Detection method for cross effects of array substrate

A technology of an array substrate and a detection method, which is applied in the field of detection of reticle defects of array substrates, can solve problems such as G/D coordinate errors, reticle defects, and high requirements for machine positioning accuracy, so as to reduce production costs and improve factory efficiency. , The effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

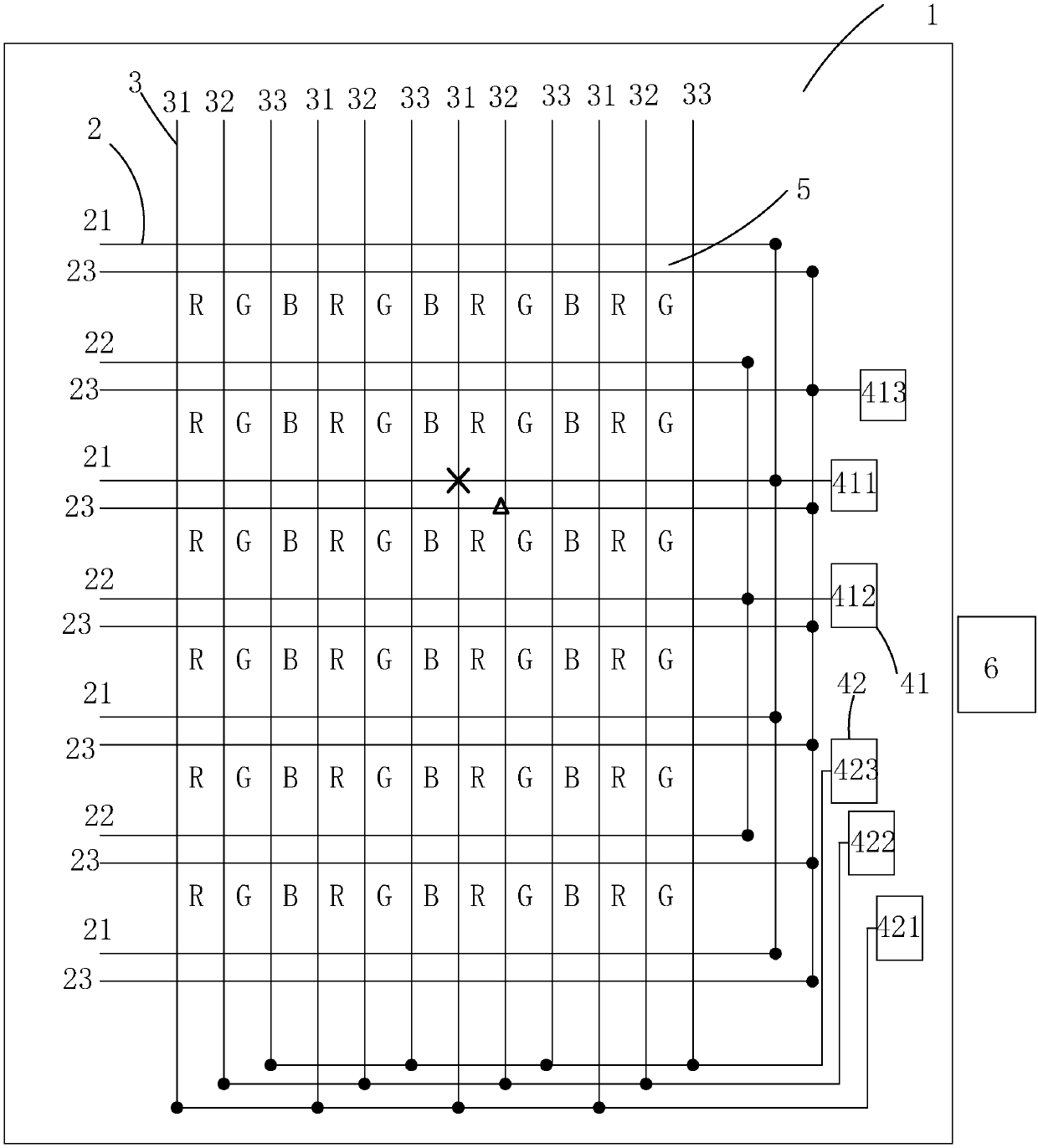

[0034] see Figure 4 , the present invention provides a method for detecting crosshair defects on an array substrate, comprising the following steps:

