Preparation method of nano-cellulose aerogel and nano-cellulose aerogel

A nanocellulose and aerogel technology, which is applied in the field of nanocellulose aerogel and nanocellulose aerogel preparation, can solve the problem that it is difficult to control the smooth progress of the TEMPO oxidation of cellulose reaction process and the decline of the physical properties of the gel. and other problems, to achieve the effect of easy control, low density, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

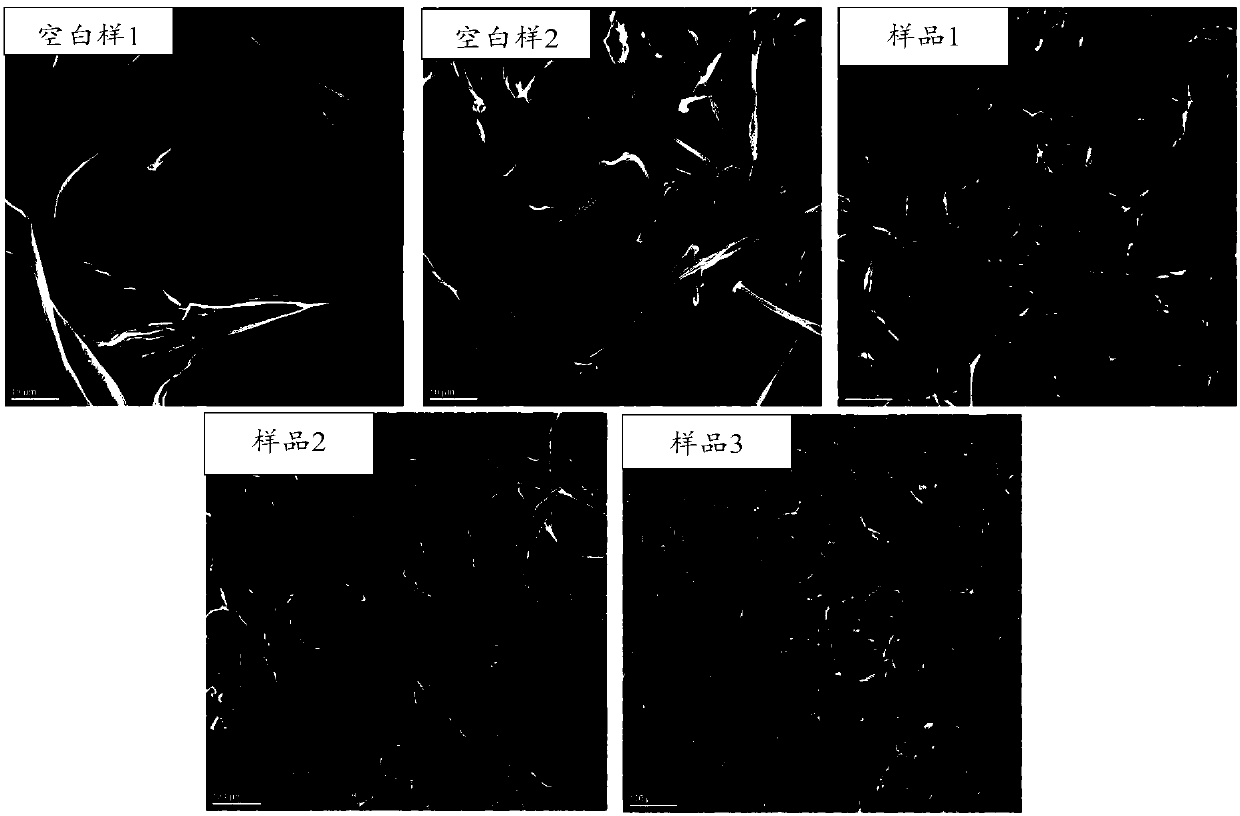

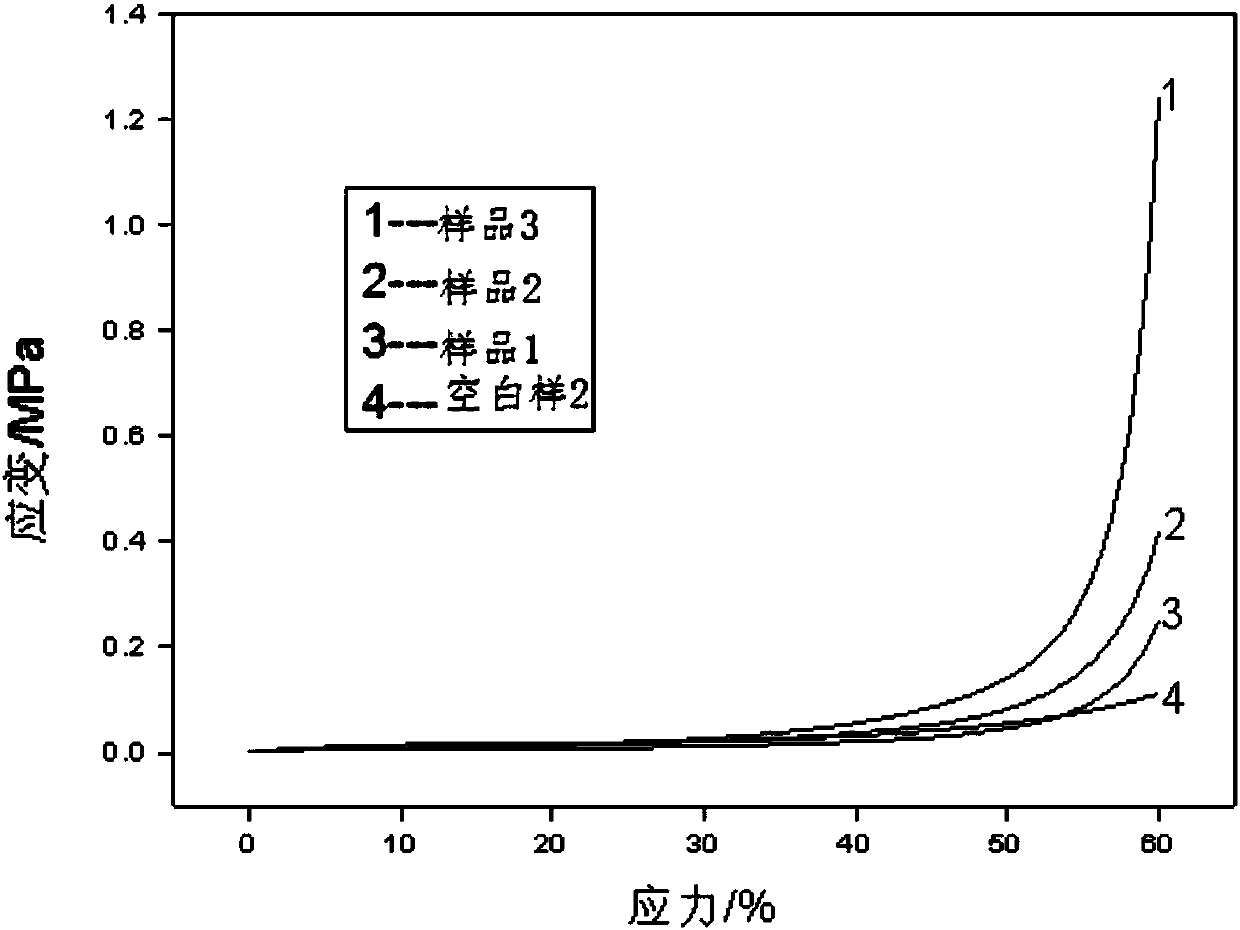

[0033] 1) Preparation of blank sample 1: soak the pulp (bleached coniferous wood pulp) in deionized water for 4 hours, disperse it for 15 minutes, prepare a pulp with a mass fraction of 10 wt%, and use a PFI refiner to refine the pulp. The beating degree is 70°-90°SR slurry; dissolve TEMPO and NaBr with distilled water, the amount of TEMPO is 0.01g / g, the amount of NaBr is 0.1g / g, and then mixed with the slurry; 10% NaClO is dissolved and diluted to 5%, The amount of NaClO is 0.5g / g, added dropwise, using NaOH solution to adjust the pH value dropwise, so that the pH value is kept at about 10.5, and the reaction time is controlled for about 1h. After 1h of reaction, a certain amount of ethanol is added to terminate the reaction; The oxidized cellulose suspension is dialyzed to neutral, suction filtered to form a filter cake, and after the moisture in the filter cake is measured, the filter cake is dissolved in deionized water to prepare a suspension slurry with a mass fraction o...

Embodiment 2

