Ink solvent for glass inkjet printing

A water solvent and ink printing technology, applied in the field of inkjet printing, can solve the problems of pattern deviation, difficult and precise positioning of patterns, low pattern size accuracy and position accuracy, etc., to reduce size deviation, promote molecular thermal motion and mutual diffusion, and improve effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

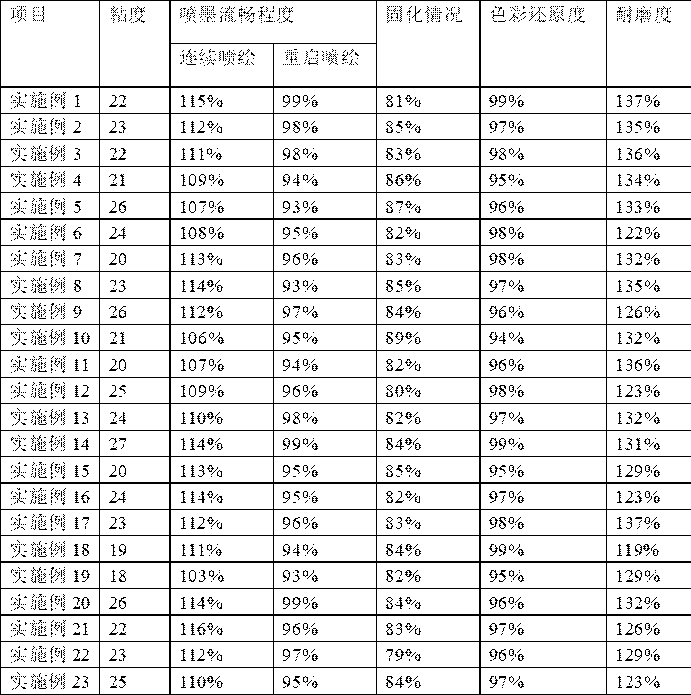

Examples

Embodiment 1

[0021] A glass ink-jet printing ink solvent, used for dissolving and / or swelling pigments, the ink solvent includes the following components in parts by weight: 40 parts of polyvinyl acetate, 40 parts of JP-TS aviation fuel, lead bisilicate 10 parts, 10 parts of diethylene glycol butyl ether, 3 parts of dipropylene glycol methyl ether, 3 parts of propylene glycol methyl ether acetate, 2 parts of titanium dioxide.

Embodiment 2

[0023] A glass inkjet printing ink solvent, used to dissolve and / or swell pigments, the ink solvent includes the following components by weight: 30 parts of polyvinyl acetate, 30 parts of JP-TS aviation fuel, lead bisilicate 8 parts, 8 parts of diethylene glycol butyl ether, 2 parts of dipropylene glycol methyl ether, 2 parts of propylene glycol methyl ether acetate, 1.5 parts of titanium dioxide.

Embodiment 3

[0025] A glass inkjet printing ink solvent, used to dissolve and / or swell pigments, the ink solvent includes the following components by weight: 50 parts of polyvinyl acetate, 50 parts of JP-TS aviation fuel, lead bisilicate 12 parts, 12 parts of diethylene glycol butyl ether, 4 parts of dipropylene glycol methyl ether, 4 parts of propylene glycol methyl ether acetate, 2.5 parts of titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com