Method for preparing self-stabilized nano zirconium oxide sol by adopting hydrothermal method

A nano-zirconia and nano-oxidation technology, applied in zirconia and other directions, can solve the problems of few research reports on zirconia sol, and achieve the effects of short preparation period, high purity and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of method that the present invention implements adopts hydrothermal method to prepare self-stabilizing nano-zirconia sol, and its specific steps are:

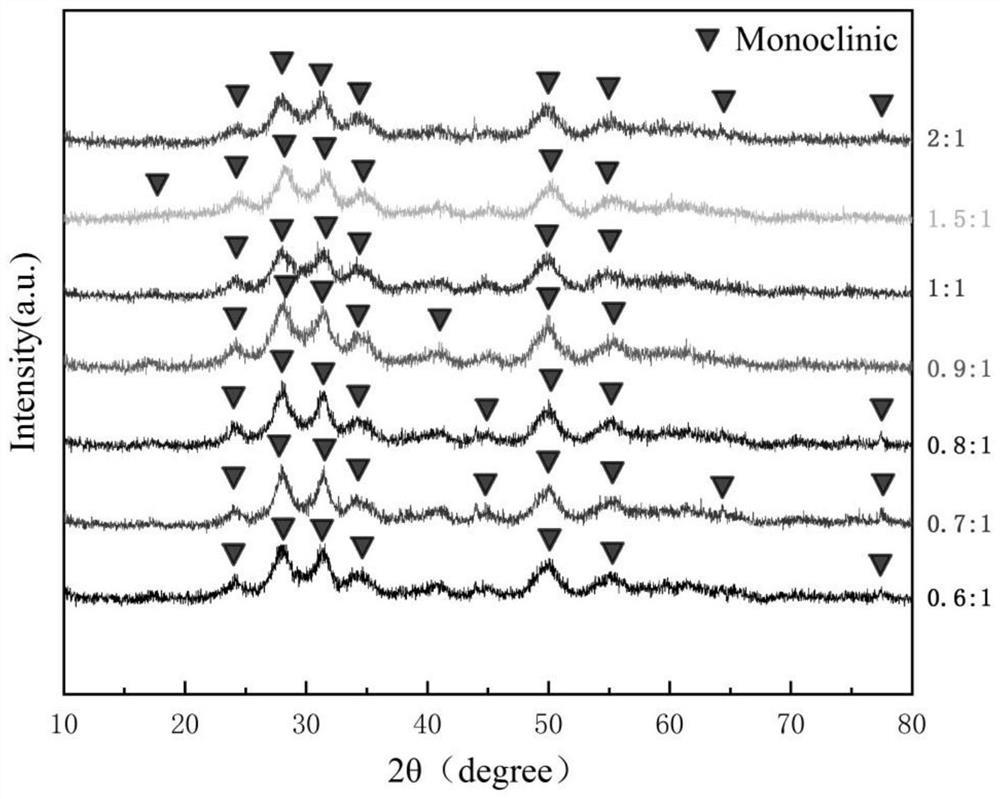

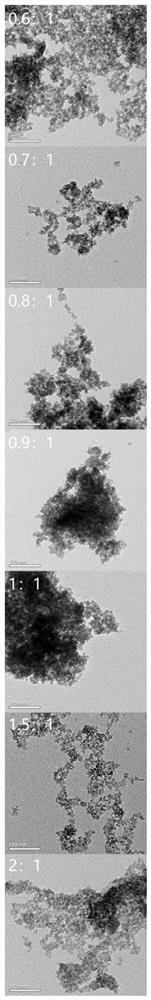

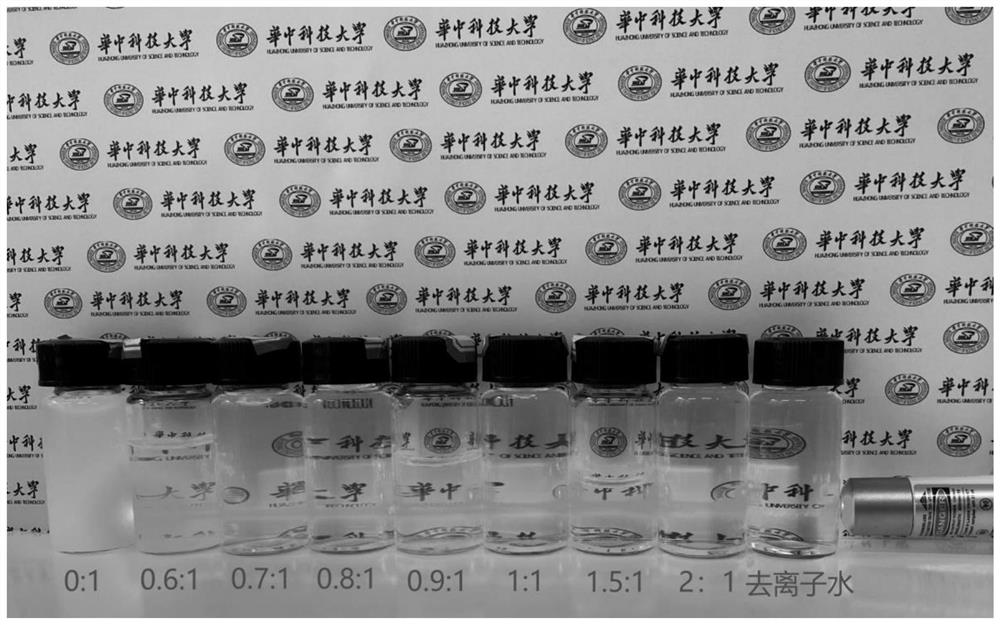

[0041] The consumption of table 1 embodiment 1 oxalic acid and zirconyl nitrate

[0042] Molar ratio of oxalic acid to zirconyl nitrate Oxalic acid / g Zirconium oxynitrate / g 0.6:1 0.5702 1.7429 0.7:1 0.6652 1.7429 0.8:1 0.76024 1.7429 0.9:1 0.8553 1.7429 1:1 0.9503 1.7429 1.5:1 1.4255 1.7429 2:1 1.9006 1.7429

[0043] At room temperature, according to the molar ratio of oxalic acid to zirconyl nitrate shown in Table 1, accurately weigh the corresponding weights of zirconyl nitrate and oxalic acid with an electronic balance, dissolve them in 34 mL of deionized water, and the concentration of zirconyl nitrate solution is 0.15 mol / L, seal the mouth of the beaker with plastic wrap. Continue magnetic stirring for 1 hour, slowly add 25 wt% tetramethylammonium h...

Embodiment 2

[0045] A kind of method that the present invention implements adopts hydrothermal method to prepare self-stabilizing nano-zirconia sol, and its specific steps are:

[0046] The consumption of table 2 embodiment 2 oxalic acid and zirconyl nitrate

