Square hole hollow type decorative sheet

A decorative board, hollow technology, applied in covering/lining, construction, building structure, etc., can solve the problems of affecting installation, poor fire resistance, low ignition point of bamboo and wood fibers, etc., to achieve easy cleaning, strong impact resistance, Physically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

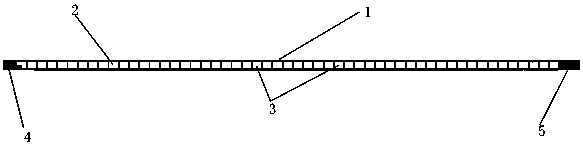

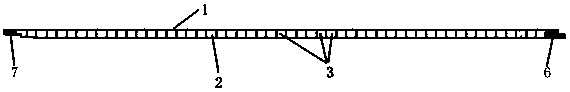

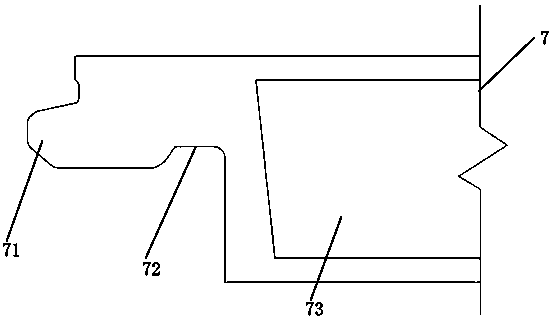

[0025] Such as Figure 2-4 As shown, according to the needs of customers, the processing end 5 of the male part of the reserved tenon and groove fixing part is processed as follows image 3 The male part 7 of the tongue-and-groove fixing part shown is processed into the processing end of the reserved female part of the tongue-and-groove fixing part as follows: Figure 4 In the female part 6 of the tongue-and-groove fastener shown, the male part of the tongue-and-groove fastener is locked with the female part of the tongue-and-groove fastener.

[0026] During the installation, one decorative board body is fixed on the decorative body first, and then multiple decorative board bodies are installed on the decorative body for decoration through the interlocking between the male part of the tongue-and-groove fixing part and the female part of the tongue-and-groove fixing part .

[0027] Such as image 3 As shown, the cross-sectional structure of the male part 7 of the tongue-and-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com