High-temperature exhaust gas filtering apparatus

A filtration device, a technology for high-temperature exhaust gas, which is applied in the fields of dispersed particle filtration, transportation and packaging, and dispersed particle separation. The effect of strong performance and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

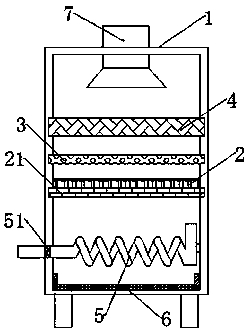

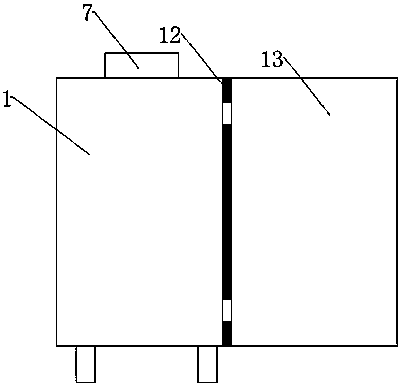

[0031] The present invention is realized through the following technical solutions, as figure 1 As shown, a high-temperature exhaust gas filtering device is connected with the exhaust gas output pipeline, and includes a box body 1 provided with an air inlet 11 and an output port. The inside of the box body 1 includes a gas cooling chamber equipped with an exhaust gas cooling mechanism and cooling A treatment chamber where the post-gas is filtered; the waste gas cooling mechanism includes a cooling pipe 5 fixedly installed in the gas cooling chamber, and one end of the cooling pipe 5 is connected to the air inlet 11; an exhaust fan 7 is installed at the output port.

[0032] It should be noted that, through the above improvements, when in use, the air inlet 11 is connected to the exhaust gas pipeline, and the exhaust fan 7 is turned on, and the exhaust gas will enter the cooling pipeline 5 for cooling, so that the temperature of the exhaust gas is lowered, and the filtration pro...

Embodiment 2

[0035] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the cooling pipeline 5 is spiral; the end of the cooling pipeline 5 close to the air inlet 11 is provided with a filter 51 , and the end of the cooling pipeline 5 away from the air inlet 11 communicates with the box body 1 .

[0036] An active carbon filter layer 4 , a PM2.5 filter screen 3 , and an open-cell foamed aluminum filter layer are slidingly installed in the treatment chamber in sequence along the vertical direction.

[0037] The open-cell foam aluminum filter layer includes an open-cell foam aluminum plate 2 and a stainless steel filter screen 21 for supporting the open-cell foam aluminum plate 2 , and the stainless steel filter screen 21 is slidably installed in the box body 1 .

[0038] The porosity of the open-cell aluminum foam filter body is 60%-90%.

[0039] A dust storage tank 6 is also slidably installed inside the bottom of the box body 1 . The du...

Embodiment 3

[0044] This embodiment is the best embodiment of the present invention, as figure 1 As shown, a high-temperature exhaust gas filtering device is connected with the exhaust gas output pipeline, and includes a box body 1 provided with an air inlet 11 and an output port. The inside of the box body 1 includes a gas cooling chamber equipped with an exhaust gas cooling mechanism and cooling A treatment chamber where the post-gas is filtered; the waste gas cooling mechanism includes a cooling pipe 5 fixedly installed in the gas cooling chamber, and one end of the cooling pipe 5 is connected to the air inlet 11; an exhaust fan 7 is installed at the output port.

[0045] The cooling pipeline 5 is spiral; the end of the cooling pipeline 5 close to the air inlet 11 is provided with a filter 51 , and the end of the cooling pipeline 5 away from the air inlet 11 communicates with the box body 1 .

[0046] The cooling pipe 5 includes an inner tube for exhaust gas flow and an outer tube sleev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com