A stacked piezoelectric transducer suitable for road piezoelectric power generation and its manufacturing method

A piezoelectric transducer and a manufacturing method technology, which are applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of short life and poor durability and other problems, to achieve the effect of long service life, good durability, and increased structural integrity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

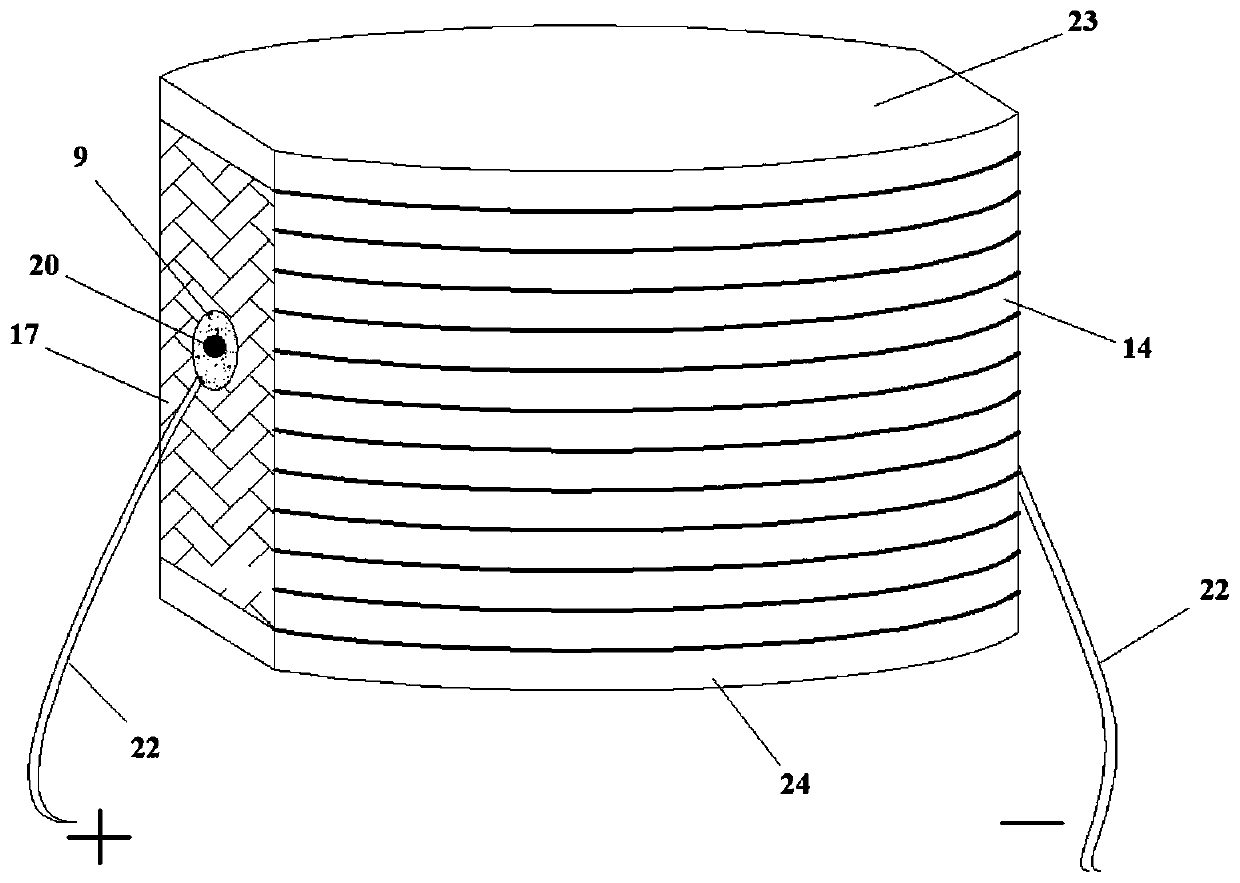

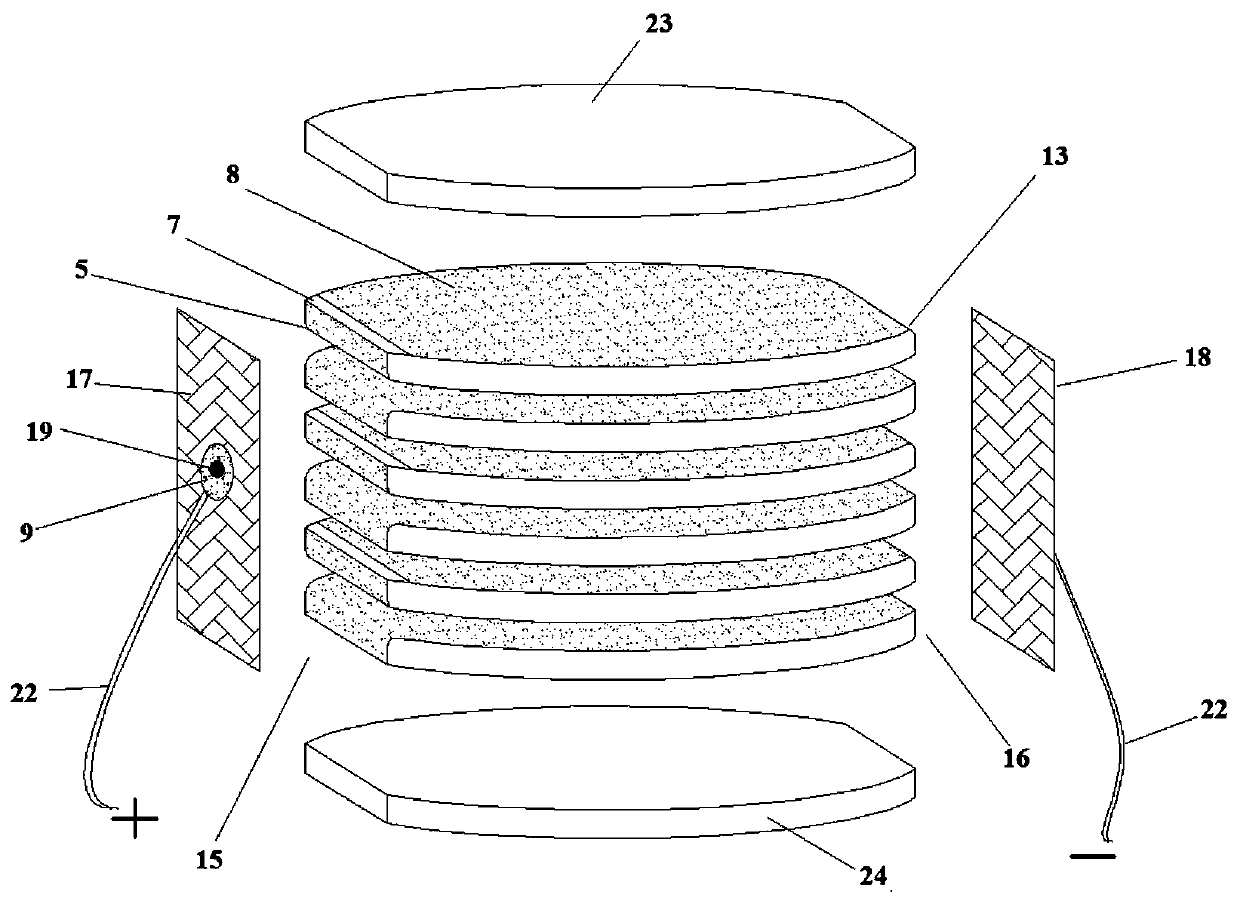

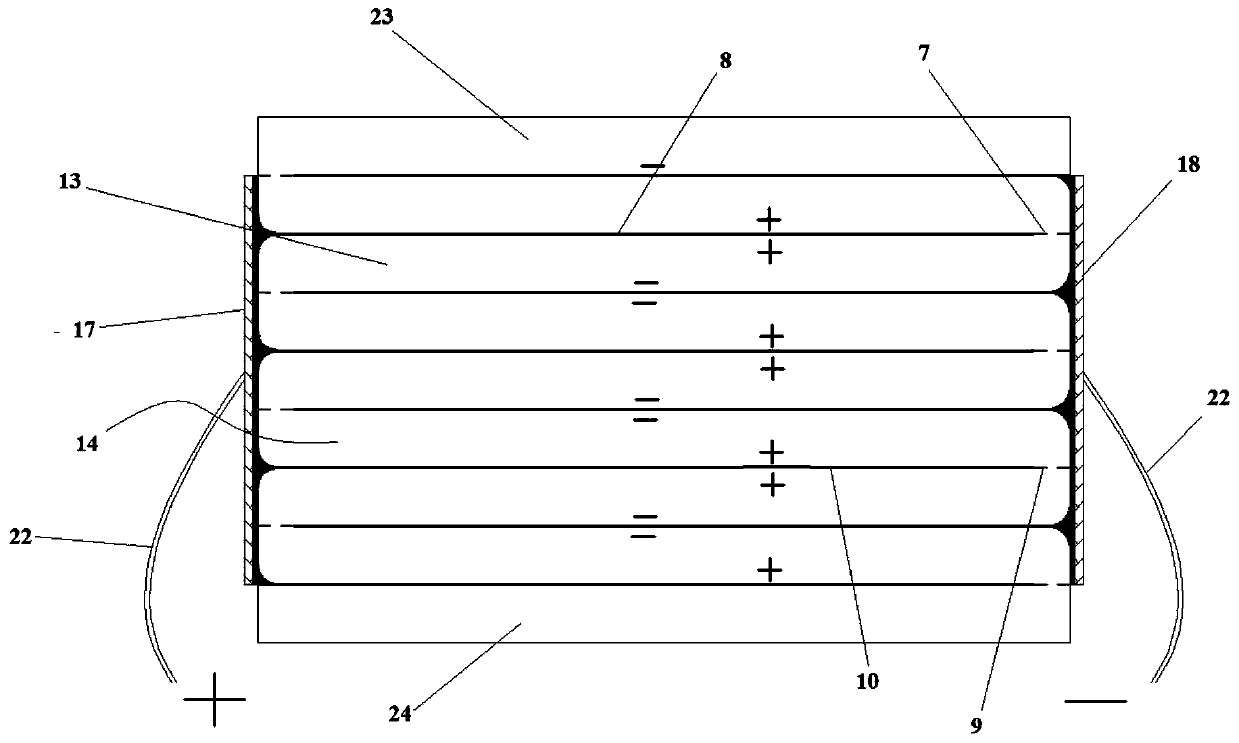

[0051]Comply with the above technical solutions, such as Figure 1 to Figure 8 As shown, this embodiment provides a method for manufacturing a stacked piezoelectric transducer suitable for road piezoelectric power generation. The method includes the following steps:

[0052] Step 1. Making a circular ceramic substrate:

[0053] A circular ceramic substrate 1 is fabricated by a conventional method.

[0054] In this embodiment, as a preferred method, the conventional method for making a circular ceramic substrate is: calcining and ball-milling the ceramic powder, mixing it with a solvent, a dispersant, and a defoamer, and then adding a binder, The plasticizer and the lubricant are mixed and milled for a second time for 12 hours to form a slurry, which is molded and cut by a tape casting machine, and a circular ceramic substrate is obtained after debinding and sintering.

[0055] Step 2. Making a rounded corner ceramic substrate:

[0056] Fix the circular ceramic substrate 1 o...

Embodiment 2

[0076] This embodiment provides a stacked piezoelectric transducer suitable for road piezoelectric power generation, such as Figure 1 to Figure 5 As mentioned above, the stacked piezoelectric transducer is manufactured using the manufacturing method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com