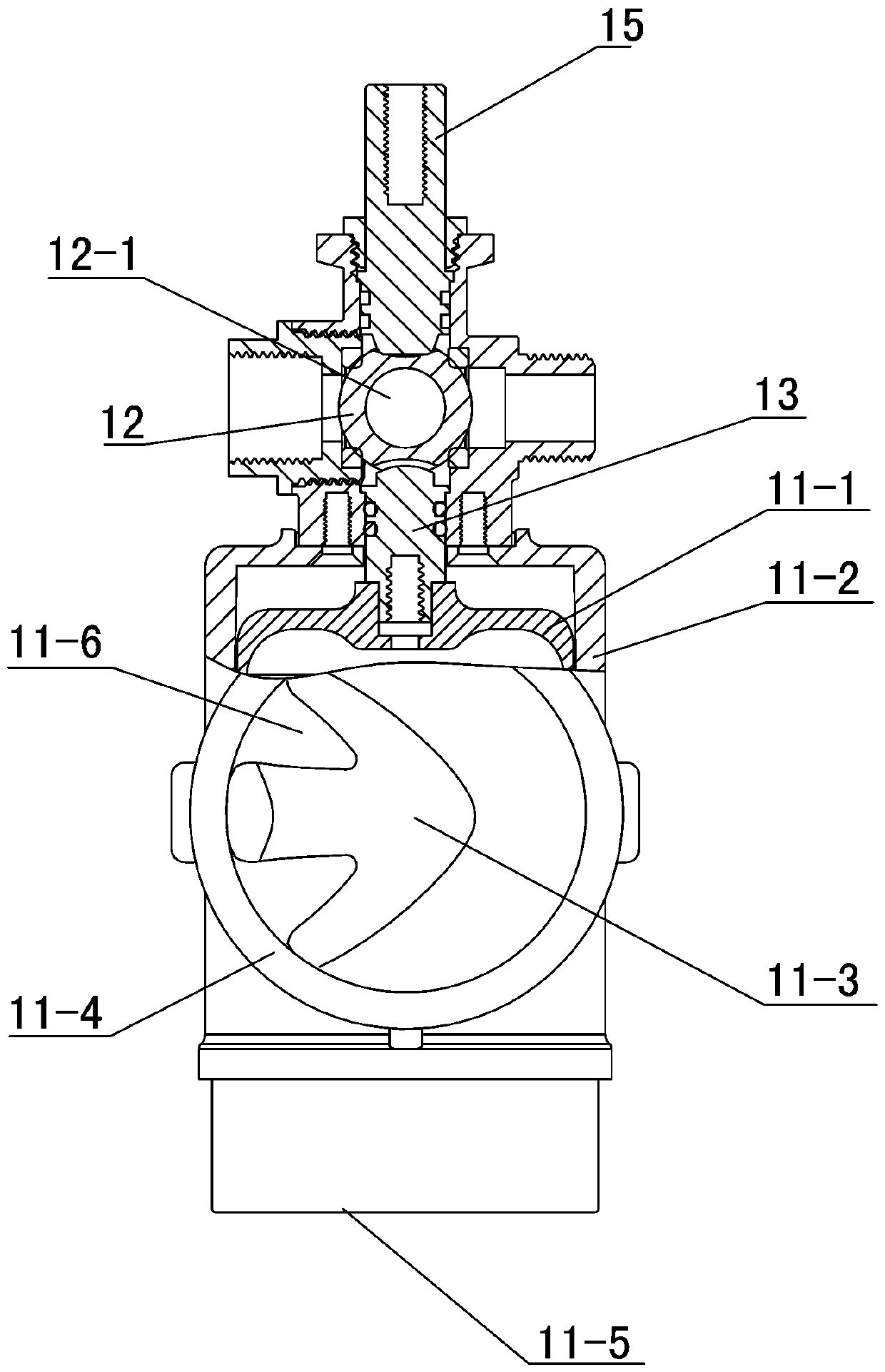

[0031] Below in conjunction with accompanying drawing embodiment, the present invention will be further described:

