Anti-poisoning Pt-based nano-catalyst, and preparation method and application thereof

A catalyst, electrocatalyst technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as affecting catalyst ability, reducing active sites, reducing battery performance, etc., to achieve high catalytic performance and anti-poisoning properties, reducing CO poisoning problems, preventing agglomeration and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

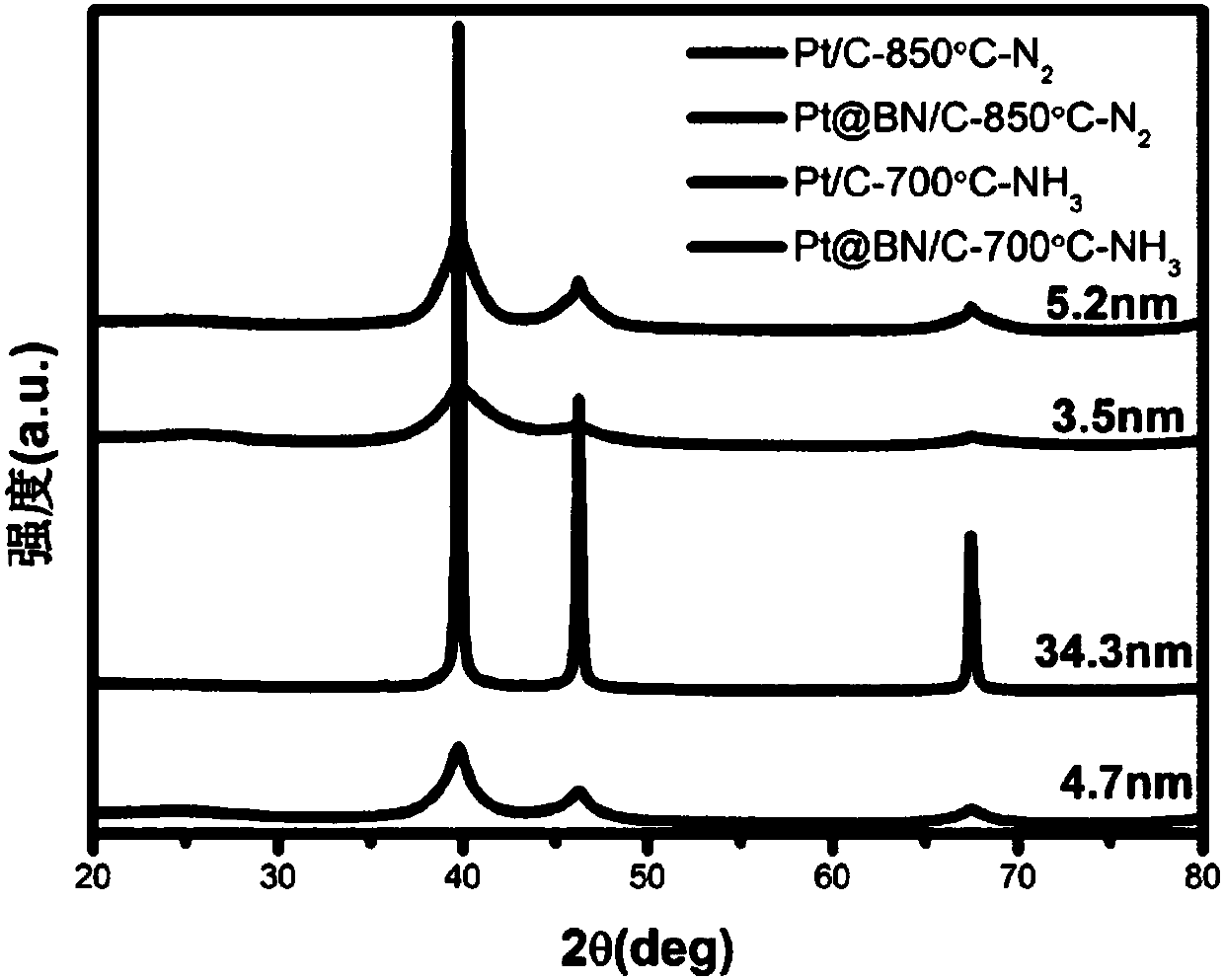

[0043] Dissolve 0.3827g ammonia borane with 10ml of anhydrous diglyme, under Ar protection condition, ammonia borane solution is added to the there-necked flask that 0.3013g 37wt.%Pt / C catalyst (TKK) is housed, wherein B / The atomic ratio of Pt was 20:1, reacted at 140°C for 3h, then centrifuged to remove the supernatant, dried at 60°C for 72h, and placed the sample in NH 3 Nitriding treatment at 500 or 700 degrees in the atmosphere for 2 hours to obtain Pt 1 @(BN) 20 / C core-shell structure nanocatalytic materials.

