Patents

Literature

30results about How to "Strong color retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pathological specimen processing method

InactiveCN106908294ABroad antimicrobial effectAntioxidantPreparing sample for investigationChlorogenic acidSpecimen Handling

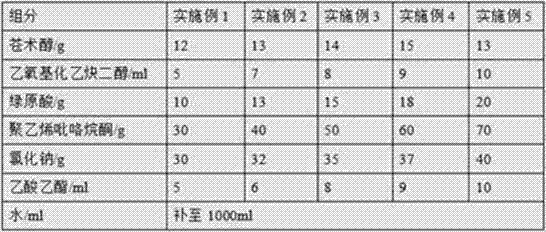

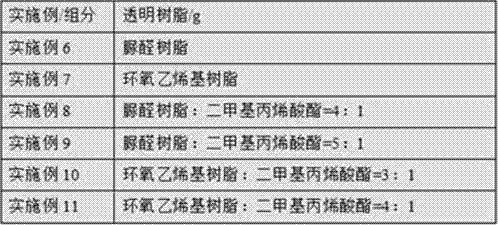

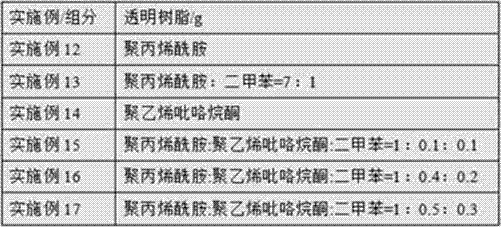

The invention discloses a pathological specimen processing method and belongs to the field of specimen processing technology. According to the processing method, sampled pathological tissues successively undergo fixation, dehydration, transparency, wax impregnation, embedding, slicing, staining and mounting so as to obtain a pathological specimen. The fixation is to fix the pathological tissues by the use of a fixative for 4-15 h. The fixative is composed of atractylol, ethoxylated acetylenediol, chlorogenic acid, polyvinylpyrrolidone, sodium chloride, ethyl acetate and pure water. The mounting is to carry out mounting on the stained pathological tissues by the use of a mixture of polyacrylamide, polyvinylpyrrolidone and xylene. According to the invention, toxicity of reagents used in the invention is obviously reduced, the fixation effect is good, degradation and transparency degree are easy to control. Then, the tissues are not easy to deform, embrittle or harden, and mounting is complete and staining is remarkable.

Owner:LUOHE MEDICAL COLLEGE

Formula of outer wall thin elastic emulsion paint

InactiveCN102181203AHas the ability to resist dust accumulationAvoid accumulationEmulsion paintsPolymer scienceRutile

The invention discloses a formula of outer wall thin elastic emulsion paint. The formula comprises water, hydroxyethyl cellulose, amino methyl propanol 95 (AMP-95), bactericide, dispersant, wetting agent, defoaming agent, propylene glycol, rutile titanium white powder, wollastonite powder with diameter of 800 meshes and heavy calcium with diameter of 800 meshes. After the materials are dispersed at a high speed and sanded, film-forming auxiliary agent, Fuchem238, Fuchem-361, bactericide, defoaming agent, AMP-95, alkali swelling thickener, polyurethane rheological auxiliary agent and water are added. The outer wall thin elastic emulsion paint does not crack, has ageing resistance, weathering resistance and strong color retention, and saves material consumption.

Owner:刘朝红

Aqueous lacquer for carpentry

InactiveCN1519284AOdorless and non-toxicEnvironmentally friendlyEmulsion paintsPolyester coatingsOrganic solventEmulsion

Owner:JIAJING COATING MATERIAL SHANGHAI

Stain-resistant fluorocarbon wall finish and preparation method thereof

InactiveCN107418341AImprove water repellencyLow film forming temperatureAntifouling/underwater paintsPaints with biocidesPolymer scienceRutile

The invention belongs to the technical field of fluorocarbon wall finish, in particular to a stain-resistant fluorocarbon wall finish and a preparation method thereof. The stain-resistant fluorocarbon wall finish comprises a deionized water, a dispersing agent, a wetting agent, a defoaming agent, antiseptic, propylene glycol, rutile titanium dioxide, fluorocarbon emulsion, film forming additive, a polyurethane thickening agent and a polyurethane leveling agent. Compared with the prior art, the stain-resistant fluorocarbon wall finish and the preparation method thereof have the advantages that since raw materials for preparing the fluorocarbon emulsion and reaction conditions are in strict control, copolymerization conversion rate is high and hydrophobicity of the fluorocarbon emulsion is enhanced; adhesive force of the fluorocarbon wall finish is improved by cooperation of other additives in corresponding weight effectively, the fluorocarbon wall finish has ultra-low surface energy and weak hydroscopicity on the basis of the corresponding preparation method, and accordingly can resist stain effectively and is easy to clean and maintain; besides, the fluorocarbon wall finish has high gloss retention and color retention, and accordingly realizes decoration and protection to wall surfaces and prolong service life of buildings.

Owner:安徽喜宝高分子材料有限公司

Gloss emulsion paint

The invention discloses gloss emulsion paint. The gloss emulsion paint comprises: by mass, 35 to 55% of an ethylene-propylene copolymer emulsion, 25 to 45% of titanium dioxide, 1.0 to 1.8% of sodium hexametaphosphate, 5 to 7% of glycol, 0.15 to 0.2% of tributyl phosphate, 1.5 to 2.5% of dibutyl phthalate, 0.05 to 0.08% of sodium benzoate, 0.03 to 0.06% of sodium pentachlorophenate, 0.01 to 0.03% of sodium nitrite, 1 to 2% of ammonia water and 15 to 30% of water. The gloss emulsion paint has the advantages of construction convenience, bright coating, strong color retention, good water resistance and good weatherability.

Owner:NANTONG HONGLIDA KNITTING

Stone-like coating for exterior wall and preparation method of stone-like coating

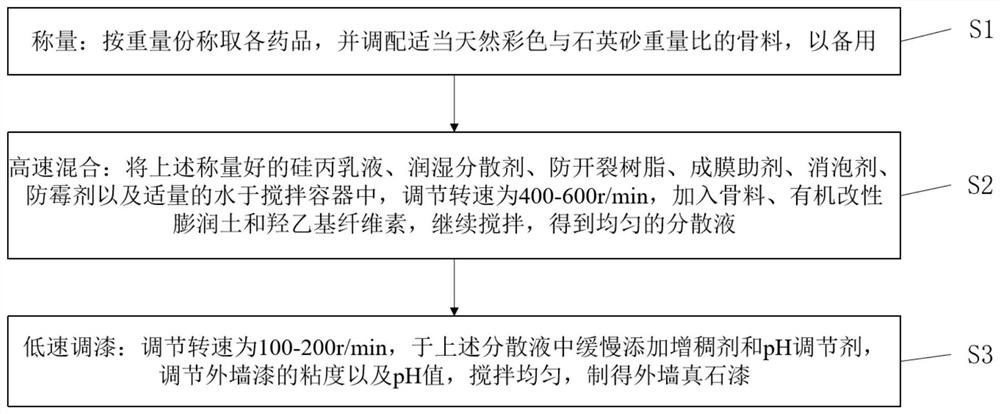

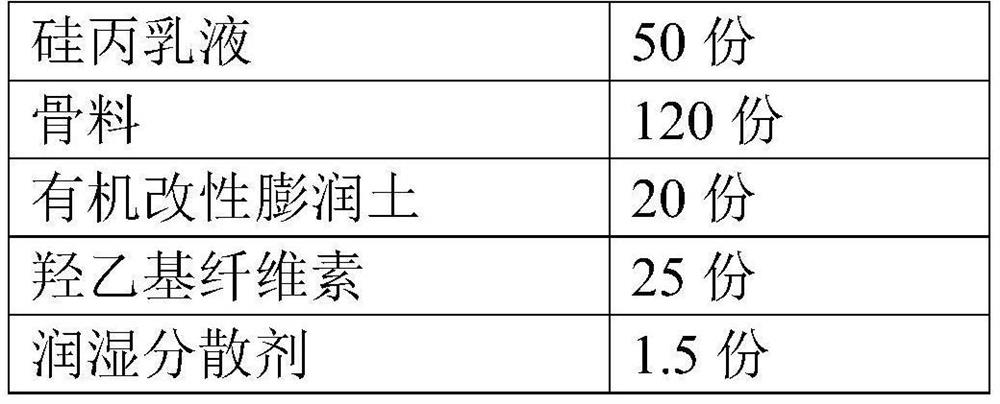

The invention relates to the technical field of decoration materials for building exterior walls, in particular to a stone-like coating for an exterior wall. The stone-like coating comprises the following components in parts by weight: 25-50 parts of a silicone acrylic emulsion, 80-120 parts of aggregate, 15-20 parts of organic modified bentonite, 10-25 parts of hydroxyethyl cellulose, 0.5-1.5 parts of a wetting dispersant, 1-2 parts of anti-cracking resin, 1-4 parts of a coalescing agent, 0.5-0.8 part of a defoaming agent, 0.5-1.2 parts of a thickening agent, 0.5-1.5 parts of a mildew preventive, 0.5-3 parts of a pH regulator and a proper amount of water, wherein the aggregate is composed of natural colored sand and quartz sand according to a weight ratio of (1-3): (1-2), the particle size of the natural colored sand is 40-80 meshes, and the particle size of the quartz sand is 80-120 meshes. The invention also provides a preparation method of the stone-like coating. The stone-like coating prepared by the invention is smooth in spraying, clear in sand grains, high in hard drying speed, more layered in paint surface tone and better in stone-like effect, the weather resistance, acid and alkali resistance, color retention, water resistance and stain resistance of the exterior wall coating are enhanced, the comprehensive functionality of the exterior wall coating is improved, and the development and application of the exterior wall coating are facilitated.

