Sheet bar class part hot blanking system with multi-station pressure cold rotary disc and process

A multi-station, turntable technology, applied in the field of sheet metal hot stamping, can solve problems such as poor welding of workpieces, reduce the load of the stamping process, and tooth shape distortion, so as to achieve work hardening, improve stamping efficiency, and accelerate heating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Such as Figure 1-6 A hot blanking system for plate parts with a multi-station press-cooling turntable is shown, including an induction heating device, a hot stamping die device and a multi-station press-cooling turntable device;

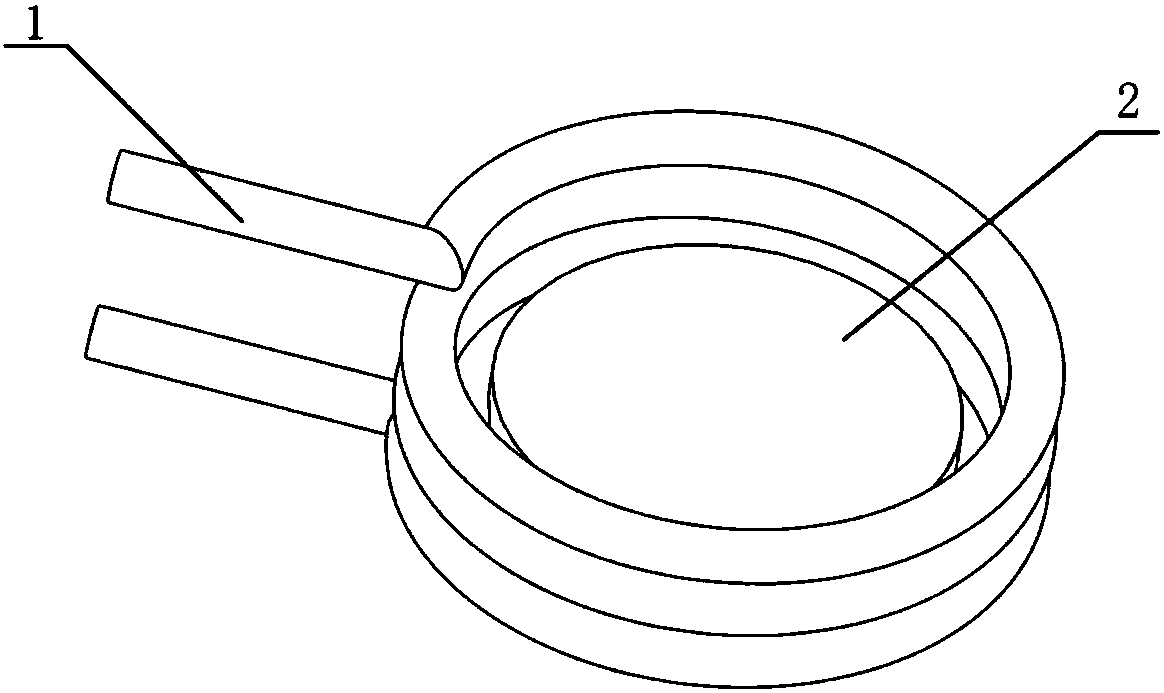

[0055] Such as figure 1 The shown induction heating device consists of an induction heating coil 1 , a temperature measuring device, a temperature controller and an induction heating controller. In the process of heating the unformed sheet 2, use the induction heating coil to heat the unformed sheet to 900°C-920°C, use the temperature measuring device to measure the temperature of the unformed sheet in real time and feed it back to the temperature controller, through The temperature controller controls the temperature of the unformed sheet to be stable at 900°C-920°C, and keeps it for 3-5 minutes to completely austenitize the unformed sheet.

