Short carbon fiber based electromagnetic shielding composite material and preparation method thereof

A chopped carbon fiber, electromagnetic shielding technology, applied in the field of chopped carbon fiber electromagnetic shielding composite material and its preparation, can solve the problems of easy corrosion, poor absorbing performance, high price, etc., achieve good electrical conductivity and electromagnetic shielding performance, improve Combined performance, adjustable effect of shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

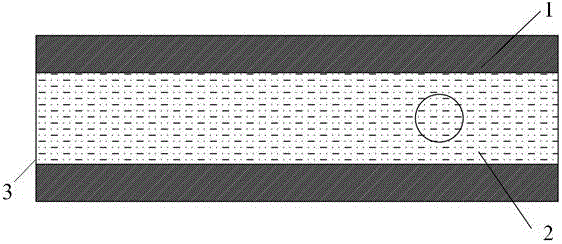

[0031] Such as figure 1 shown. A chopped carbon fiber electromagnetic shielding composite material, the chopped carbon fiber electromagnetic shielding composite material 3 has a three-layer structure, including two insulating resin layers 1 located on the outside, and chopped carbon fiber shielding sandwiched between the two insulating resin layers 1 Felt layer 2.

[0032] The material of the insulating resin layer 1 is PE or PC film.

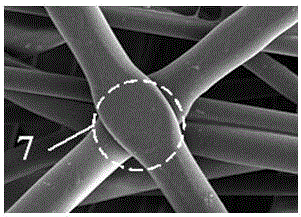

[0033] The insulating resin layer 1 and the chopped carbon fiber shielding felt layer 2 are integrated by hot pressing, and the carbon fibers in the chopped carbon fiber shielding felt layer 2 are overlapped by hot pressing to form a three-dimensional conductive network.

Embodiment 2

[0035] A preparation method of chopped carbon fiber electromagnetic shielding composite material, comprising the steps of:

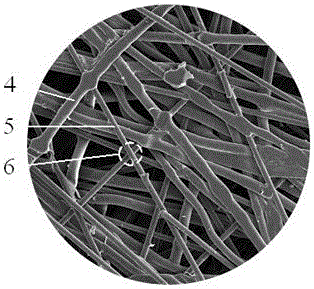

[0036] (1) Put a certain proportion of chopped ES fiber 4 and chopped carbon fiber 5 into 1.2% hydroxyethyl cellulose solution by mass fraction to disperse and mix, and stir with a mixer at a high speed, then let stand, and the chopped carbon fiber The ES fiber 4 is a polyethylene / polypropylene fiber with a skin-core structure, the skin layer is polyethylene, and the core layer is polypropylene; the mass ratio of the chopped carbon fiber 5 to the chopped ES fiber 4 is 2:3, and the fiber length is 6mm , the stirring rate of the mixer is 700rpm, the stirring time is 4min, and the standing time is 5min.

[0037] (2) Pour the dispersed solution into a paper machine with a capacity greater than 10L, and make it through the 80-mesh copper mesh on the paper machine, and then put the finished chopped carbon fiber shielding felt layer 2 into a constant temperatur...

Embodiment 3

[0042] A preparation method of chopped carbon fiber electromagnetic shielding composite material, comprising the steps of:

[0043] (1) Put a certain proportion of chopped ES fiber 4 and chopped carbon fiber 5 into the hydroxyethyl cellulose solution with a mass fraction of 1.5% to disperse and mix, and stir with a mixer at a high speed, then let stand, and the chopped carbon fiber The ES fiber 4 is a polyethylene / polypropylene fiber with a skin-core structure, the skin layer is polyethylene, and the core layer is polypropylene; the mass ratio of the chopped carbon fiber 5 to the chopped ES fiber 4 is 3:7, and the fiber length is 6mm , the stirring rate of the mixer is 600rpm, the stirring time is 5min, and the standing time is 5min.

[0044] (2) Pour the dispersed solution into a paper machine with a capacity greater than 10L, and make it through the 80-mesh copper mesh on the paper machine, and then put the finished chopped carbon fiber shielding felt layer 2 into a constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com