Micro expansion grouting material for tunnel lining filling

A grouting material and micro-expansion technology, which is applied in the field of micro-expansion grouting material, high-speed railway, and highway tunnel construction, to achieve the effect of simple operation, improving cohesive force, and solving the problem of voiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

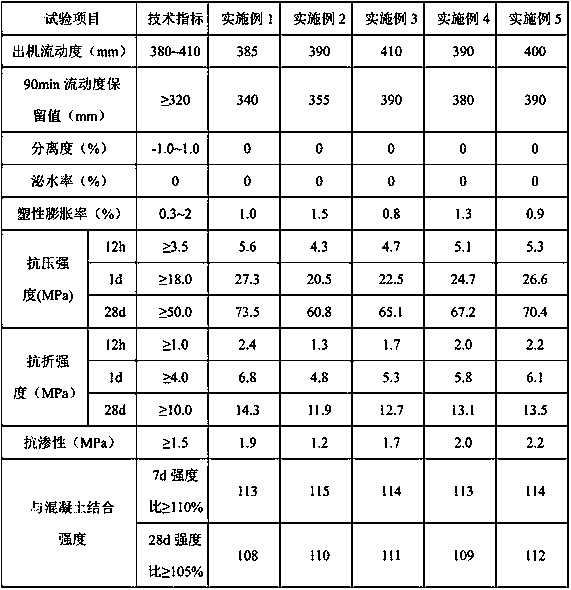

Examples

Embodiment 1

[0046] 50 parts of ordinary cement,

[0047] Microbeads 5 parts,

[0048] 3 parts of silica fume,

[0049] 4 parts of calcium sulfoaluminate expansion agent,

[0050] 35 parts of quartz sand,

[0051] 1 part of water reducing agent,

[0052] 0.5 parts of sodium gluconate,

[0053] 0.1 part of water retaining agent,

[0054] Sodium sulfate 0.4 parts,

[0055] 0.2 parts of plastic expansion agent,

[0056] Redispersible latex powder 0.3 parts,

[0057] 0.3 part of defoamer.

Embodiment 2

[0059] 35 parts of ordinary cement,

[0060] microbeads 7 parts,

[0061] 5 parts of silica fume,

[0062] 5 parts of magnesium oxide type expansion agent,

[0063] 45 parts of quartz sand,

[0064] 1 part of water reducing agent,

[0065] 0.3 parts of borax,

[0066] Citric acid 0.2

[0067] 0.3 parts of water retaining agent,

[0068] Lithium sulfate 0.2 parts,

[0069] 0.3 parts of plastic expansion agent,

[0070] Redispersible latex powder 0.1 part,

[0071] Defoamer 0.1 part.

Embodiment 3

[0073] 40 parts of ordinary cement,

[0074] microbeads 8 parts,

[0075] 4 parts of silica fume,

[0076] 4 parts of lime-based expansion agent,

[0077] 40 parts of quartz sand,

[0078]2 parts of water reducing agent,

[0079] 0.5 parts of sodium gluconate,

[0080] Sodium hexametaphosphate 0.5 parts

[0081] 0.3 parts of water retaining agent,

[0082] Calcium formate 0.2 part,

[0083] Lithium carbonate 0.1 parts

[0084] 0.2 parts of plastic expansion agent,

[0085] Redispersible latex powder 0.2 parts,

[0086] Defoamer 0.1 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com