A flange with an anti-slip grooved gasket and a pressure sensor and its manufacturing method

A technology of pressure sensor and anti-slip groove, which is applied in the direction of manufacturing tools, additive manufacturing, instruments, etc., can solve problems such as pipeline gas or liquid leakage, pre-tightening force is too loose, equipment failure, etc., to improve reliability, prevent loosening, The effect of long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

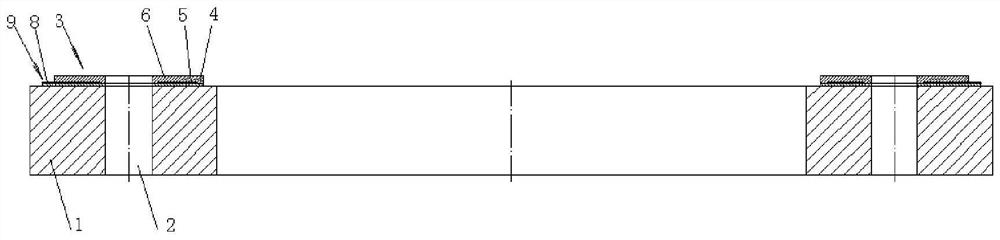

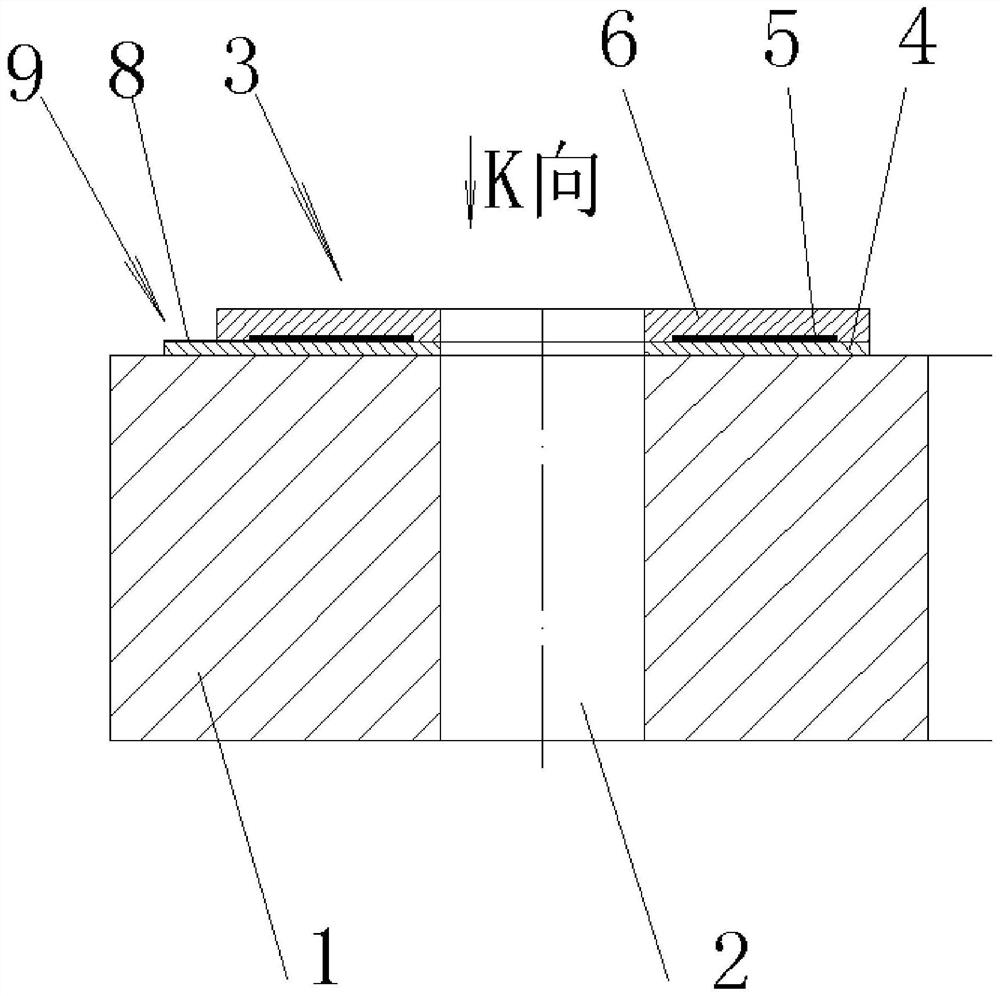

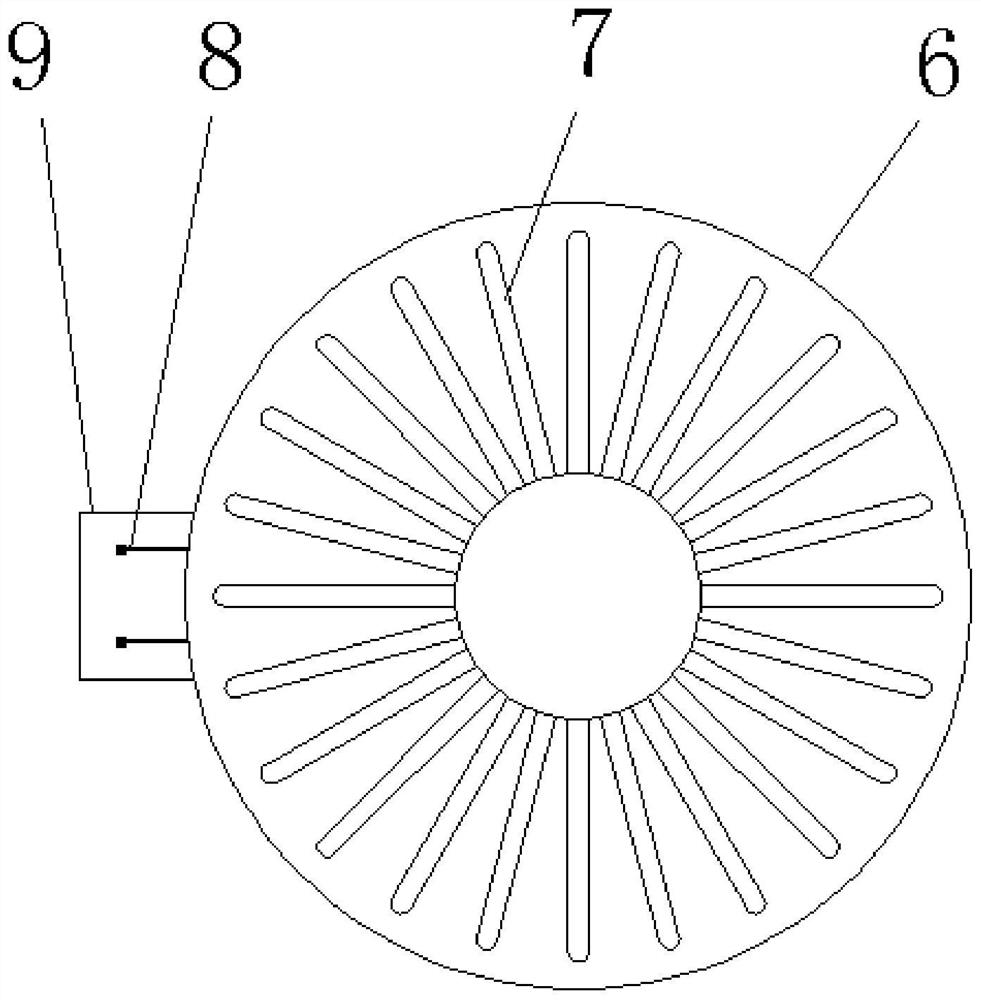

[0036]Such asFigure 1 to 4The illustrated embodiment of the present invention is a flange of a non-slip groove type gasket with a pressure sensor, including the flange 1, the bolt mounting hole 2 provided on the flange 1, located on the flange 1 in a bolt An annular gasket 3 is integrated on the end face of the mounting hole 2, and the annular gasket 3 includes a non-conductive underlayer 4, a metal resistance strain sheet 5, a non-conductive anti-skid layer 6, the bottom layer 4 and a bolt mounting hole. The end surface of 2 is combined with the bottom layer 4, and the anti-slip layer 6 is combined with the metal resistance strain layer 5, and a non-slip groove 7 is provided on the anti-slip surface of the anti-slip layer 6.

[0037]As one of the preferred embodiments of the present embodiment, the metal resistance strain sheet 5 is a foil metal strain piece and is provided with two extraction terminals 8.

[0038]As a preferred embodiment of the present embodiment, the metal resistance ...

Embodiment 2

[0044]The method of manufacturing the flange of the above Example 1 includes the following process steps:

[0045]Step 1, the flange blank is made, the blank is a metal blank, the metal blank is any one of forgings, sheets, and castings;

[0046]Step 2, machine processing flange outer circles, inner holes and two end faces;

[0047]Step 3, machining bolt mounting holes;

[0048]Step 4, perform the computer 3D shape of the annular gasket, 3D modeling data input 3D printer;

[0049]Step 5, use a 3D printer printing the bottom layer of the ring gasket;

[0050]Step 6, printing a metal resistance strain layer using a 3D printer;

[0051]Step 7, a non-slip layer of the annular gasket is printed with a 3D printer, and the non-slip layer comprises a non-slip groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com