Owner:安徽朗凯奇科技股份有限公司

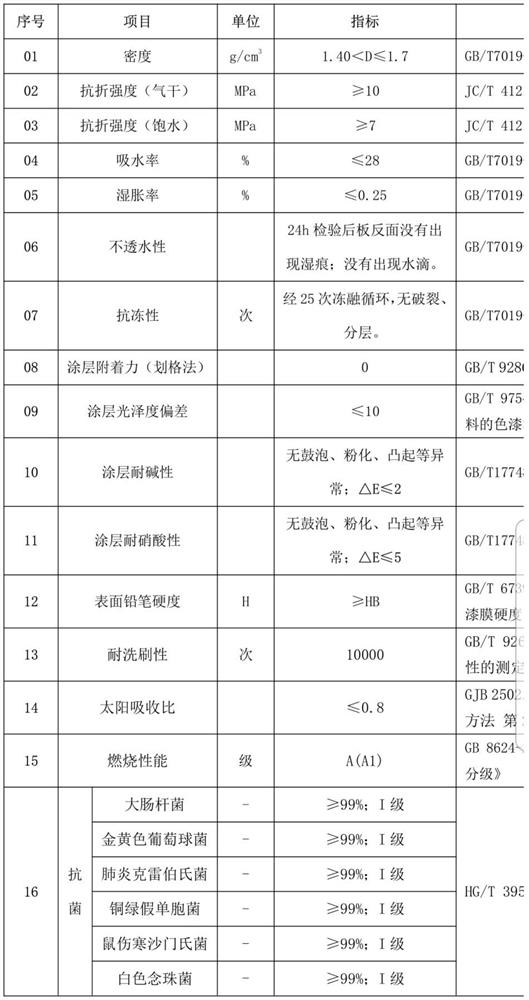

Antibacterial composite coating

InactiveCN104987782ASimple processImprove water resistanceFireproof paintsAntifouling/underwater paintsChemical industryPolyester

The invention discloses an antibacterial flame resistant composite coating and relates to the technical field of chemical industry. The coating comprises the components in parts by weight: 20-25 parts of colophony resins, 45-50 parts of butyl emulsion, 5-8 parts of a nanometer oxide granule reinforcing agent, 13-15 parts of an aliphat curing agent, 7-9 parts of sodium sulphate, 3-5 parts of talcum powder, 2-4 parts of carbon black, 1-6 parts of a thickening agent , 8-9 parts of nanometer silicon dioxide, 4-6 parts of nanometer zinc oxide, 1-3 parts of a nanometer double hydrophobic agent, 7-9 parts of a nanometer reinforcing agent, 1-2 parts of a nanometer anti-ager, 4-6 parts of nanometer silver powder and 5-8 parts of polyester acrylate. According to the antibacterial flame-resistant composite coating disclosed by the invention, a formula is provided, so that the composite coating has favorable bacteria resisting and bacteria killing characteristics, and can voluntarily kill bacteria and pathogenic bacteria, adhered on the coating. Through the adoption of the coating, the water resistance, the adhesive force and the chemical performance are stable, and besides, under the circumstance that the coating is heated, the fire resistance performance of a flame resistant system is not influenced; from the view of the using effect, the coating is good in ductility, high in stretching strength and good in color protecting performance.

Owner:鲍克胜

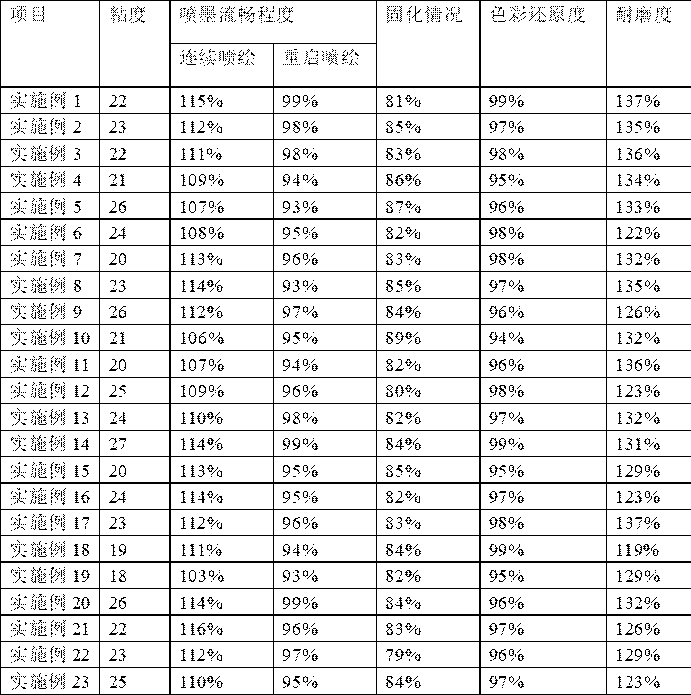

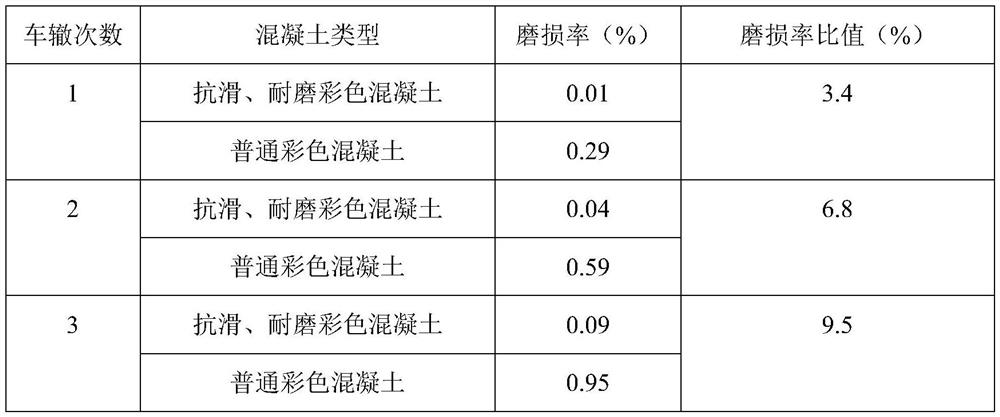

Antiskid and wear-resistant colored asphalt concrete

InactiveCN111689717AStrong skid resistanceAngularIn situ pavingsEpoxy resin coatingsBus laneFirming agent

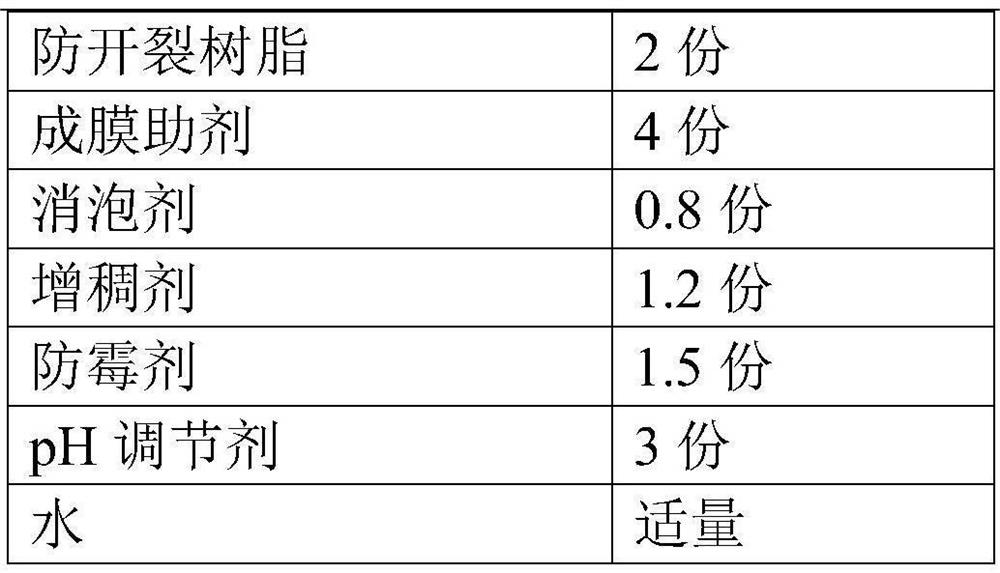

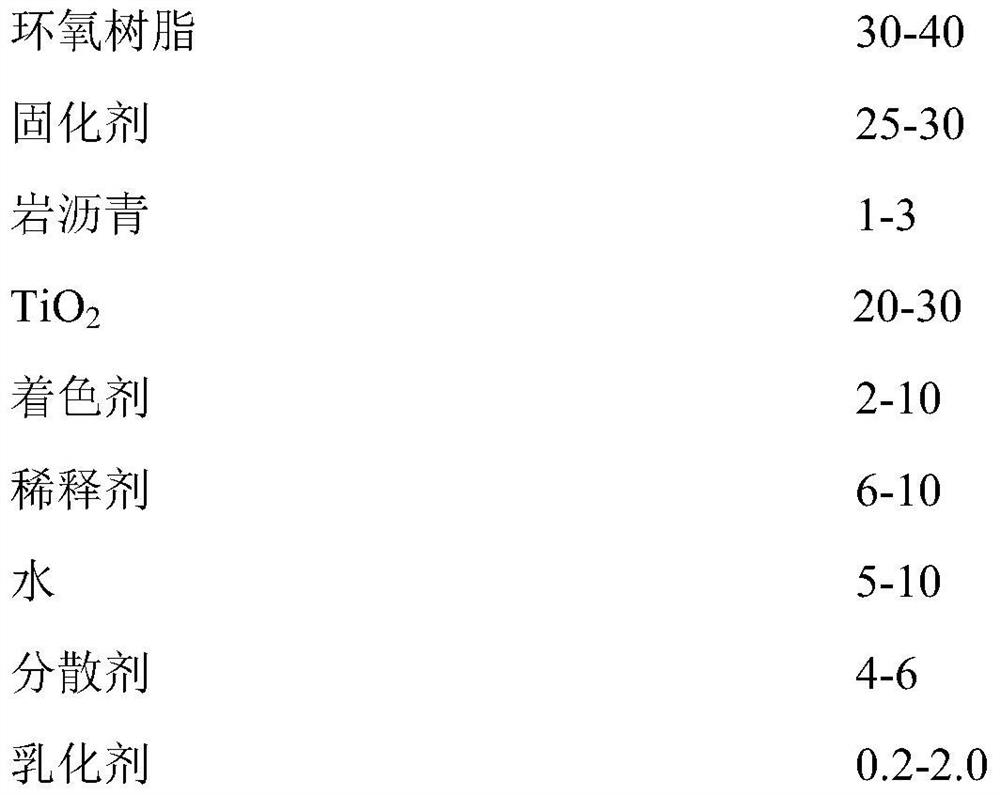

The invention discloses anti-skid and wear-resistant colored asphalt concrete. The asphalt concrete is prepared from, by weight, 5-7 parts of asphalt, 4-63 parts of steel slag, 25-75 parts of broken stone and 7-11 parts of mineral powder, totaling 100 parts. Color coating comprises the following components in parts by weight: 30-40 parts of epoxy resin, 25-30 parts of a curing agent, 2-10 parts ofa coloring agent, 1-3 parts of rock asphalt, 20-30 parts of TiO2, 6-10 parts of a diluent, 5-10 parts of water, 4-6 parts of a dispersing agent and 0.2-2.0 parts of an emulsifier, based on 100 parts.The concrete is uniformly sprayed with 1.1-2.0 kg / m<2> of the coating to finish the preparation. The rock asphalt, steel slag and other materials are utilized to prepare the colored asphalt concrete,thereby enhancing the skid resistance, wear resistance and color retention capacity of the product. The colored asphalt concrete is suitable for road sections with anti-skid and color induction requirements, such as bus lanes.

