Al/Ge10Sb90 type superlattice phase change thin film material used for phase change memory and preparation method

A phase change memory and thin film material technology, applied in the field of microelectronics, can solve the problems of unsatisfactory thermal stability of storage materials, and achieve the effects of low power consumption, enhanced stability and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

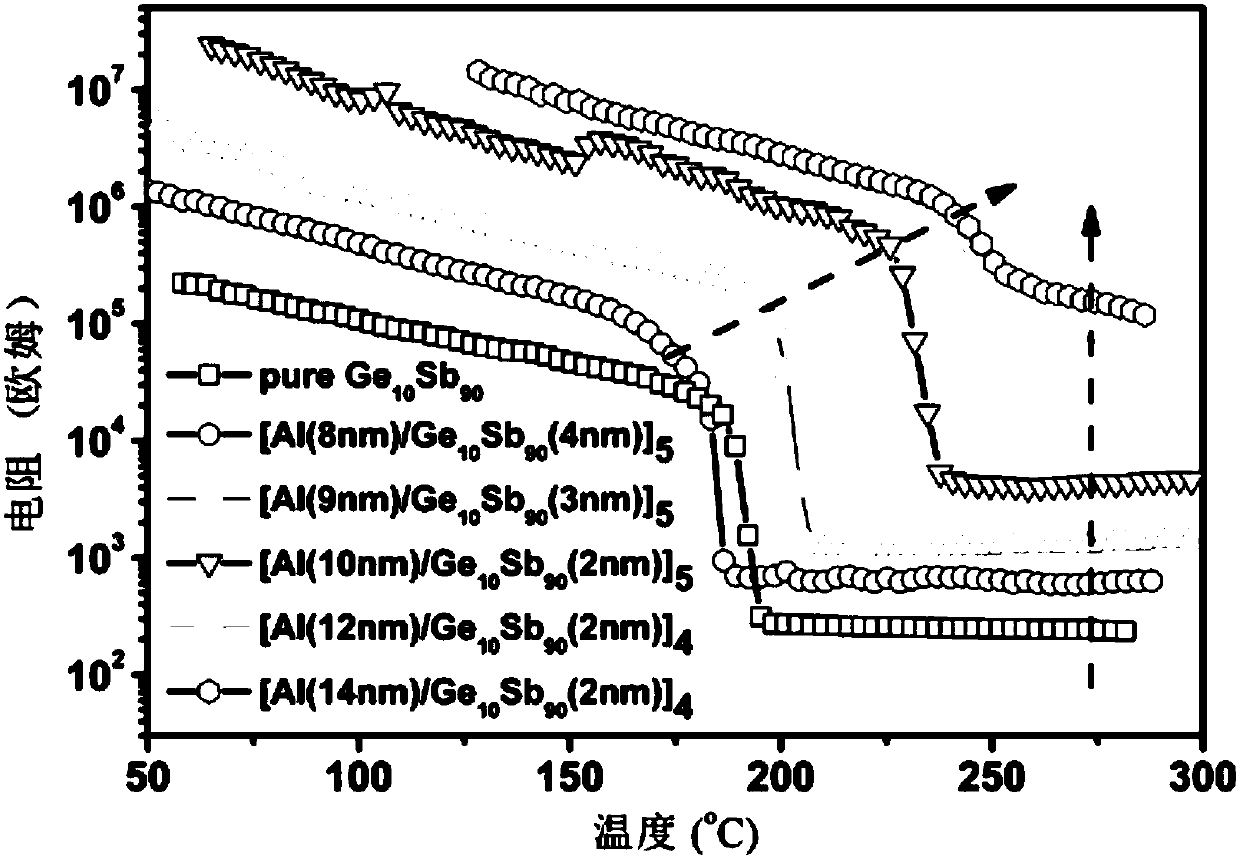

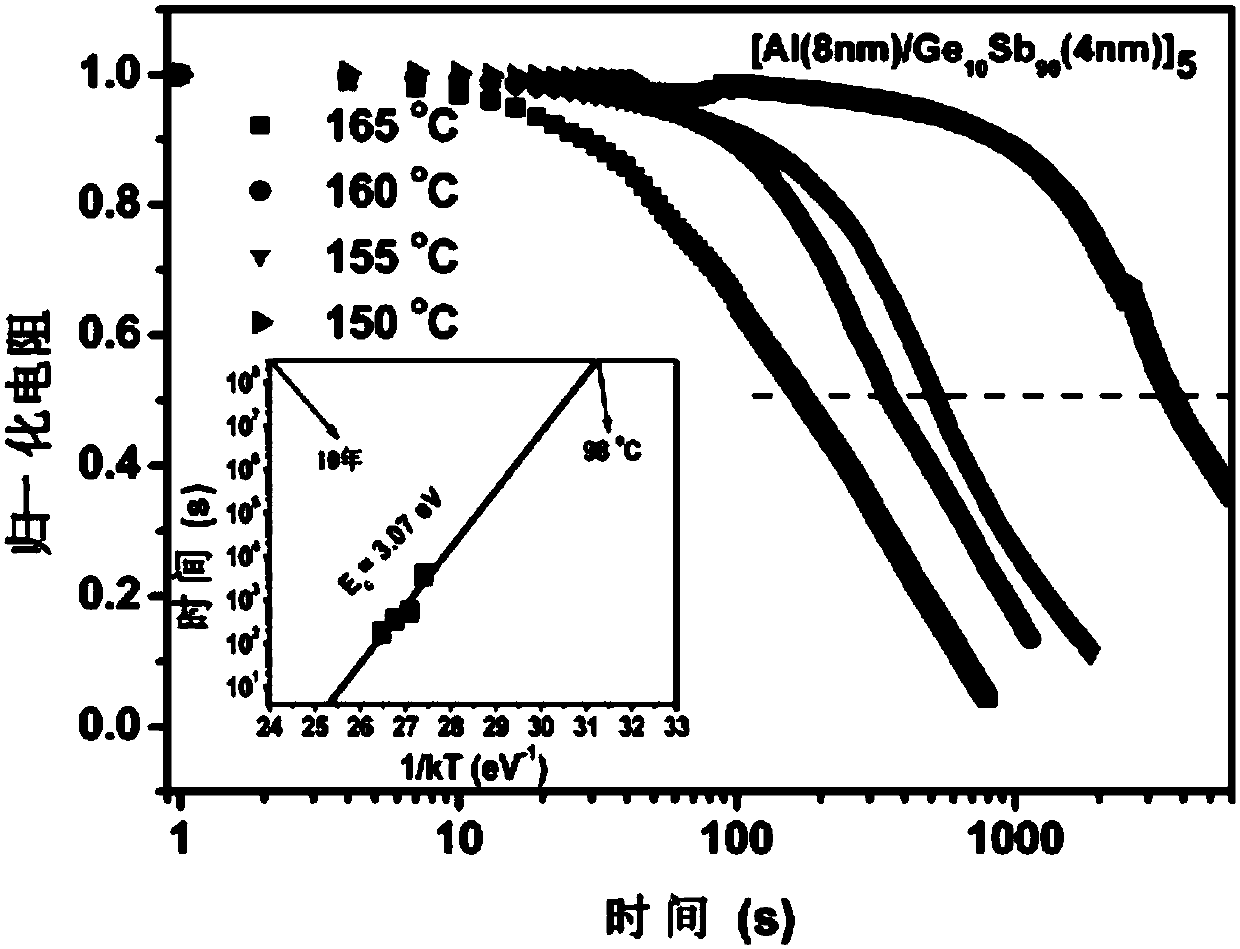

[0036] Al / Ge of this embodiment 10 Sb 90 The film structure of the superlattice-like phase change thin film material is [Al(8nm)Ge 10 Sb 90 (4nm)] 5 , that is, the thickness of each layer of Al layer is 8nm, each layer of Ge 10 Sb 90 layer thickness is 4nm, Al layer and Ge 10 Sb 90 The number of alternating periods of layers is 5, [Al(8nm)Ge 10 Sb 90 (4nm)] 5 The thickness of the superlattice phase change film material is 60nm.

[0037] [Al(8nm)Ge of the present embodiment 10 Sb 90 (4nm)] 5 The superlattice phase change thin film material is prepared by magnetron sputtering, and the specific preparation method includes the following steps:

[0038] ① Substrate preparation.

[0039] Select SiO with a size of 5mm×5mm 2 / Si (100) substrate, the substrate is ultrasonically cleaned in acetone (a purity of more than 99%) in an ultrasonic cleaning machine for 3 to 5 minutes, and after washing, it is taken out and rinsed with deionized water; then in an ultrasonic clean...

Embodiment 2

[0050] Al / Ge of this embodiment 10 Sb 90 The film structure of the superlattice-like phase change thin film material is [Al(9nm)Ge 10 Sb 90 (3nm)] 5 , that is, the thickness of each layer of Al layer is 9nm, each layer of Ge 10 Sb 90 layer thickness is 3nm, Al layer and Ge 10 Sb 90 The number of alternating periods of layers is 5, [Al(9nm)Ge 10 Sb 90 (3nm)] 5 The thickness of the superlattice phase change film material is 60nm.

