Anti-condensation ring main unit, manufacturing method thereof and power distribution system

A ring main unit, anti-condensation technology, applied in the substation/distribution device shell, electrical components, switchgear and other directions, can solve the hidden danger of ring main unit, reduce the humidity of the ring main unit, etc., to reduce condensation phenomenon, avoid uneven foaming, and increase the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

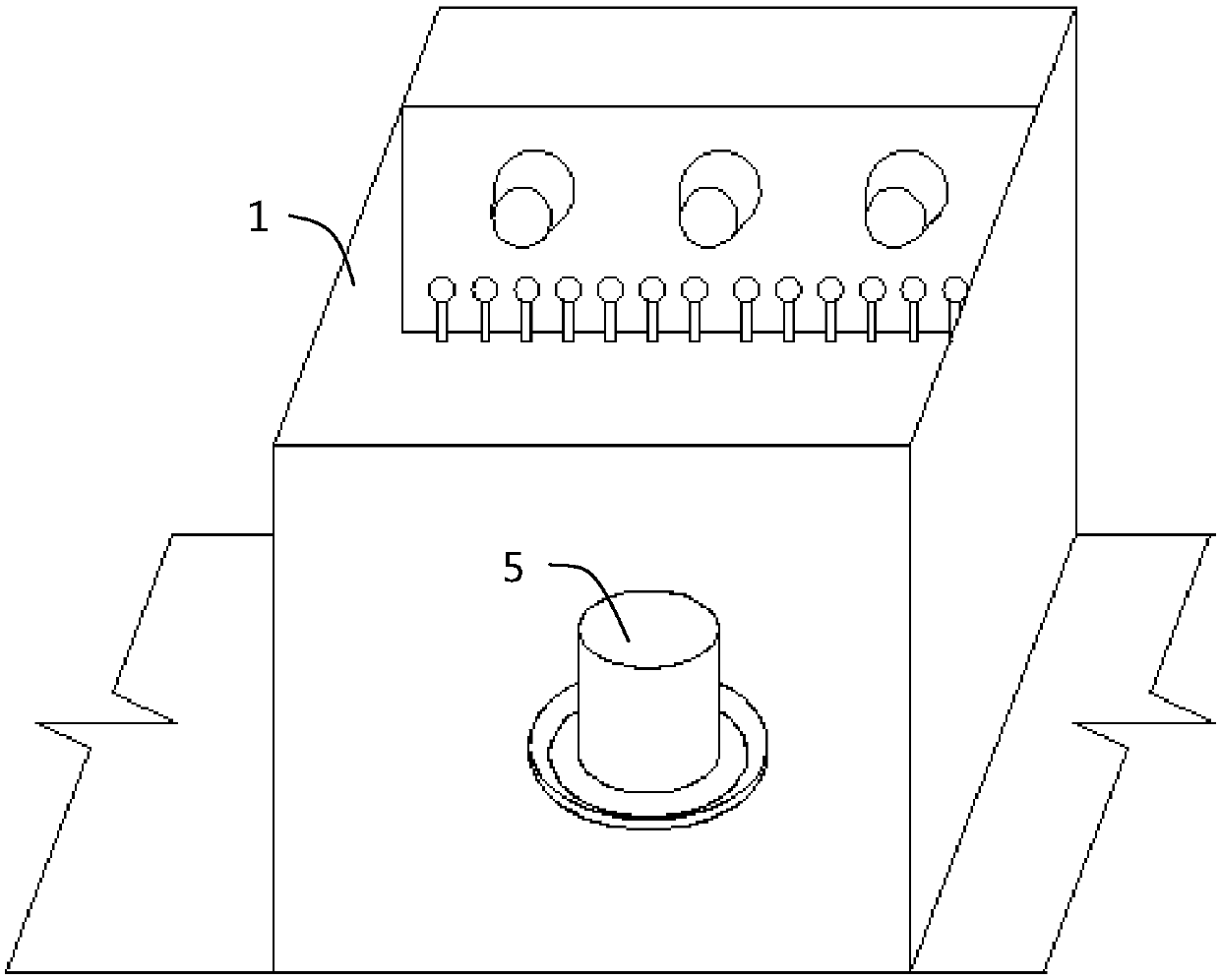

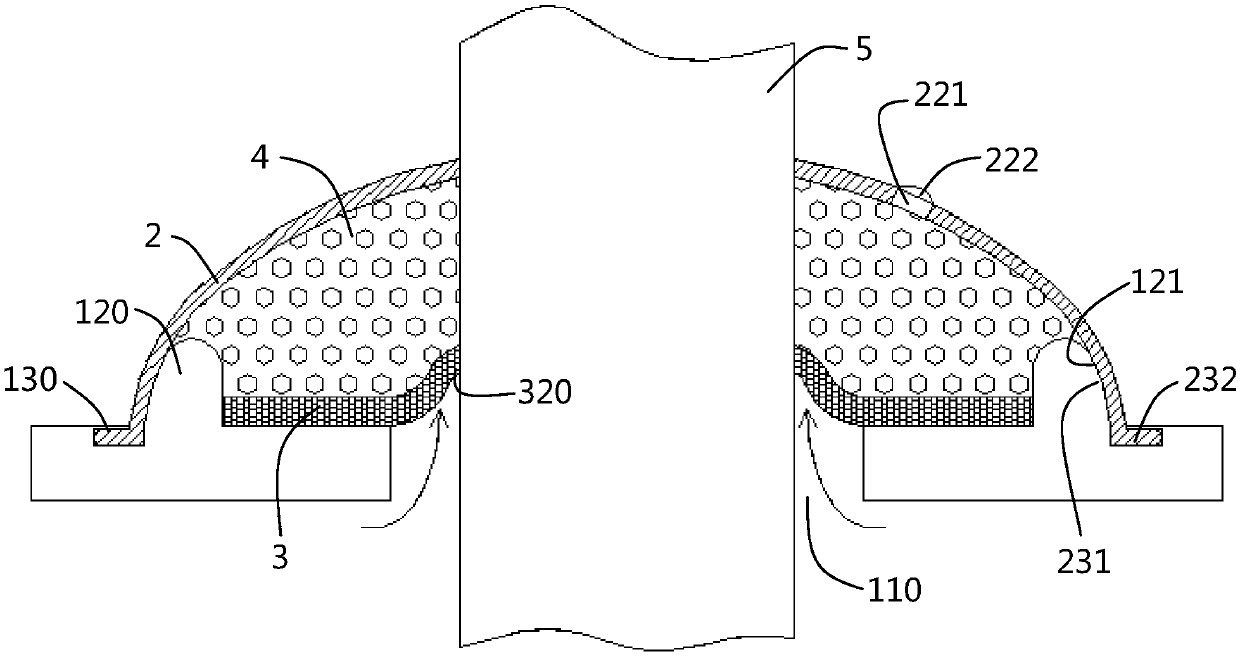

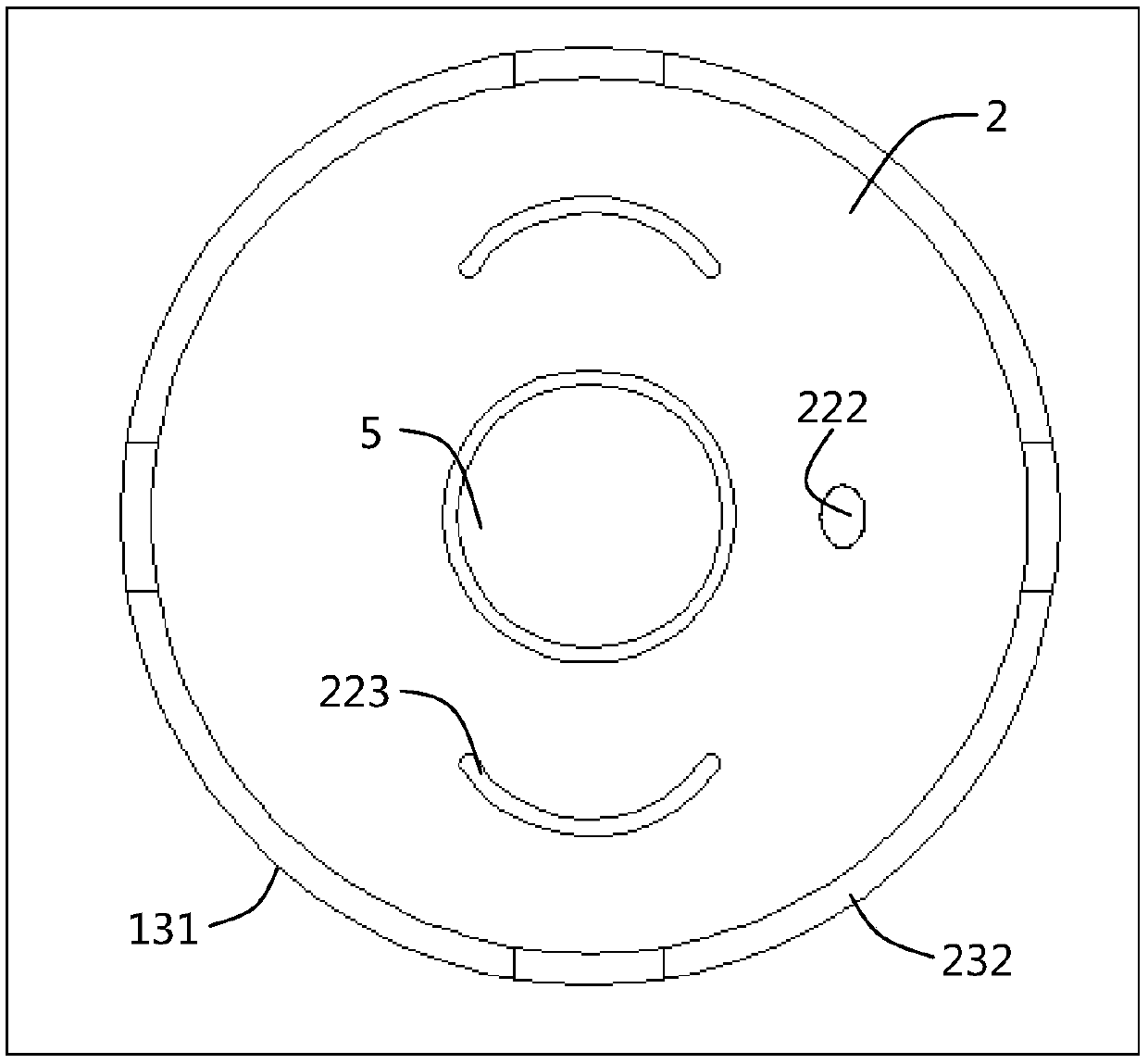

[0061] Please refer to Figure 1 to Figure 8 , figure 1 It is a partial structural schematic diagram of the anti-condensation ring main unit of the present invention. The anti-condensation ring network cabinet of this embodiment includes a cabinet body 1, and an inlet hole 110 is arranged on the bottom plate of the cabinet body 1, and the wire inlet cable 5 is introduced into the cabinet body 1 through the wire inlet hole 110, and is sequentially connected with the terminal , in order to facilitate installation, there is a large gap between the incoming cable 5 and the incoming hole 110, the size of this gap is generally 10-20mm, and the water vapor in the cable pit enters the channel of the cabinet body 1, and the water vapor It is the main source of moisture for condensation.