[0042] Preparation of sample 2: Preparation of sample 1: soak the pulp (bleached coniferous wood pulp) in deionized water for 4h, disintegrate for 15min, prepare a slurry with a mass fraction of 10wt%, and use a PFI refiner to refine the slurry , to obtain a beating degree of 70°-90°SR slurry; dissolve TEMPO and NaBr with distilled water, the amount of TEMPO is 0.01g / g, and the amount of NaBr is 0.1g / g, and then mixed with the slurry, and 10% NaClO is dissolved and diluted to 5 %, the amount of NaClO is 0.5g / g, added dropwise, using NaClO 2 CO 3 / NaHCO 3 The buffer solution is added dropwise to adjust the pH value, so that the pH value is kept at about 10.5, and the reaction time is controlled for about 1 hour. After 1 hour of reaction, a certain amount of ethanol is added to terminate the reaction; Filter into a filter cake, after measuring the moisture in the filter cake, dissolve the filter cake in deionized water, prepare a suspension slurry with a mass fraction of 1 wt%...

Embodiment 3

[0046] Preparation of Sample 3: Soak the slurry (bleached softwood pulp) in deionized water for 4h, disperse it for 15min, prepare a slurry with a mass fraction of 10wt%, and use a PFI refiner to refine the slurry to obtain a beating degree It is 70°-90°SR slurry; dissolve TEMPO and NaBr with distilled water, the dosage of TEMPO is 0.01g / g, the dosage of NaBr is 0.1g / g, then mix with the slurry, dissolve and dilute 10% NaClO to 5%, the dosage of NaClO 0.5g / g, added dropwise, using Na 2 CO 3 / NaHCO 3 The buffer solution is added dropwise to adjust the pH value, so that the pH value is kept at about 10.5, and the reaction time is controlled for about 1 hour. After 1 hour of reaction, a certain amount of ethanol is added to terminate the reaction; Filter into a filter cake, after measuring the moisture in the filter cake, dissolve the filter cake in deionized water, prepare a suspension slurry with a mass fraction of 1wt%, add 20% sorbitol with a quality of the absolute dry slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com