Method for preparing sulfuric oxide ceramic scintillating medium

A technology of oxysulfide and scintillator, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of high cost and achieve the effect of improving sintering performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of a sulfur oxide ceramic scintillator. The present invention uses sulfur oxide powder as a raw material and adopts the technology of pressureless sintering + hot isostatic pressing to prepare a dense sulfur oxide ceramic scintillator. Hereinafter, as an example, the method of the present invention will be specifically described.

[0031] In the present invention, the chemical composition of the sulfur oxide powder as raw material can be expressed as: R 2(1-x) m 2x o 2 S, R is one or more combinations of Y, Gd, La, Lu, M is one or more of Pr, Ce, Tb, Eu, Yb, Nd, Er, Ho, 0≤x-6 ≤x≤5×10 -2 , further preferably, 2×10 -6 ≤x≤5×10 -3 .

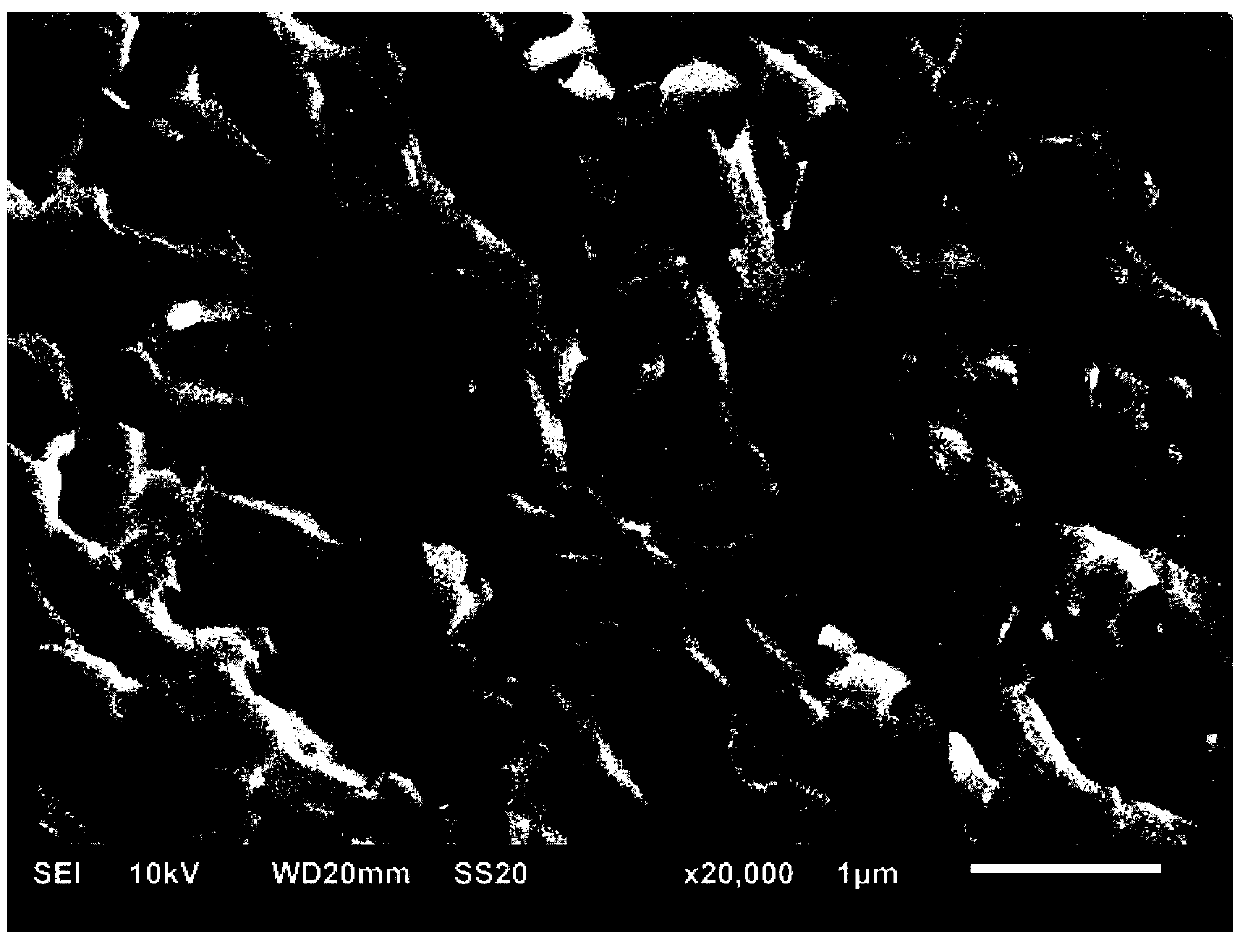

[0032] The sulfur oxide powder is preferably an ultrafine powder, for example, its size is about 0.5 micron (preferably below 0.5 micron), and its specific surface area is not less than 5m 2 / g, which can have higher sintering activity, and is suitable for sintering by pressureless sintering c...

Synthetic example 1

[0050] Gd 2 o 2 Synthesis of S powder:

[0051] Weigh 50g Gd 2 o 3 , 0.1g Pr 6 o 11 and 0.01g CeO 2 , mix and add in 30mL nitric acid (concentration is 68%) to obtain rare earth nitrate solution. Add the above-mentioned rare earth nitrate solution into 45mL of ammonia water (concentration: 2mol / l), make the pH of the mixed solution 10, react at room temperature to 50°C for about 0.5 hours, and a white precipitate will appear, and the white suspension solution is repeatedly sucked and filtered , drying at 100 degrees to obtain the precursor. Then the precursor was placed in a tube furnace at 850 °C, and H 2 S gas, last for 3h, then get Gd 2 o 2 S: Pr, Ce pure phase luminescent powder. After testing, the obtained Gd 2 o 2 The purity of S powder is 100%, the average particle size is 30nm, and the specific surface area is 10m 2 / g.

Synthetic example 2

[0053] Gd 2 o 2 Synthesis of S powder:

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com