Fan-shaped breeding net

A netting and fan-shaped technology, applied in the field of breeding equipment, can solve the problems of insufficient overall structural strength of the netting, unfavorable breeding safety, improper setting of mesh bars, etc., to improve breeding safety, excellent compression effect, and improve wind and wave resistance The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

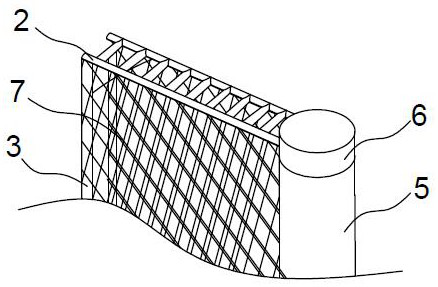

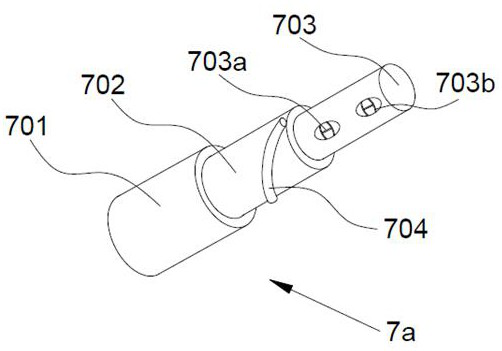

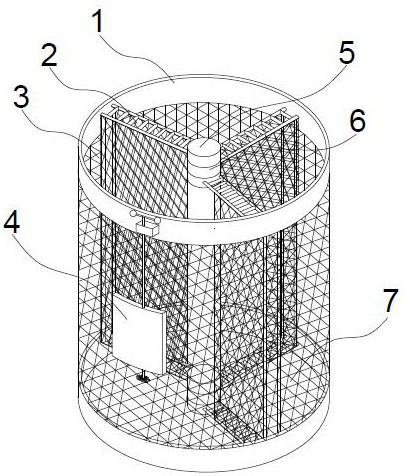

[0030] Such as Figure 1-9As shown, the fan-shaped breeding net clothing includes the net clothing 7 connected to the cage frame 1, the cage frame 1 axis is provided with a floating column 5, and the upper and lower ends of the floating column 5 are evenly distributed with sliding rings 6, and the sliding ring 6 The floating bridge 2 is connected with the net cage frame 1 through the floating bridge 2, the floating bridge 2 at the upper and lower ends is connected through the balance connecting rod 3, the inner and outer sides and the bottom of the net cage frame 1 are connected with net clothes 7, and the corresponding floating bridge 2 sides at the upper and lower ends are connected with net clothes 7. The inner wall of the net cage frame 1 is provided with a chute corresponding to the pontoon 2, and the surface of the chute is provided with fixing holes, and both sides of the contact end of the pontoon 2 and the chute are provided with a movable fixed curved plate 201, and t...

Embodiment 2

[0036] Such as Figure 1-9 As shown, the cultivators can fix the fixed curved plate 201 after rotating the pontoon 2, and then divide the internal space of the cultivating cage of the present invention according to the cultivating requirements, and cultivate fish with different space requirements in different separated spaces without much effort. And the flexibility is high, by rationally distributing the culture space, it is beneficial to improve the culture yield of fish, and the survival rate of juvenile fish can be improved by separating the large and small fish, and the net opening closing mechanism 4 can be arranged on the side of the net clothes connected up and down on the pontoon bridge 2, and Corresponding network ports are set to realize the cultivation of fish of different specifications in different breeding areas in the cages. The breeding cages can be connected through cylindrical cages to realize the combination of breeding areas, and 4 pairs of network port clo...

Embodiment 3

[0038] Select 10 folding culture net cages of the present invention (experimental group) and 10 markets to buy the culture net cages (control group) of the same capacity, carry out culture experiment in a certain farm in Dinghai District, Zhoushan, when 3~4 months, above-mentioned 20 cages were put into use, and 800 female broodstock (more than 600 g / tail) and 400 male broodstock (more than 400 g / tail) were put into the experimental group and the control group respectively. The above-mentioned fish species were large yellow croakers, which were cultivated in spring When the water temperature of broodstock is below 14°C, feed the feed once every 1-2 days, and the feeding rate is 1-2%. 3~6%, culture one year, in the breeding process again, the experimental group divides the net cage culture space by the mode of embodiment 2, and the control group is cultured by the conventional culture mode, and in the one year culture process, the maintenance of the net cage is all by routine ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com