[0051] The rest of the preparation method is the same as in Example 1, except that: in the preparation of ② magnetron sputtering, the Ar gas flow rate is set to 30SCCM, and the argon sputtering pressure is adjusted to 0.25Pa, and the sputtering of the radio frequency power supply is set The transmit power is 28W. In step 3. b, the sputtering rate of the Al layer is 4s / nm, and the sputtering time is 18s; in the step 3. c, Ge 10 Sb 90 The layer sputtering rate is 3s / nm and the sputtering time is 9s.

Embodiment 3

[0053] Al / Ge of this embodiment 10 Sb 90 The film structure of the superlattice-like phase change thin film material is [Al(10nm)Ge 10 Sb 90 (2nm)] 5 , that is, the thickness of each layer of Al layer is 10nm, each layer of Ge 10 Sb 90 layer thickness is 2nm, Al layer and Ge 10 Sb 90 The number of alternating periods of layers is 5, [Al(10nm)Ge 10 Sb 90 (2nm)] 5 The thickness of the superlattice phase change film material is 60nm.

[0054] The rest of the preparation method is the same as in Example 1, except that: in the preparation of ② magnetron sputtering, the Ar gas flow rate is set to 35SCCM, and the argon sputtering pressure is adjusted to 0.25Pa, and the sputtering of the radio frequency power supply is set The transmitting power is 30W.

[0055] In the step 3. b, the sputtering rate of the Al layer is 5s / nm, and the sputtering time is 20s; in the step 3. c, the Ge 10 Sb 90 The layer sputtering rate is 4s / nm, and the sputtering time is 6s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com