Novel membrane drying machine

A drying machine, a new type of technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as cost increase, dust generation, threat to the health of operators and other personnel, etc., to improve use efficiency, energy low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

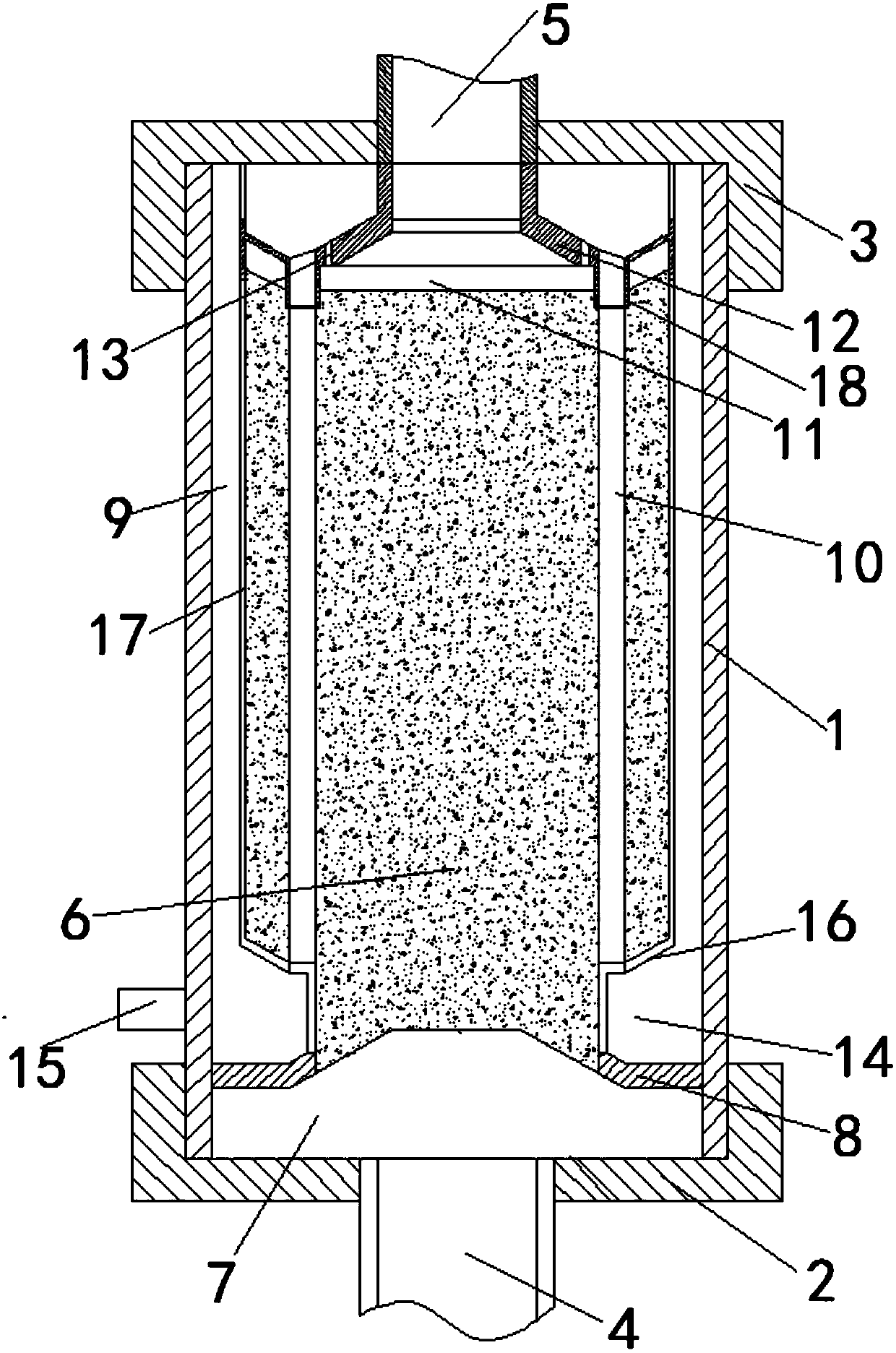

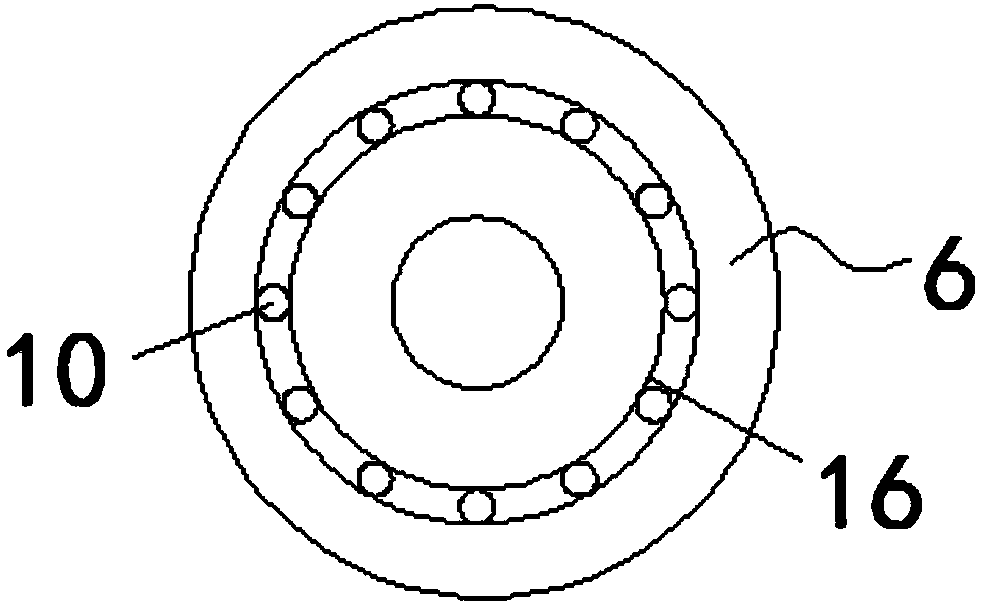

[0020] Such as figure 1 Shown is the structural representation of the novel membrane dryer of the present invention; figure 2 Shown is a schematic structural view of the hollow fiber membrane filter element in the novel membrane dryer of the present invention; a novel membrane dryer of the present invention includes a tank body 1 and a lower installation cover 2 and an upper installation cover installed on the bottom and top of the tank body 1 3. The tank body 1 is provided with a hollow fiber silk membrane filter element 6, the lower mounting cover 2 is provided with an air intake pipe 4 communicating with the tank body 1, and the upper mounting cover 3 is provided with a The air outlet pipe 5 connected inside, the water vapor exhaust pipe 15 is arranged on the side wall of the tank body 1, and the water vapor exhaust pipe 15 communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com