Owner:SHANGHAI MARITIME UNIVERSITY

Preparation method of papermaking filling materials

InactiveCN103061203AHigh opacityHigh glossInorganic compound additionFilling materialsUltimate tensile strength

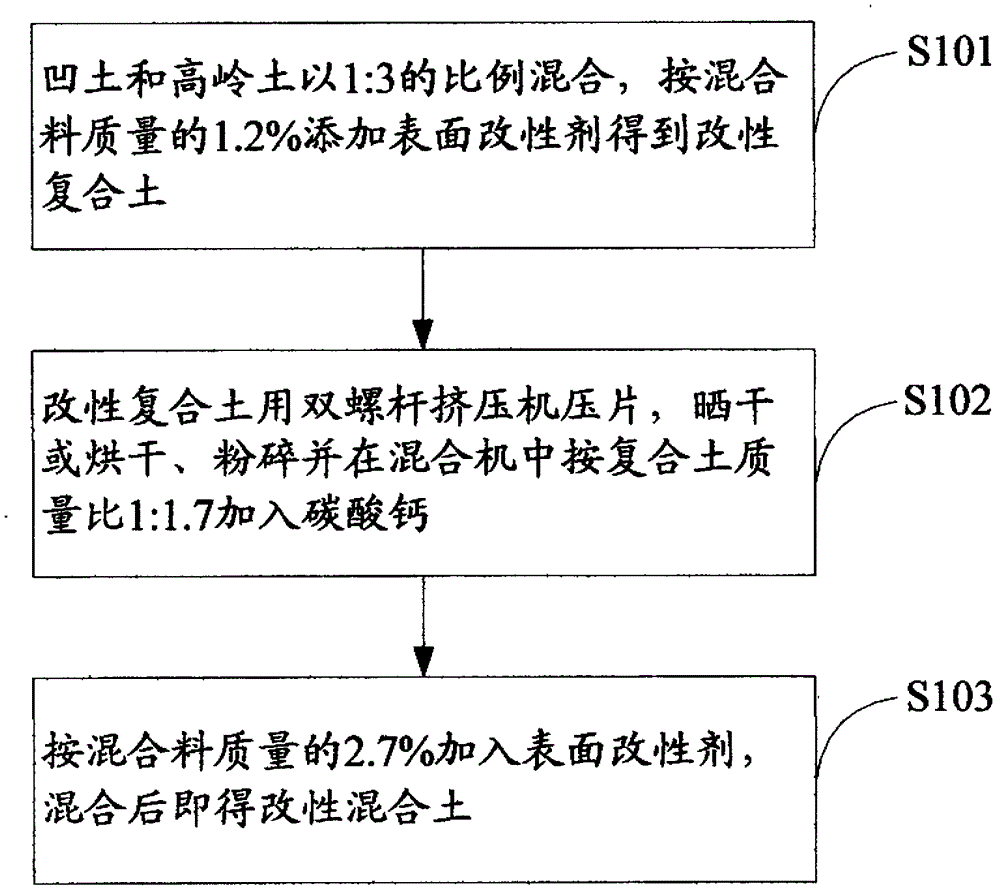

The invention belongs to a field of compound preparation, and provides a preparation method of papermaking filling materials. The method comprises mixing attapulgite clay and kaolin in proportion, adding a surface modifier to obtain modified composite soil, tabletting, drying in the sun or an oven, and crushing the modified composite soil, adding a certain proportion of calcium carbonate in a mixer, uniformly mixing, finally adding the surface modifier, and mixing under a certain temperature to obtain the modified composite soil. The compound modified attapulgite clay and kaolin can be used for paper filling materials, substantially improve retention rate and intensity of the paper products, and has an important reality meaning for environment protection.

