Pipe material with excellent high temperature strength and stability and preparation method of pipe material

A high-temperature strength and stability technology, applied in the field of metal materials, can solve the problems of high thermal expansion coefficient, poor heat transfer, high cost, etc., and achieve the effects of good high-temperature processing performance, good oxidation resistance, excellent high-temperature strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

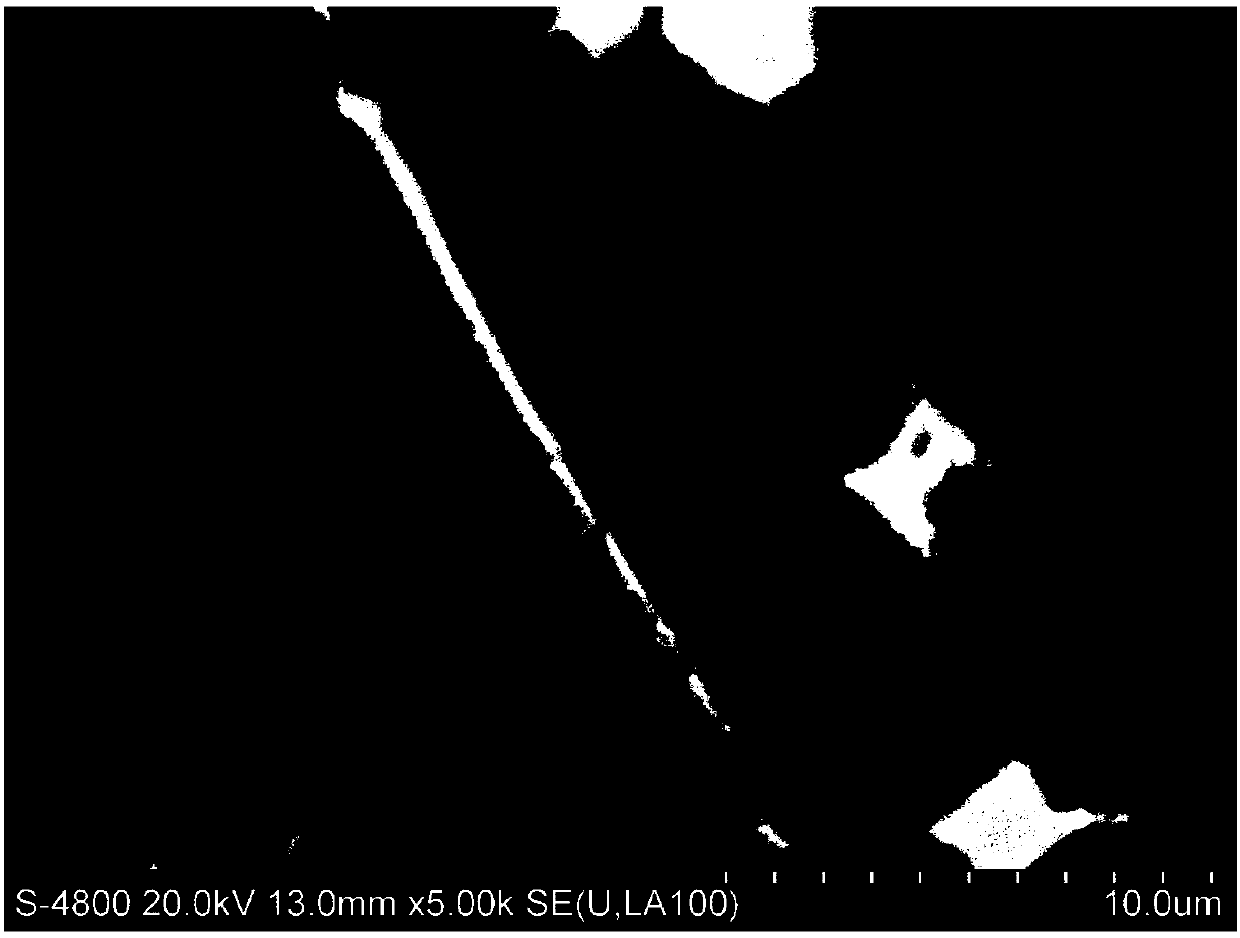

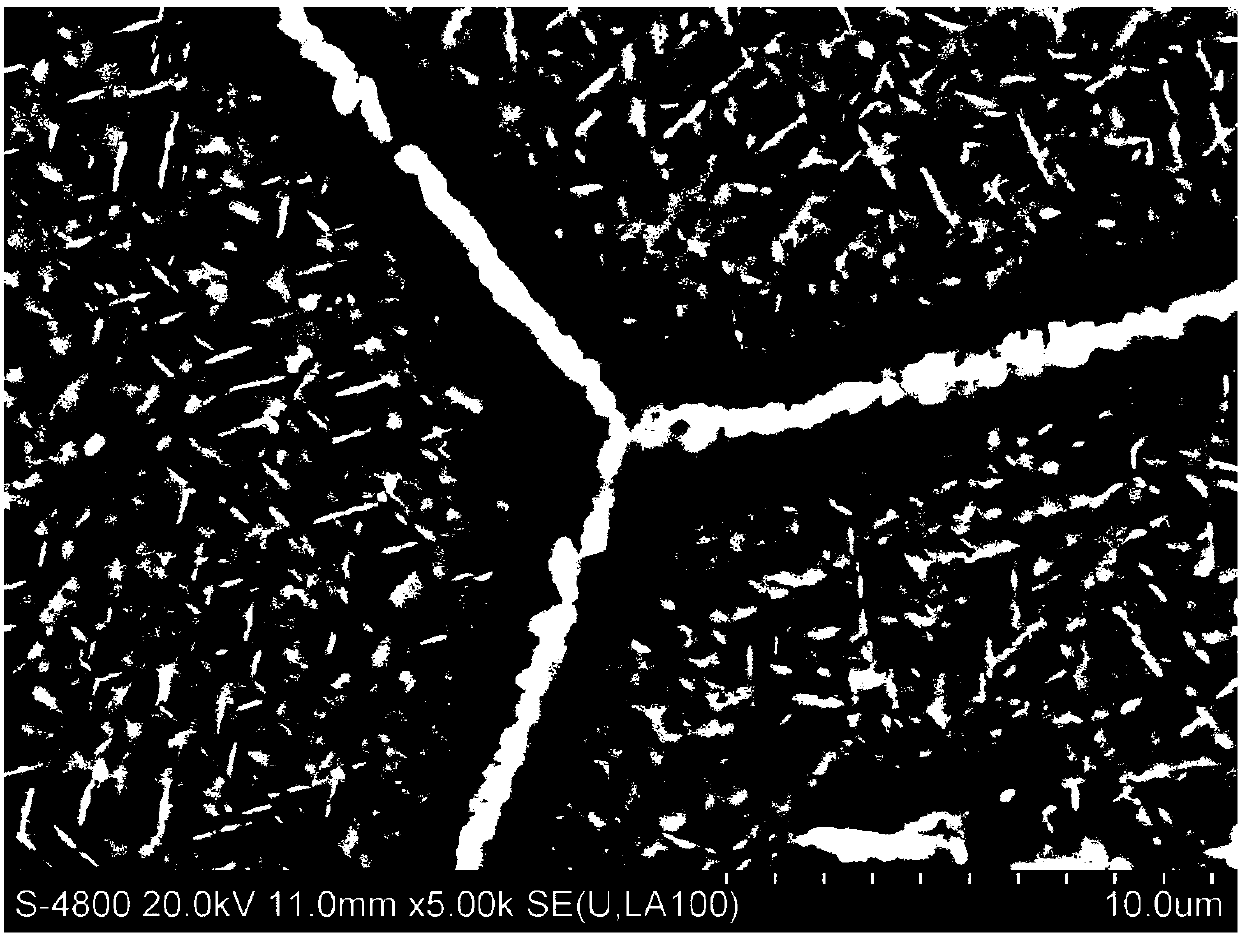

Image

Examples

Embodiment 1

[0025] The heat-resistant steel material of this embodiment comprises: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 2.0%, Mo: 2.0%, W: 6.0%, Nb: 1.8%, Ti: 0.3%, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0026] The preparation method of the present embodiment comprises the following steps:

[0027] 1) Raw material preparation: The ingredients include by mass percentage: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 2.0%, Mo: 2.0%, W: 6.0%, Nb: 1.8%, Ti: 0.3 %, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0028] 2) Melting step: the prepared alloy is melted into alloy mother liquor by using a vacuum induction furnace, and finally prepared into an alloy ingot by suction casting (negative pressure casting process).

[0029] 3) High-temperature hot rolling: the alloy ingot is rolled at 1050°C to form a plate. During rolling, the rolling deformation of each pass is not less than 10%, and the final total deformation is not less than 30%.

[0030] 4) Alloy heat treatment: The alloy-rolled plate is s...

Embodiment 2

