Chemical phloretin preparing raw material pulverizing device

A raw material crushing and phloretin technology, which is applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of reducing the production rate of bark powder and shortening the life of the pulverizer, so as to achieve easy promotion, The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

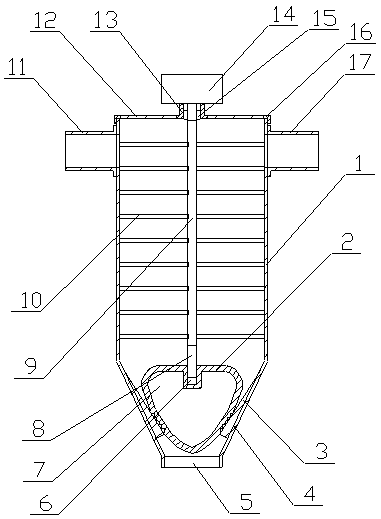

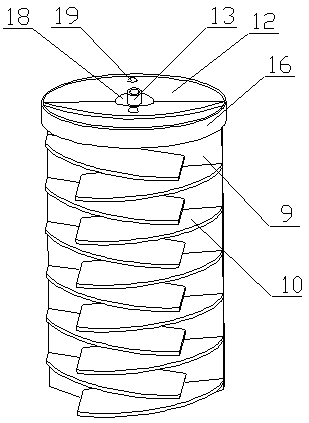

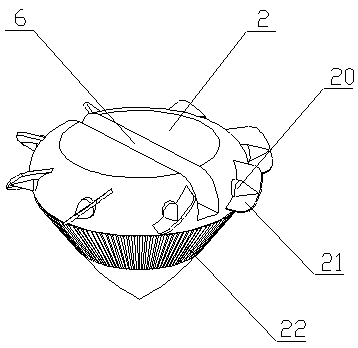

[0017] A kind of crushing device for preparing raw materials of phloretin in chemical industry of the present invention is realized in the following way: when in use, connect the air intake pipe (17) with the hot air blower, open the cover plate (12), and put the raw materials for preparing phloretin into the main body In the tube (1), such as apple bark and apple leaves, the raw materials are spread flat on the turbulence blade (10). Since the surface of the turbulence blade (10) is a mushroom head structure, there is a gap between the raw material and the surface, and then the The cover plate (12) is closed, and the driving motor (14) is started. The driving motor (14) drives the middle partition (9) to rotate at a low speed through the motor shaft. Since the spoiler blade (10) is obliquely fixed on the middle partition (9 ), so when the spoiler blade (10) rotates, it will change from the windward side to the leeward side, and when it is on the windward side, the raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com