Owner:GUANGXI PUXIN PAPER IND

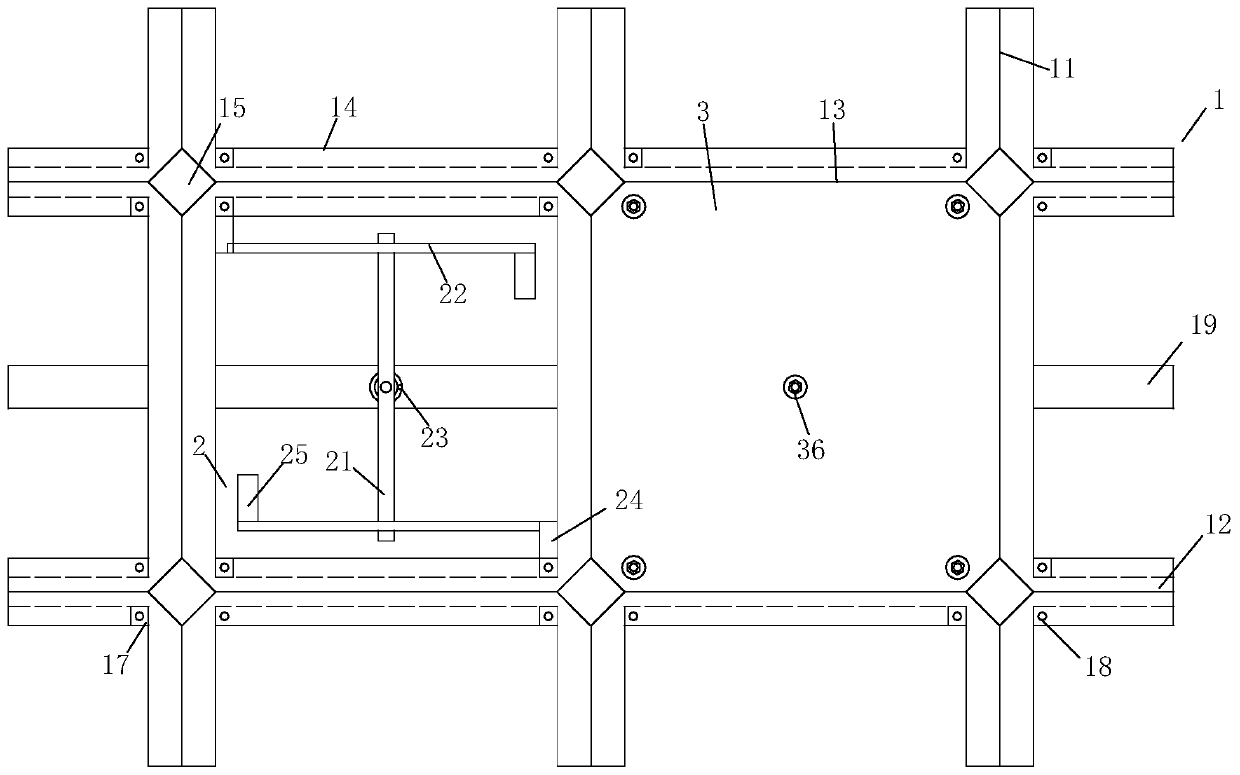

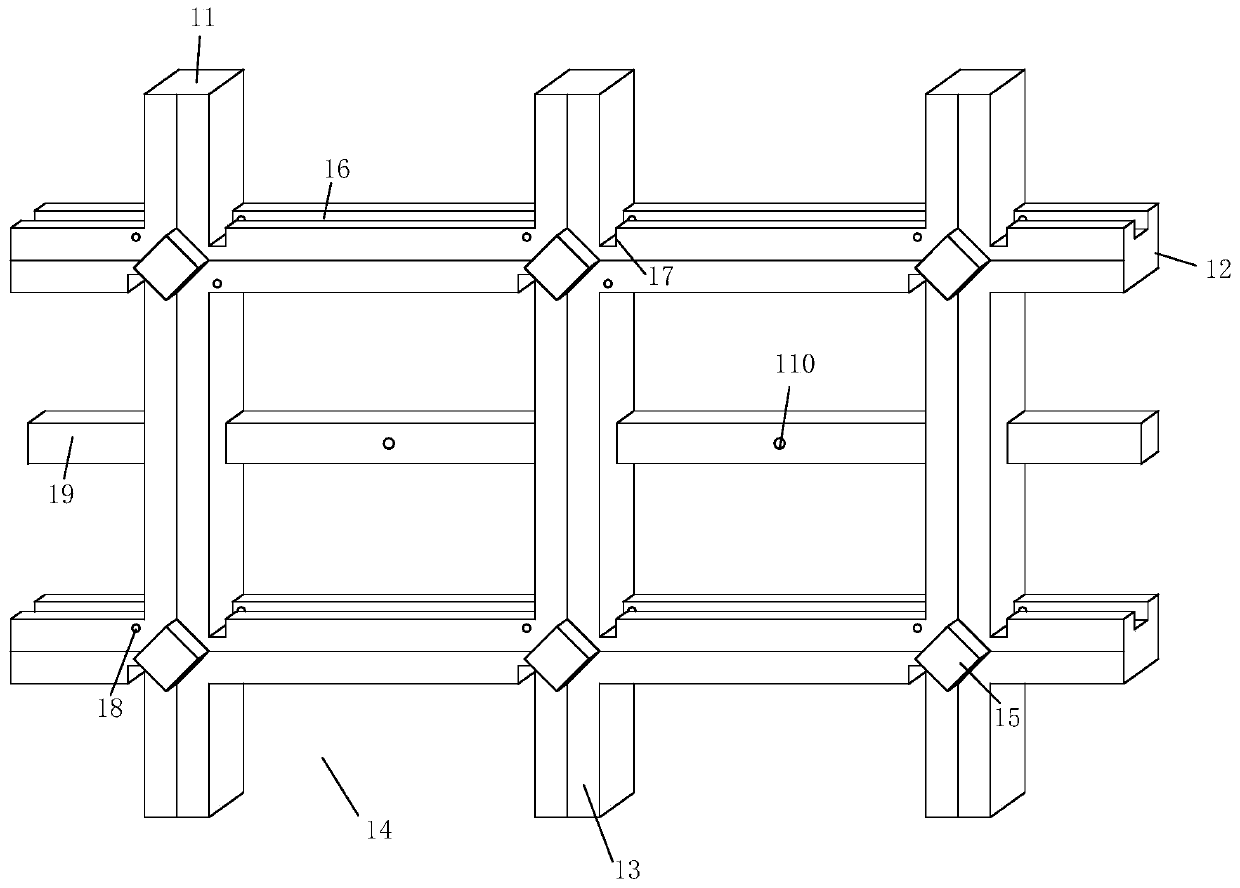

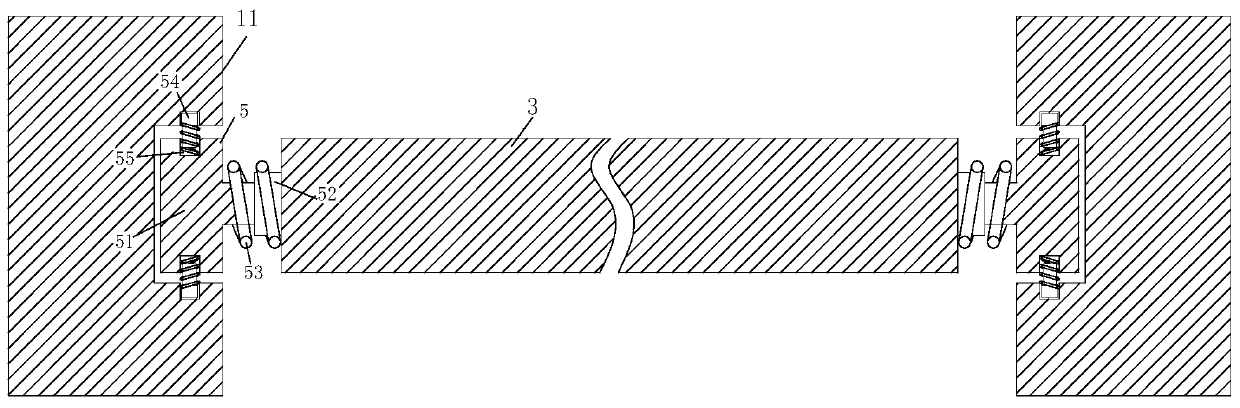

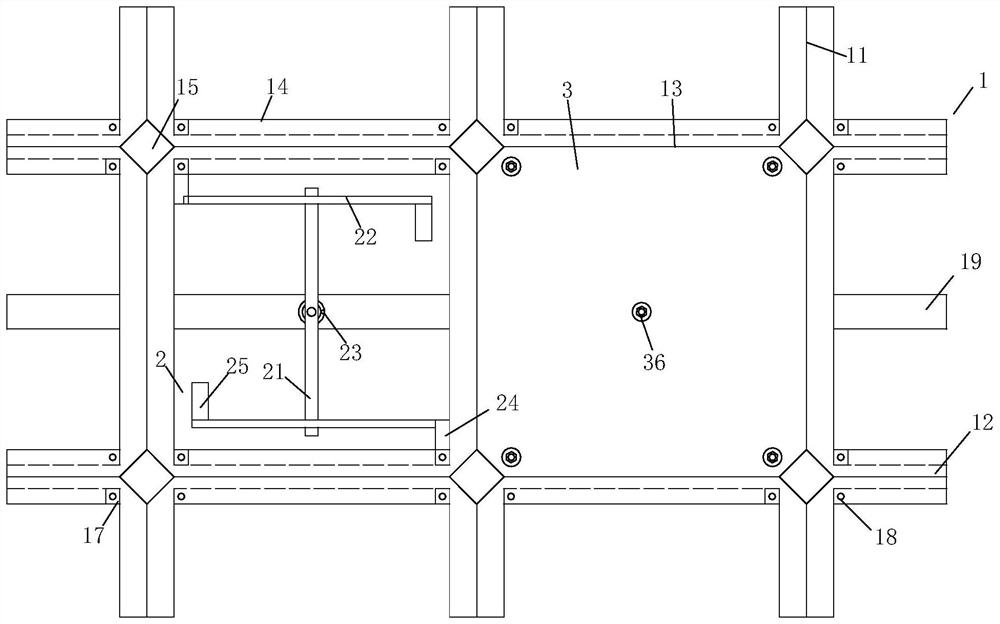

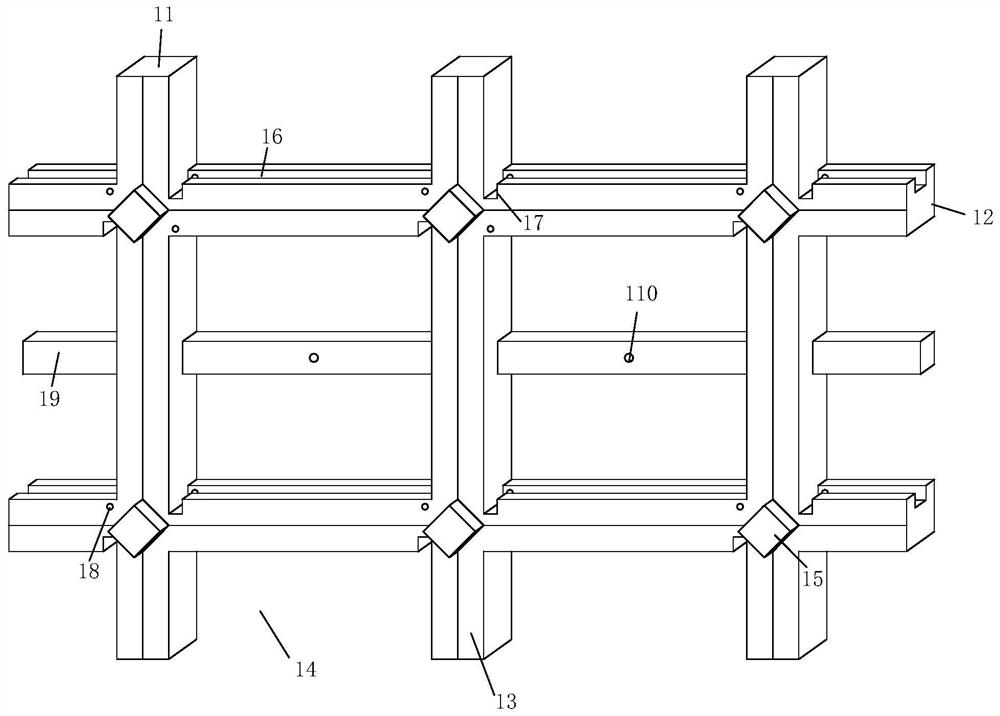

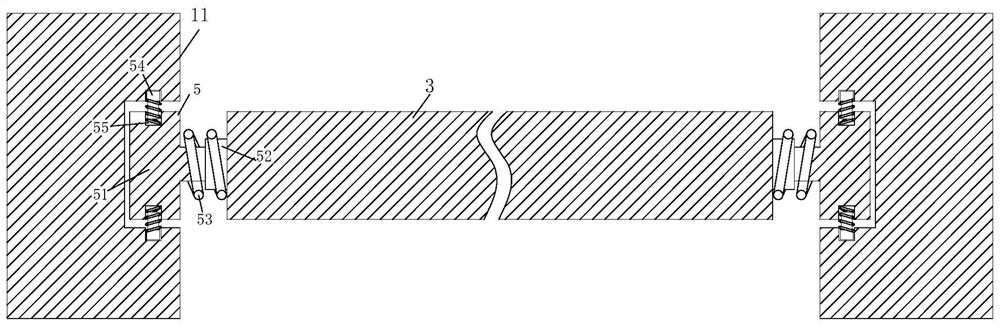

Assembly type steel structure outer wall

ActiveCN111287349AAlignment accuracy and convenienceImprove water resistanceWallsExternal claddingMechanical engineering

The invention relates to the field of assembly type outer walls, in particular to an assembly type steel structure outer wall. The assembly type steel structure outer wall comprises a supporting assembly, a connecting assembly, a steel structure outer wall plate outer assembly and a steel structure outer wall plate inner assembly, the connecting assembly, the steel structure outer wall plate outerassembly and the steel structure outer wall plate inner assembly are mounted in the supporting assembly, through the connecting assembly, a limiting sliding strip can be inserted into an inserting groove, a steel structure wall plate is pressed into a groove, the limiting sliding strip slides into a limiting sliding groove, connection between a steel structure wall plate and the supporting assembly can be finished, position dividing convex blocks are mounted on the four corners of the wall plate, when the wall plate is mounted, alignment is more precise and portable, during mounting, the wallplate can be fixed through bolts without manual holding of the wall plate, and work efficiency can be greatly improved.

