Preparation method of superhigh-temperature ceramic boride sosoloid powder

An ultra-high temperature ceramic and boride technology is applied in the field of preparation of boride solid solution powder, and achieves the effects of low cost, wide source of raw materials and simple powder preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Step 1: Put Ta 2 o 5 Powder, B 2 o 3 Weigh the powder and C powder according to the molar ratio of 1:2:11 to synthesize TaB 2 Required mixed powder a;

[0049] Step 2: Add ZrO 2 Powder, B 2 o 3 The powder and C powder are weighed to synthesize ZrB according to the molar ratio of 1:1:5 2 Required mixed powder b;

[0050] Step 3: Add HfO 2 Powder, B 2 o 3 Weigh the powder and C powder according to the molar ratio of 1:1:5 to synthesize HfB 2 Required mixed powder c;

[0051]Step 4: Put the weighed mixed powders a, b, and c into ball milling jars, and then place the ball milling jars on the ball mill for dry or wet ball milling. The ratio of balls to materials is 3:1, and the speed of the ball mill barrel 300 rev / min, ball milling time is 6h, after ball milling, sieve and dry to get evenly mixed mixed powder A, B, C.

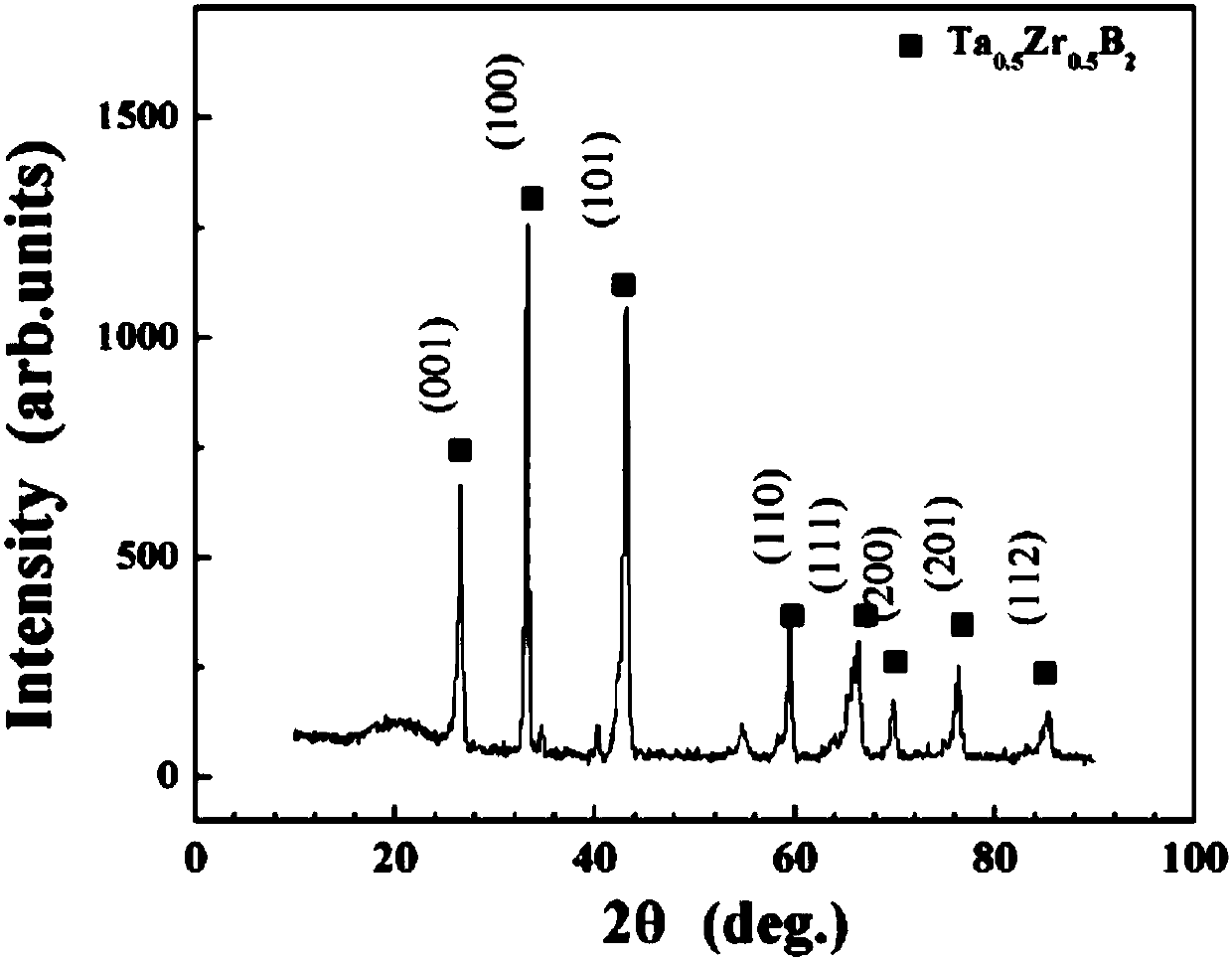

[0052] Step 5: Select two mixed powders A and B from the mixed powders A, B, and C after uniform mixing, and weigh the corresponding powders f...

