Pull-type cyperus esculentus harvester

A kind of oil sand bean and harvester technology, which is applied in the direction of digging harvesters, harvesters, excavators, etc., can solve the problems of fruit residue, multiple levels of transmission mechanism, and low transmission efficiency, so as to save manpower and time, and power transmission Fewer levels, guarantee the effect of harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

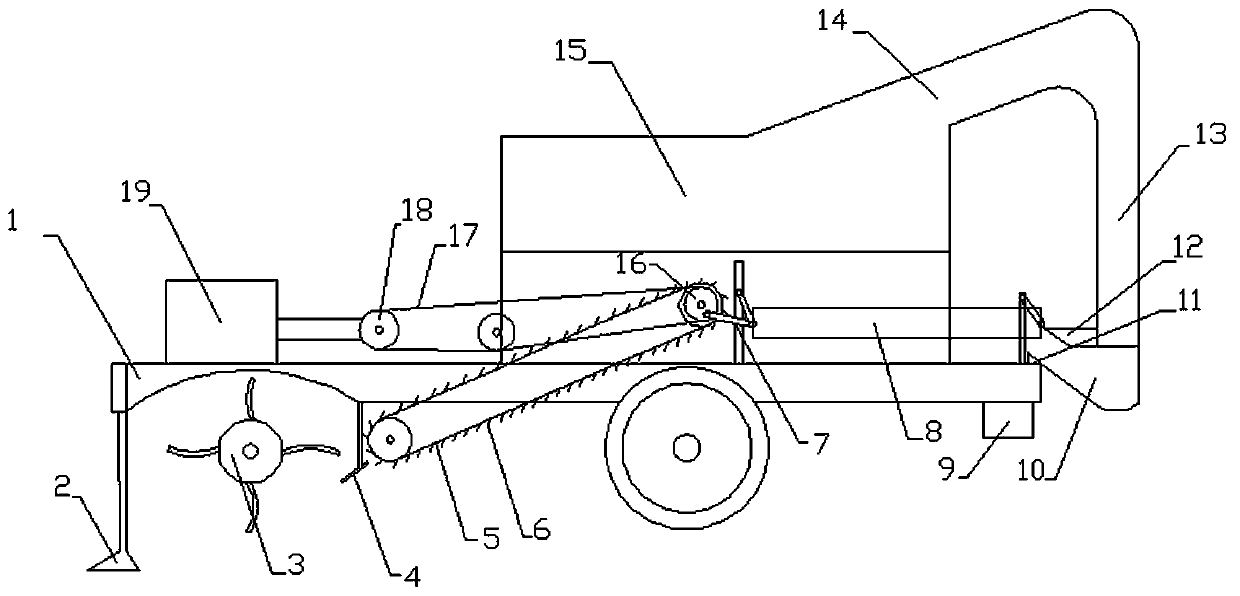

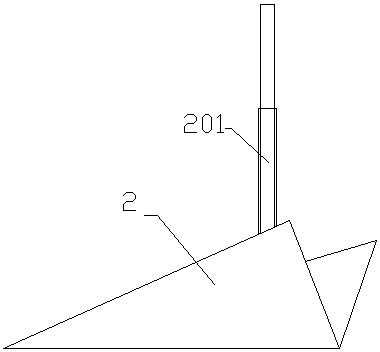

[0033] As shown in the figure: a traction-type oily bean harvester, including a tractor-tracted car body 1 and a transmission mechanism, a harvesting mechanism, a conveying mechanism, a screening mechanism and a collecting mechanism respectively arranged on the car body 1, and the car body 1 One end of the set gearbox 19 is connected to the power output shaft of the tractor, and the other end is connected to the transmission mechanism, and at the same time drives the harvesting mechanism below the gearbox 19 to harvest the oily beans.

[0034] Described transmission mechanism is made up of transmission shaft, driving sprocket 18, driven sprocket 16 and chain 17, and driven sprocket 16 drives conveying mechanism and screening mechanism respectively;

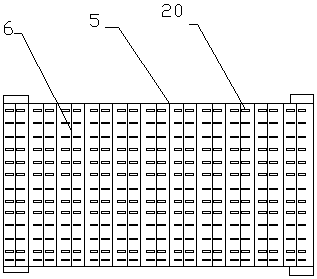

[0035] The harvesting mechanism is located under the front of the car body 1, and includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com