Chelated and concentrated beef cattle feed and preparation method thereof

A beef cattle, chelation technology, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of poor nutritional stability, nutrient loss, easy loss, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

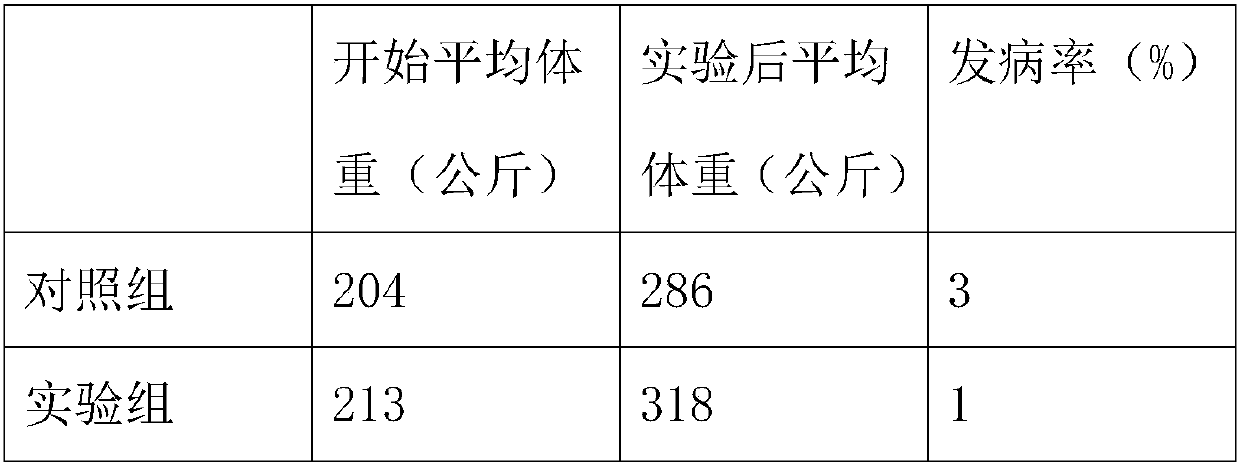

Examples

Embodiment 1

[0018] A kind of chelated beef cattle feed, it is made up of following raw material of weight part:

[0019] Straw powder 120, barley vinegar grains 7, citrus peel 9, bagasse 4, ethylenediaminetetraacetic acid 2, cactus powder 4, thiamine nitrate 0.02, potato pulp residue 20, coconut peat 7, choline chloride 0.02, sulfurous acid Iron 2, rice wine 6, Panax notoginseng 4, Polygonatum 4.

[0020] A preparation method for chelated lean beef cattle feed, comprising the following steps:

[0021] (1) Mix notoginseng and Polygonatum, add to absolute ethanol with 14 times the weight of the mixture, heat and stir at 65-70°C for 2 hours, filter to obtain the alcohol extract;

[0022] (2) Mix citrus peel and bagasse, add to deionized water 8 times its weight, stir evenly, mix with the above-mentioned alcohol extract, stir evenly, add choline chloride, and ultrasonicate for 4 minutes to obtain a mixed solution of alcohol and water ;

[0023] (3) Take the potato pulp residue, add it to t...

Embodiment 2

[0028] A kind of chelated beef cattle feed, it is made up of following raw material of weight part:

[0029] Straw powder 100, barley vinegar grains 5, citrus peel 6, bagasse 3, ethylenediaminetetraacetic acid 1-2, cactus powder 3, thiamine nitrate 0.01, potato pulp 16, coconut peat 5, choline chloride 0.01, Ferrous Sulfate 1, Rice Wine 4, Panax notoginseng 2, Polygonatum 3.

[0030] A preparation method for chelated lean beef cattle feed, comprising the following steps:

[0031] (1) Take notoginseng and Polygonatum and mix them, add them to absolute ethanol whose weight is 10 times that of the mixture, heat and stir at 65°C for 1 hour, filter to obtain an alcohol extract;

[0032] (2) Mix citrus peel and bagasse, add to deionized water 6 times its weight, stir evenly, mix with the above-mentioned alcohol extract, stir evenly, add choline chloride, and ultrasonicate for 3 minutes to obtain a mixed solution of alcohol and water ;

[0033] (3) Take the potato pulp residue, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com