Embodiment 2

[0057] Step 1: Put Ta 2 o 5 Powder, B 2 o 3 The powder and C powder are weighed to synthesize TaB according to the molar ratio of 1:2.5:11 2 Required mixed powder a;

[0058] Step 2: Add ZrO 2 Powder, B 2 o 3 The powder and C powder are weighed to synthesize ZrB according to the molar ratio of 1:1.3:5 2 Required mixed powder b;

[0059] Step 3: Add HfO 2 Powder, B 2 o 3 The powder and C powder are weighed to synthesize HfB according to the molar ratio of 1:1.3:5 2 Required mixed powder c;

[0060] Step 4: Put the weighed mixed powders a, b, and c into ball milling jars respectively, and then place the ball milling jars on the ball mill for dry or wet ball milling. 500 rev / min, ball milling time is 4h, after ball milling, sieve and dry to obtain evenly mixed mixed powder A, B, C.

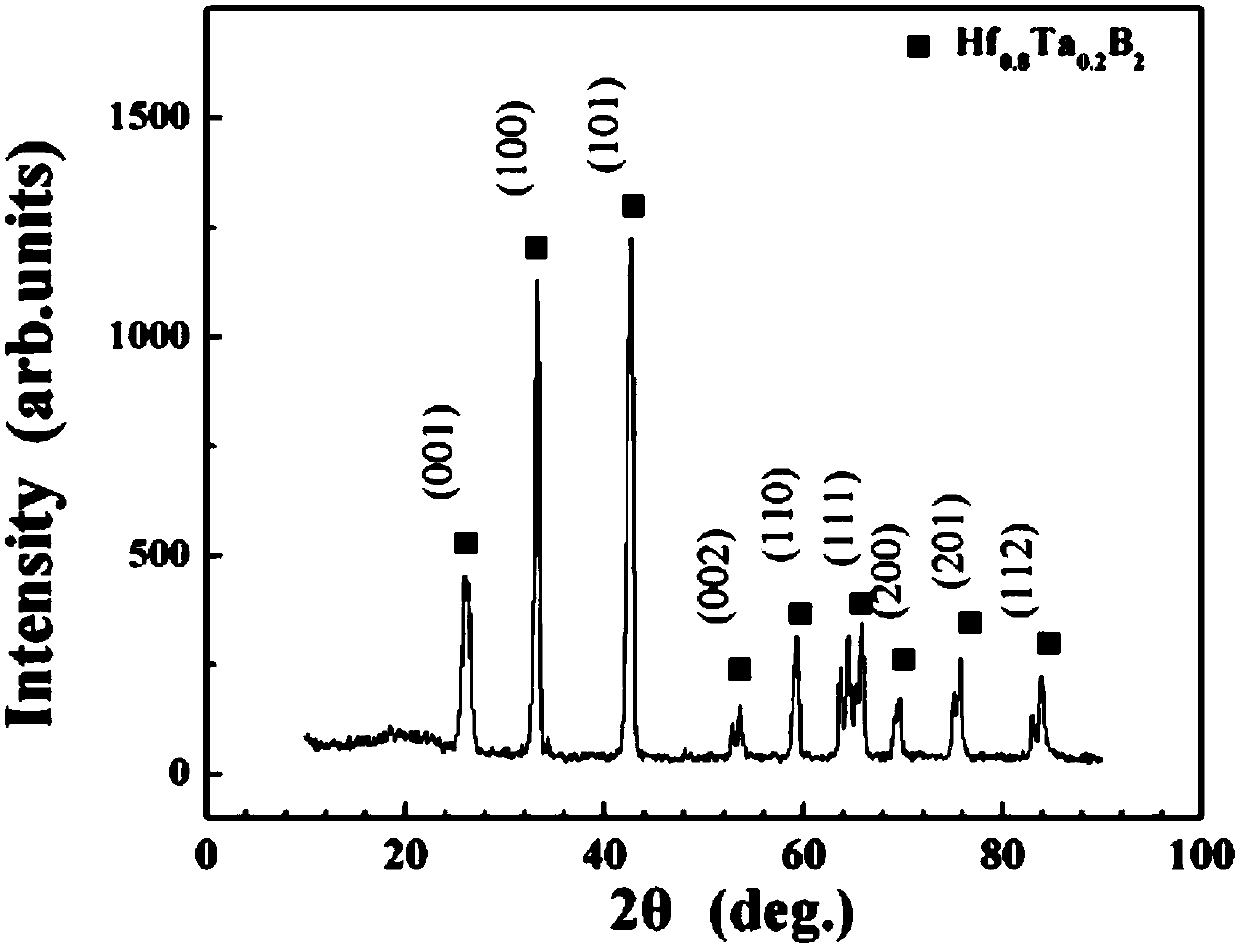

[0061] Step 5: Select two mixed powders A and C from the mixed powders A, B, and C after uniform mixing, and weigh the corresponding powders from mixed powders A and C according to the ...