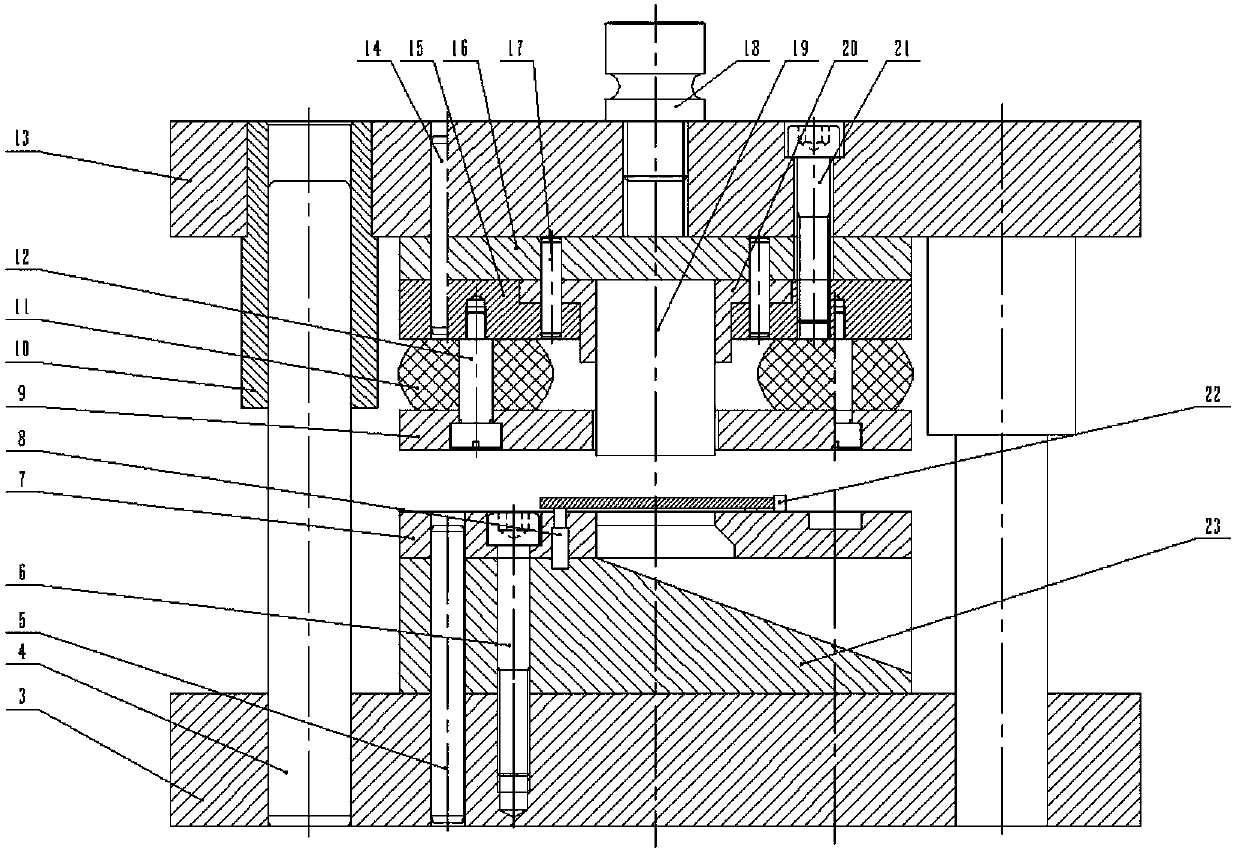

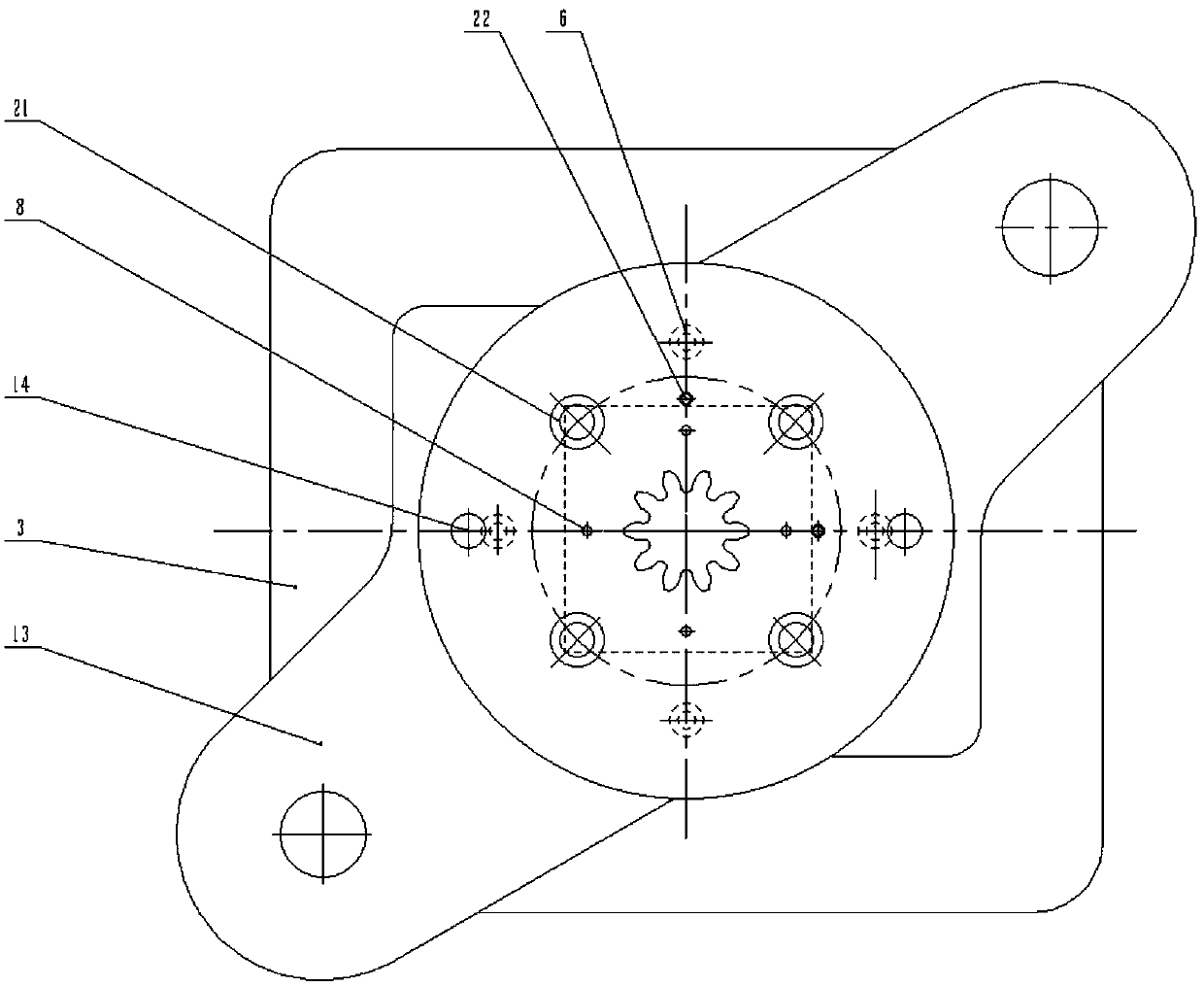

[0056] Such as Figure 2-4 The shown hot stamping die device comprises a standard frame consistin...

Embodiment 2

[0060] The hot stamping process is carried out by taking the unformed sheet material of B1500HS with a thickness of 4mm as an example.

[0061] (1) Place the sheet in the induction heating device for induction heating, use the induction coil to heat the unformed sheet to 900°C-920°C, and use the temperature measuring device and temperature controller to keep the sheet warm for 3-5 minutes, make it fully austenitized;

[0062] (2) Install the hot blanking die device on the WDW-200E microcomputer-controlled electronic universal testing machine, quickly transfer the heated unformed sheet to the die with elastic ejector pins and elastic positioning pins, and pass the elastic positioning pins Carry out positioning and support it by elastic ejector pins to avoid contact with the mold, so that the temperature of the sheet can drop rapidly, and air cool the heated unformed sheet for 4-7 seconds, and air cool to 700°C-800°C (blanking temperature) ;

[0063] (3) Turn on the press to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com