Owner:四川海聚环保科技有限责任公司

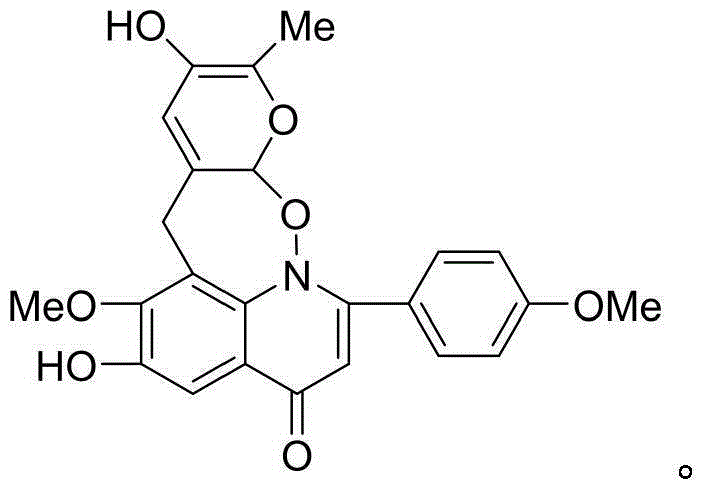

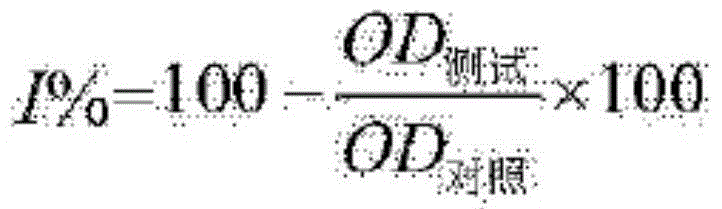

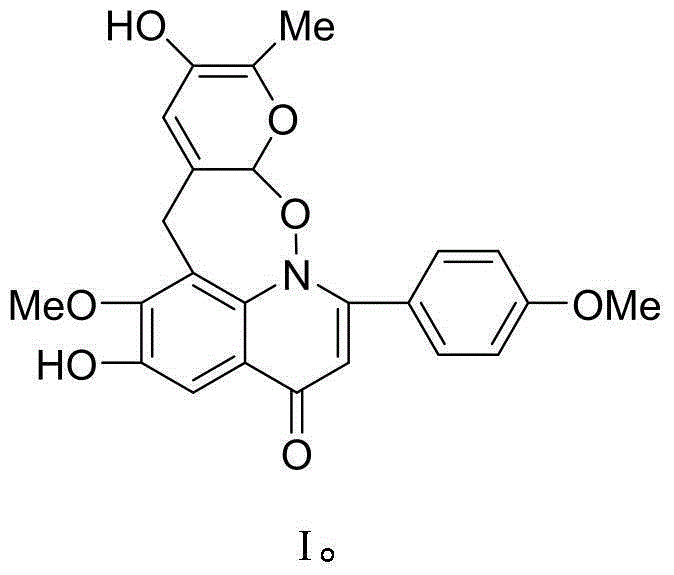

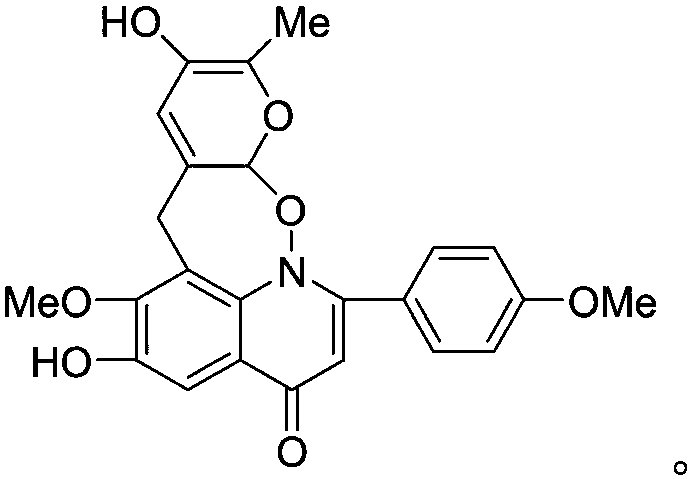

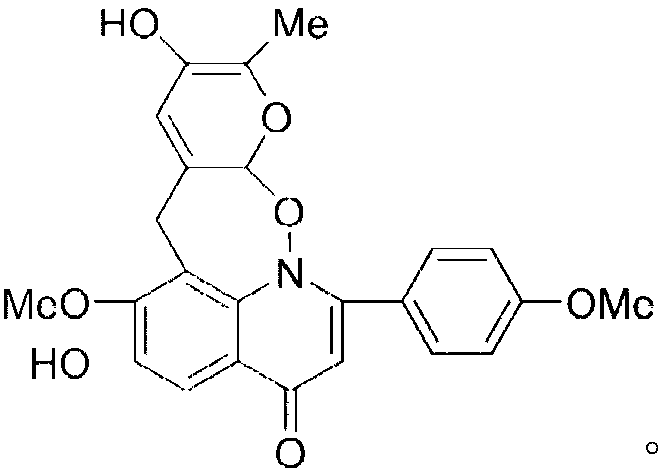

Nail polish with sequins, laser powder and rhinestone powder

ActiveCN105816354AGood moisturizing effectImprove water resistanceCosmetic preparationsAntimycoticsCross-linkMethyl cellulose

The invention relates to a nail polish with sequins, laser powder and rhinestone powder. The nail polish comprises, by weight, 48 to 52 parts of deionized water, 22 to 25 parts of polyurethane-35, 16 to 17 parts of acrylic acid / VO cross-linked polymer, 4 to 5 parts of hydroxypropyl methyl cellulose, 0.9 to 1.5 parts of triethanolamine, 0.7 to 0.8 part of laurinol polyether-21, 0.01 to 0.05 part of a compound as shown in a formula I, 0.9 to 3 parts of mica, 0.08 to 2 parts of glycerin and 1 to 3 parts of a mixture of sequins, laser powder and rhinestone powder. The nail polish is environment-friendly and nontoxic, poses no harm to the human body and no pollution to the environment and has a brilliant color.

Owner:LES FINS NETWORK TECH

An assembled steel structure exterior wall

ActiveCN111287349BAlignment accuracy and convenienceImprove water resistanceWallsClassical mechanicsExternal cladding

The present invention relates to the field of fabricated exterior walls, in particular to a fabricated steel structure exterior wall, comprising a support assembly, a connection assembly, an exterior assembly of a steel structure exterior wall panel and an interior assembly of a steel structure exterior wall panel, the connection assembly , the outer component of the steel structure exterior wall panel and the inner component of the steel structure exterior wall panel are all arranged inside the support component. Through the provided connection components, insert the limit slide bar into the slot, press the steel structure wall panel to the inside of the groove, and slide the limit slide bar to the inside of the limit chute, so that the steel structure wall panel and The connection between the support components is completed, and the set dividing protrusions are located at the four corners of the wall panel, which can make the alignment of the wall panel more accurate and convenient during installation. During installation, the bolts can be used to align the wall panel with the wall panel. The board is fixed, which greatly improves the work efficiency.

Owner:四川海聚环保科技有限责任公司

Nanometer mildewproof coating for woodware

InactiveCN108373701AGood extensibilityGood color retentionAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention discloses a nanometer mildewproof coating for woodware. The nanometer mildewproof coating comprises, by weight, 40-50 parts of an aqueous acrylic emulsion, 30-40 parts of a fluorinated emulsion, 15-20 parts of water-based polyurethane, 5-8 parts of a nanoparticle reinforcing agent, 8-12 parts of nano-silica, 4-7 parts of a mildewproof anti-bacterial agent, 3-7 parts of stone-like particles, 3-5 parts of an aliphatic curing agent, 0.6-0.9 parts of a dispersing agent, and 1-3 parts of a nanometer amphiphobic agent. The nanometer mildewproof coating has good antibacterial and sterilization properties and can kill bacteria and pathogens attached to the coating. The nanoparticle reinforcing agent and stone-like particles can effectively improve the flame retardancy, compatibilityand environmental protection performances of the transparent coating. The nanometer mildewproof coating has excellent stain resistance, adhesion and wear resistance, has no activation period and lessorganic volatilization, and has good elongation performances, large tensile strength and strong color retention ability.

Owner:青岛国福实业有限公司

Ink solvent for glass inkjet printing

The invention relates to the technical field of jet printing, and discloses an ink solvent for glass inkjet printing, which is used for dissolving and / or swelling pigment. The ink solvent is preparedfrom resin, fuel and silicate, wherein the resin is used for immobilizing pigment onto glass; the fuel is used for carrying the pigment; the silicate is heated to be melted and softened so as to position ink on the glass; the solution which has fluidity and can be sprayed is formed. The ink solvent has the advantages that under the heating condition, the silicate molecules in the ink and the silicon dioxide or silicate molecules at the glass surface mutually disperse and permeate via the molecule thermal movement; in the heating process, the fuel for carrying the pigment can generate flash burn and produce heat, the temperature at the ink layer and glass surface is further increased, the molecule thermal movement and mutual dispersion between the ink layer and the glass surface are promoted, the positioning and fixing of jet printing patterns are accelerated, the size deviation of the jet printing patterns on the surface of a glass plate is effectively decreased, and the size and position accuracy of the patterns on the surface of the glass plate is obviously improved.

Owner:万弋林

Purple vegetable dye

The invention belongs to the technical field of dyes, and particularly relates to a purple vegetable dye. The purple vegetable dye is prepared from, by weight, 60-100 parts of pterocarpus santalinus,30-50 parts of purple perilla, 30-50 parts of caulis spatholobi, 5-9 parts of mulberries, 6-9 parts of sodium sulfite, 5-10 parts of polydimethylsiloxane, 1 part of a color fixing agent and 1 part ofa dispersing agent. The dye prepared by mixing plant raw materials with chemical agents is very environment-friendly; after the dye is used, the skin of a human body is not damaged, the dye retains the plant smell, the dyed cloth has a plant fragrance, and the color is natural and bright; and the preparation method is simple, and the preparation cost of the traditional plant dye is greatly reduced. Nontoxic raw materials are adopted, so the purple vegetable dye is safe and environment-friendly, has good biological solubility and environmental compatibility, is especially non-irritant to humanbodies, is suitable for dyeing underwear fabrics, and has good color and luster degree and good color fixing effect.

