Ceramic-simulating flame-retardant PET/PC (polyethylene terephthalate/polycarbonate) resin composition and preparation method thereof

A resin composition and a technology of imitating ceramics, which are applied in the field of imitating ceramic flame-retardant PET/PC resin compositions and their preparation, can solve the problems of brittleness, difficulty in recycling, complicated processes, etc., and achieve good impact resistance and good weather resistance. , good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

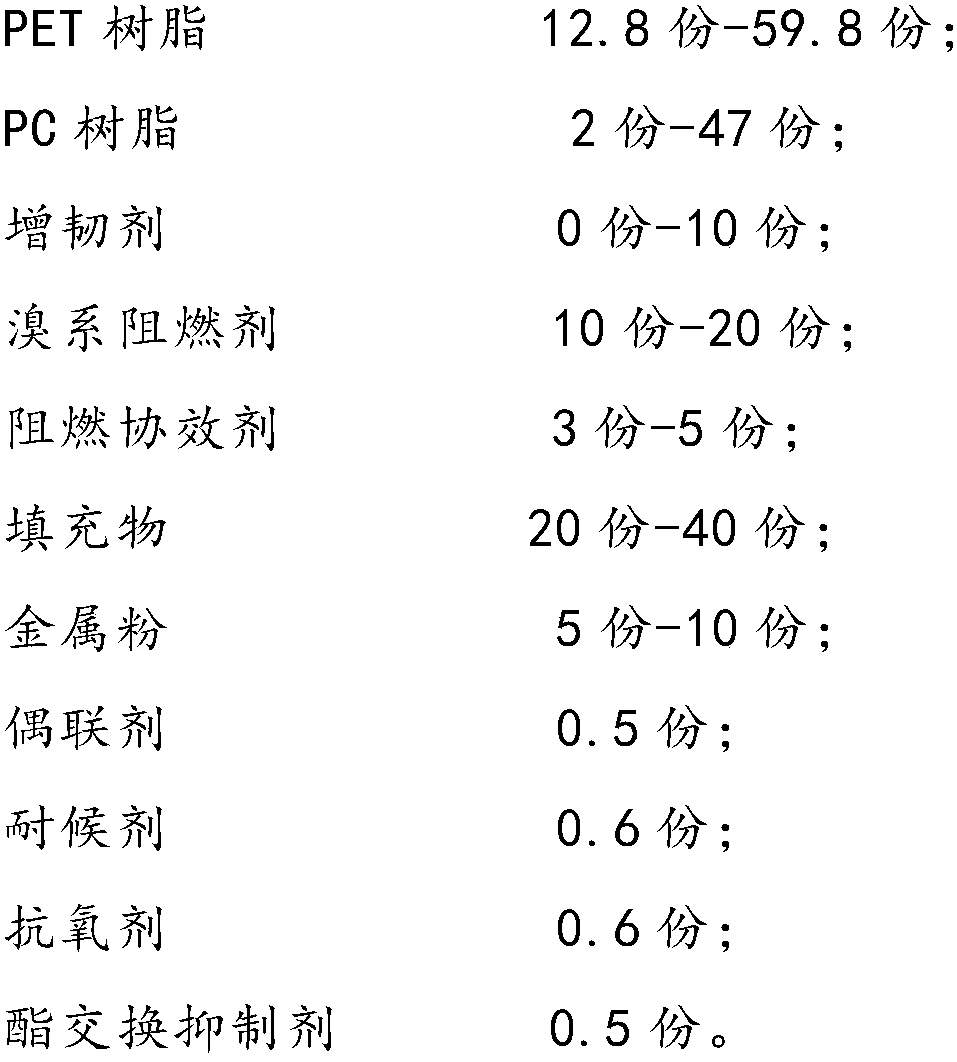

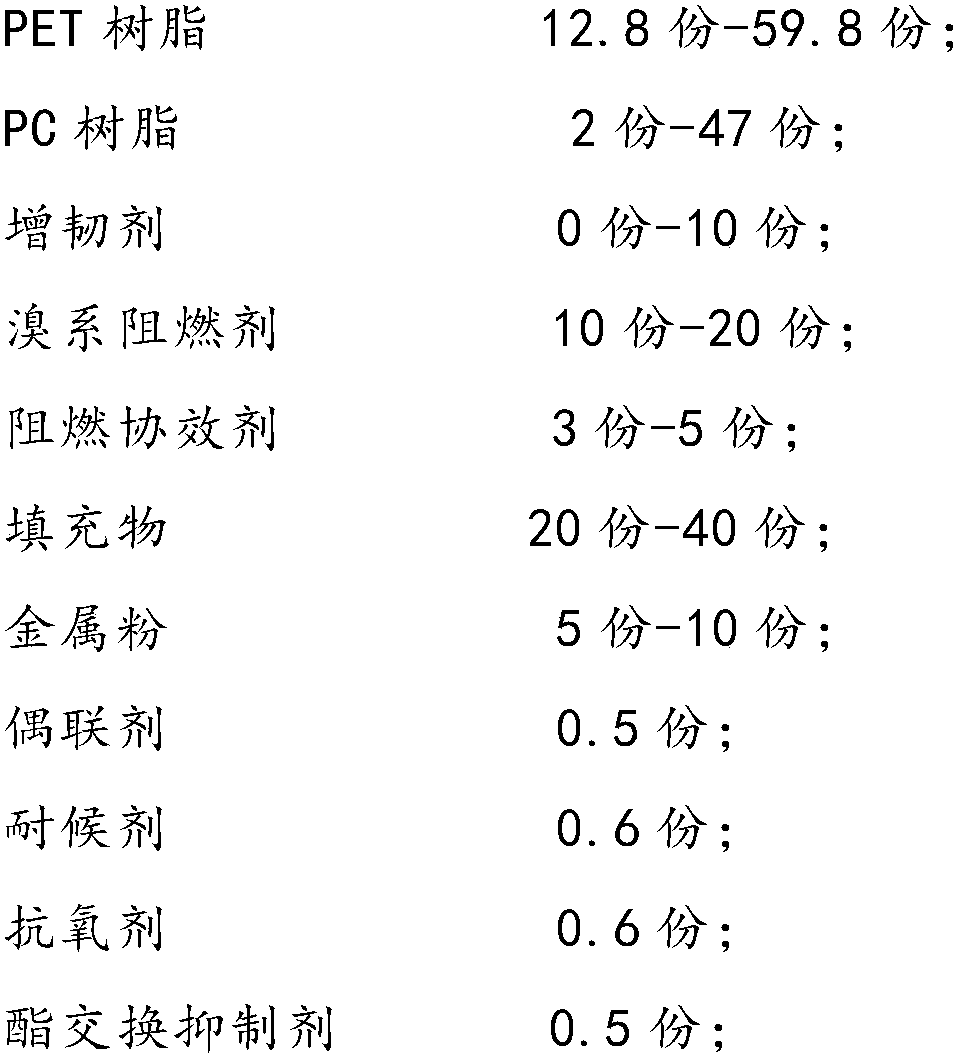

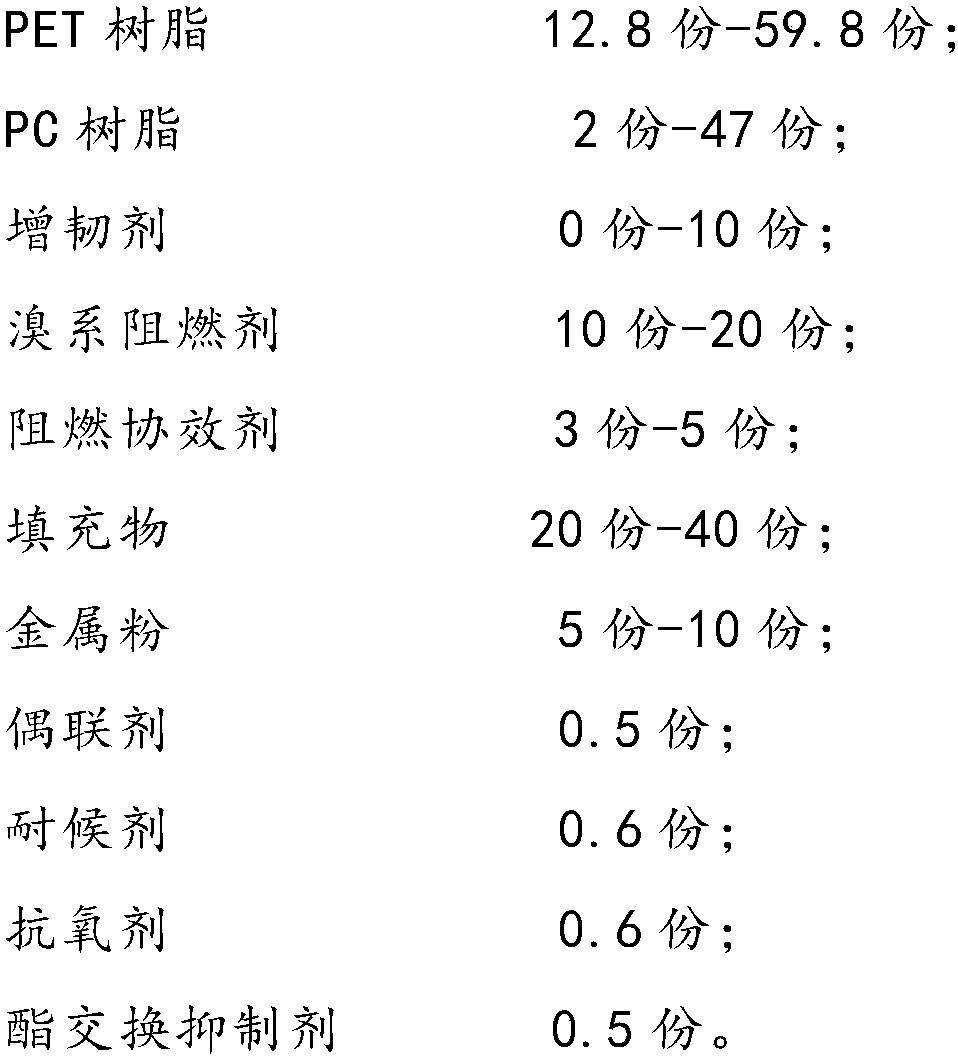

Method used

Image

Examples

Embodiment 1

[0048] Mix AB-3000N1, HYFE-300, Z-6040 in a high-speed mixer at room temperature for 5-10 minutes; then mix PET BG80, PC 1300-10, PBS-64HW, S-05N, TINUVIN 327, CHIMASSORB 944 , Irganox 