Highly efficient and easy-to-use field-effect transistor (FET)

A field effect tube, high-efficiency technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems that affect the normal use of field effect tubes, cannot quickly find field effect tubes, and field effect tubes are scrapped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

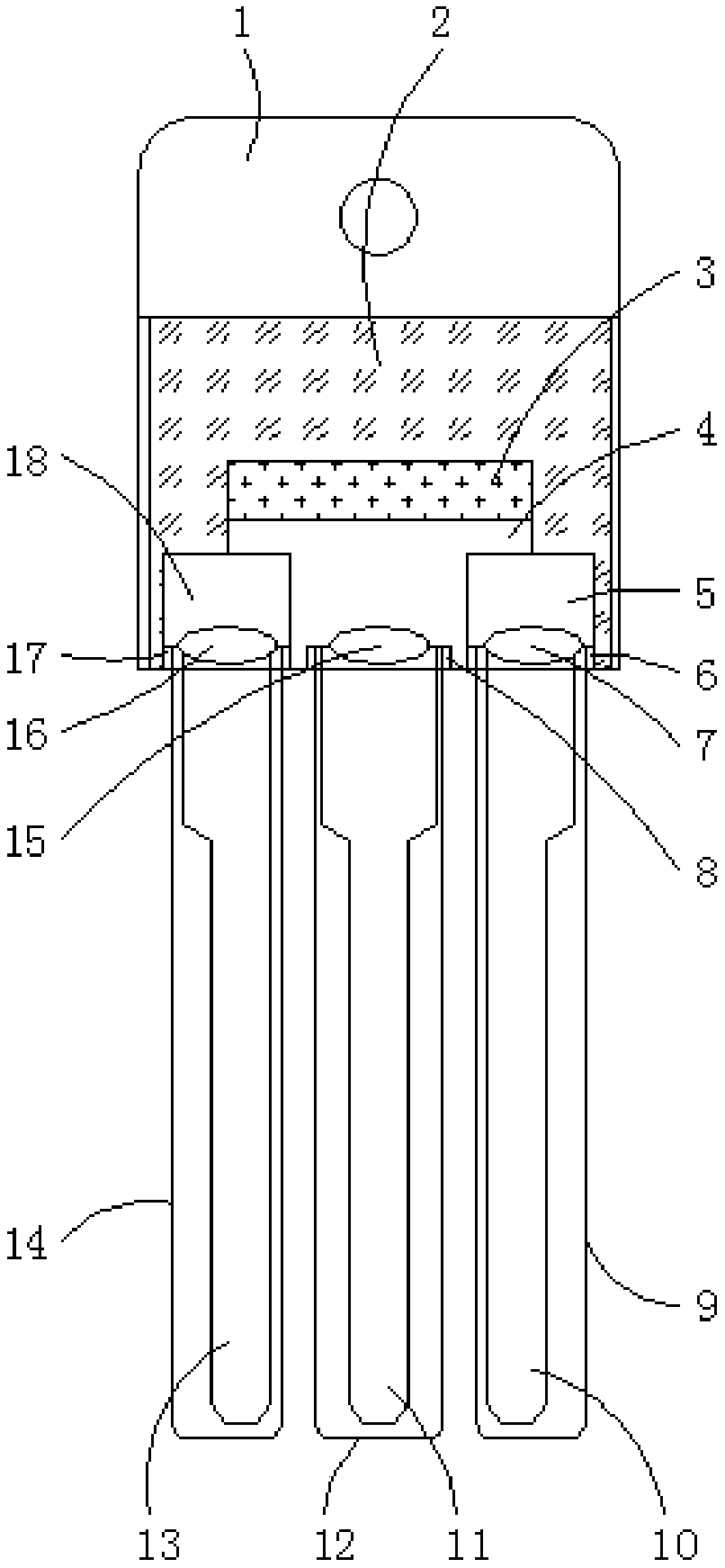

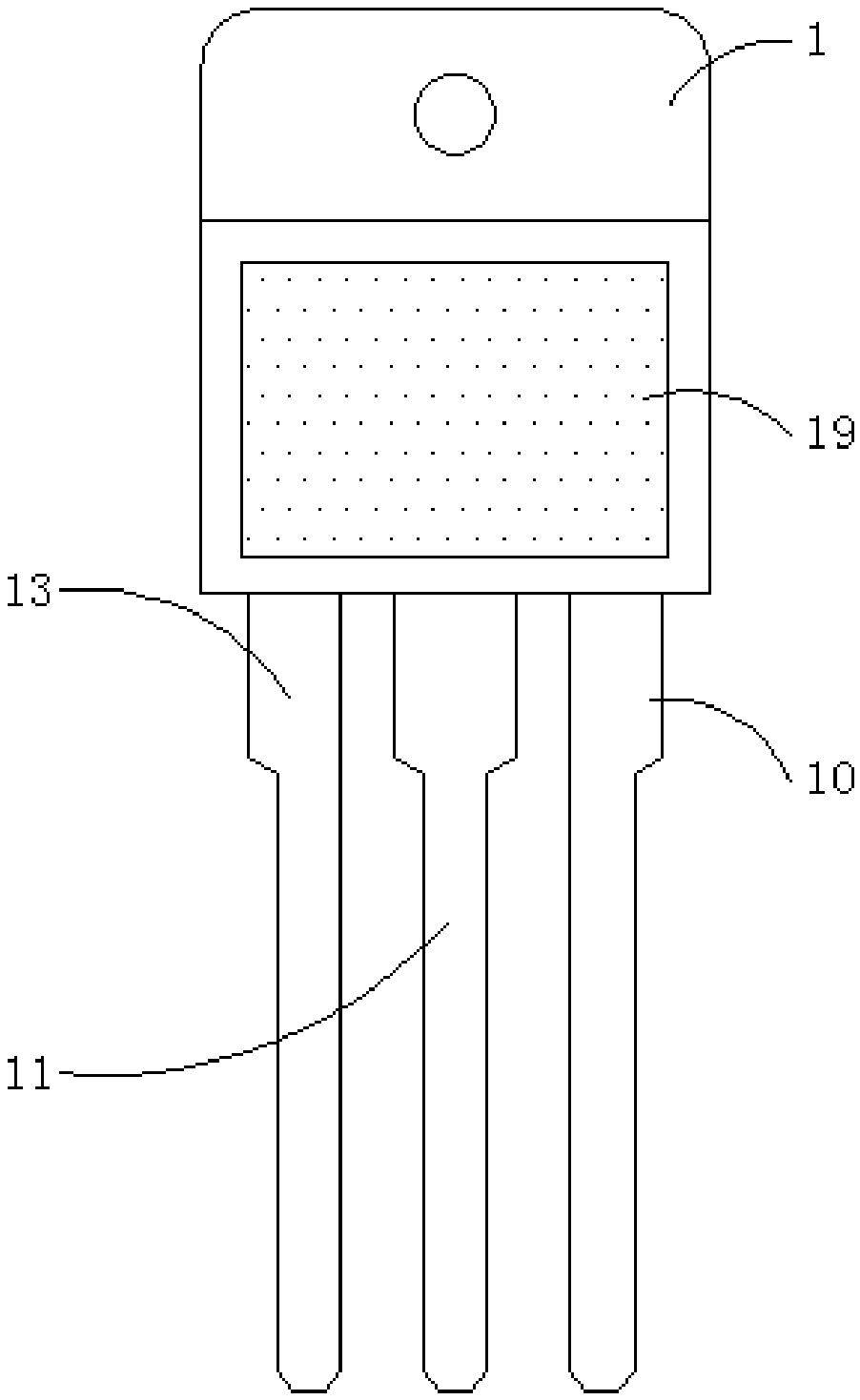

[0023] see Figure 1-3 , the present invention provides a technical solution: a highly efficient and easy-to-use field effect tube, including a field effect tube outer shell 1, a fluorescent plate 19 is embedded on the front surface wall of the field effect tube shell 1, and the field effect A P-type semiconductor 2 , an oxide 3 , a metal 4 , a first N-type semiconductor 5 , and a second N-type semiconductor 18 are arranged inside the tube shell 1 .

[0024] Further, the oxide 3 and the metal 4 are embedded in the P-type semiconductor 2, the metal 4 is installed under the oxide 3, and the first N-type semiconductor 5 and the second N-type semiconductor 18 are embedded in the metal 4. , and the first