Owner:黎平县侗品源旅游商品服务有限责任公司

Mortar exterior wall coating and preparation method

InactiveCN105295604AAdhesiveFrost-resistantAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceHydroxyethyl cellulose

The invention discloses a mortar exterior wall coating and a preparation method, wherein the mortar exterior wall coating comprises components with weight proportion: water 18 parts, hydroxyethyl cellulose 0.9 part, calcium carbonate 6 parts, acrylic polymer latex paints 39 parts, ethylene glycol 1.1 parts, defoamers 0.6 part, ammonia water 0.4 part, preservatives 0.07 part, dispersants 0.7 part, 80 meshes silica sands 88 parts, titanium dioxide 6 parts, talcum powder 8 parts and heavy calcium carbonate 11 parts. The mortar exterior wall coating and the preparation method can be used to press and wipe building exterior walls of stadiums, cultural palaces, residences, grogshops, schools and hospitals and the like, has the advantages of excellent environmental protective performance, simple construction, simple process, no pollution, no toxicity and no flavor and the like, and has the characteristics of strong adhesive force, frost resistance, strong corrosion resistance, gloss retention, color retention, strong weatherability, mold prevention and algae resistance and the like.

Owner:景晓丽

Special paper for print and preparation method thereof

PendingCN112376314AStrong color retentionLong storage timeWater-repelling agents additionPulp beating methodsPapermakingHollander beater

The invention discloses a preparation method of special paper for a print. The preparation method comprises the following steps of: pulping clear water, paper mulberry bark pulp, wood pulp and an AKDsizing agent in a pulping machine, standing, and controlling water to obtain raw material pulp; enabling the weight ratio of the broussonetia papyrifera bark dry pulp to the wood pulp is 7-9: 1-3, andenabling the weight of the AKD sizing agent to be 0.2-0.5% of the weight of the broussonetia papyrifera bark dry pulp; and adding the raw material pulp into a papermaking tank to prepare pulp with the mass concentration of 12-17%, adding a first part of dispersing agent solution, stirring, adding a second part of dispersing agent solution, stirring to obtain papermaking pulp, carrying out papermaking manually, pressing paper and drying the paper, wherein the papermaking comprises three times of papermaking, papermaking pulp is splashed within 2 seconds after being beaten during the first timeof papermaking, the papermaking pulp is shaken for 20-25 times after being beaten and excessive papermaking pulp is splashed during the second time of papermaking, and during the third time of papermaking, an angle of 30 degrees is formed between the back surface of a papermaking device and the liquid level of the papermaking pulp, and the papermaking pulp is shaken for 20-25 times back and forth, shaken for 10-15 times left and right and then shaken for 20-25 times front and back.

Owner:黄山市凝霜文化发展有限公司

Preparation method of antiskid and wear-resistant colored asphalt concrete

The invention discloses a preparation method of an antiskid and wear-resistant colored asphalt concrete. The preparation method comprises the following three steps: firstly, putting steel slag, brokenstone, asphalt and mineral powder into a mixing pot according to a sequence and proportion, mixing, compacting and molding to prepare steel slag concrete; secondly, uniformly stirring epoxy resin, acuring agent, rock asphalt, TiO2, a coloring agent, a diluent, water, a dispersing agent and an emulsifying agent according to a sequence and a proportion to prepare colored spraying; and finally, spraying the colored epoxy coating to the surface of the asphalt concrete. The skid resistance, the wear resistance and the color retention performance of the prepared colored asphalt concrete are remarkably improved, and the application effect in special road sections such as bus lanes is good.

Owner:SHANGHAI MARITIME UNIVERSITY

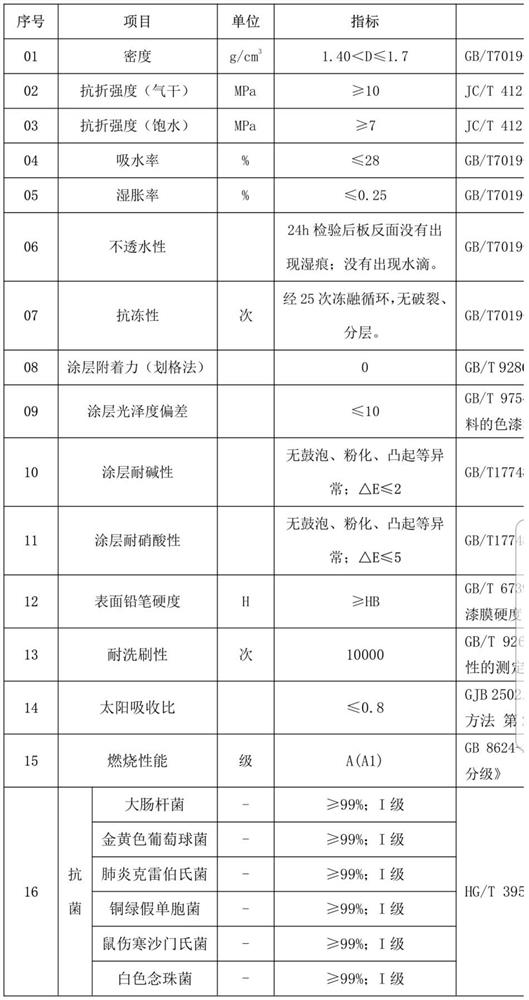

Ecological wall membrane plate and heat transfer printing preparation method

ActiveCN112608628AGood weather resistanceStrong color retentionFireproof paintsAntifouling/underwater paintsCelluloseSilicic acid

The invention relates to an ecological wall membrane plate and a heat transfer printing preparation method. The ecological wall membrane plate is prepared from a high-curing component transfer printing coating material and a curing agent through heat transfer printing curing, wherein the mass percentage ratio of the high-curing component transfer printing coating material to the curing agent is 3-5:1, the high-curing-component transfer printing coating material is prepared from the following substance components in percentage by weight: 25-30% of silica powder, 15-25%of kaolin, 15-25% of muscovite powder, 0.2-0.3% of magnesium aluminum silicate, 0.1-0.2% of polymer cellulose, 0.15-0.25% of preservative, 0.4-0.6% of a dispersing agent, 0.15-0.25% of a wetting agent, 0.6-0.8% of a defoaming agent and the balance of clean water, wherein the sum of the mass percentages of the components is 100%. The ecological wall membrane platehas the outstanding substantive characteristics and remarkable progress that the film forming temperature is low, the fast-paced transfer printing requirement of mechanical equipment is met, and the like.

Owner:佛山市顺德区清大润彩涂料有限公司

Emulsion used for gloss latex coating

InactiveCN109423091AHigh glossStrong color retentionEmulsion paintsSodium bicarbonateDodecylsulfonic acid

The invention relates to an emulsion used for gloss latex coating. The emulsion comprises the following components in parts by mass: 416 parts of vinyl acetate, 24 parts of butyl acrylate, 2.4 parts of acrylic acid, 5.7 parts of TX-10, 3.7 parts of sodium dodecyl sulfate, 1.4 parts of ammonium persulfate, 2.9 parts of sodium polymethacrylate, 6.9 parts of sodium bicarbonate, 537 parts of distilledwater and a proper amount of ammonia water. The invention has the beneficial effects of low cost, greenness, environment friendliness, good gloss, high color retention property, high drying speed, convenient construction and good ageing resistance.

Owner:中山市智博企业管理咨询有限公司

Manufacturing process and application process of wall surface decoration coating material

The present invention relates to a manufacturing process and an application process of a wall surface decoration coating material. The manufacturing process comprises: mixing 3.3 kg of water, 50 g of cellulose HPMC, 125 g of a styrene-acrylic emulsion and 10 ml of a whitening liquid to prepare a mixed liquid A for spare; mixing 550 g of water and 150 g of corn starch to prepare a mixed liquid P, mixing 260 g of water and 30 g of caustic soda to prepare a mixed liquid Q, and mixing the mixed liquid P and the mixed liquid Q to prepare a mixed liquid B for spare; mixing 2.3 kg of ash calcium, 6 kg of calcium carbonate and 125 g of bentonite to prepare mixed powder C for spare; and uniformly mixing the mixed liquid A, the mixed liquid B and the mixed powder C so as to obtain the coating material matrix. According to the present invention, the manufacturing process is simple, the cost is stable and reliable, the effect of the ceramic tile can be achieved through the coating material coating, the wall surface decoration cost is effectively reduced, water washing thousands of times can be achieved, the pressing calendaring is easy and rapid, and the coating material is the ideal wall surface decoration coating material.

Owner:安庆余

A method of a phenyl -bonacharin anhydride distillation of heavy -quality residual liquid to prepare alcoholic acid resin

ActiveCN111004374BImprove performanceEasy to mass manufacturePolyester coatingsBenzeneOrganic solvent

The invention belongs to the technical field of fine chemicals, and specifically relates to a method for preparing alkyd resin based on trimellitic anhydride rectification heavy raffinate, the reaction of trimellitic anhydride rectification heavy raffinate, monohydric alcohol and catalyst in a molten state, through a water separator Separate the water phase to obtain the monohydric alcohol esterification product of trimellitic anhydride rectification heavy raffinate. After the acid value meets the requirements, lower the temperature, add organic solvent and water, stir and mix evenly, then stand still, drain the water phase, and recover the reaction product through the rectification separation column. Solvent and monohydric alcohol, start the vacuum pump, distill out the reacted polyhydric alcohol in the reaction liquid, add organic solvent, stir and mix evenly to obtain the alkyd resin product. The preparation process of the present invention is simple and has high productivity, which is conducive to the batch preparation of high-performance alkyd resins. The polybasic acid in the heavy residual liquid of trimellitic anhydride rectification is used as a raw material to reduce the production cost of the product alkyd resin, improve economic benefits, and make the product have a strong price advantage.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

A finger color added with glitter flakes, laser powder, and artificial diamond powder

ActiveCN105816354BGood moisturizing effectImprove water resistanceCosmetic preparationsAntimycoticsCelluloseMeth-

The invention relates to a finger color added with glitter, laser powder and artificial diamond powder, comprising: 48-52 parts by weight of deionized water, 22-25 parts by weight of polyurethane-35, and 16-17 parts by weight of acrylic acid / VP cross-linked polymer, 4-5 parts by weight of hydroxypropyl methylcellulose, 0.9-1.5 parts by weight of triethanolamine, 0.7-0.8 parts by weight of laureth-21, 0.01-0.05 parts by weight of formula Compound I, 0.9-3 parts by weight of mica, 0.08-2 parts by weight of glycerin; 1-3 parts by weight of glitter, laser powder and synthetic diamond mixture. The invention is environmentally friendly, non-toxic, harmless to human body, non-polluting to the environment, and bright in color.

