Discrete double rectangular gate controlled u-shaped channel source-drain double tunneling transistor and manufacturing method thereof

A technology of tunneling transistor and rectangular gate, which is applied to discrete double-rectangular gate-controlled U-shaped channel source-drain double tunneling transistor and its manufacturing field, can solve the problems of unidirectional switching, sub-threshold swing cannot be reduced, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further explained below in conjunction with the drawings:

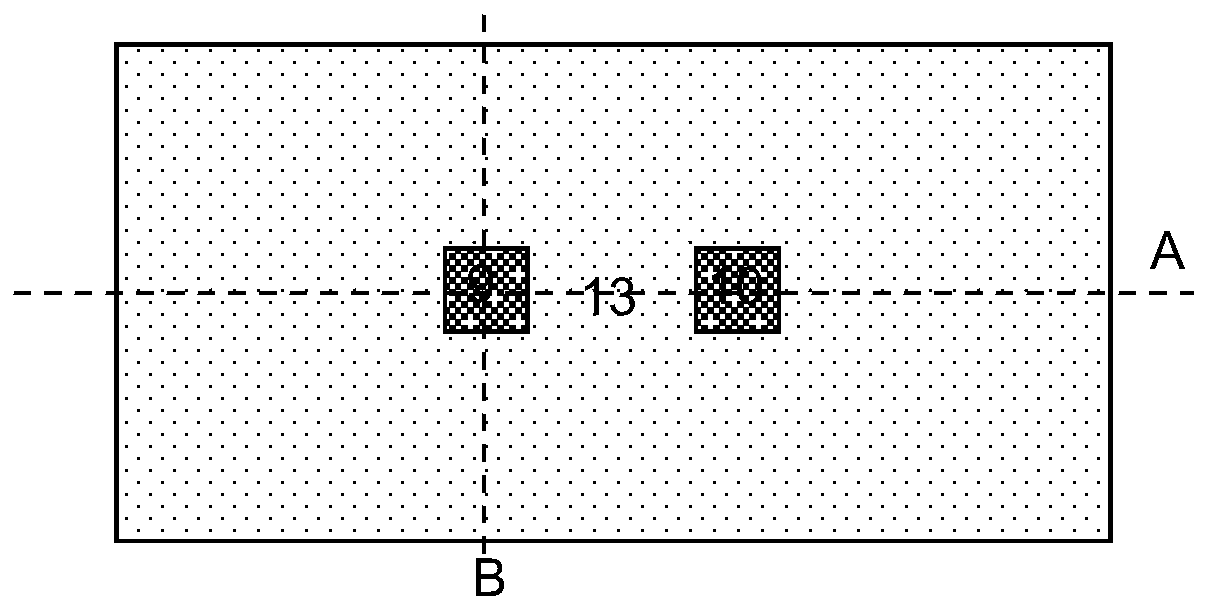

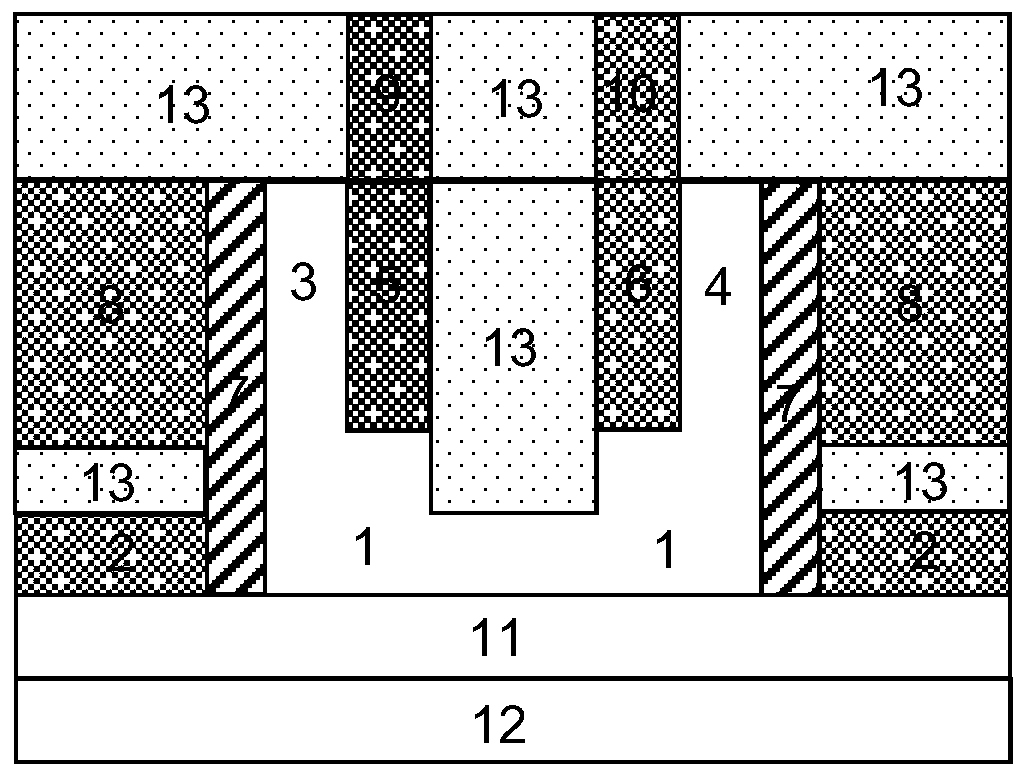

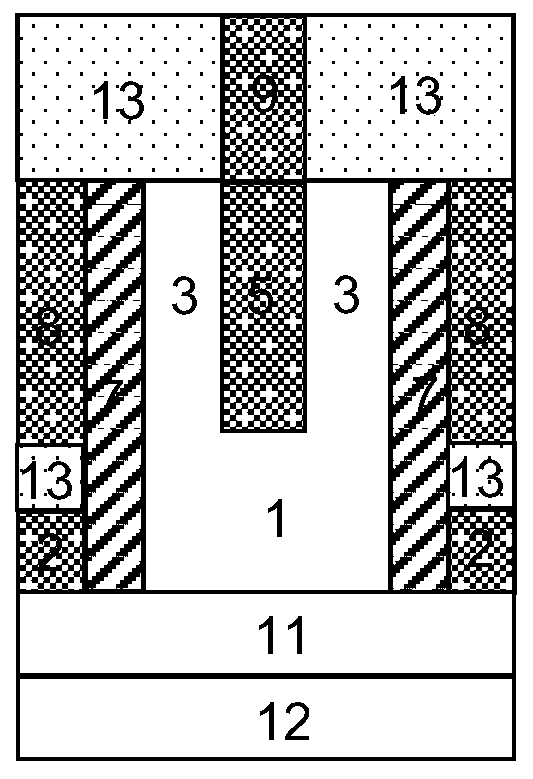

[0065] Such as figure 1 , figure 2 with image 3 As shown, a discrete dual rectangular gated U-shaped channel source and drain dual tunneling transistor includes a silicon substrate 12 of an SOI wafer, and the silicon substrate 12 of the SOI wafer is above the substrate insulating layer 11 of the SOI wafer Above the substrate insulating layer 11 of the SOI wafer is a part of the monocrystalline silicon film 1, the rectangular barrier control gate 2 and the insulating dielectric barrier layer 13. Among them, the monocrystalline silicon film 1 has an impurity concentration lower than 10 16 cm -3 The single crystal silicon semiconductor material has the characteristics of a U-shaped groove structure; the left and right sides of the vertical part of the U-shaped groove structure formed by the single crystal silicon film 1 are outside the gate electrode insulating layer 7, and the middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com