[0032] The heat-resistant steel material of this embodiment includes: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 4.0%, Mo: 2.0%, W: 6.0%, Nb: 1.8%, Ti: 0.3%, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] 1) Raw material preparation: The ingredients include by mass percentage: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 4.0%, Mo: 2.0%, W: 6.0%, Nb: 1.8%, Ti: 0.3 %, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0035] 2) Melting step: the prepared alloy is melted into alloy mother liquor by using a vacuum induction furnace, and finally prepared into an alloy ingot by suction casting (negative pressure casting process).

[0036] 3) High-temperature hot rolling: the alloy ingot is rolled at 1050°C to form a plate. During rolling, the rolling deformation of each pass is not less than 10%, and the final total deformation is not less than 30%.

[0037] 4) Alloy heat treatment: The alloy-rolled plate is so...

Embodiment 3

[0039] The heat-resistant steel material of this embodiment comprises: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 6.5%, Mo: 2.0%, W: 6.0%, Nb: 1.8%, Ti: 0.3%, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0040] The preparation method of the present embodiment comprises the following steps:

[0041] 1) Raw material preparation: The ingredients include by mass percentage: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 6.5%, Mo: 2.0%, W: 6.0%, Nb: 1.8%, Ti: 0.3 %, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0042] 2) Melting step: the prepared alloy is melted into alloy mother liquor by using a vacuum induction furnace, and finally prepared into an alloy ingot by suction casting (negative pressure casting process).

[0043] 3) High-temperature hot rolling: the alloy ingot is rolled at 1050°C to form a plate. During rolling, the rolling deformation of each pass is not less than 10%, and the final total deformation is not less than 30%.

[0044] 4) Alloy heat treatment: The alloy-rolled plate is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com