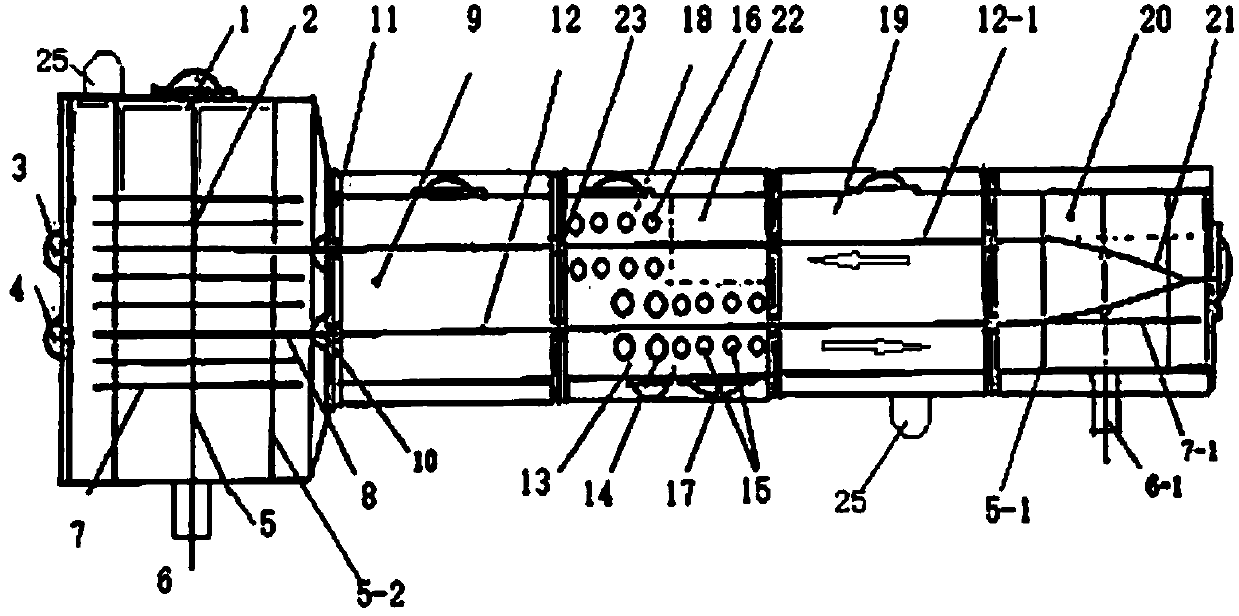

Metal plate film plating method and device

A metal plate, metal substrate technology, applied in metal material coating process, sputtering plating, ion implantation plating, etc., to achieve the effect of wide application range, fine ion plating and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