Embodiment 3

[0066] Step 1: Put Ta 2 o 5 Powder, B 2 o 3 The powder and C powder are weighed to synthesize TaB according to the molar ratio of 1:3:11 2 Required mixed powder a;

[0067] Step 2: Add ZrO 2 Powder, B 2 o 3 The powder and C powder are weighed to synthesize ZrB according to the molar ratio of 1:1.5:5 2 Required mixed powder b;

[0068] Step 3: Add HfO 2 Powder, B 2 o 3 The powder and C powder are weighed to synthesize HfB according to the molar ratio of 1:1.5:5 2 Required mixed powder c;

[0069] Step 4: Put the weighed mixed powders a, b, and c into the ball milling tank respectively, and then place the ball milling tank on the ball mill for dry or wet ball milling. The ball-to-material ratio is 7:1, and the ball milling cylinder speed 700 rev / min, ball milling time is 2h, after ball milling, sieve and dry to get uniformly mixed mixed powder A, B, C.

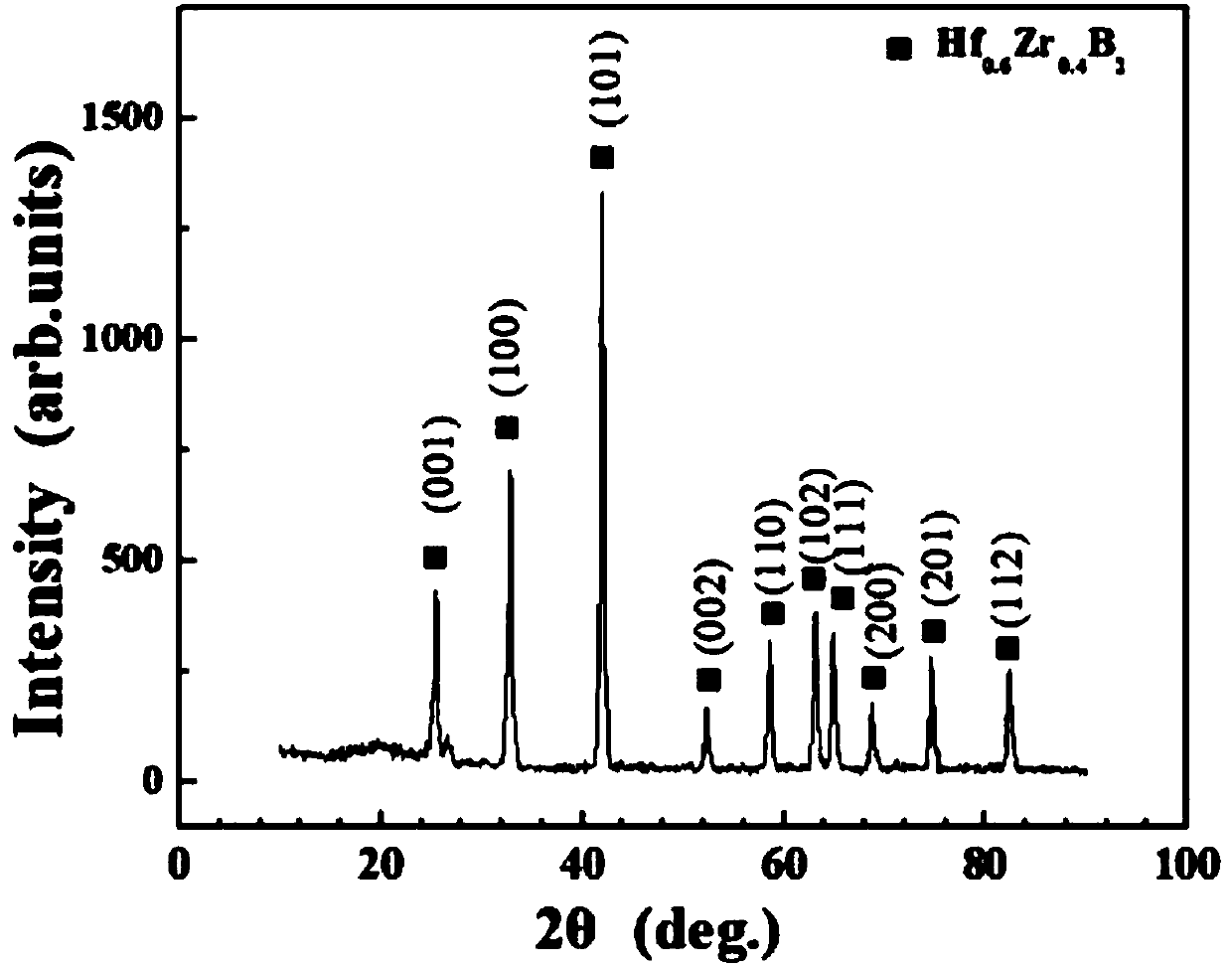

[0070] Step 5: Select two mixed powders B and C from the uniformly mixed mixed powders A, B, and C, and weigh th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com