A heat-shrinkable film suitable for automatic and rapid packaging in production lines

A heat-shrinkable film and production line technology, applied to layered products, synthetic resin layered products, sacks, etc., to achieve high strength, excellent machine performance, and reduce the risk of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

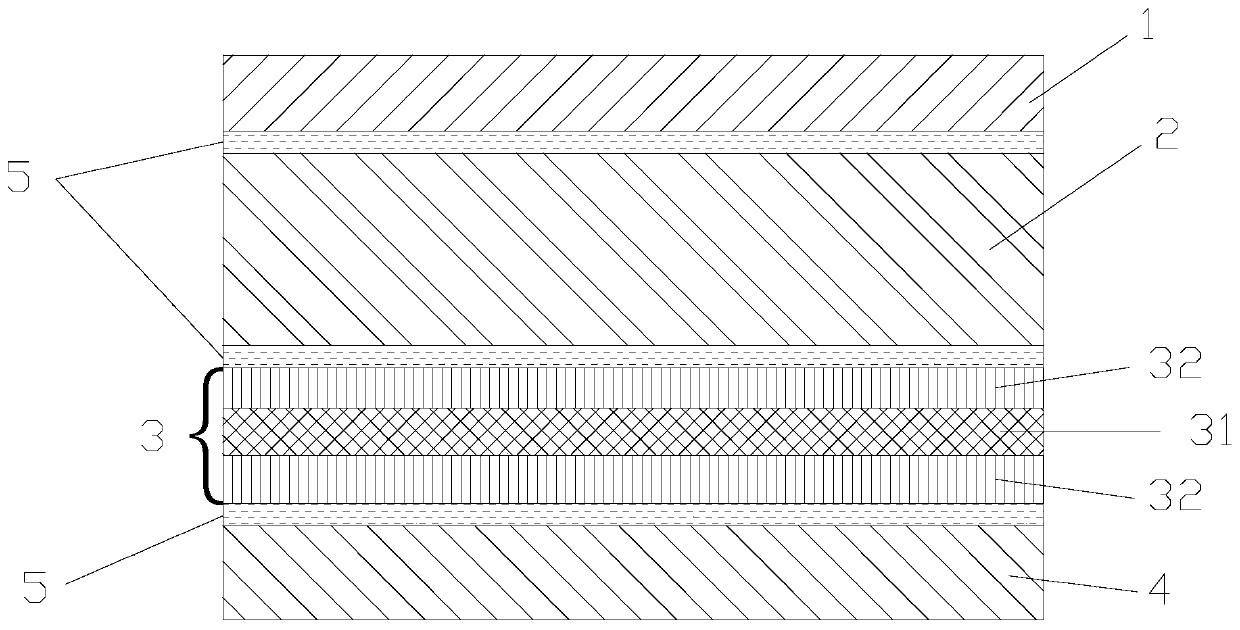

[0076] The heat-shrinkable film includes a surface layer 1 (PA), a structural layer 2 (PE), a barrier layer 3 (PA / EVOH / PA) from outside to inside, including an EVOH barrier middle layer 31 and barrier layer protection layers 32 on both sides. PA layer), heat seal layer 4 (POP+mLLDPE). The surface layer 1, the structural layer 2, the barrier layer 3 and the heat-sealing layer 4 are respectively connected by an adhesive resin 5 (Tie).

[0077] The specific membrane structure is: PA / Tie / PE / Tie / PA / EVOH / PA / Tie / POP+mLLDPE;

[0078] The PA of the surface layer 1 and the middle two layers are all blended by PA6, copolymerized PA and amorphous PA. The mass percentage of copolymerized PA in the resin of the PA layer is 10%, the content of 4POP in the heat-sealing layer is 90%, and the total thickness of the film is It is 75um. PE is a lower density (≤0.91g / cm 3 ) PE.

[0079] The production process includes the following steps:

[0080] S1: Place the raw materials in an extruder to...

Embodiment 2-4

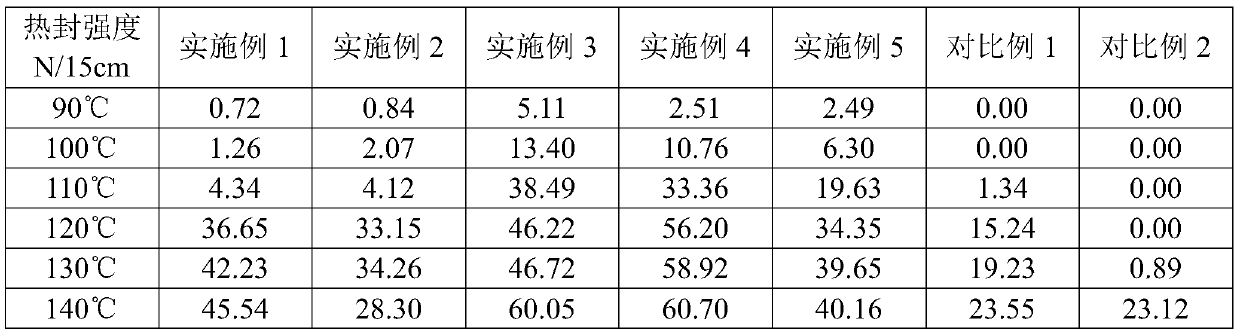

[0084] The metallocene material mLLDPE is added to the heat-sealing layer, and the difference from Example 1 is that the contents of POP in the heat-sealing layer are 85%, 70%, and 50%, respectively.

Embodiment 5-8

[0086] There are two layers of PA in the surface layer and the middle layer, and the mass percentages of the resin copolymerized PA in the PA layer are 20%, 30%, 40%, and 50% respectively. The inflation ratio of the secondary inflation in S2 is 2.0-4.5, and the traction ratio is 3.0-3.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com