Flexible OLED display panel

A display panel, flexible technology, applied in photovoltaic power generation, electrical components, electric solid devices and other directions, can solve the problems of easy penetration by water and oxygen, poor water and oxygen barrier performance, shortened life of OLED, etc., to prevent water and oxygen penetration, use Long life and the effect of improving the life of OLED

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

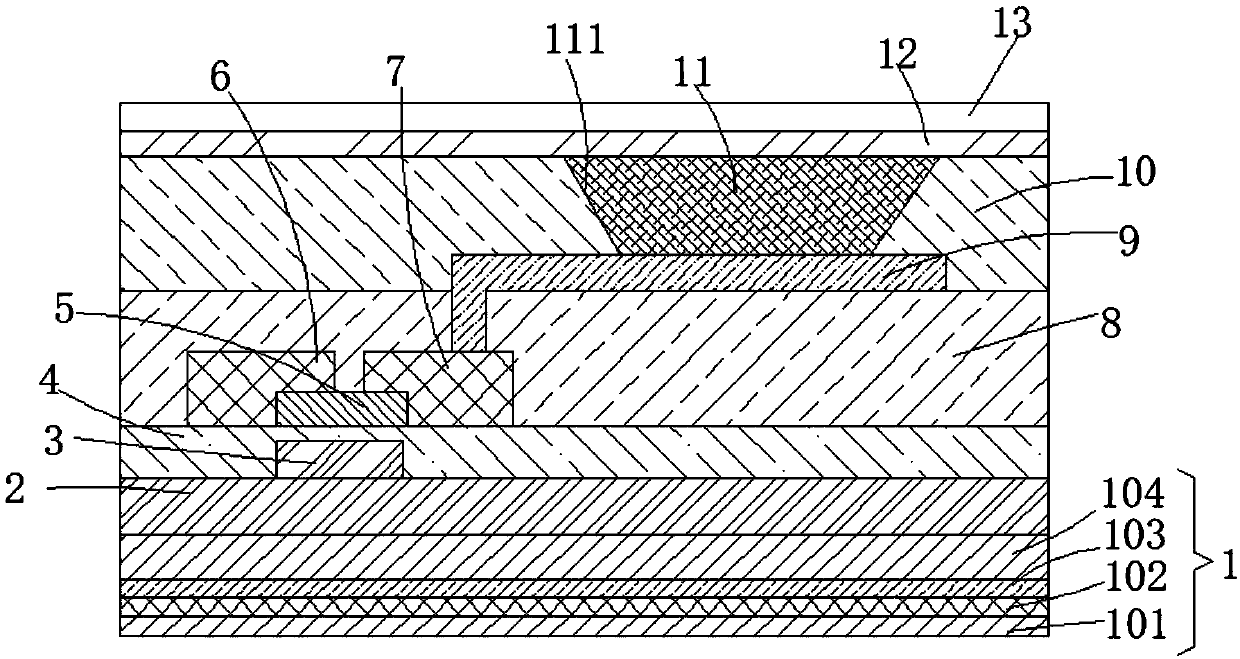

[0030] see figure 1 , the present invention provides a flexible OLED display panel, comprising: a flexible substrate 1, a buffer layer 2 covering the flexible substrate 1, a gate 3 arranged on the buffer layer 2, covering the gate 3 and a buffer The first insulating layer 4 of layer 2, the active layer 5 disposed on the first insulating layer 4, the source electrode disposed on the first insulating layer 4 and in contact with both ends of the active layer 5 6 and the drain 7, the second insulating layer 8 covering the source 6, the drain 7, and the first insulating layer 4, which is arranged on the second insulating layer 8 and is electrically connected to the drain 7 The connected first electrode 9, the pixel definition layer 10 covering the first electrode 9 and the second insulating layer 8, the pixel definition groove 111 arranged on the pixel definition layer 10 above the first electrode, and the pixel definition groove 111 arranged on the The organic light emitting laye...

Embodiment 2

[0038] A method for manufacturing a flexible substrate assembly of a flexible OLED display panel, the steps are as follows:

[0039] 1), structure and separate processing

[0040] a flexible substrate assembly, comprising a first polymer layer thus stacked, an inorganic barrier layer, a metal foil layer and a second polymer layer having a thickness greater than the thickness of said first polymer layer, The first polymer layer and the second polymer layer are doped with desiccant;

[0041] The material of the inorganic barrier layer is a combination of one or more of silicon oxide and silicon nitride;

[0042] The materials of the first polymer layer and the second polymer layer are polyimide doped with a desiccant material;

[0043] The material of the metal sheet layer is aluminum;

[0044] The compositing before the layers is performed using existing technologies;

[0045] 2), pretreatment

[0046] After compounding, spray the pretreatment liquid on the outer surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com