[0047] PH value Oxalic acid / g Zirconium oxynitrate / g Precipitation 7.0 1.5838 2.9049 no precipitation, transparent 8.0 1.5838 2.9049 no precipitation, transparent 10.0 1.5838 2.9049 no precipitation, transparent

[0048] At room temperature, according to the molar ratio of oxalic acid to zirconyl nitrate 1:1, use an electronic balance to accurately weigh 2.9049g of zirconyl nitrate and 1.5838g of oxalic acid, and dissolve them in 34mL of deionized water. The concentration of the zirconyl nitrate solution is 0.25mol / L, seal the mouth of the beaker with plastic wrap. Continue magnetic stirring for 1 hour, slowly add 25 wt% tetramethylammonium hydroxide to the stock solution at a rate of 10-1...

Embodiment 3

[0050] A kind of method that the present invention implements adopts hydrothermal method to prepare self-stabilizing nano-zirconia sol, and its specific steps are:

[0051] At room temperature, according to the molar ratio of oxalic acid to zirconyl nitrate 1:1, use an electronic balance to accurately weigh 2.9049g of zirconyl nitrate and 1.5838g of oxalic acid, and dissolve them in 34mL of deionized water. The concentration of the zirconyl nitrate solution is 0.25mol / L, seal the mouth of the beaker with plastic wrap. Continue magnetic stirring for 1 hour, slowly add 25 wt% tetramethylammonium hydroxide to the stock solution at a rate of 10-15 drops / min, adjust the pH to 8.0, and continue stirring for 1 hour. The stock solution was then transferred to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, the autoclave was sealed, placed in a constant temperature drying oven, and reacted at 140° C. for 8 hours. After the autoclave was naturally cooled to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com