Solvent-free environment-friendly printed rubber blanket and production process thereof

A blanket and environment-friendly technology, applied in the field of printing blankets and its production process, can solve the problems of large environmental impact, waste of energy, etc., and achieve the effect of reasonable method, reasonable structure and strong viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

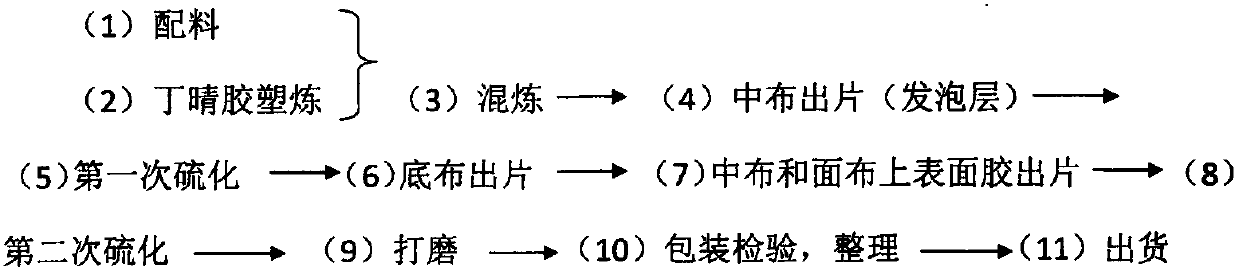

Method used

Image

Examples

Embodiment 1

[0042] A solvent-free and environment-friendly printing blanket is composed of a face cloth, a middle cloth and a base cloth.

[0043] Wherein, the face cloth includes the following components by weight components: NBR: 80 parts, titanium dioxide: 1 part, sulfur: 0.3 parts, tetramethyldithiothiuram: 0.5 parts, 2.2 parts '-Dithiodibenzothiazole: 1 part, N-cyclohexyl-2-benzothiazole sulfenamide: 0.5 part, white carbon black: 30 parts, stearic acid: 0.8 part, zinc oxide: 1 part, Styrenated phenol: 0.5 parts, titanium blue: 0.2 parts.

[0044] In addition, the middle cloth includes the following components by weight components: NBR: 90 parts, zinc oxide: 3 parts, sulfur: 1 part, tetramethyldithiothiuram: 0.8 parts, 2.2' -Dithiodibenzothiazole: 1 part, N-cyclohexyl-2-benzothiazole sulfenamide: 0.5 part, carbon black: 20 parts, white carbon black: 3 parts, stearic acid: 1 part, physical Foaming agent: 5 parts.

[0045] Further, the base cloth includes the following components in ...

Embodiment 2

[0059] A solvent-free and environment-friendly printing blanket is composed of a face cloth, a middle cloth and a base cloth.

[0060] Wherein, the face cloth includes the following components by weight components: NBR: 110 parts, titanium dioxide: 8 parts, sulfur: 3 parts, tetramethyldithiothiuram: 1.5 parts, 2.2 parts '-Dithiodibenzothiazole: 5 parts, N-cyclohexyl-2-benzothiazole sulfenamide: 4 parts, white carbon black: 50 parts, stearic acid: 1.6 parts, zinc oxide: 5 parts, Styrenated phenol: 2 parts, titanium blue: 1.5 parts.

[0061] In addition, the middle cloth includes the following components by weight components: nitrile rubber: 120 parts, zinc oxide: 8 parts, sulfur: 5 parts, tetramethyldithiothiuram: 1.2 parts, 2.2' -Dithiodibenzothiazole: 4 parts, N-cyclohexyl-2-benzothiazole sulfenamide: 2.5 parts, carbon black: 40 parts, white carbon black: 8 parts, stearic acid: 4 parts, physical Foaming agent: 20 parts.

[0062] Further, the base cloth includes the followi...

Embodiment 3

[0076] A solvent-free and environment-friendly printing blanket is composed of a face cloth, a middle cloth and a base cloth.

[0077] Wherein, the face cloth includes the following components by weight components: NBR: 80 parts, titanium dioxide: 8 parts, sulfur: 1 part, tetramethyldithiothiuram: 1.2 parts, 2.2 parts '-Dithiodibenzothiazole: 1 part, N-cyclohexyl-2-benzothiazole sulfenamide: 4 parts, white carbon black: 30 parts, stearic acid: 1.2 parts, zinc oxide: 4 parts, Styrenated phenol: 1.5 parts, titanium blue: 0.8 parts.

[0078] In addition, the middle cloth includes the following components by weight components: nitrile rubber: 120 parts, zinc oxide: 3 parts, sulfur: 5 parts, tetramethyldithiothiuram: 1 part, 2.2' -Dithiodibenzothiazole: 3 parts, N-cyclohexyl-2-benzothiazole sulfenamide: 1.5 parts, carbon black: 30 parts, white carbon black: 5 parts, stearic acid: 2 parts, physical Foaming agent: 15 parts.

[0079] Further, the base cloth includes the following c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com