Owner:LES FINS NETWORK TECH

A kind of ecological wall film plate and heat transfer printing preparation method

ActiveCN112608628BGood weather resistanceStrong color retentionFireproof paintsAntifouling/underwater paintsCelluloseFiber

Owner:佛山市顺德区清大润彩涂料有限公司

Luban stone coating system and construction method thereof

InactiveCN109667398AStrong Grainy TextureDecorative effect with strong granular textureCovering/liningsCoatingsCrack resistanceWeather resistance

The invention discloses a luban stone coating system and a construction method thereof. According to the invention, pure 10 to 20-mesh high-temperature calcined sand is used as an aggregate, and aggregate sand is sprayed onto a luban stone bonding intermediate coating layer by adopting a special sand spraying gun, so that a strong particle textured decoration effect is achieved; the luban stone bonding intermediate coating layer is prepared from a pure acrylic emulsion combined with an inorganic weather-proof pigment, a filler and an accessory ingredient so as to have relatively strong cohesive property and flexibility, strong ability of sticking sand, crack resistance, water resistance and capability of providing a ground color; a paint filler layer adopts a Xiaguang anti-cracking putty for an exterior wall so as to be easy to construct, good in water resistance, resistant to crack, easy in levelling, and combined with rigidity and flexibility; a prime coat is a Xiaguang alkali-resistant sealing primer so as to have the characteristic of alkali-resistant sealing; and a finish-coat paint layer is a Xiaguang acrylic silicon finish coat painting layer so as to have the characteristics of pollution resistance, water resistance, yellowing resistance, and inner coating protection. To sum up, according to the invention, the texture is strong; the granular sensation is strong; the sand is calcined purely at high temperature; the weather resistance and the color retention are good; the decoration effect is strong; and the crack resistance is good.

Owner:浙江厦光涂料有限公司

A formulation of thick elastic latex paint for exterior walls

InactiveCN102277052AHas the ability to resist dust accumulationAvoid accumulationEmulsion paintsWeather resistanceWollastonite

The invention discloses a formula of thick elastic latex paint for exterior walls, comprising: water, bactericide, dispersant, wetting agent, defoamer, propylene glycol, rutile titanium dioxide, 1250 mesh kaolin, 800 mesh heavy calcium, 800 mesh Mesh wollastonite powder, the above materials are dispersed at high speed and sand milled before adding film-forming aids, Fuchem238, Fuchem-361, fungicides, defoamers, AMP-95, polyurethane rheological additives, alkali swelling thickeners, water. The thick elastic latex paint for exterior walls produced has no cracking, aging resistance, weathering resistance, strong color retention, and saves materials.

Owner:刘朝红

Water-base fast-drying high gloss ambient crosslinking nail paint resin and preparation method thereof

InactiveCN101810548BLow in VOCsAvoid harmCosmetic preparationsToilet preparationsWater basedHazardous substance

The present invention relates to a water-base fast-drying high gloss ambient crosslinking nail paint resin and a preparation method thereof. The composition components comprise n-butyl acrylate, n-butyl methacrylate, methyl methacrylate, styrene, methacrylic acid, diacetone acrylamide, adipic dihydrazide, ammonium persulfate, emulsifier OP-10, emulsifier sodium dodecyl sulfate, ammonia and deionized water. After the resin is prepared into water-base nail paint (also called nail polish), the content of volatile organic compounds is less than 20 gram per liter, the nail paint does not contain harmful substances, such as triphenyl, formaldehyde and the like, has no poison and no smell, is harmless to human bodies and has no pollution to the environment, short drying time, strong adhesion and water resistance, high brightness of the paint film, bright color and strong color retention, as the solid content of the resin is high, the paint film thickness of thin painting is guaranteed, the surface is full and smooth, and the resin is an environmental-friendly product which can protect human health and is a substitute of nitro-nail paint which is commonly used in market currently.

