Preparation method of antiskid and wear-resistant colored asphalt concrete

A technology of asphalt concrete and colored asphalt, which is applied in coatings, epoxy resin coatings, etc., can solve the problems of insufficient wear resistance and anti-skid performance of colored pavements, achieve rich raw materials, strong anti-skid performance, and improve anti-skid performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In order to verify the feasibility of the present invention, an embodiment of anti-slip and wear-resistant colored asphalt concrete is provided here.

[0028] Step 1, preparing steel slag asphalt mixture. Prepare the following raw materials, based on 100 parts of total weight, the weight ratio of each raw material is as follows: 5 parts of asphalt, 28 parts of steel slag, 58 parts of crushed stone (20 parts of 0-3mm crushed stone, 10 parts of 3-5mm crushed stone, 28 parts of 5-10mm gravel), 9 parts of mineral powder. Among them, SBS asphalt is selected as asphalt; electric furnace slag with a particle size of 5-10mm is screened by shaking method for steel slag; limestone is used for 0-3mm crushed stone, and basalt is selected for 3-5mm and 5-10mm crushed stone. Raise the temperature of the asphalt to 160-170°C and maintain for 4-6 hours; raise the temperature of the stone to 170-180°C, raise the temperature of the steel slag to 180-200°C, and maintain for 5-8 hours; ra...

Embodiment 2

[0033] In order to verify the skid resistance of the present invention's anti-skid, wear-resistant colored asphalt concrete, it is necessary to measure BPN, that is, to evaluate the road surface skid resistance with a pendulum instrument, the larger the BPN, the stronger the road surface skid resistance, and the smaller the BPN. The weaker the anti-slip ability of the road surface. First, with reference to Example 1, form anti-skid, wear-resistant colored asphalt concrete and ordinary colored asphalt concrete, wherein the 5-10 mm gravel of ordinary colored asphalt concrete is basalt gravel, and 2% carbon black is used in the coating without adding steel slag and rock asphalt. Secondly, refer to the "Test Method for Measuring Pavement Friction Coefficient with Pendulum Instrument" in "Highway Subgrade Pavement Field Test Regulations" (JJG E60) to measure BPN, and compare the difference in anti-skid ability. Finally, the material differences between ordinary asphalt concrete an...

example 3

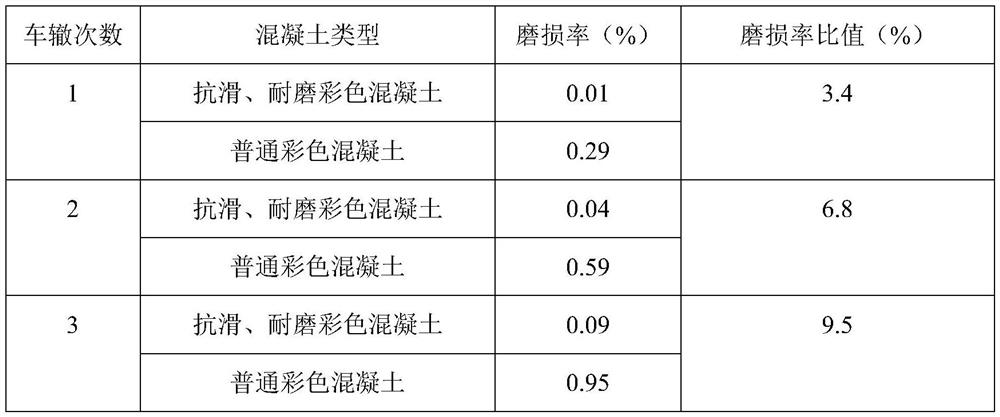

[0040]In order to verify the wear resistance of the anti-skid, wear-resistant colored asphalt concrete of the present invention, the anti-skid, wear-resistant colored asphalt concrete and ordinary colored asphalt concrete formed in Example 2 are used to carry out comparative tests. Carry out the rutting test (temperature is 20°C, compaction time is 2h) in the method of "Asphalt Mixture Rutting Test" (JTG E20-2011). "Test Method for Measuring Pavement Friction Coefficient with Pendulum Instrument" in "Measurement of Pavement Friction Coefficient" was used to measure BPN, and compare the difference in anti-skid ability after rutting wear. The table below shows the test results.

[0041] Table 3 Test results of BPN pendulum value after rutting wear

[0042]

[0043] As can be seen from Table 3, the BPN of the anti-skid and wear-resistant colored asphalt concrete of the present invention is always higher than the BPN of the ordinary colored asphalt concrete without steel slag;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com