1010, Irganox 168, and SAPP were added to a high-speed mixer to mix, and then extruded in a twin-screw extruder. The processing conditions are: zone one temperature 245℃, zone two temperature 255℃, zone three temperature 255℃, zone four temperature 255℃, zone five temperature 255℃, zone six temperature 260℃, zone seven temperature 260℃, zone eight temperature 260 ℃, the temperature of the nine zones is 250℃; the speed of the main engine is 250 rpm.

Embodiment 2

[0050] Mix AB-3000N1, HYFE-300, Z-6040 in a high-speed mixer at room temperature for 5-10 minutes; then mix PET BG80, PBS-64HW, S-05N, TINUVIN 327, CHIMASSORB 944, Irganox 1010, Irganox 168, SAPP was added to a high-speed mixer to mix, and then extruded in a twin-screw extruder. The processing conditions are: zone one temperature 245℃, zone two temperature 255℃, zone three temperature 255℃, zone four temperature 255℃, zone five temperature 255℃, zone six temperature 260℃, zone seven temperature 260℃, zone eight temperature 260 ℃, the temperature of the nine zones is 250℃; the speed of the main engine is 250 rpm.

Embodiment 3

[0052] Mix AB-3000N1, HYFE-300, Z-6040 in a high-speed mixer at room temperature for 5-10 minutes; then mix PET BG80, PTW, PBS-64HW, S-05N, TINUVIN 327, CHIMASSORB 944, Irganox 1010 , Irganox168, and SAPP are added to a high-speed mixer to mix, and then extruded in a twin-screw extruder. The processing conditions are: zone one temperature 245℃, zone two temperature 255℃, zone three temperature 255℃, zone four temperature 255℃, zone five temperature 255℃, zone six temperature 260℃, zone seven temperature 260℃, zone eight temperature 260 ℃, the temperature of the nine zones is 250℃; the speed of the main engine is 250 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com