Owner:BEIJING CARL RES INST FOR CHEM IND

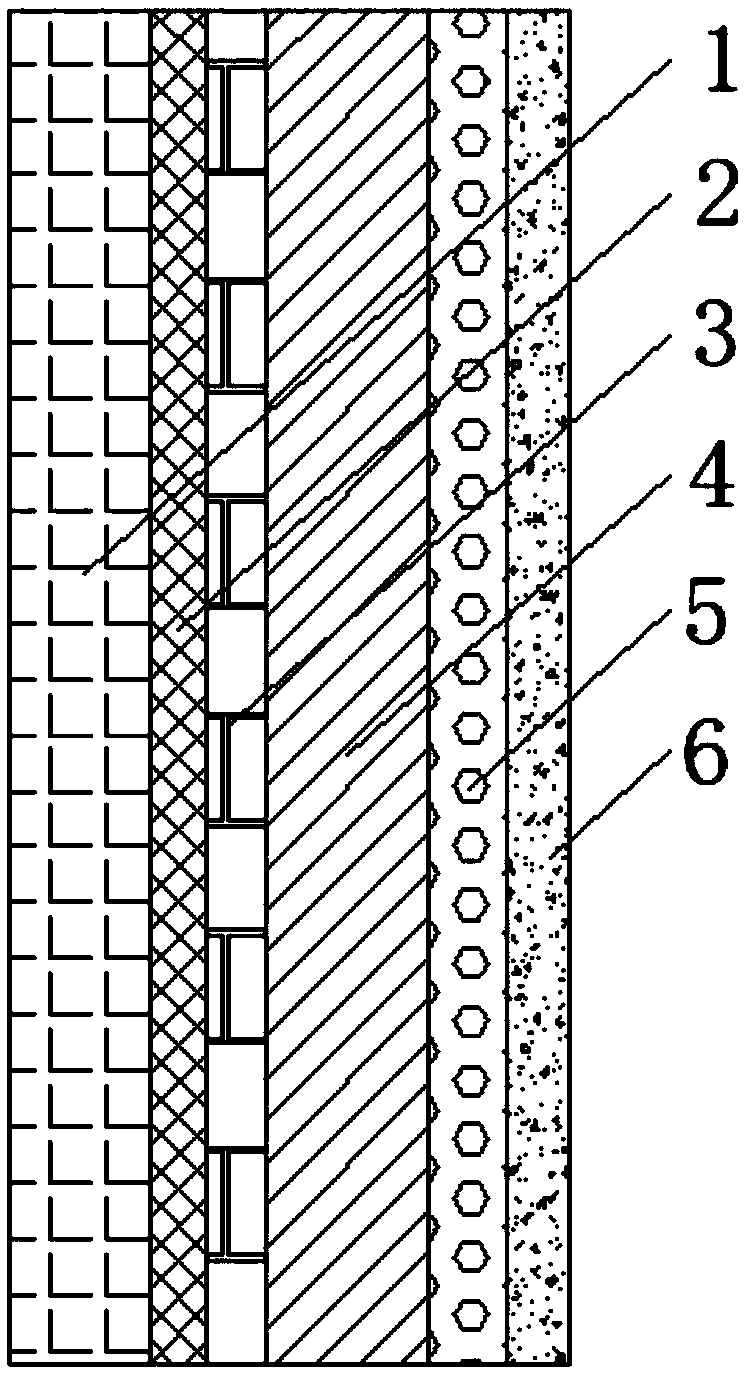

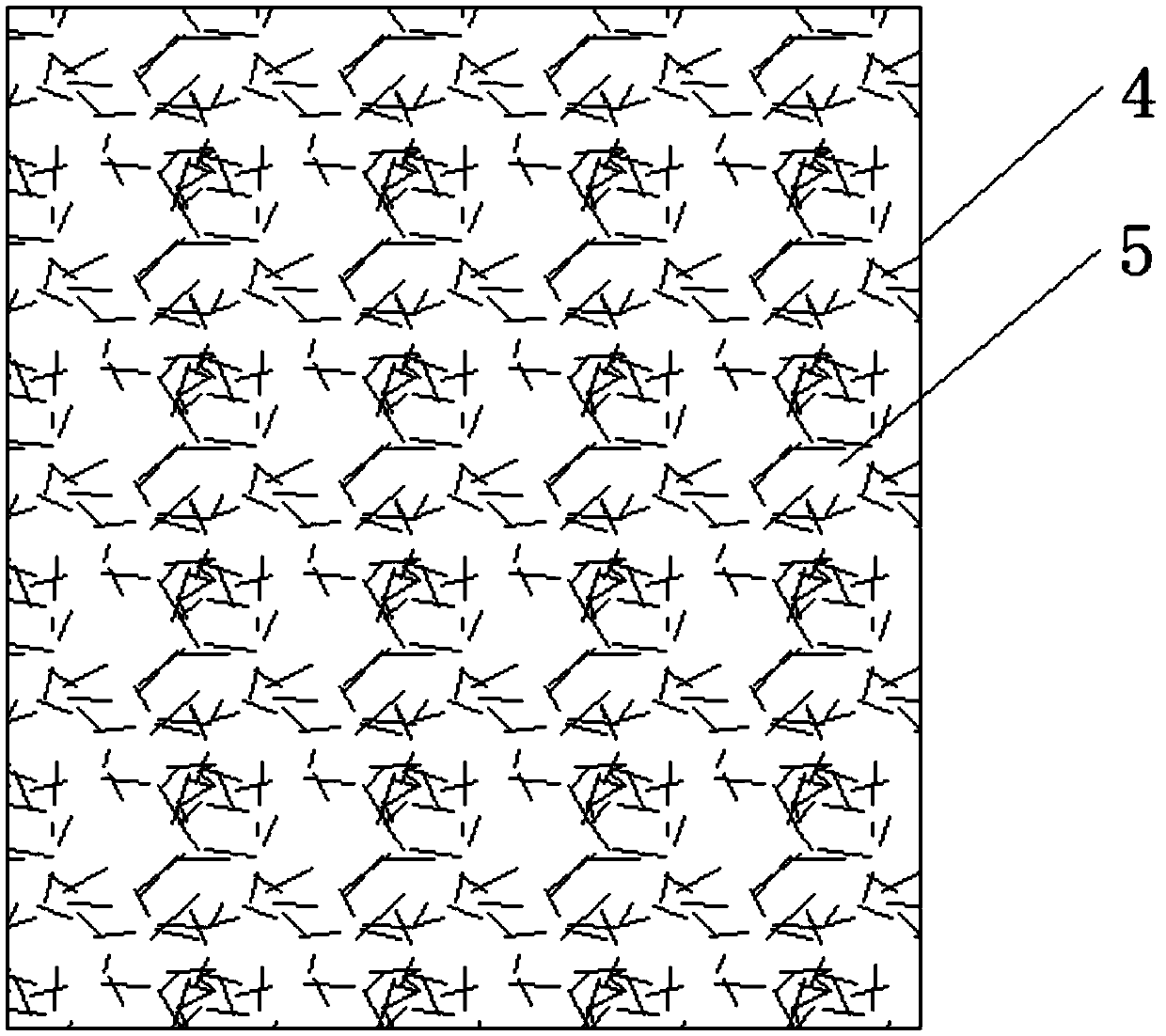

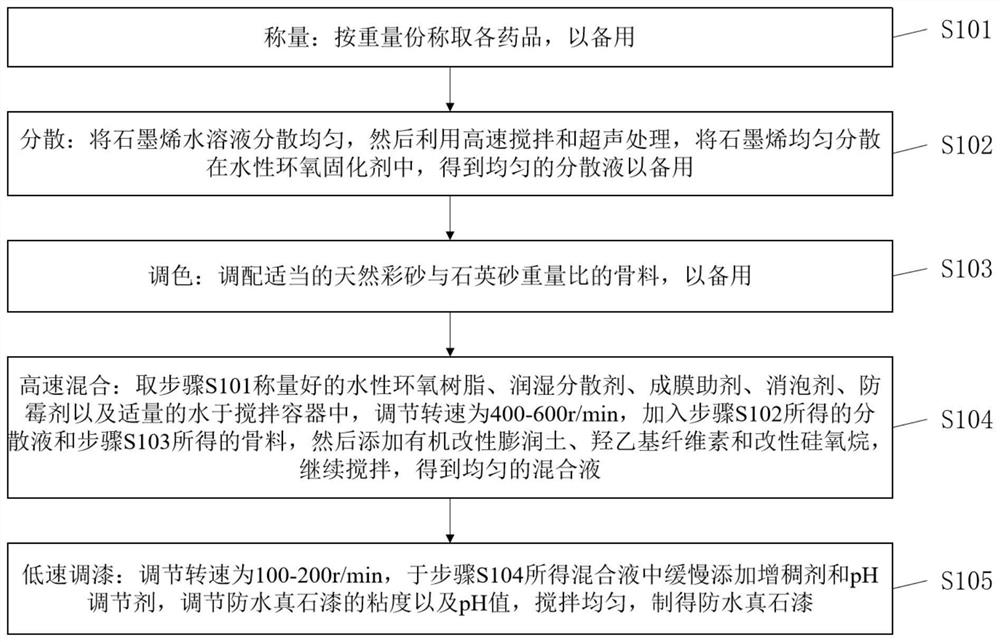

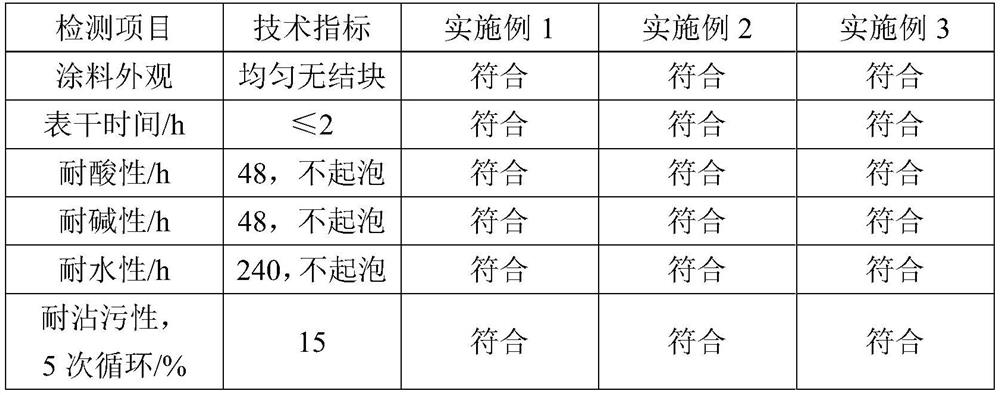

Waterproof stone-like coating and preparation method thereof

InactiveCN113563747AImprove shielding effectImprove water resistanceCoatingsCellulosePolymer science

The invention relates to the technical field of building decoration materials, in particular to a waterproof stone-like coating. The stone-like coating is prepared from the following ingredients in parts by weight: 15 to 35 parts of waterborne epoxy resin, 3 to 15 parts of a waterborne curing agent, 5 to 18 parts of graphene, 80 to 120 parts of aggregates, 15 to 20 parts of organic modified bentonite, 10 to 25 parts of hydroxyethyl cellulose, 0.5 to 2 parts of modified siloxane, 0.5 to 1.5 parts of a wetting dispersant, 1 to 4 parts of a coalescing agent, 0.5 to 0.8 part of a defoaming agent, 0.5 to 1.2 parts of a thickening agent, 0.5 to 1.5 parts of a mildew preventive, 0.5 to 3 parts of a pH regulator and a proper amount of water, wherein the aggregate is composed of natural colored sand and quartz sand according to a weight ratio of (1-3): (1-2), the particle size of the natural colored sand is 40-80 meshes, and the particle size of the quartz sand is 80-120 meshes. The invention also provides a preparation method of the waterproof stone-like coating. The waterproof stone-like coating is greatly enhanced in water resistance, weather resistance and stain resistance, so the development and application of the stone-like coating are promoted.

Owner:安徽朗凯奇科技股份有限公司

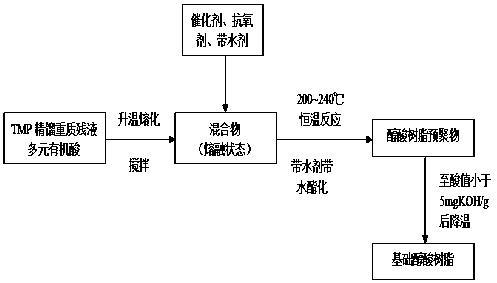

A kind of method for preparing alkyd resin based on tmp rectification heavy raffinate as raw material

The invention discloses a method for preparing alkyd resin by taking TMP rectified heavy residual liquid as a raw material. The method is characterized by being conducted according to the following steps that the raw material-TMP rectified heavy residual liquid raw material, polybasic organic acid, an acid catalyst and a water carrying agent are added into a reactor or added with an antioxidant, wherein an acid antioxidant or a phosphite antioxidant is adopted as the antioxidant; the temperature of the reactor is slowly increased, stirring starts after the raw material is fused, a constant-temperature reaction is conducted for 4-6 h after the temperature reaches a set reaction temperature of 200 DEG C to 240 DEG C; sampling is conducted every 55-65 min, the acid value of a reaction system is measured, and an alkyd resin prepolymer is obtained; the acid value of the reaction system needs to be controlled to be smaller than 5 mgKOH / g, and after the acid value meets the requirement, heating stops at once; after the temperature is lowered to the set 100+ / -5 DEG C, an organic solvent is added, after the liquid is stirred and mixed to be uniform, discharging is conducted, and then the alkyd resin product is obtained. The method is beneficial for protecting the environment and preparing the alkyd resin which has the cost performance advantage and the high performance in a batched mode.

Owner:江西高信前沿科技有限公司 +1

Broussonetia papyrifera bark paper and processing method thereof

PendingCN112411237APure and tough paperWhite and smooth colorSpecial paperWashing/displacing pulp-treating liquorsPapermakingRaw material

The invention discloses a processing method of broussonetia papyrifera bark paper. The processing method comprises the following steps: washing, wringing and picking steamed and bleached broussonetiapapyrifera bark to obtain broussonetia papyrifera bark dry pulp; mixing the broussonetia papyrifera bark dry pulp, warm water of 60-65 DEG C and a surfactant, conducting pulping, conducting standing,and conducting cleaning with clear water to obtain raw material pulp; naturally draining water in the raw material pulp, adding the raw material pulp into a papermaking tank filled with water, addinga dispersing agent solution, and conducting uniform stirring to obtain papermaking pulp; carrying out manual papermaking on the papermaking slurry to obtain wet paper, wherein the papermaking comprises three times of papermaking, the first time of papermaking comprises the steps of directly conducting spilling after papermaking, the second time of papermaking comprises the steps of conducting shaking front and back for 25-30 times after papermaking, and the third time of papermaking comprises the steps of conducting shaking front and back for 20-25 times, conducting shaking left and right for15-20 times, then conducting shaking front and back for 15-20 times after papermaking, and splitting out remaining papermaking pulp; and neatly loading obtained wet paper into a paper pressing machinefor paper pressing, and conducting drying to obtain the broussonetia papyrifera bark paper.

Owner:黄山市凝霜文化发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com