Lithium battery positive electrode, and preparation method and application thereof

A lithium battery and positive electrode technology, applied in the field of lithium battery positive electrode and its preparation, can solve the problems of reducing the contact resistance of aluminum oxide foil, reducing the mechanical strength of aluminum foil, etc., and achieve the effects of preventing lithium dendrites, easy promotion, and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

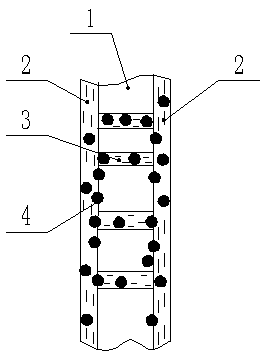

[0027] A positive electrode of a lithium battery, comprising: a positive electrode collector 1, a binder, a positive electrode powder, and conductive carbon black, at least one side of the electrode collector is coated with a composite layer 2 composed of the binder, the positive electrode powder, and conductive carbon black , the positive electrode powder is either a ternary material, or lithium iron phosphate, or lithium cobalt oxide; the through holes 3 and / or blind holes 4 are composed of binder, positive electrode powder and conductive carbon black The composite layer is the same as that of the prior art.

[0028] The positive current collector is a microporous aluminum foil, and each square centimeter of the microporous aluminum foil is distributed with 1000-1500 through holes with a diameter of 10-50 μm and / or 1000-3000 blind holes with a diameter of 10-50 μm. Holes; the through holes and / or blind holes are coated with a mixture of positive electrode powder and binder, ...

Embodiment 2

[0049] A positive electrode of a lithium battery, comprising: a positive electrode collector, a binder, a positive electrode powder, and conductive carbon black, at least one side of the electrode collector is coated with a composite layer of the binder, the positive electrode powder, and conductive carbon black, and the The positive electrode powder is either a ternary material, or lithium iron phosphate, or lithium cobalt oxide; there is a composite layer of binder, positive electrode powder and conductive carbon black in the through holes and / or blind holes.

[0050] The positive current collector is a microporous aluminum foil made of battery aluminum foil, and the battery microporous aluminum foil has 1000-1500 through holes with a diameter of 10-15 μm and 1000-3000 through holes with a diameter of 10-15 μm per square centimeter. For blind holes with uneven sizes of 10-50μm, each through hole and blind hole is irregular in shape, and the junction of each hole and the surfa...

Embodiment 3

[0060] A lithium battery positive electrode, comprising: a positive electrode collector, a binder, a positive electrode powder, and conductive carbon black, at least one side of the electrode collector is coated with a composite layer of the binder, the positive electrode powder, and conductive carbon black, the The positive electrode powder is either a ternary material, or lithium iron phosphate, or lithium cobalt oxide; there is a composite layer of binder, positive electrode powder and conductive carbon black in the through holes and / or blind holes.

[0061]The positive current collector is a microporous aluminum foil, the material of which is a battery microporous aluminum foil, and the battery microporous aluminum foil has 1000-1500 through holes with a diameter of 10-15 μm and 1000-3000 holes per square centimeter. Blind holes with a diameter of 10-50 μm, each through hole and blind hole are irregular in shape, and the junction of each hole and the surface of the aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com