Sulfamate water reducing agent preparation method

A technology of sulfamic acid salt and sodium sulfamic acid is applied in the field of water reducing agent, which can solve the problems of easy segregation and bleeding, short side chain length, low water reduction rate and low water reduction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

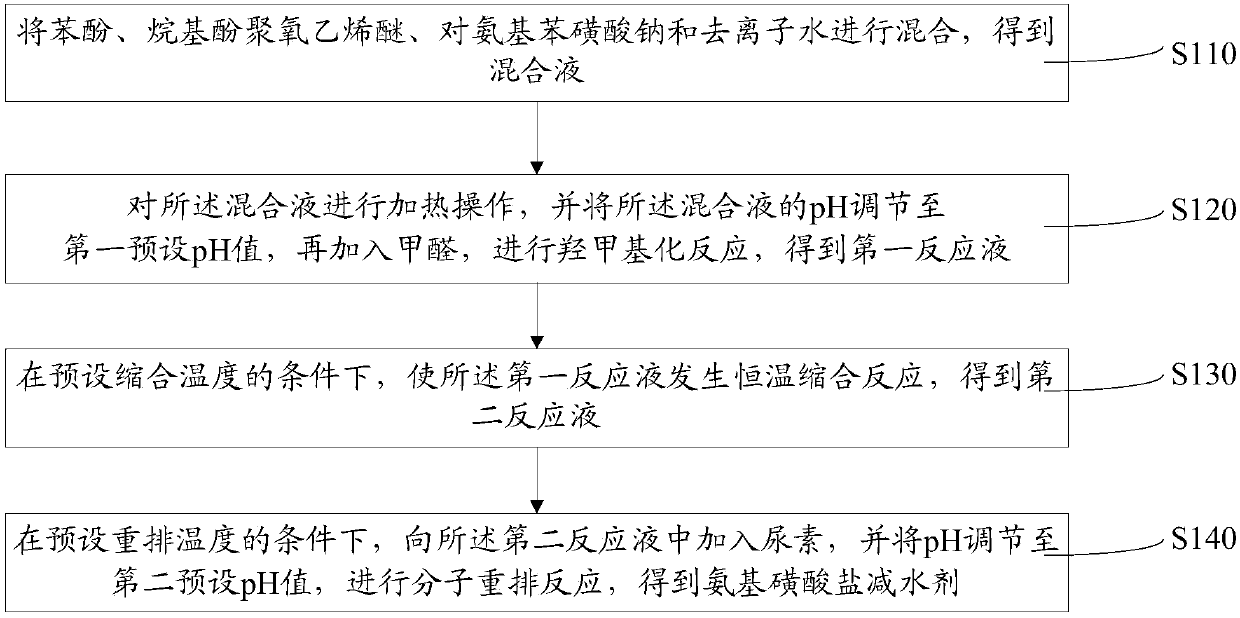

[0022] see figure 1 , the preparation method of sulfamate water-reducer in one embodiment, comprises the steps:

[0023] S110: Mix phenol, alkylphenol polyoxyethylene ether, sodium p-aminobenzenesulfonate and deionized water to obtain a mixed solution.

[0024] By mixing phenol, alkylphenol polyoxyethylene ether, sodium p-aminobenzenesulfonate and deionized water, it can be more uniformly mixed with other components in subsequent operations.

[0025] In one embodiment, the alkylphenol polyoxyethylene ether is nonylphenol polyoxyethylene ether, octylphenol polyoxyethylene ether, dodecylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether. at least one.

[0026] S110: Perform a heating operation on the mixed solution, adjust the pH of the mixed solution to a first preset pH value, and then add formaldehyde to perform a methylolation reaction to obtain a first reaction solution.

[0027] By adding formaldehyde, a methylol group can be introduced on the benzene ...

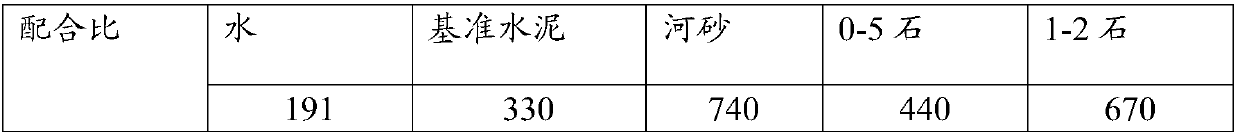

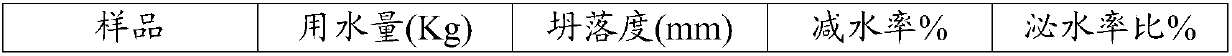

Embodiment 1

[0047] Put 160g of sodium p-aminobenzenesulfonate, 80g of phenol, 20g of OP-10, and 360g of deionized water into the reaction kettle, and stir for 10 minutes. Add 5g of 20% dilute sulfuric acid, raise the temperature to 90°C and add 150g of formaldehyde solution dropwise to the system at a constant speed for 3 hours. Incubate at 90°C to 95°C for 4 hours to carry out the condensation reaction. Lower the temperature to 85°C, add 15g of 32% liquid caustic soda and 2g of urea, and keep the temperature between 85°C and 90°C for 4 hours.

Embodiment 2

[0049] Put 160g of sodium p-aminobenzenesulfonate, 80g of phenol, 24g of TX-12, and 370g of deionized water into the reaction kettle, and stir for 10 minutes. Add 5g of 20% dilute sulfuric acid, raise the temperature to 90°C and add 150g of formaldehyde solution dropwise to the system at a constant speed for 3 hours. Incubate at 90°C to 95°C for 4 hours to carry out the condensation reaction. Lower the temperature to 85°C, add 15g of 32% liquid caustic soda and 2g of urea, and keep the temperature between 85°C and 90°C for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com