High carrying capacity protein A immune adsorption material and preparation method thereof

An immunoadsorption material and protein technology, which is applied in the field of high-load protein A immunoadsorption materials and its preparation, can solve the problems of low adsorption performance, low activity, low coupling rate, etc., achieve high reactivity, and improve clinical The effect of the therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

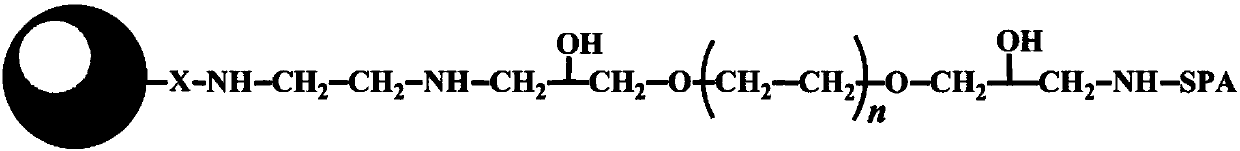

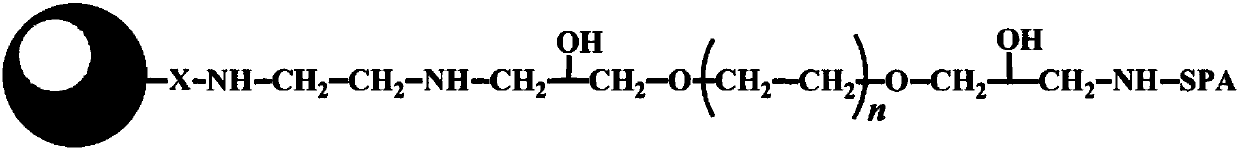

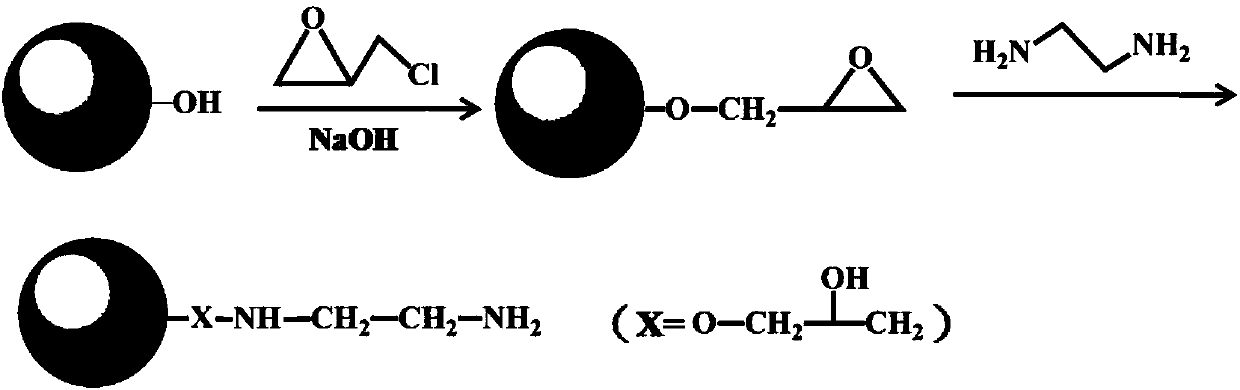

[0038] 1. Preparation of gel microspheres containing primary amino groups

[0039] Take 100mL agarose gel microspheres (Sepharose 6FF), rinse with distilled water, drain, rinse with 20%, 50% and 80% dimethyl sulfoxide in turn, drain, and add to a 1000mL round bottom flask , add 500mL dimethylsulfoxide, 10g sodium hydroxide, 0.3g sodium borohydride, 100mL epichlorohydrin, place in a constant temperature shaker, react at 40°C for 2 hours, then use 80%, 50%, 20 % dimethyl sulfoxide and distilled water to end the reaction. The amount of epoxy groups on the support was detected by the sodium thiosulfate method, and it was measured that there were 100 μmol of epoxy groups per gram of support.

[0040] Put the above product into a 1000mL round bottom flask, add 500ml of 1M ethylenediamine solution (adjust the pH to 9 with hydrochloric acid), react at 40°C for 6 hours, rinse with distilled water, and drain to obtain the primary amino group containing For gel microspheres, it is meas...

Embodiment 2

[0059] 1. Preparation of gel microspheres containing primary amino groups

[0060] Take 100mL of agarose gel microspheres (Sepharose 4FF), rinse with distilled water, drain, add to a 1000mL round bottom flask, add 500mL of 0.2M sodium periodate solution, react at 40°C for 1 hour, Rinse with a large amount of distilled water to end the reaction. According to the concentration of sodium periodate before and after the reaction, it is measured that there are 110 μmol of aldehyde groups per gram of carrier.

[0061] Put the above product into a 1000mL round bottom flask, add 500ml of 0.2M ethylenediamine solution (adjust the pH to 8 with hydrochloric acid), react at 20°C for 4 hours, add 1 gram of sodium borohydride to continue the reaction for 4 hours, Rinse with distilled water and drain to obtain a gel containing primary amino groups. It is measured that there are about 110 μmol of primary amino groups per gram of carrier.

[0062] 2. Preparation of protein A immunosorbent mat...

Embodiment 3

[0069] 1. Preparation of gel microspheres containing primary amino groups

[0070] Take 100mL cellulose microspheres (MT500, 80-100μm), rinse with distilled water, drain, rinse with 20%, 50% and 80% dimethyl sulfoxide in turn, drain, and add to a 1000mL round bottom flask Add 500mL dimethyl sulfoxide, 10g sodium hydroxide, 0.3g sodium borohydride, 100mL epichlorohydrin, place in a constant temperature shaker, react at 20°C for 6 hours, then use 80%, 50%, Wash with 20% dimethyl sulfoxide and a large amount of distilled water to end the reaction. The amount of epoxy groups on the carrier was detected by the sodium thiosulfate method, and it was measured that there were 80 μmol of epoxy groups per gram of carrier.

[0071] Put the above product into a 1000mL round bottom flask, add 500ml of 0.2M ethylenediamine solution (adjust the pH to 11 with hydrochloric acid), react at 20°C for 10 hours, rinse with distilled water, and drain to obtain the primary amino group containing For...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com