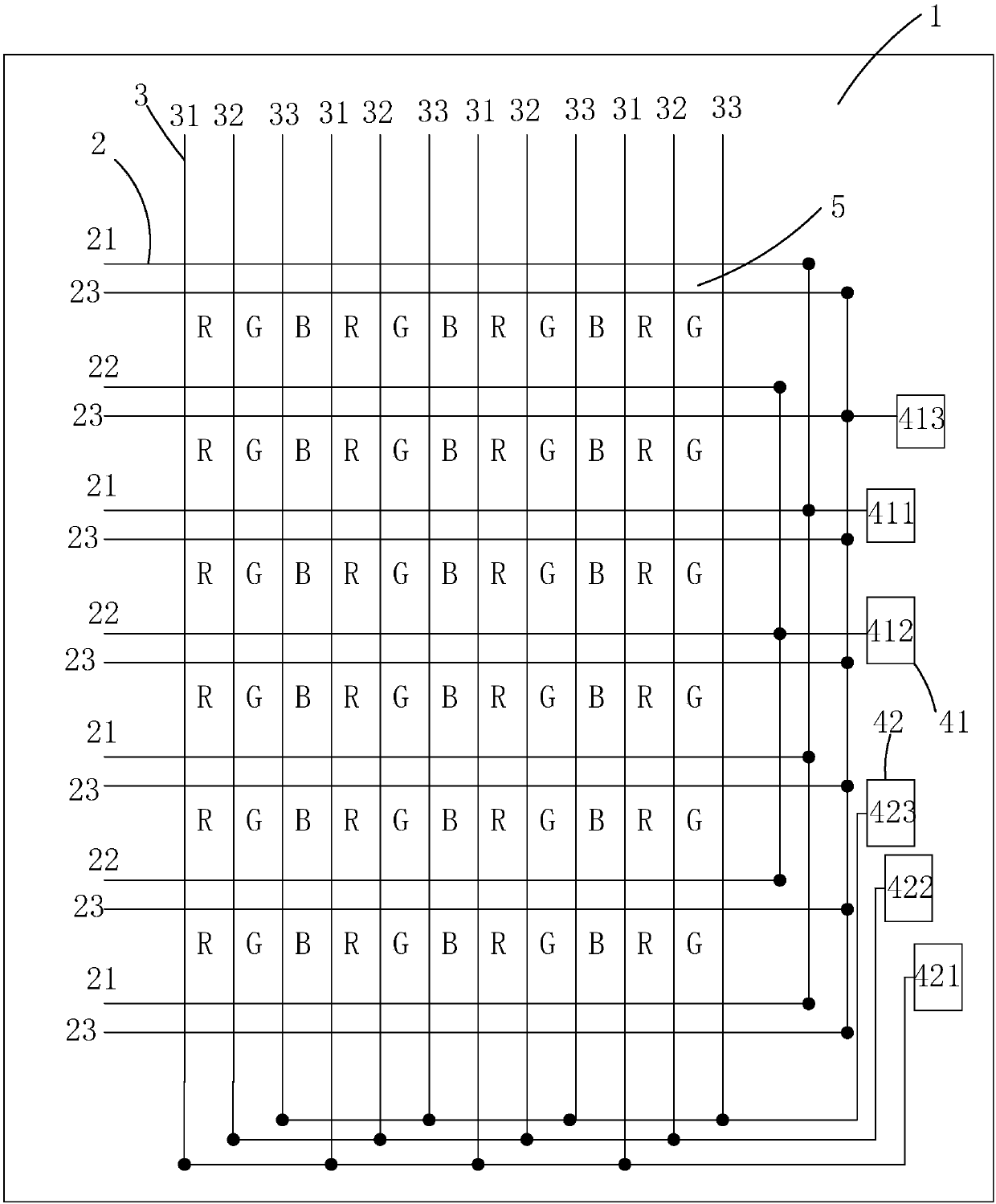

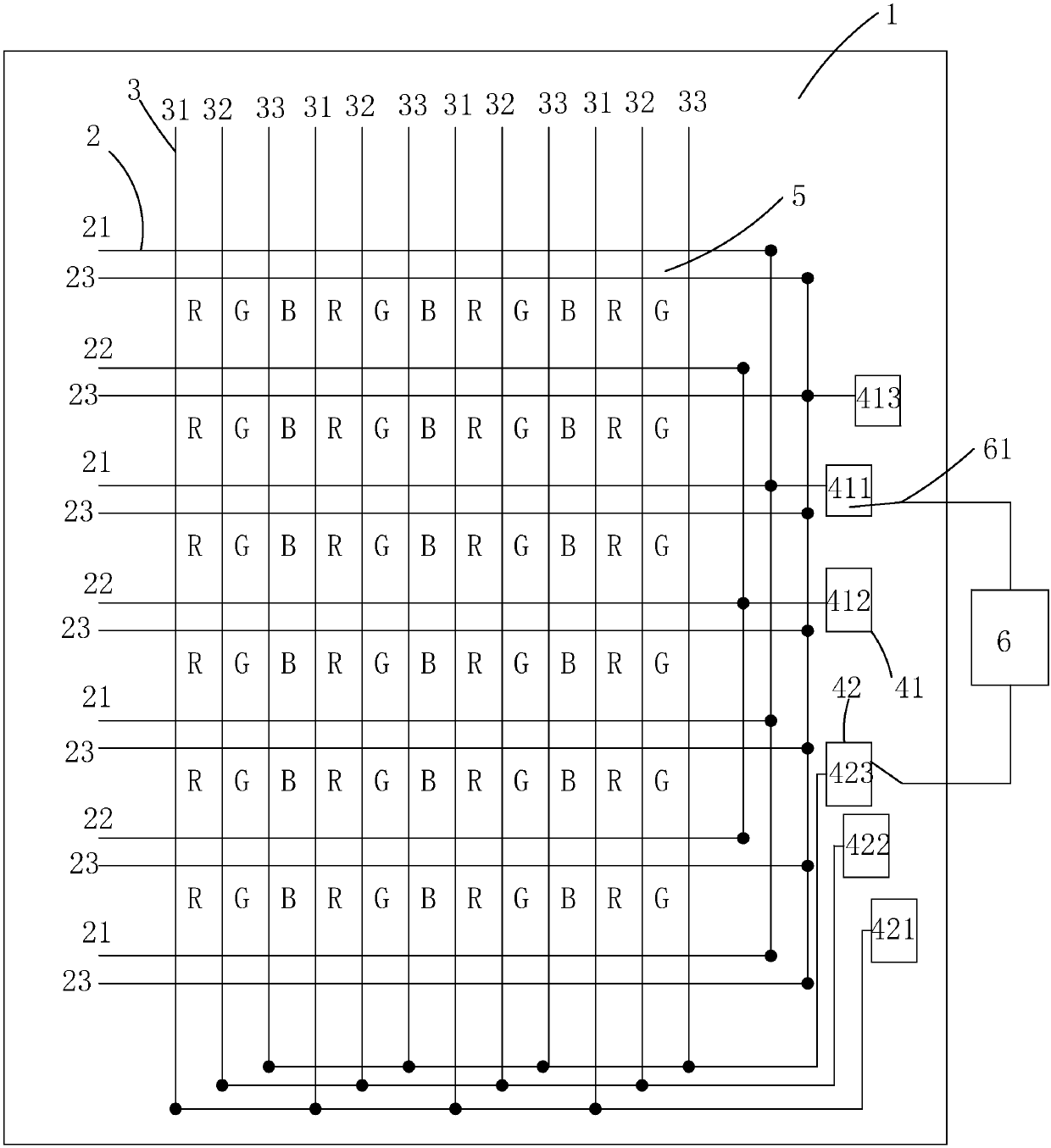

[0035] Step 1. Please refer to figure 1 , providing an array substrate, including: a substrate 1, a plurality of horizontal scan lines 2 arranged in parallel and spaced along the vertical direction arranged on the substrate 1, a plurality of horizontal scan lines 2 arranged in parallel and spaced in a vertical direction arranged on the substrate 1 Conductive wires 2 , and multiple rows of vertical conductive wires 3 arranged in parallel and spaced apart on the substrate 1 .

[0036] Specifically, in a preferred embodiment of the present invention, the array substrate adopts 2G3D technology, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com