N-type semiconductor 5 and the gate groove 8 both extend from the inside of the metal 4 to the inside of the P-type semiconductor 2, so that the field effect transistor can function as an amplifying circuit and changing resistance.

[0025] Specifically, a drain groove 17 is opene...

Embodiment 2

[0030] Figure 4 It is a structural schematic diagram of Embodiment 2 of an efficient protection and easy-to-use field effect tube of the present invention; as Figure 4 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

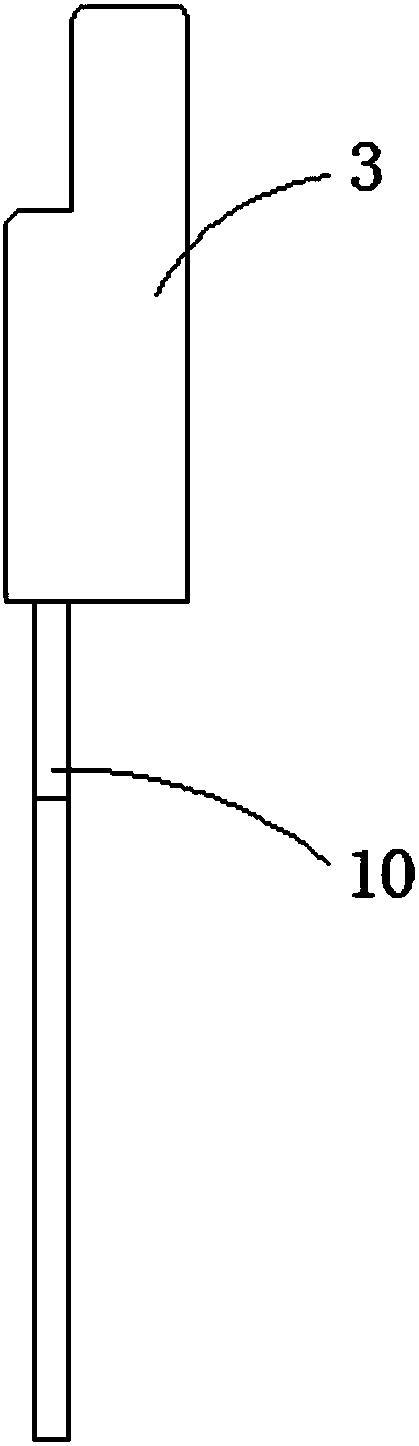

[0031] Such as Figure 4As shown, a field effect transistor with high efficiency protection and easy to use, when in use, the drain bellows 14, the gate bellows 12 and the source bellows 9 can also be separated from the drain groove 17, the gate Tear off the groove 8 and the source groove 6, and fall off from top to bottom along the drain 13, the gate 11 and the source 10 respectively, so that the drain 13, the gate 11 and the source 10 are exposed, and then Insert the drain 13 , the gate 11 and the source 10 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com