[0062] The structure of this embodiment is: a first component for blocking, a second component, and a sealing layer 4 filled between the first component and the second component are arranged around ...

Embodiment 2

[0077] In the present embodiment, the manufacturing method of the ring network cabinet with a sealed structure includes the following specific steps:

[0078] Step S101, making the bottom plate of the cabinet body 1, stamping the flat plate made of alloy steel, and grinding the matching contact surface 121 of the stopper protrusion 120 to ensure that the roughness is Ra0.8;

[0079] Step S102, making the sealing plate 3, measuring its diameter according to the inner ring formed by the stop protrusion 120, the diameter of the sealing plate 3 is less than the diameter of the inner ring 2 mm, and welding a semicircle with a radius of 2 mm on the upper surface of the sealing plate 3 Shaped convex rib 310;

[0080] Step S103, making the housing 2, measuring its diameter according to the outer ring formed by the stop protrusion 120, the minimum inner diameter of the housing 2 is consistent with the diameter of the outer ring, and the third section 230 of the housing 2 The inner mou...

Embodiment 3

[0085] In this embodiment, the manufacturing method of the ring network cabinet with a sealed structure includes the following specific steps:

[0086] Step S101, making the bottom plate of the cabinet body 1, stamping a flat plate made of alloy steel, wherein the mating contact surface 121 of the stopper protrusion 120 is polished to ensure that the roughness of the mating contact surface 121 is Ra1.6;

[0087] Step S102, making the sealing plate 3, measuring its diameter according to the inner ring formed by the stop protrusion 120, the diameter of the sealing plate 3 is less than the diameter of the inner ring 3 mm, and welding a semicircle with a radius of 4 mm on the upper surface of the sealing plate 3 Shaped convex rib 310;

[0088] Step S103, making the housing 2, measuring its diameter according to the outer ring formed by the stop protrusion 120, the minimum inner diameter of the housing 2 is consistent with the diameter of the outer ring, and the third section 230 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com