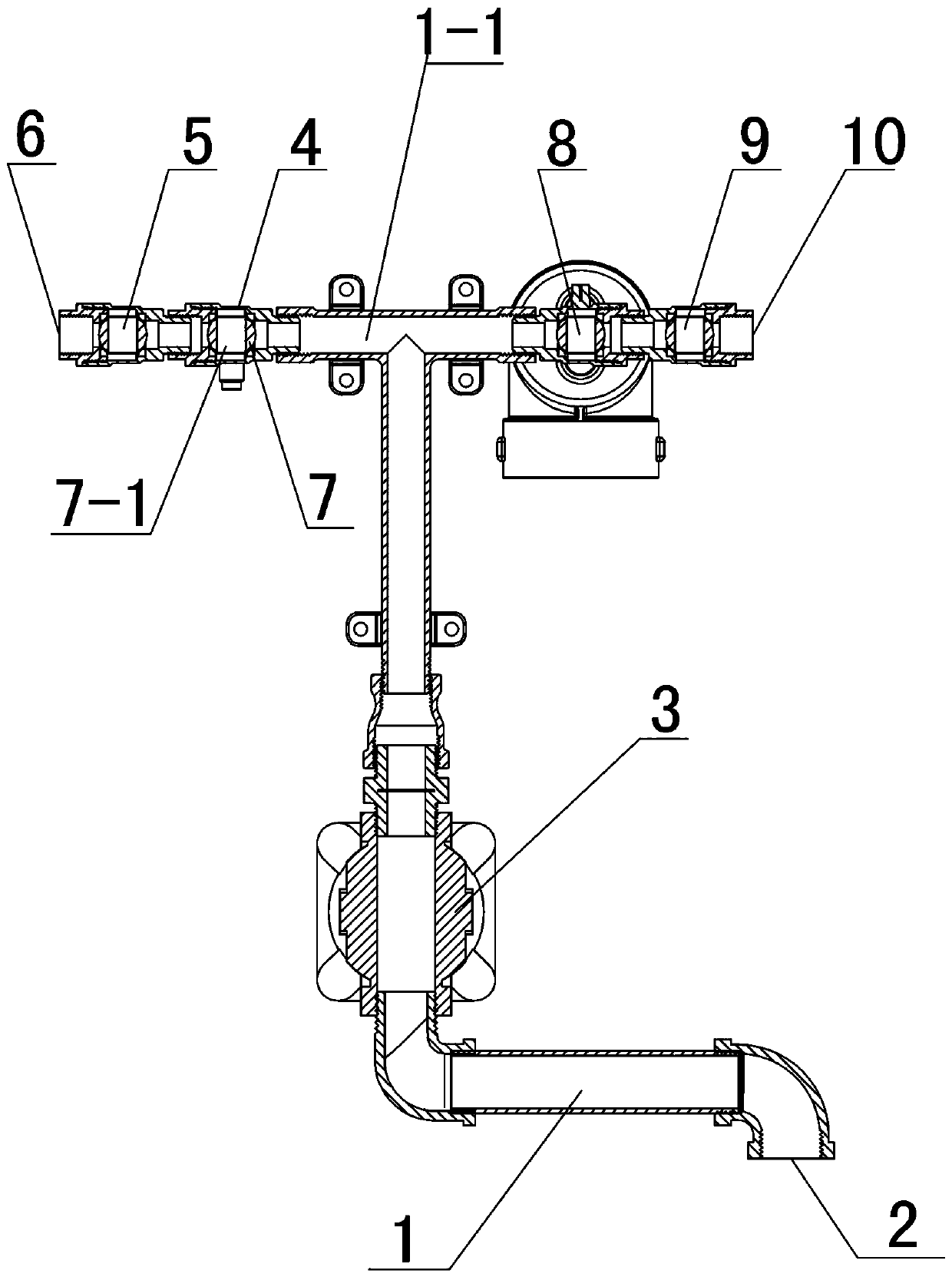

[0032] Such as figure 1 As shown, a commercial stove includes a furnace 16 with a built-in burner 17; it also includes an air-air linkage device. In the air-air linkage device, the air intake pipe 1 is a T-shaped structure and is divided into a horizontal pipe 1-1 and a longitudinal pipe 1. -2, the horizontal pipe 1-1 is connected with the longitudinal pipe 1-2, the end of the longitudinal pipe 1-2 is an air inlet 2, and a voltage stabilizer 3 is arranged in the middle of the longitudinal pipe 1-2, so that the air flowing through The gas pressure is stable.

[0033] At one end of the horizontal pipe 1-1, a kindling ignition valve 4, a kindling gas limiting valve 5 and a kindling gas outlet 6 are set outward in sequence. The kindling ignition valve 4 has a built-in spherical valve core 7 through the air hole 7-1 in the middle, and a spherical valve core 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com