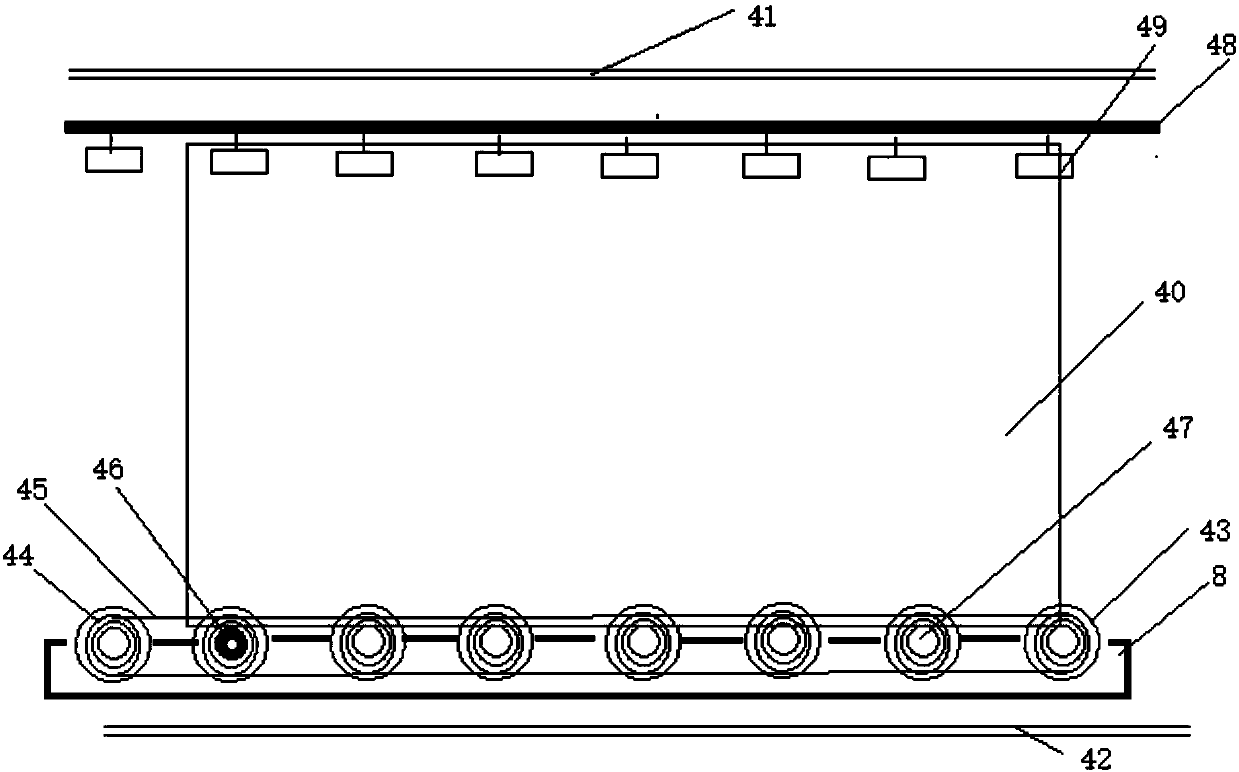

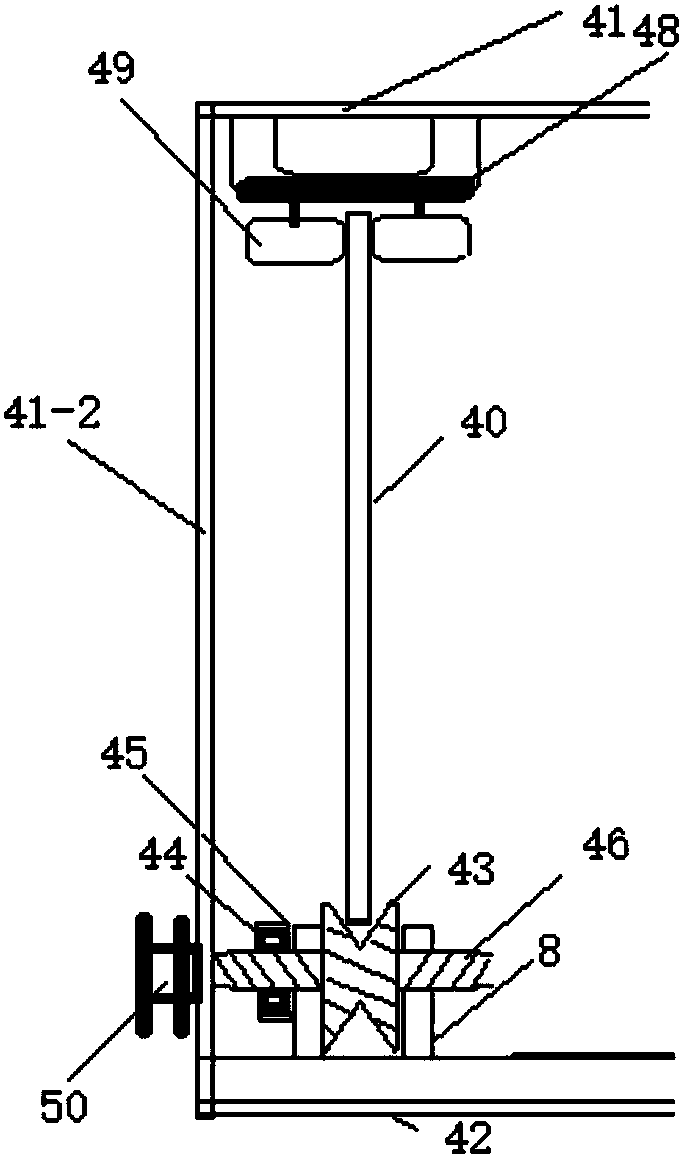

Method used

Image

Examples

Embodiment

[0049] Embodiment: Plating stainless steel plate 30 substrate, typically adopting 304 grade, thickness 1.5-8mm, commonly used is about 4-6mm, area is more than 2 square meters, the stainless steel plate substrate is first coated with a layer of titanium and chromium in the vacuum coating chamber , and then plated with 2 to 10 cycles of hard film coating of titanium 31 and carbide alloy 32 or titanium 31 and boride alloy 32, the total thickness is 2-8 microns, generally 5-6 microns, carbide alloy Or the boride alloy is sandwiched in the middle of the titanium transition layer, and the hard film coating has both hardness and toughness. The distribution of the target material will be different when there are two warehouses with the same capacity.

[0050] Hard film coating including titanium and chromium (nickel) and carbide alloy or titanium and boride alloy, the total thickness is 2-8 microns, carbide alloy or boride alloy is sandwiched between titanium transition layer, hard f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com