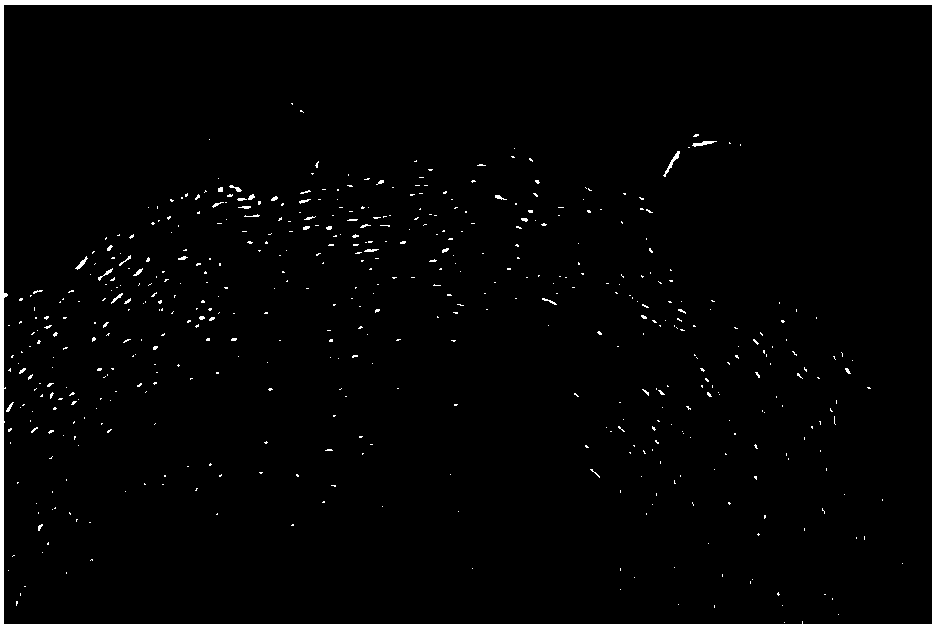

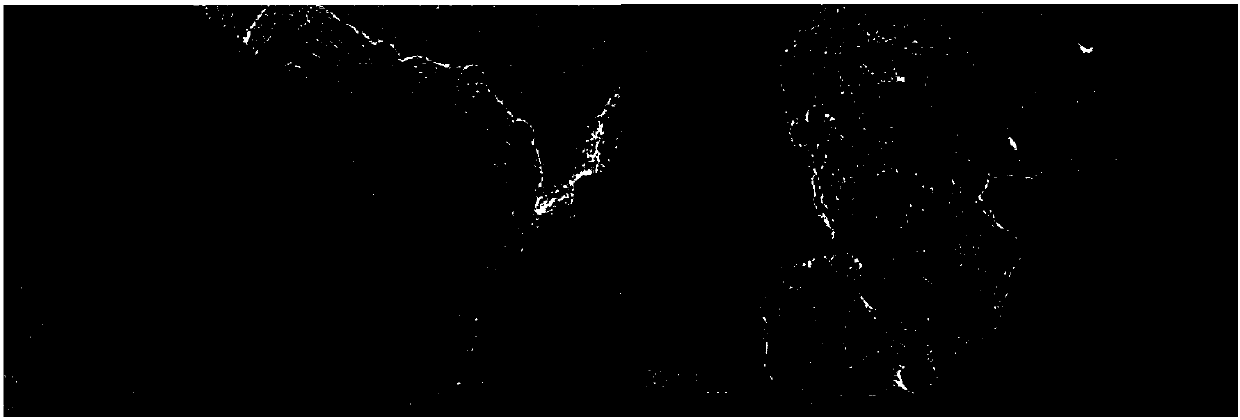

[0044] High-resolution electron microscopy (see figure 1 ) shows that the surface of Pt nanoparticles supported by carbon black is coated with boron nitride to form a core-shell structure.

Embodiment 2

[0046] Dissolve 0.0185g ammonia borane with 5ml of anhydrous diglyme, under Ar protection condition, ammonia borane solution is added to the there-necked flask that 0.1004g 37wt.%Pt / C catalyst (TKK) is housed, wherein B / The atomic ratio of Pt is 3:1, react at 140°C for 3h, then centrifuge to remove the supernatant, dry at 60°C for 48h, put the sample in NH 3 Nitriding treatment at 500 or 700 degrees in the atmosphere for 2 hours to obtain Pt 1 @(h-BN) 3 / C core-shell structure nanocatalytic materials.

Embodiment 3

[0048] Dissolve 0.2534g ammonia borane with 20ml of anhydrous diglyme, under Ar protection condition, ammonia borane solution is added to the there-necked flask that 0.1017g 37wt.%Pt / C catalyst (TKK) is housed, wherein B / The atomic ratio of Pt was 40:1, reacted at 140°C for 3h, then centrifuged to remove the supernatant, dried at 60°C for 70h, and placed the sample in NH 3 Nitriding treatment at 500 or 700 degrees in the atmosphere for 2 hours to obtain Pt 1 @(h-BN) 40 / C core-shell structure nanocatalytic materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com